Blog by Steve Laug

Not long ago I received a phone call from an interesting woman who had been given my phone number by a local pipe and cigar shop. She had a couple of pipes that needed some stem repair. In our conversation it turned out that they belonged to her husband and he had a total of two pipes. Both of them needed work and she was determined to get them repaired for him. In our talking we spoke of the options – either repairing the stem or making a new stem. She spoke with him and they decided to repair them. A few days later her husband stopped by the house to show me the two pipes. We talked and he decided to work on one pipe at a time so that he would have one to smoke while I repaired the other one. I finished the repair on the stem of his Big Ben Nautic 252 bent apple kind of quasi brandy shaped pipe. Here is the link to the stem repair on that pipe. https://rebornpipes.com/2017/12/22/restoring-repairing-a-damaged-stem-on-a-big-ben-nautic-252/ I returned it to him and he dropped off his second pipe for a repair as well. Two days later he called and said he had already chomped through the repair on the one he took with him. Even with a rubber softee bit he had demolished the repair. So we decided on this one to replace the stem.

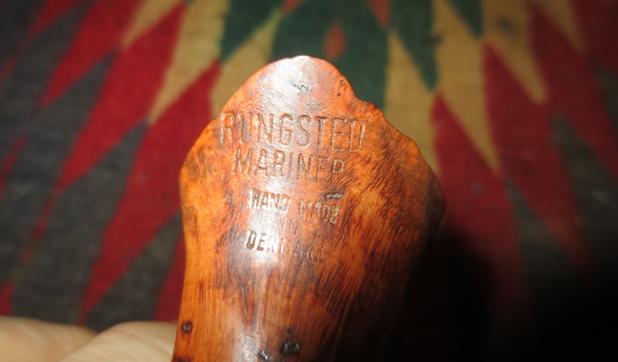

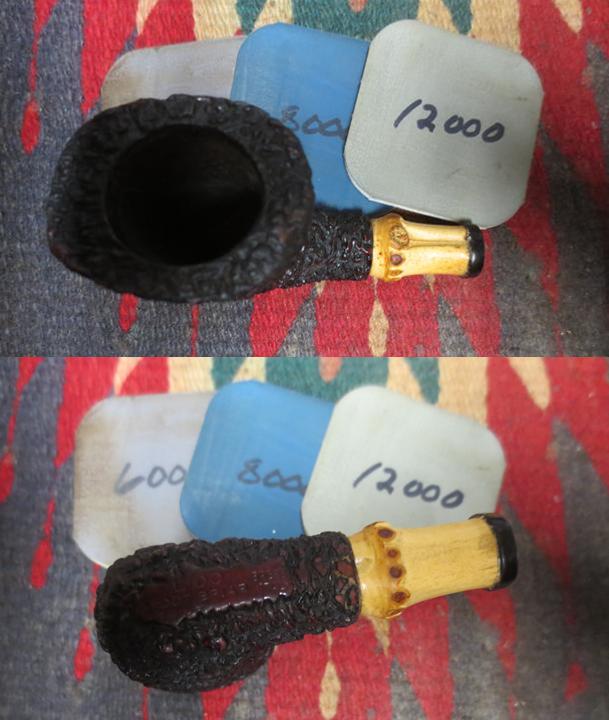

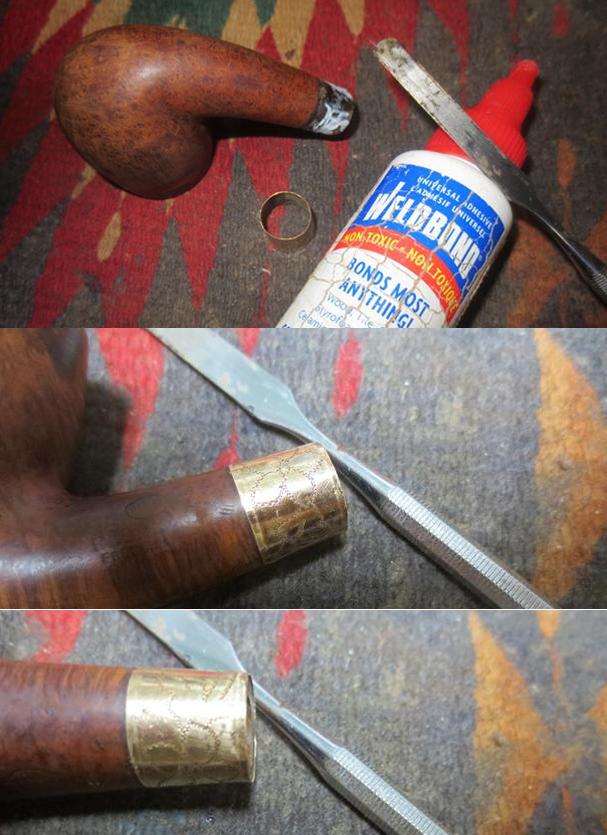

The second pipe is a Lorenzetti Galatea Bent apple shape. It is stamped on the left side of the shank Lorenzetti over Italy. On the right side it is stamped Galatea. There is no shape number on the bowl or shank. The end of the shank has a decorative ferrule that is silver with two silver rings and a Lucite ring. The original stem also had a silver band between the shank and the rest of the stem. Lots of bling on this Italian beauty. The stem was black acrylic. From the side view photos below the pipe looked pretty good. The finish was dirty but the pipe appeared to be in decent condition. The top view photos show what the bowl and stem looked like from the top and underside views. Like the other pipe the bowl on this one had never been reamed and there was a thick cake that was composed of aromatic tobacco. It was soft and sticky. The lava overflow on the rim top was also sticky to touch. The smell of the pipe was a sickly sweet and sour smell of a pipe that had never seen a pipe cleaner and never had been cleaned. Once again he had gnawed the stem and had broken the top edge and a bit of the stem in front of the button. It was a mess. The underside had deep tooth marks and was also damaged. The poor pipe was a mess but he obviously smoked it as much as he did the first one. Now I had a task – clean and replace the stem on this one so that I could put a new stem on the first one. I had a mission. I took photos of the pipe before I cleaned it up.

