Blog by Steve Laug

The next pipe on my work table is a shape I would call a Bulldog but Orlik called a Rhodesian. It is stamped on the left side of the shank and reads ORLIK [over] Straight Grain. On the right side it is stamped MADE IN ENGLAND [over] the shape number 90S near the shank/bowl junction. The bent saddle vulcanite stem is inlaid with a brass “O” on the top left side of the stem. The briar has great looking straight grain around the bowl and shank. This pipe was purchased in October of 2018 from an antique store in Brookings, Oregon, USA. The finish was dirty and but the briar was good looking. The rim top was caked with lava more heavily on the top back and inner edge of the bowl. There was a thick cake in the bowl and some tobacco debris. The shank and stem airway was very dirty. The stem was very oxidized, calcified and had some tooth marks and chatter on both sides ahead of the button. Jeff took photos of the pipe before he started his clean up.

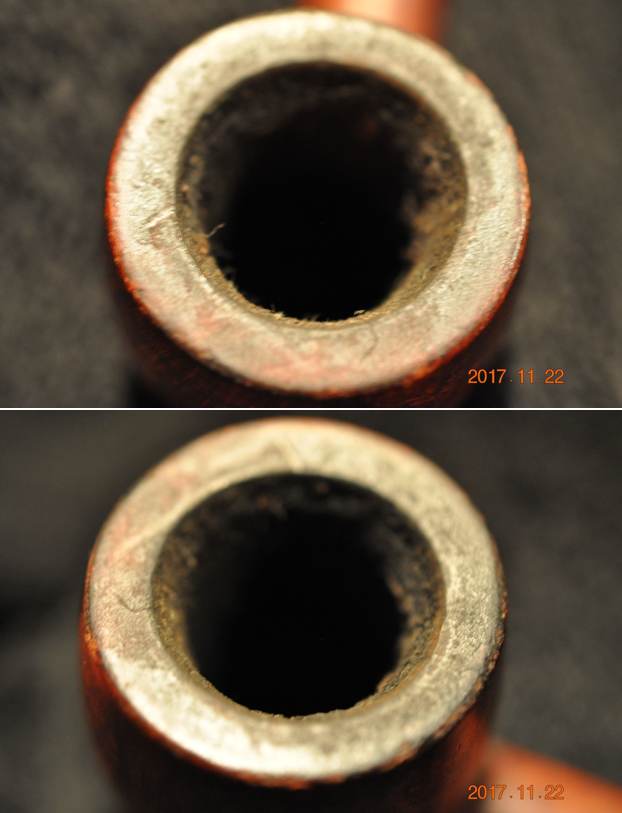

He took photos of the rim top and bowl to show the cake in the bowl, and the lava on the top and inner edge. The stem photos show the oxidation, calcification and tooth chatter and marks very well.

He took photos of the rim top and bowl to show the cake in the bowl, and the lava on the top and inner edge. The stem photos show the oxidation, calcification and tooth chatter and marks very well.

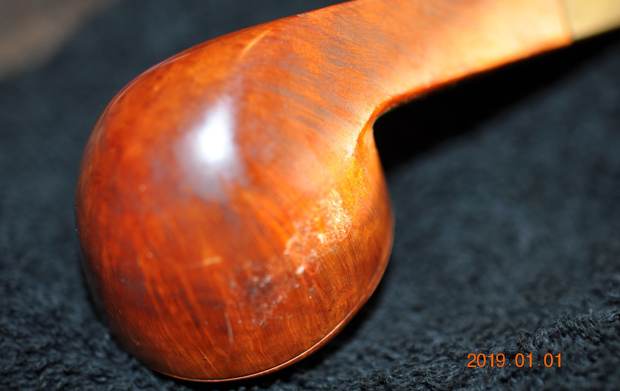

Jeff took a photo of the heel and side of the bowl to highlight the condition and the grain around the bowl sides and base.

