Blog by Steve Laug

The next pipe on the work table came to us from an online auction in Wilkes Barre, Pennsylvania, USA. The pipe is an interesting looking piece – a smooth oil finished Poker shaped pipe with some nice grain around the bowl. The pipe is stamped on the left side of the shank and has a Bullseye target [over] JB in a circle and on the right side it is stamped Imported Briar. There was a lot of grime ground into the smooth finish on the briar. The bowl was heavily caked with a light lava coat on the top of the rim. The inside edges looked to be in good condition. There were some nicks in the briar on the top of the rim and the outer edges were beat up from being tapped against hard surfaces. The stem had tooth chatter and marks on the top and underside near the button. There were not markings or a logo on the taper stem. It had promise but it was very dirty. Jeff took some photos of the pipe before he started his cleanup work.

He took photos of the rim top and bowl to give a clear picture of the thickness of the cake and tobacco debris as well as the damage on the rim top and outer edges. He also took photos of the top and underside of the stem to show the oxidation and the chatter and tooth marks.

He took photos of the rim top and bowl to give a clear picture of the thickness of the cake and tobacco debris as well as the damage on the rim top and outer edges. He also took photos of the top and underside of the stem to show the oxidation and the chatter and tooth marks.

Jeff took photos of the sides and heel of the bowl to give a picture of what the briar looked like. There is some nice grain around the sides. You can also see the damage to the rim edges and the heel of the bowl in the photos below.

Jeff took photos of the sides and heel of the bowl to give a picture of what the briar looked like. There is some nice grain around the sides. You can also see the damage to the rim edges and the heel of the bowl in the photos below.

The stamping on the left and right sides of the shank are clear and readable and read as noted above.

The stamping on the left and right sides of the shank are clear and readable and read as noted above.  I have worked on quite a few Bessai pipes over the years and back in 2014 I restemmed a bowl. I wrote a blog on the pipe and did quite an extensive amount of research on the brand (https://rebornpipes.com/2014/07/14/restemming-and-restoring-a-john-bessai-special-diamond-shank-bent-brandy/). I am including that information here for ease of reference. If you have read it before feel free to skip ahead to the work on the pipe.

I have worked on quite a few Bessai pipes over the years and back in 2014 I restemmed a bowl. I wrote a blog on the pipe and did quite an extensive amount of research on the brand (https://rebornpipes.com/2014/07/14/restemming-and-restoring-a-john-bessai-special-diamond-shank-bent-brandy/). I am including that information here for ease of reference. If you have read it before feel free to skip ahead to the work on the pipe.

HISTORY & BACKGROUND

I started out with what I had found previously and written about on the blog. I quote the following paragraph from Pipedia http://pipedia.org/index.php?title=Bessai

John Bessai was a long time pipemaker, repairman and tobacco shop owner who operated his pipe shop at the “Old Arcade” in Cleveland, Ohio. The shop was opened in approximately 1898. It was a small 2-room shop where he hand-crafted his own pipes in the back room and could work when customers were not there. Like so many other shop made brand, John Bessai’s limited production was quickly acquired by regular customers and thus his craftsmanship remained little known outside of Ohio and the Midwest. While his name is known by pipe collectors in the Midwest, his work is seldom seen elsewhere! He died before 1969. Nevertheless, John Bessai left behind a small number of classic shaped pipes; all were made on-site. They are praised worthy of collecting and reflecting skills well beyond most American pipe makers. John Bessai’s logo “JB” appeared as one letter as the “back” of the “J” and the “back” of the “B” share a single line. The logo was stamped on the stem and on the left side of the shank. His son Herb Bessai took over the business and also continued making pipes. He closed the shop in about 1978.

I suspected that there would be more information three years later. I did some further research and came across the information found in the paragraph below on one of the pipe forums.

John Bessai was located in the Colonial Arcade at least into the late 1980s. After his death, his son Herb ran the shop. It was taken over after Herb’s retirement by a male and then name was changed to “Old Erie Pipes”. This was then located in the Erieview Plaza and when that mall closed, taken over by Cousin’s Cigars which has a store on Euclid Avenue near CSU, and a store on Chagrin Boulevard in Woodmere Village.