I took a close up photo of the bowl and rim to show the thickness and composition of the cake and the thick overflow of lava on the rim top. It looked to me that there was some damage to the inner edge and bevel of the rim on the right side of the bowl toward the back. I would know more once I reamed the cake back and could see what was underneath. It was not in nearly the condition of the Big Ben that finished for him early. I also took some photos of the stem damage so that you could see what I was up against. The sad thing to me was that this second pipe had exactly the same damage to the stem and the bowl looked identical as well.

I took a close up photo of the bowl and rim to show the thickness and composition of the cake and the thick overflow of lava on the rim top. It looked to me that there was some damage to the inner edge and bevel of the rim on the right side of the bowl toward the back. I would know more once I reamed the cake back and could see what was underneath. It was not in nearly the condition of the Big Ben that finished for him early. I also took some photos of the stem damage so that you could see what I was up against. The sad thing to me was that this second pipe had exactly the same damage to the stem and the bowl looked identical as well. I reamed the bowl back to bare briar with a PipNet pipe reamer. I started reaming it with the smallest cutting head and worked my way up to the second cutting head which matched the diameter of the bowl. I touched up the reaming with a Savinelli Fitsall Pipe knife.

I reamed the bowl back to bare briar with a PipNet pipe reamer. I started reaming it with the smallest cutting head and worked my way up to the second cutting head which matched the diameter of the bowl. I touched up the reaming with a Savinelli Fitsall Pipe knife. The rim was in rough condition. There was gouging around the inner edge of the bowl cause by a knife and there was some charring in that area as well. The rest of the rim was in rough condition and appeared to have been knocked about a bit. It would need to be topped and reworked.

The rim was in rough condition. There was gouging around the inner edge of the bowl cause by a knife and there was some charring in that area as well. The rest of the rim was in rough condition and appeared to have been knocked about a bit. It would need to be topped and reworked. I topped the bowl on a hard board with a piece of 220 grit sandpaper. I was able to remove much of the surface damage to the rim top. The second photo below shows the top of the rim after the topping. You can see the charred area in that photo as well.

I topped the bowl on a hard board with a piece of 220 grit sandpaper. I was able to remove much of the surface damage to the rim top. The second photo below shows the top of the rim after the topping. You can see the charred area in that photo as well. I used a folded piece of 220 grit sandpaper to re-bevel the inner edge of the rim and smooth out the damaged areas on the right inner edge. I blended that area into the rest of the beveled rim. Once it was shaped correctly I wiped it down and polished the briar with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-6000 grit pads. I restained the top and inner edge of the rim with a dark brown stain pen. The colour blended well with the rest of the bowl.