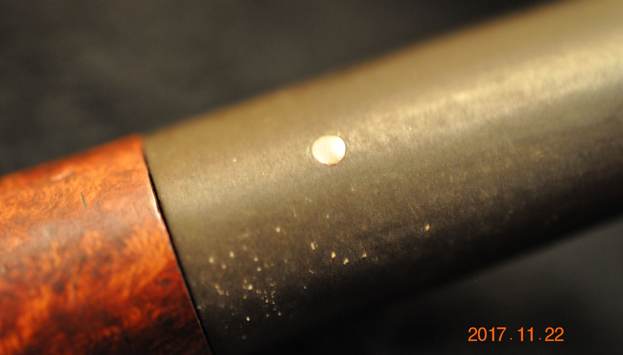

Jeff took a photo of the heel and side of the bowl to highlight the condition and the grain around the bowl sides and base. He captured the stamping on the sides of the shank in the next photos. They are clean and readable as noted above. The stem also had a faint crown stamped on the left side.

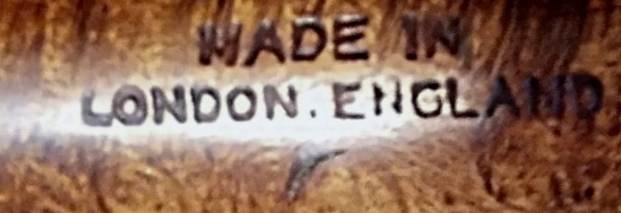

He captured the stamping on the sides of the shank in the next photos. They are clean and readable as noted above. The stem also had a faint crown stamped on the left side.

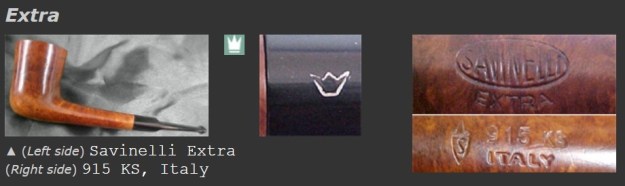

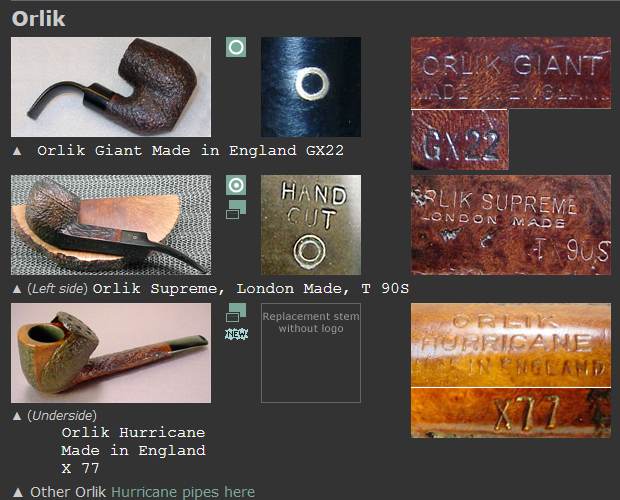

I turned to Pipephil (http://www.pipephil.eu/logos/en/logo-o2.html) to get a quick view of the Orlik Brand and see if there was a Straight Grain line. There was not a specific listing for the Straight Grain but I did a screen capture of the site’s information and have included that below.

I turned to Pipephil (http://www.pipephil.eu/logos/en/logo-o2.html) to get a quick view of the Orlik Brand and see if there was a Straight Grain line. There was not a specific listing for the Straight Grain but I did a screen capture of the site’s information and have included that below. I turned to Pipedia (https://pipedia.org/wiki/Orlik) for a quick read. The site is worth reading the history of the Orlik brand and some information on dating the brand. I quote below.

I turned to Pipedia (https://pipedia.org/wiki/Orlik) for a quick read. The site is worth reading the history of the Orlik brand and some information on dating the brand. I quote below.

Dating guide – In the Pre-Cadogan era of the Orlik, the name is ORLIK in a straight line, capital block letters. Also the MADE IN ENGLAND is in a straight line, capital block letters. However, there are a known model (ORLIK NATURAL T 1155) stamped with MADE IN ENGLAND in a straight line, capital serif letters. Date is unknown. The mouth piece have the Orlik logo, a circular O as a brass inlay.

After joining Cadogan the same origin stamp as other Cadogan brands like Comoy´s etc. was used, MADE IN LONDON in circular an below ENGLAND in straight.

