Blog by Steve Laug

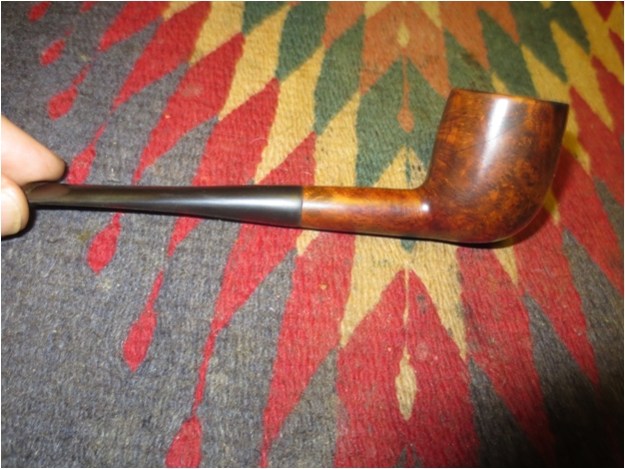

I have repaired 6 of the 7 older pipes (1937-1950s) left to Paresh by his Grandfather. I have enjoyed working on and researching them. His Grandfather was a pipeman who worked for the Indian Railroad. Paresh recently learned that his Grandfather smoked a pipe. This 7th pipe is a Charatan’s Make De Luxe 140 Billiard with a taper stem. I took photos of the pipe before I stated to work on it. The bowl was in rough shape with a series of cracks running down two spots on the bowl – one on the left side at the centre of the top and running down the bowl and connecting with another crack just right of the centre of the bowl at the back. It was a U shaped crack that went all the way through the bowl. The finish was dirty and the rim top had damage and lava on the rim top. The bowl was out of round. The outer edge of the bowl was damaged from knocking out against hard surfaces. The stem had tooth marks on the top and underside near the button. The stem had the CP stamped on the left side.

The rim top had been cleaned and the bowl reamed. There was still some cake in the bowl. Abha (Paresh’s wife) had once again done a great job cleaning the finish. She had scrubbed it with Murphy’s Oil Soap and removed all of the debris and dust from the smooth finish. The cracks showed up on the outside of the bowl and also on the inside of the bowl. The inner edge of the bowl was damaged and slightly out of round. I also took a close up photos of both sides of the stem. You can see the tooth marks on both the top and underside of the stem just in front of the button. The surface of the stem is lightly oxidized.

The rim top had been cleaned and the bowl reamed. There was still some cake in the bowl. Abha (Paresh’s wife) had once again done a great job cleaning the finish. She had scrubbed it with Murphy’s Oil Soap and removed all of the debris and dust from the smooth finish. The cracks showed up on the outside of the bowl and also on the inside of the bowl. The inner edge of the bowl was damaged and slightly out of round. I also took a close up photos of both sides of the stem. You can see the tooth marks on both the top and underside of the stem just in front of the button. The surface of the stem is lightly oxidized. The stamping is readable. On the left side of the shank reads Charatan’ Make over London, England over De Luxe. Next to that is the shape number 140 next to the stem shank junction. There was no stamping on the right side of the shank. I looked up an article on determining dates of manufacture of Charatan Make pipes (https://pipedia.org/wiki/Dating_of_Charatans). That article helped me date this pipe with some level of certainty to the Rueben Era Charatan made between the years 1910-1960. I quote from the portion of the article that gave the identifying characteristics of that era. I quote in full.

The stamping is readable. On the left side of the shank reads Charatan’ Make over London, England over De Luxe. Next to that is the shape number 140 next to the stem shank junction. There was no stamping on the right side of the shank. I looked up an article on determining dates of manufacture of Charatan Make pipes (https://pipedia.org/wiki/Dating_of_Charatans). That article helped me date this pipe with some level of certainty to the Rueben Era Charatan made between the years 1910-1960. I quote from the portion of the article that gave the identifying characteristics of that era. I quote in full.

Identification of a second era pipe (Rueben’s era, 1910-1960)

Pipes belonging to this period are rare, however is it possible to come across one. They can be distinguished from a pipe of the first era mainly because their larger size. Their characteristics are similar to the ones of the previous era.

1) Pipes can be larger, up to the dimension of a Dunhill group 5

2) The mouthpiece is tapered or saddle.

3) No double comfort

4) the CP logo is engraved so that the C enters the P

5) Absence of £ on the pipe shank (note that from 1955 all the pipe imported in the USA by Lane has it, however that stamping is not synonymous of the Lane era).