I used a folded piece of 220 grit sandpaper to re-bevel the inner edge of the rim and smooth out the damaged areas on the right inner edge. I blended that area into the rest of the beveled rim. Once it was shaped correctly I wiped it down and polished the briar with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-6000 grit pads. I restained the top and inner edge of the rim with a dark brown stain pen. The colour blended well with the rest of the bowl. I had enough of the smell of the pipe permeating the workspace so I decided to rid it of the smell filled my work area. I used pipe cleaners, cotton swabs and alcohol to clean out the interior of mortise and the airway in the shank. I used a dental spatula to scrape the walls of the mortise area. It took a lot of pipe cleaners to remove all of the buildup but once it was clean the pipe smelled better and it would be more pleasant for me to work on.

I had enough of the smell of the pipe permeating the workspace so I decided to rid it of the smell filled my work area. I used pipe cleaners, cotton swabs and alcohol to clean out the interior of mortise and the airway in the shank. I used a dental spatula to scrape the walls of the mortise area. It took a lot of pipe cleaners to remove all of the buildup but once it was clean the pipe smelled better and it would be more pleasant for me to work on. With internals clean I turned my attention to the outside of the briar. I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the smooth finish, enliven and protect the briar. I hand rubbed it with my fingers and wiped it off with a soft cloth. I buffed the bowl with a soft cotton cloth to polish it. It really began to have a rich shine in the briar. I took some photos of the bowl at this point to mark the progress in the restoration.

With internals clean I turned my attention to the outside of the briar. I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the smooth finish, enliven and protect the briar. I hand rubbed it with my fingers and wiped it off with a soft cloth. I buffed the bowl with a soft cotton cloth to polish it. It really began to have a rich shine in the briar. I took some photos of the bowl at this point to mark the progress in the restoration.

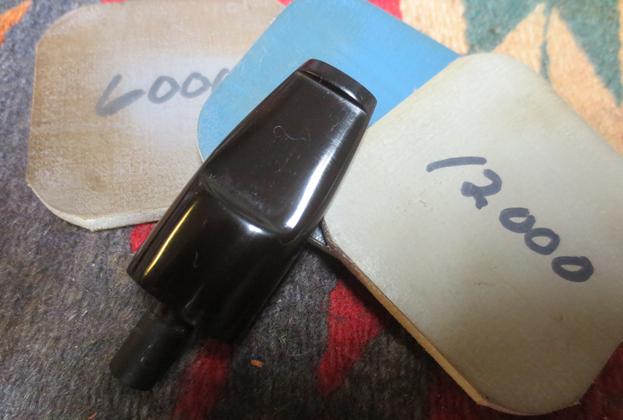

With the bowl finished I set it aside and went through my can of stems to find one that would work well with the pipe. I had two that could work – one was a vulcanite stem that had promise and looked good on the shank. It was the same length but slightly smaller in diameter than the original stem. The other stem was Lucite/acrylic. It was the same diameter as the previous stem and about 1/8 inch shorter. It also looked good with the pipe. Neither stem had the metal adornment on the end. I had nothing like that in my available stems. I chose the acrylic stem as it as harder than the vulcanite and I believe it will outlast the vulcanite stem with this particular pipe man. The tenon was slightly shorter but the shank was wide open with a deep mortise that was designed for a filter. I figured the length of the tenon did not matter in this case. I bent the stem over a heat gun to match the original stem. I sanded out the nicks and marks on the stem surface. The second and third photos below show the stem after the bend.

With the bowl finished I set it aside and went through my can of stems to find one that would work well with the pipe. I had two that could work – one was a vulcanite stem that had promise and looked good on the shank. It was the same length but slightly smaller in diameter than the original stem. The other stem was Lucite/acrylic. It was the same diameter as the previous stem and about 1/8 inch shorter. It also looked good with the pipe. Neither stem had the metal adornment on the end. I had nothing like that in my available stems. I chose the acrylic stem as it as harder than the vulcanite and I believe it will outlast the vulcanite stem with this particular pipe man. The tenon was slightly shorter but the shank was wide open with a deep mortise that was designed for a filter. I figured the length of the tenon did not matter in this case. I bent the stem over a heat gun to match the original stem. I sanded out the nicks and marks on the stem surface. The second and third photos below show the stem after the bend.