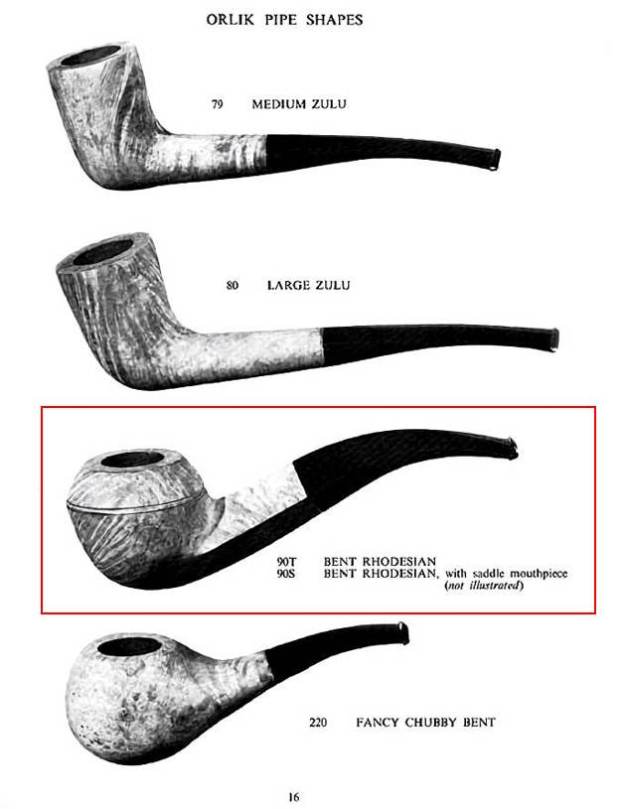

In the margins on the Pipedia site there was a link to a catalogue scanned as a PDF. I have included the link here (https://pipedia.org/images/0/00/Orlik_Pipe_Shapes.pdf). I did a screen capture of the cover of catalogue and the page that had the 90S shape number. Orlik called it a Bent Rhodesian with the S signifying a saddle stem (I have drawn a red box around the shape).

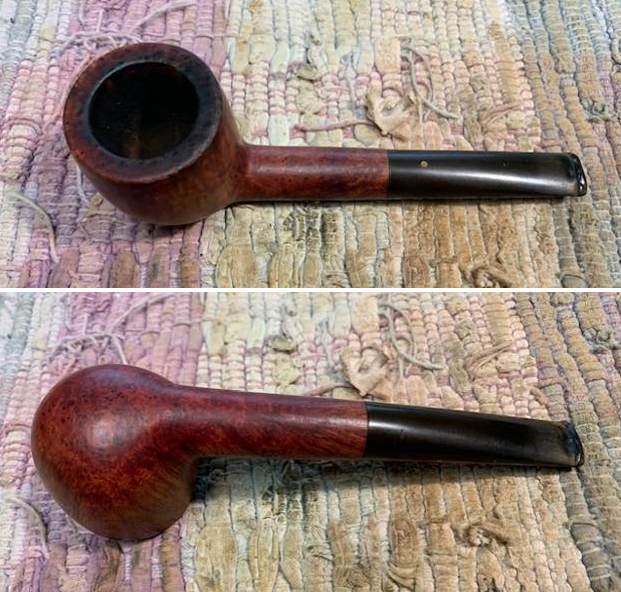

Jeff cleaned up the pipes with his usual thoroughness – reaming the bowl with a PipNet pipe reamer and cleaning up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed the internals of the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior with Murphy’s Oil Soap to clean off the dust and grime on the finish. When he sent it the pipe was ready to restore. I could not believe how good the rim top looked in comparison to what it was when he started. I took photos of the pipe when I unpacked it. The briar was clean and the grain quite stunning. The finish looked dull and lifeless.

Jeff cleaned up the pipes with his usual thoroughness – reaming the bowl with a PipNet pipe reamer and cleaning up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed the internals of the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior with Murphy’s Oil Soap to clean off the dust and grime on the finish. When he sent it the pipe was ready to restore. I could not believe how good the rim top looked in comparison to what it was when he started. I took photos of the pipe when I unpacked it. The briar was clean and the grain quite stunning. The finish looked dull and lifeless.