That small quotation gave me a bit more information of the state of the store after John’s death and Herb’s retirement. But I still wanted more information. I wanted to know about the history of the brand and if there was any information on the various grades in the brand and the stamping on the pipes. I wanted to know a bit of a timeline for the brands. Finally my digging paid off. ON one of the pipe forums I came across a link that led me to a gold mine of information gathered by a man after my own heart, Andrew Hross. He has a blog called Classic Pipe Shop on Blogspot. I have included the link below for those who want more information. Andrew has done an amazing job of gathering information on the Bessai Brand so rather than rewrite the history I am quoting portions of Andrew’s work on The John Bessai Pipe Clinic. (http://classicpipeshop.blogspot.ca/2014/04/the-john-bessai-pipe-clinic-information.html)

The John Bessai Pipe Clinic, 35 Colonial Arcade, Cleveland, OH 44115 – by Andrew HrossOwner(s): **John Bessai 1920s until his passing in 1969, **Herb Bessai ~1962-1983, **Daniel Gottschall 1984-~1993, **Purchased by Dad’s Smoke Shop / Cousin’s Smoke Shop and rolled into the Old Erie Smoke Shop about 1993. Cousin’s Cigars purchased the remaining stock of Bessai pipes near after Herb Bessai passed away in 2002.

Years of Operation: 1920s (unkown specific date at this time) – 1983. After 1983 the business was sold to Daniel Gottschall who later sold it to Cousin’s Cigar (Euclid Ave) around 1993. The name was changed to “Old Erie Tobacco Company”. They were forced to move to the Galleria when all the tenants of the Old Arcade were cleared out to make room for renovations. Their new address was The Galleria at Erieview, 1301 East 9th Street in Cleveland.

After this move the location wasn’t as busy as they had hoped and Cousin’s moved all the Old Erie Tobacco assets to their Euclid Avenue Store. The store has since moved to a St. Clair location after Cleveland State forced them out due to anti-smoking regulations on campus. Their St. Clair location offers many of John Bessai Pipe Clinic’s old tobacco blends.

Their new store opened in the Merriman Valley area in Akron, Ohio where the store manager John Coleman oversees the day to day operations. John was instrumental in helping me piece together a lot of loose ends during Bessai Pipe Clinic’s transition years.

My father visited their shop several times in the early 60s as he attended Fenn College (now Cleveland State University) as an undergrad before moving on to Ohio State University for his Masters. He’s way smarter than I am so I just go with the flow…

He mentioned meeting John at that time who quickly gave my father some pointers on smoking a pipe and how to take samples from the shop’s expansive sample jar collection. His pipes were on display in the shop although I don’t believe he had a lot of pipes on display at any given time due to production in-shop.

John’s son Herb took over the shop in the early 60s after he graduated from Cleveland State University / Fenn College (unclear) as he is listed as having played Basketball for CSU. Herb was also a helpful, informative and friendly individual. Articles exist from the Herald in 1962 where they interviewed Herb (with photograph) about the state of smoking in the new age of the early 60s. I visited the shop in the late 70s / early 80s with my father during a trip to Cleveland and couldn’t tell you much about the shop other than the guy working was very friendly. Back then it wasn’t unusual to be a kid and walk into a smoke shop with your father. Clearly I didn’t purchase anything but my father probably picked up some tobacco but I remember him looking at pipes displayed on a back wall. The shop was small but impressive.

If anyone has any pictures of the shop or old catalogs, I would love any additional information as it’s tough to come by 30+ years later!

Pipes offered by John Bessai Pipe Clinic: Most of the pipes that were offered by the John Bessai Pipe Clinic were fairly standard in shape… I would say most of the pipes Bessai offered were smooth pipes. My assessment would be 90% smooth and 10% rusticated / sandblasted…

…The story is that John crafted pipes in the back room or off site and finished them in house while the store wasn’t busy. Very little information is available on the accuracy of this statement. Some of his pipes from the late 1960s through the 1970s (John passed away in 1969) I feel were left over stock from previous turnings and sometimes showed fills or sand pits. Some of these pipes even carry Herb’s markings (see below). These pipes still smoke very well but are not as eye-appealing as other earlier pipes from the store’s career.

Stampings and rough dating of John Bessai Pipe Clinic Pipes: Which pipes did John make and which ones did Herb make/finish? All Bessai pipes carry his standard large JB stamp either on the stem or shank or both. Typically the JB on the stem is within a circle.

All pipes created by John Bessai’s hands reportedly contain the miniscule ‘jb’ stamp on the shank or body of the pipe. I have older pipes in my possession that do not contain this stamp (condenser, old stamps, etc) that were clearly shop made pipes. I feel he started using the tiny ‘jb’ stamp in the 50s to early 60s.

An interesting note about John Bessai’s stems – they always clean very nicely and aren’t prone to as much oxidation (that brownish / green color) as most dunhill and Charatan pipes tend to oxidize. His cuts to his stems were very impressive and often transitioned from diamond-shaped shanks almost architecturally. Very comfortable to smoke.