I continued to sand out the nicks and scratches with 220 grit sandpaper to smooth out the stem surface. There were a lot of rough places on the stem and the tenon that needed to be smoothed out and blended into the surface.

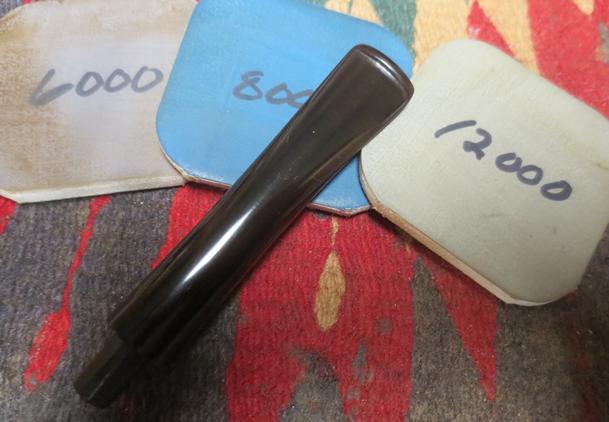

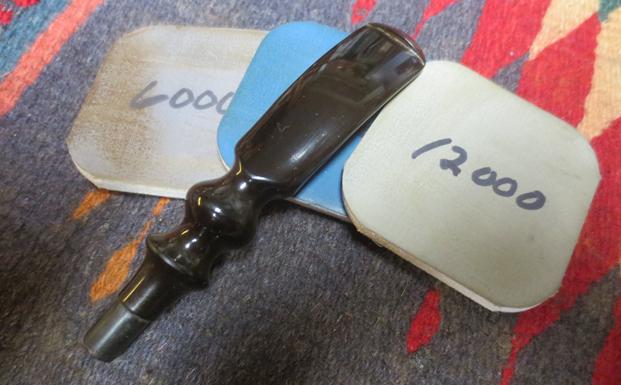

I continued to sand out the nicks and scratches with 220 grit sandpaper to smooth out the stem surface. There were a lot of rough places on the stem and the tenon that needed to be smoothed out and blended into the surface. I polished out the sanding scratches and marks in the acrylic on both sides of the stem and the button surface itself with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped down the stem after each pad with a damp cloth to remove the sanding dust. I used a series of needle files to open the stem and funnel the airflow. After that I buffed the stem on the buffing wheel with Blue Diamond to polish out the final scratches in the acrylic.

I polished out the sanding scratches and marks in the acrylic on both sides of the stem and the button surface itself with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped down the stem after each pad with a damp cloth to remove the sanding dust. I used a series of needle files to open the stem and funnel the airflow. After that I buffed the stem on the buffing wheel with Blue Diamond to polish out the final scratches in the acrylic.

I put the stem on the bowl and worked the pipe bowl over on the buffing wheel using Blue Diamond to polish the bowl and stem. I hand buffed the stem to raise the gloss on the stem and polished the metal stem adornment with a silver polishing cloth. I gave the bowl and stem multiple coats of carnauba wax and buffed it with a clean buffing pad to raise the shine. I buffed the entire pipe with a clean microfiber cloth to deepen the shine. The finished pipe is shown in the photos below. The medium brown stains on the smooth finish of the apple shaped bowl works well with the rich black of the Lucite stem. The new stem and the polishing revealed a beautiful piece of briar and a well-shaped pipe. Thanks for looking.

I put the stem on the bowl and worked the pipe bowl over on the buffing wheel using Blue Diamond to polish the bowl and stem. I hand buffed the stem to raise the gloss on the stem and polished the metal stem adornment with a silver polishing cloth. I gave the bowl and stem multiple coats of carnauba wax and buffed it with a clean buffing pad to raise the shine. I buffed the entire pipe with a clean microfiber cloth to deepen the shine. The finished pipe is shown in the photos below. The medium brown stains on the smooth finish of the apple shaped bowl works well with the rich black of the Lucite stem. The new stem and the polishing revealed a beautiful piece of briar and a well-shaped pipe. Thanks for looking.