Blog by Steve Laug

Jeff and I no longer remember where or when we purchased this pipe. It is a large rusticated saddle stem Billiard with panel sides. It is stamped on the left side of the shank and reads Courtley [over] Imported Briar. The stamping was clear and readable. There was no other stamping on the other sides of the shank. I am not sure if Jeff even had this pipe on his table. Perhaps it is one that came to me in a trade. I have no clear memory of that. However, the bowl appeared to have been lightly reamed but the shank was dirty and the a light cake remained. The rim top and briar were dusty but clean. There was some darkening on the back top of the rim but the inner edge looked good. The vulcanite saddle stem is clean but has some tooth marks on the top and underside ahead of the button. I took some photos of the pipe before I started my work on it.

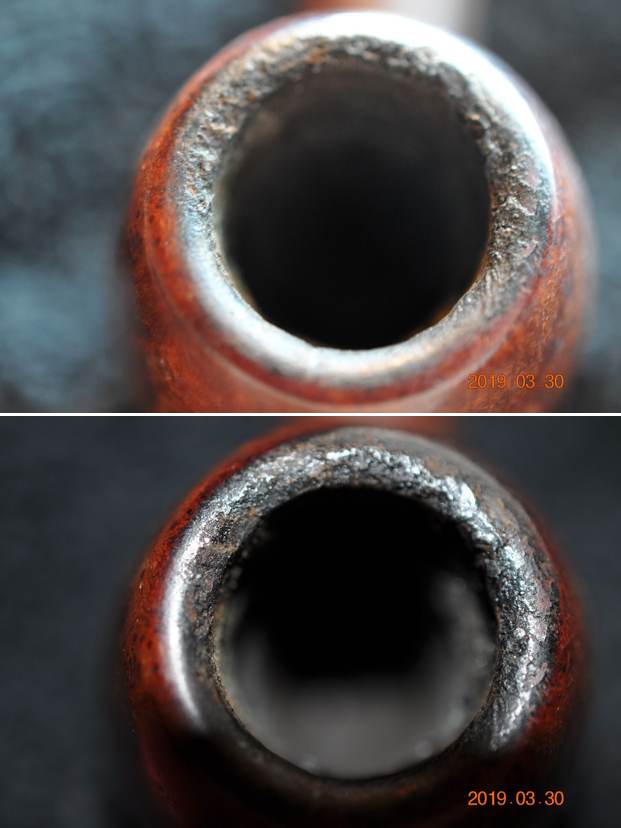

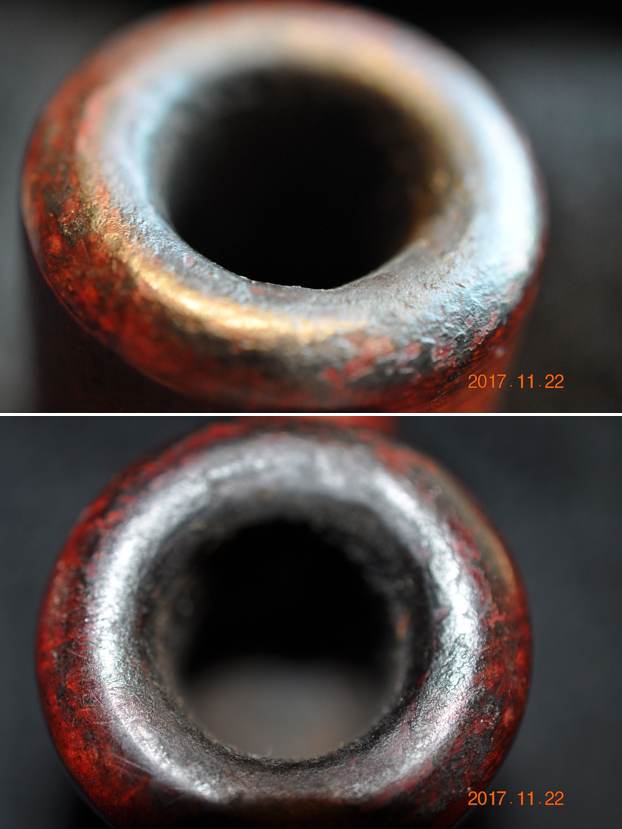

I took photos of the bowl and rim top to show the condition of both. The bowl is very clean but you can see some darkening on the inner beveled edge. There was some slight darkening was also on the rim top and inner edge on the back of the bowl. I took photos of the stem as well to show the tooth marks on the top and underside ahead of the button and on the button surface as well.

I took photos of the bowl and rim top to show the condition of both. The bowl is very clean but you can see some darkening on the inner beveled edge. There was some slight darkening was also on the rim top and inner edge on the back of the bowl. I took photos of the stem as well to show the tooth marks on the top and underside ahead of the button and on the button surface as well. I took a photo of the stamping on the left side of the shank. The stamping on the left side is clear and very readable.

I took a photo of the stamping on the left side of the shank. The stamping on the left side is clear and very readable. I removed the stem from the shank and took a photo of the pipe. It is proportionally pleasing and quite an eye catching pipe.

I removed the stem from the shank and took a photo of the pipe. It is proportionally pleasing and quite an eye catching pipe. I knew that there was connection between Courtley Imported Briar and Custombilt but I was not 100% certain of the nature of the connection. So I turned to Pipedia to see what I could find out about my supposed connection (https://pipedia.org/wiki/Courtley). I quote from the site in full below and follow that with a screen capture of a catalogue page from the site that was provided on the PipesMagazine.com pipe forum by member “ichbinmuede” – to whom, thanks.