John Bessai Special Pipes:

… I have a couple Bessai Special pipes. These stand out either by large size, graining or possibly shape. Most Specials are unique pipes and are rare to find in comparison to his regular issue pipes.

John Bessai Special X pipes:

I only have one of these and it’s a beauty. This one is a larger bowl (around a group 4 dunhill) with deep colored grain and a hefty substantial shank. Special X pipes are probably the rarest of John Bessai pipes and should be sought out if possible. I’ve smoke mine roughly 4 or 5 times and it performs with the best of my pipes…

Herb Bessai Pipes:

Unfortunately none of these pipes that I’ve seen have astounded me with grain or general appearance. Having said this, these pipes smoke nicely and are a great value if you can find them. I have one that my father found at an Antique Show in the South. There’s another author shape on reborn pipe’s blog that someone refinished because of the amount of fills in the pipe. He also states it’s a wonderful smoker (Editor’s note: This is my pipe and the write up I did on the blog). These pipes are likely from the late 60s through the early 70s. I believe many pipes after this period were created en masse at a factory in the US. It is unclear what stamp was used on these later pipes…

Dating / Circa era Bessai Pipes: If the pipe carries a stamp stating Cleveland, O U.S.A. it’s considered an older production pipe (pre1960s). I’ve not seen any newer pipes with that stamp.

Bullseye stamping usually indicates an earlier pipe as that stamp seems to have been abandoned pre1960 as well.

Most of the earlier Bessai pipes have an unusual ‘stinger’ or condenser at the end of the tenon which is unique to Bessai pipes. They are either a hard plastic or created out of wood. They are typically easy to remove and could have been easily lost if misplaced. These pipes I would consider pre-1960 and possibly 1940s-early 1950s production based on their stamps and patina of the pipes.

1970s 1980s and beyond: My feeling on these pipes after John’s passing is that they purchased finished pipes from a large manufacturer and stamped them with the John Bessai or Bessai stamp (on shank and/or stem). Most of these shapes are standard among many stores from that period and offer less than spectacular grain (and sometimes fills). Stamps on these pipes are probably fairly plain and don’t have the tiny ‘jb’ stamp on the shank indicating it was produced by John Bessai.

I know that is a lot of information and if you want to you can skip ahead to read about the restoration. I started my restoration with cleaning the internals and the externals of the pipe. I cleaned out the inside of the pipe with pipe cleaners, cotton swabs and alcohol. It was a filthy pipe on the inside.

The pipe in hand was a John Bessai Circle JB Imported Briar. As noted above the pipe is stamped with a Bullseye Stamp that seems to have been abandoned pre-1960. So I am dealing with an earlier Bessai pipe. Now on to working on the pipe.

Jeff had cleaned up the pipe with his usual penchant for thoroughness. He reamed the pipe with a PipNet pipe reamer and removed the rest of it with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He soaked the stem in Before & After Deoxidizer and rinsed it off with warm water. I took photos of the pipe once I received it.

The rim top cleaned up really well. The rim top and outer edge of the bowl show some damage. The stem surface looked very good with a few small tooth marks and chatter on both sides near the button.

The rim top cleaned up really well. The rim top and outer edge of the bowl show some damage. The stem surface looked very good with a few small tooth marks and chatter on both sides near the button.  The stamping on both sides of the shank is clear and readable. The left side is stamped with a Bullseye [over] JB in a Circle. On the right side of the shank it is stamped Imported Briar.

The stamping on both sides of the shank is clear and readable. The left side is stamped with a Bullseye [over] JB in a Circle. On the right side of the shank it is stamped Imported Briar.  I removed the stem and took a photo of the pipe to give a sense of the whole. The stem is tapered and narrow.

I removed the stem and took a photo of the pipe to give a sense of the whole. The stem is tapered and narrow. Now it was time to do my work on the pipe. I topped the bowl on a topping board with 220 grit sandpaper. I repaired the damaged areas on the heel of the bowl and the sandpit on the right side of the bowl with clear super glue. I sanded the repaired areas smooth with 220 grit sandpaper to blend them into the surrounding briar. Once I had smoothed out the repairs I used a Maple stain pen to touch up the sanded area on the bottom of the bowl and the rim top. I knew that once I polished it with micromesh, it would blend in very well.

Now it was time to do my work on the pipe. I topped the bowl on a topping board with 220 grit sandpaper. I repaired the damaged areas on the heel of the bowl and the sandpit on the right side of the bowl with clear super glue. I sanded the repaired areas smooth with 220 grit sandpaper to blend them into the surrounding briar. Once I had smoothed out the repairs I used a Maple stain pen to touch up the sanded area on the bottom of the bowl and the rim top. I knew that once I polished it with micromesh, it would blend in very well.