6) Absence of the letter X on the shape code engraved on the shank (for ex. 2502 and not 2502X)

7) Absence of letters DC after the shape number (for ex. 2502 and not 2505DC)

8) Absence of the engraving “MADE BY HAND” on the shank (introduced for the first time in 1958)

9) Presence of the writing “CHARATAN’S MAKE LONDON ENGLAND” on 2 lines

10) The CP logo is finer than in following eras

All ten of the items in the above list apply to the pipe in hand. From the stamping on the stem where the C enters the P to the missing L which places it as pre-1955 to the lack of a double comfort bit all help to place this pipe in this time period.

With that I reread Paresh’s biographical write up on his Grandfather once again. There Paresh stated that his Grandfather had visited England in 1946 and that later after 1947 the British left India for good. Many of the Superior Officers gave his Grandfather pipes as parting gifts. I am fairly confident that this was one of those gift pipes given to him around 1947. I am including his bio now as part of the background information on this pipe. Here is Paresh’s tribute.

Respected Sir,

Now that the first batch of my Grandfather’s pipes has reached you, I would like to share my memories of him with you, the aim being to provide you with an insight to his personality, the era in which he lived, and a brief history associated with the pipes that I have inherited from him.

My Grandfather, Ananta (named after an exotic seasonal white flower having lovely fragrance), was born in a small coastal town of Konkan region of Maharashtra, India, in 1918. These were very turbulent times when India’s freedom struggle against British rule was gathering momentum and the atmosphere was charged with “Quit India Movement”. Having completed his graduation from Bombay, he joined Railways in 1937. This also marked the beginning of his journey into the world of pipe smoking!!!!!

Having seen his potential, in 1945, he was sponsored by the Government to visit England, for gaining further experience and expertise in his profession. This was a period when India’s Independence was round the corner and efforts were being made to train Indians for various administrative appointments in future Independent India. He returned back to India after a year, in 1946 and with him came some pipes that he had purchased in England. I believe a few of his Petes, Barlings, Charatans and GBDs are from this visit.

In 1947, when the British finally left India for good, my Grandfather was gifted pipes by his British peers, subordinates and Superior Officers as a parting gift. He stayed in touch with a few of them over all these years, even visiting them in 1959-60. Some of his later era Charatans and Barlings and Petes are from this trip. He quit smoking in early 1970s (before I was even born!!!!) and his pipes were packed up. There were a number of pipes which were used as TINDER for lighting fires (CAN’T BELIEVE IT…… I have not overcome my grief of this loss till date!!!!!) due to ignorance!!!!!!

My Grandfather was a very strict disciplinarian and temperamental (I did not know this as he was neither when dealing with me as I am the youngest of all his grandchildren!!!!!! He was always the most understanding and loving person in my life). I later learned that in his office, he was not to be disturbed when his pipe was lit, as he would be in his thinking/ contemplating mode while it was just the opposite as he lit his pipe in the evening while at home, when he would be at his relaxed best!!!!.

The interesting part is that neither of us knew that we each smoked a pipe until after his demise in Jan 2018!!!! In our culture, to this day, smoking or alcohol consumption is socially never talked about (mute acceptance!!!). It was during his last rites that absent mindedly I lighted my pipe and looking into the flickering flames of his funeral pyre, remembered and recollected all the wonderful memories and talks that we had shared. No one said a word to me about my lighting up a pipe!!!!!! Immediately thereafter, I rejoined my duty station. A few days later, my wife, Abha, received a box from my Uncle with a note that said “Grandfather would have loved Paresh to have these”. This box contained a collection of his fountain pens and 8-10 of his pipes (since then as my folks are winding up his belongings, I have received 2-3 packets and a large number of pipes, some in decent condition and some in unspeakable state). Abha immediately messaged me with pictures of these pipes and pens. I had been collecting and restoring (no major repairs, though) fountain pens since long and immediately recognized some of them as highly collectibles, however, pipes were a totally different ball game! I was inexperienced with no knowledge/ information regarding various brands/ pipe makers, shapes and materials. I knew nothing about the value of these pipes, nothing about pipe restorations, nothing about caring for them; I mean zero knowledge about collecting pipes. I smoked some real cheap Chinese pipes which were readily and unfortunately, the only ones, available in India and some inexpensive pipes from eBay India!!!!! Also regular pipe cleaning, pipe rotation, pipe cleaners and such things were unknown to me.

Thus, to know more about the REAL pipes, I embarked upon the journey of exploring finer nuances of pipe brands/ makers, their history and watching “How to videos” on packing a pipe, cleaning, repairing and caring for ones pipes. I found it extremely interesting and satisfying. It was while meandering through this confusing quagmire of pipe world that I came across rebornpipes.com website and eventually established contact with you, Mr Steve, who has since been my mentor, guide and GURU, making this journey a wonderful and satisfying experience.