I knew that there was connection between Courtley Imported Briar and Custombilt but I was not 100% certain of the nature of the connection. So I turned to Pipedia to see what I could find out about my supposed connection (https://pipedia.org/wiki/Courtley). I quote from the site in full below and follow that with a screen capture of a catalogue page from the site that was provided on the PipesMagazine.com pipe forum by member “ichbinmuede” – to whom, thanks.

Courtley was a sub-brand or second of Custom-Bilt and quite inexpensive, retailing for $1.79 in 1957. However, His Nibs was another Custom-Bilt sub-brand or second that was even cheaper, retailing for $1.00 the same year.

Below is an ad from Rogers Imports Catalog of 1957, showing different Courtley shapes for sale, describing Courtley as an economical version of the distinctive Custombilt Pipe (as spelled in the ad). They had a walnut finish and vulcanite bit. And they were packed one dozen to a display box. The brochure clearly link the Custombilt and Courtley. It says that the Courtley by Custombilt is an economical version of the distinctive Custombilt Pipe – handsomely carved with choice briar, fitted with a pure vulcanite bit, walnut finish.

The brochure clearly link the Custombilt and Courtley. It says that the Courtley by Custombilt is an economical version of the distinctive Custombilt Pipe – handsomely carved with choice briar, fitted with a pure vulcanite bit, walnut finish.

The information was very clear that the pipe was indeed connected to Custombilt pipes. I also found it interesting that it was an economic version of the famous pipe. Now it was time to work on this old timer.

I started my work on the pipe by sanding out thin light cake in the bowl with 220 grit sandpaper wrapped around a piece of dowel. I sanded until the walls of the bowl were smooth and clear. I scrubbed the bowl and shank with undiluted Murphy’s Oil Soap and a tooth brush and rinsed it off with running water. I worked on the rustication on the bowl and rim top to clean up the dust and debris in the finish. While the rim top looked better it still needed some more work to remove the darkening on the top and edges of the bowl.

I scrubbed the bowl and shank with undiluted Murphy’s Oil Soap and a tooth brush and rinsed it off with running water. I worked on the rustication on the bowl and rim top to clean up the dust and debris in the finish. While the rim top looked better it still needed some more work to remove the darkening on the top and edges of the bowl.

I cleaned up the rim top some more with a brass bristle wire brush. I was able to remove the debris and to minimize the darkening. It looks much better.

I cleaned up the rim top some more with a brass bristle wire brush. I was able to remove the debris and to minimize the darkening. It looks much better. I cleaned out the inside of the shank and the stem with 99% isopropyl alcohol, cotton swabs and pipe cleaners. It was quite dirty inside the shank and airway in the stem. It came out very clean and looks very good.

I cleaned out the inside of the shank and the stem with 99% isopropyl alcohol, cotton swabs and pipe cleaners. It was quite dirty inside the shank and airway in the stem. It came out very clean and looks very good.  I polished the briar with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I wiped the briar down with a damp cloth to remove the sanding dust. The briar really took on a rich shine with the polishing.

I polished the briar with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I wiped the briar down with a damp cloth to remove the sanding dust. The briar really took on a rich shine with the polishing.

I rubbed the bowl down with some Before & After Restoration Balm. I worked it into the briar with my finger tips to clean, revive and preserve the wood. It really brings the grain alive once again. I let it sit for 15 minutes then buffed it off with a soft cloth. The grain really pops at this point in the process.

I rubbed the bowl down with some Before & After Restoration Balm. I worked it into the briar with my finger tips to clean, revive and preserve the wood. It really brings the grain alive once again. I let it sit for 15 minutes then buffed it off with a soft cloth. The grain really pops at this point in the process.

I set the bowl aside and turned my attention to the stem. I sanded the tooth marks and chatter out around the button with 220 grit sandpaper and started the polishing with 400 grit wet dry sandpaper.

I set the bowl aside and turned my attention to the stem. I sanded the tooth marks and chatter out around the button with 220 grit sandpaper and started the polishing with 400 grit wet dry sandpaper.  I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped the stem down after each pad with a cloth impregnated with Obsidian Oil. I finished the polishing with some Before & After Pipe Stem Polish – both Fine and Extra Fine. I wiped it down a final time with Obsidian Oil. The stem looked very good.

I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped the stem down after each pad with a cloth impregnated with Obsidian Oil. I finished the polishing with some Before & After Pipe Stem Polish – both Fine and Extra Fine. I wiped it down a final time with Obsidian Oil. The stem looked very good.

As always I am excited to finish a pipe that I am working on. I put the Courtley Imported Briar Panel Billiard back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad and hand buffed it to raise the shine. It is fun to see what the polished bowl looks like with the grain popping through on the smooth portions and the variety of colour in the rustication. Added to that the polished vulcanite saddle stem was a beautiful touch. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 43 grams/1.52 ounces. It is a beautiful pipe and one that will be on the rebornpipes store in the American Pipe Makers section. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog. I want to keep reminding us of the fact that we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next pipeman or woman.

As always I am excited to finish a pipe that I am working on. I put the Courtley Imported Briar Panel Billiard back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad and hand buffed it to raise the shine. It is fun to see what the polished bowl looks like with the grain popping through on the smooth portions and the variety of colour in the rustication. Added to that the polished vulcanite saddle stem was a beautiful touch. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 43 grams/1.52 ounces. It is a beautiful pipe and one that will be on the rebornpipes store in the American Pipe Makers section. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog. I want to keep reminding us of the fact that we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next pipeman or woman.