I polished the repaired areas and the rest of the briar with micromesh sanding pads – wet sanding with 1500-12000 grit pads and wiping it down after each pad with a damp cloth.

I polished the repaired areas and the rest of the briar with micromesh sanding pads – wet sanding with 1500-12000 grit pads and wiping it down after each pad with a damp cloth.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The grain came alive and the fills while visible look better than when I began.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The grain came alive and the fills while visible look better than when I began.

I set the bowl aside and turned to work on the stem. It was in good condition and the tooth marks were light so I figured they would polish out fairly easily. I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I set the bowl aside and turned to work on the stem. It was in good condition and the tooth marks were light so I figured they would polish out fairly easily. I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This JB (John Bessai) Bullseye stamped Poker is a great looking pipe now that it has been restored.The smooth oil cured finish around the bowl is quite beautiful and highlights the grain and works well with the polished vulcanite taper stem. The repaired gouges on the heel look much better and are now smooth to touch. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished John Bessai Poker fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. I will be putting it on the rebornpipes store shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This JB (John Bessai) Bullseye stamped Poker is a great looking pipe now that it has been restored.The smooth oil cured finish around the bowl is quite beautiful and highlights the grain and works well with the polished vulcanite taper stem. The repaired gouges on the heel look much better and are now smooth to touch. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished John Bessai Poker fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. I will be putting it on the rebornpipes store shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

He took photos of the rim top and bowl to give a clear picture of the thickness of the cake and tobacco debris as well as the lava on the top and inner edge of the rim. He also took photos of the top and underside of the stem. The shank was too dirty for the stem to fit in correctly. The photos show the overall condition of the stem.

He took photos of the rim top and bowl to give a clear picture of the thickness of the cake and tobacco debris as well as the lava on the top and inner edge of the rim. He also took photos of the top and underside of the stem. The shank was too dirty for the stem to fit in correctly. The photos show the overall condition of the stem.

Jeff took photos of the sides and heel of the bowl to give a picture of what the briar looked like. It really does not look like briar but more like a hard wood which would also be another argument for it being a salesman’s sample pipe. The nickel band should look great once it is polished.

Jeff took photos of the sides and heel of the bowl to give a picture of what the briar looked like. It really does not look like briar but more like a hard wood which would also be another argument for it being a salesman’s sample pipe. The nickel band should look great once it is polished.

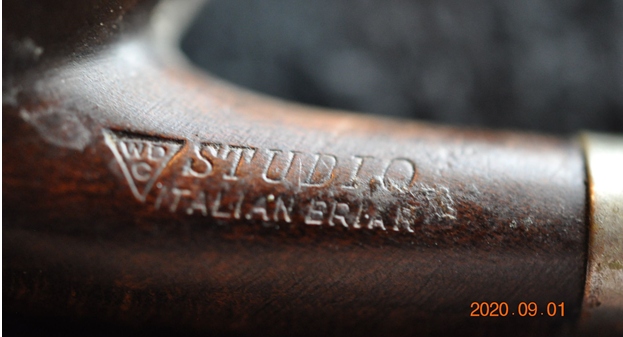

The stamping on the left side of the shank is clear and readable and read as noted above.

The stamping on the left side of the shank is clear and readable and read as noted above. Jeff had cleaned up the pipe with his usual penchant for thoroughness. He reamed the pipe with a Savinelli Fitsall Pipe Knife as the bowl was too small for even the smallest PipNet reaming head. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He soaked the stem in a Before & After Deoxidizer bath and rinsed it off with warm water. I took photos of the pipe before I started my part of the restoration work.

Jeff had cleaned up the pipe with his usual penchant for thoroughness. He reamed the pipe with a Savinelli Fitsall Pipe Knife as the bowl was too small for even the smallest PipNet reaming head. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He soaked the stem in a Before & After Deoxidizer bath and rinsed it off with warm water. I took photos of the pipe before I started my part of the restoration work.

The rim top cleaned up really well. The rim top, inner and outer edges of the bowl are in excellent condition. The stem surface looked very good with a few tooth marks and chatter on both sides near the button.

The rim top cleaned up really well. The rim top, inner and outer edges of the bowl are in excellent condition. The stem surface looked very good with a few tooth marks and chatter on both sides near the button.  The stamping on the shank side is clear and readable. It is stamped as noted above.

The stamping on the shank side is clear and readable. It is stamped as noted above.  I removed the stem and took a photo of the pipe to give a sense of the whole. The taper stem is nice and the photo gives a sense of what the pipe looks like.