Sir, there is one more thing that I need to thank you for and that is when you asked me to write a brief about my grandfather and his pipes, I realized how little I knew about him, in fact, knew nothing, as I was not even aware that he was a “pipeman” as no one in my family ever spoke about it being taboo subject and since he had quit a long time before I was even born!!!! This led me to ask the elders in my family, questions on the subject and came to know the above details. I cannot thank you enough for prodding me to get to know my grandfather and his pipes a lot better. Sir, these pipes of his, with your help and guidance, will remain with me forever in mint condition…

I began work on the pipe by cleaning up the reaming of the bowl first with a PipNet pipe reamer. I began with the smallest cutting head and worked on cleaning up the inside of the bowl. While I cleaned it up the cracked section of the bowl came loose. I cleaned up the unbroken portion of the bowl and the broken chunk with a Savinelli Fitsall Pipe Knife to remove the remnants of cake left behind.  I cleaned off the edges of the broken chunk of bowl and the remaining bowl with alcohol on cotton swabs. I used a slow curing clear super glue to repair the cracked chunk of briar. I painted the edges of the bowl and the chunk with the super glue and pressed the chunk in place in the bowl side. I held it in place until the glue had set and the chunk was firmly in place. I wiped the bowl down with alcohol on a cotton pad to wipe off the excess glue.

I cleaned off the edges of the broken chunk of bowl and the remaining bowl with alcohol on cotton swabs. I used a slow curing clear super glue to repair the cracked chunk of briar. I painted the edges of the bowl and the chunk with the super glue and pressed the chunk in place in the bowl side. I held it in place until the glue had set and the chunk was firmly in place. I wiped the bowl down with alcohol on a cotton pad to wipe off the excess glue.  I sanded the repaired cracks with 220 grit sandpaper and smoothed out the finish to blend in the repairs with the rest of the bowl. Once I had cleaned up the repairs I touched them up with clear super glue to fill in the divots in the repair.

I sanded the repaired cracks with 220 grit sandpaper and smoothed out the finish to blend in the repairs with the rest of the bowl. Once I had cleaned up the repairs I touched them up with clear super glue to fill in the divots in the repair.  I sanded the bowl with 220 grit sandpaper to smooth out the repair further after the touch ups. I took pictures of the repair at this point to show the progress.

I sanded the bowl with 220 grit sandpaper to smooth out the repair further after the touch ups. I took pictures of the repair at this point to show the progress. I topped the bowl with 220 grit sandpaper and a topping board to smooth out the finish on the top. I removed the damaged areas, removed the glue that had squeezed out from the repairs and cleaned up the rough areas on the outer edge of the rim.

I topped the bowl with 220 grit sandpaper and a topping board to smooth out the finish on the top. I removed the damaged areas, removed the glue that had squeezed out from the repairs and cleaned up the rough areas on the outer edge of the rim. I polished the bowl with micromesh sanding pads to blend the repairs into the finish of the bowl. I wet sanded with 1500-2400 grit pads and dry sanded it with 3200-12000 grit pads. I wiped it down with a damp cotton pad after each grit sanding pad.

I polished the bowl with micromesh sanding pads to blend the repairs into the finish of the bowl. I wet sanded with 1500-2400 grit pads and dry sanded it with 3200-12000 grit pads. I wiped it down with a damp cotton pad after each grit sanding pad.

I mixed up a batch of JB Weld and applied it to the inside of the bowl with a paper clip and a folded pipe cleaner. I worked it into the inside of the cracks and lined the bowl walls all around the cracks until it was smooth. I set it aside to let it cure.

I mixed up a batch of JB Weld and applied it to the inside of the bowl with a paper clip and a folded pipe cleaner. I worked it into the inside of the cracks and lined the bowl walls all around the cracks until it was smooth. I set it aside to let it cure. Abha had done a great job cleaning out the internals of the mortise and shank with pipe cleaners, cotton swabs and alcohol. I ran a pipe cleaner through the shank to remove any of the debris that I had loosened when reaming the bowl. It was pretty clean so it did not take much as the interior was clean.

Abha had done a great job cleaning out the internals of the mortise and shank with pipe cleaners, cotton swabs and alcohol. I ran a pipe cleaner through the shank to remove any of the debris that I had loosened when reaming the bowl. It was pretty clean so it did not take much as the interior was clean. I worked Before & After Restoration Balm deep into the briar of the bowl and shank to clean, enliven and protect it. I worked it in with my fingertips and set it aside for a few minutes to let the balm work. I wiped it off and buffed it with a soft cloth to polish it. The briar really began to have a deep shine and the grain began to shine through. I took photos of the bowl at this point to mark the progress in the restoration.