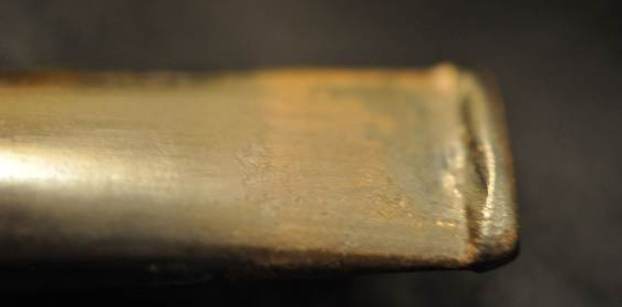

I took a close up photo of the bowl and rim top after Jeff had cleaned it up. The look of the rim top and edges is very good. There were some spots where the stain was worn away. He had been able to remove the cake and the lava very well. The bowl was spotless. The stem is also shown and was very clean. He had scrubbed it with Soft Scrub and then soaked it in Mark’s Before & After Deoxidizer. There was tooth chatter and deep marks still remaining.

I took a close up photo of the bowl and rim top after Jeff had cleaned it up. The look of the rim top and edges is very good. There were some spots where the stain was worn away. He had been able to remove the cake and the lava very well. The bowl was spotless. The stem is also shown and was very clean. He had scrubbed it with Soft Scrub and then soaked it in Mark’s Before & After Deoxidizer. There was tooth chatter and deep marks still remaining. I took a photo of the stamping on the sides of the shank. It is clear and readable as noted above.

I took a photo of the stamping on the sides of the shank. It is clear and readable as noted above. I removed the stem from the shank and took a photo of the pipe to show the look of the pipe. It is a real beauty.

I removed the stem from the shank and took a photo of the pipe to show the look of the pipe. It is a real beauty. The bowl was very clean and the briar looked good. I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down with a damp cloth after each sanding pad.

The bowl was very clean and the briar looked good. I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down with a damp cloth after each sanding pad.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips. The product cleans, enlivens and preserves the briar. I let it do its magic. It sat for 10 minutes and then I buffed it off with a cotton cloth. The bowl really is looking good at this point.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips. The product cleans, enlivens and preserves the briar. I let it do its magic. It sat for 10 minutes and then I buffed it off with a cotton cloth. The bowl really is looking good at this point.

I “painted” the tooth marks with the flame of a Bic Lighter. I was able to raise all of them except for one on the topside. I filled it in with a spot of black superglue. Once it cured I flattened the repairs with a small file to blend them into the surface. I sanded the stem with a folded piece of 220 grit sandpaper. I started polishing it with 400 grit wet dry sandpaper.

I “painted” the tooth marks with the flame of a Bic Lighter. I was able to raise all of them except for one on the topside. I filled it in with a spot of black superglue. Once it cured I flattened the repairs with a small file to blend them into the surface. I sanded the stem with a folded piece of 220 grit sandpaper. I started polishing it with 400 grit wet dry sandpaper.

I set the bowl aside and turned my attention to the stem. I scrubbed the stem down with Soft Scrub to remove the deep oxidation on the stem surface. I was able to remove much of what was present.

I set the bowl aside and turned my attention to the stem. I scrubbed the stem down with Soft Scrub to remove the deep oxidation on the stem surface. I was able to remove much of what was present. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with a cloth impregnated with Obsidian Oil. I polished it with Before & After Stem Polish – both Fine and Extra Fine then gave it a final coat of Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with a cloth impregnated with Obsidian Oil. I polished it with Before & After Stem Polish – both Fine and Extra Fine then gave it a final coat of Obsidian Oil and set it aside to dry.

There is something about the amazing straight grain on this beautiful pipe. This Orlik Straight Grain 90S Bent Rhodesian looks great. The straight grain really stands out on the bent pipe. I put the stem on the shank and buffed the pipe with Blue Diamond on the wheel (being careful of the stamping so as not to damage that). I gave the bowl and the stem multiple coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The dimensions of this pipe are – Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¾ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.48 ounces/ 42 grams. It is a great looking pipe and one that will be going on the rebornpipes store in the British Pipe Makers section. If you want to add it to your collection let me know via email to slaug@uniserve.com or by message. Thanks for walking through the restoration with me.

There is something about the amazing straight grain on this beautiful pipe. This Orlik Straight Grain 90S Bent Rhodesian looks great. The straight grain really stands out on the bent pipe. I put the stem on the shank and buffed the pipe with Blue Diamond on the wheel (being careful of the stamping so as not to damage that). I gave the bowl and the stem multiple coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The dimensions of this pipe are – Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¾ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.48 ounces/ 42 grams. It is a great looking pipe and one that will be going on the rebornpipes store in the British Pipe Makers section. If you want to add it to your collection let me know via email to slaug@uniserve.com or by message. Thanks for walking through the restoration with me.