I removed the stem and took a photo of the pipe to give a sense of the whole. The taper stem is nice and the photo gives a sense of what the pipe looks like.  I started my work on this little pipe by addressing a flaw in the wood on the front of the bowl. I filled it in with briar dust and super glue. Once the repair cured I sanded it with 220 grit sandpaper to smooth it out. I stained the repair on the front of the bowl with a walnut stain pen.

I started my work on this little pipe by addressing a flaw in the wood on the front of the bowl. I filled it in with briar dust and super glue. Once the repair cured I sanded it with 220 grit sandpaper to smooth it out. I stained the repair on the front of the bowl with a walnut stain pen.

I sanded the bowl smooth with 1500-3200 grit micromesh sanding pads (I forgot to take photos of that process). I stained the pipe with a dark brown aniline stain, flamed it to set it in the grain and repeated the process until I was happy with the coverage.

I sanded the bowl smooth with 1500-3200 grit micromesh sanding pads (I forgot to take photos of that process). I stained the pipe with a dark brown aniline stain, flamed it to set it in the grain and repeated the process until I was happy with the coverage.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for about 10-15 minutes and buffed with a cotton cloth to raise the shine. The grain came alive and the fills while visible look better than when I began.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for about 10-15 minutes and buffed with a cotton cloth to raise the shine. The grain came alive and the fills while visible look better than when I began.

I set the bowl aside and turned to work on the stem. I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I set the bowl aside and turned to work on the stem. I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

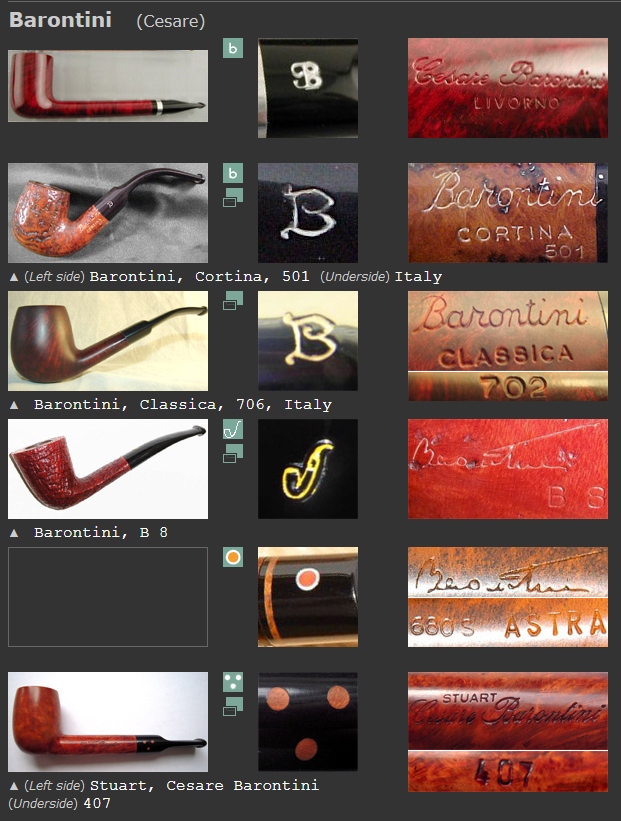

This Tiny WDC Studio Italian Briar Bent Billiard is a great looking little pipe now that it has been restored. The rich brown stain gives the bowl depth and elegance. The flow of the bowl and stem are well done make for a great hand feel or maybe I should say “finger” feel. The polished nickel band looks very good with the brown briar and polished vulcanite stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. Once I was finished the bowl and a matte look to it that I liked. The finished WDC Studio Bent Billiard fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 4 ¾ inches, Height: 1 ¼ inch, Outside diameter of the bowl: 1 inch, Chamber diameter: 5/8 of an inch. The weight of this pipe is 18 grams/.63oz. I will be putting it on the rebornpipes store shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This Tiny WDC Studio Italian Briar Bent Billiard is a great looking little pipe now that it has been restored. The rich brown stain gives the bowl depth and elegance. The flow of the bowl and stem are well done make for a great hand feel or maybe I should say “finger” feel. The polished nickel band looks very good with the brown briar and polished vulcanite stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. Once I was finished the bowl and a matte look to it that I liked. The finished WDC Studio Bent Billiard fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 4 ¾ inches, Height: 1 ¼ inch, Outside diameter of the bowl: 1 inch, Chamber diameter: 5/8 of an inch. The weight of this pipe is 18 grams/.63oz. I will be putting it on the rebornpipes store shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

H

H