I worked Before & After Restoration Balm deep into the briar of the bowl and shank to clean, enliven and protect it. I worked it in with my fingertips and set it aside for a few minutes to let the balm work. I wiped it off and buffed it with a soft cloth to polish it. The briar really began to have a deep shine and the grain began to shine through. I took photos of the bowl at this point to mark the progress in the restoration.

I worked on the inside edge of the rim with a folded piece of 220 grit sandpaper to smooth out the damage to the edge of the bowl.

I worked on the inside edge of the rim with a folded piece of 220 grit sandpaper to smooth out the damage to the edge of the bowl. I stained the briar with a Dark Brown aniline stain and flamed it with a Bic lighter to set the stain. I repeated the process until I had even coverage on the bowl.

I stained the briar with a Dark Brown aniline stain and flamed it with a Bic lighter to set the stain. I repeated the process until I had even coverage on the bowl.

I wanted to leave the stain pretty opaque to blend the repaired crack into the rest of the briar. I let the Dark Brown stain dry. Once it was dried I gave the bowl a coat of Conservator’s Wax, let it dry and then buffed the bowl by hand. I repeated the wax until the pipe looked good to my eye.

I wanted to leave the stain pretty opaque to blend the repaired crack into the rest of the briar. I let the Dark Brown stain dry. Once it was dried I gave the bowl a coat of Conservator’s Wax, let it dry and then buffed the bowl by hand. I repeated the wax until the pipe looked good to my eye.

I set the bowl aside and began the work on the stem. There were some deep tooth marks in the surface of the stem near button. I cleaned the areas with alcohol and filled in the marks with black super glue.

I set the bowl aside and began the work on the stem. There were some deep tooth marks in the surface of the stem near button. I cleaned the areas with alcohol and filled in the marks with black super glue.  When the super glue cured I sanded it with 220 grit sandpaper to blend it into the surface of the stem. I used a needle file to sharpen the inside edge of the button.

When the super glue cured I sanded it with 220 grit sandpaper to blend it into the surface of the stem. I used a needle file to sharpen the inside edge of the button. I sanded the repaired areas with 220 grit sandpaper to smooth out the repairs and blend them into the surface of the surrounding vulcanite.

I sanded the repaired areas with 220 grit sandpaper to smooth out the repairs and blend them into the surface of the surrounding vulcanite. I cleaned out the airway on the stem with pipe cleaners and alcohol to clean out the tar and oils. It did not take much work to remove all of the remaining tars because Abha had done a really good job cleaning out the stem.

I cleaned out the airway on the stem with pipe cleaners and alcohol to clean out the tar and oils. It did not take much work to remove all of the remaining tars because Abha had done a really good job cleaning out the stem. I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit sanding pads and dry sanding with 3200-12000 grit pads. I wiped the stem down with Obsidian Oil after each sanding pad and set it aside to dry. I polished it with Before & After Pipe Polish – both Fine and Extra Fine polishes. I wiped it down with some Obsidian Oil to fine the polishing process.

I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit sanding pads and dry sanding with 3200-12000 grit pads. I wiped the stem down with Obsidian Oil after each sanding pad and set it aside to dry. I polished it with Before & After Pipe Polish – both Fine and Extra Fine polishes. I wiped it down with some Obsidian Oil to fine the polishing process.

With the stem polished I put it back on the pipe and lightly buffed the bowl and stem with Blue Diamond. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine and hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. I left a little oxidation around the CP stamp on the stem so as not to damage it. The finished pipe is shown in the photos below. It is the final pipe from Paresh’s Grandfather’s pipes that I finished and I will get them packed up and sent across the sea to India where he can carry on the legacy. I know that he is looking forward to having them in hand and enjoying a bowl of his favourite tobacco in memory of his Grandfather. Thanks for walking through the restoration with me as I worked this pipe over.

With the stem polished I put it back on the pipe and lightly buffed the bowl and stem with Blue Diamond. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine and hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. I left a little oxidation around the CP stamp on the stem so as not to damage it. The finished pipe is shown in the photos below. It is the final pipe from Paresh’s Grandfather’s pipes that I finished and I will get them packed up and sent across the sea to India where he can carry on the legacy. I know that he is looking forward to having them in hand and enjoying a bowl of his favourite tobacco in memory of his Grandfather. Thanks for walking through the restoration with me as I worked this pipe over.