Blog by Steve Laug

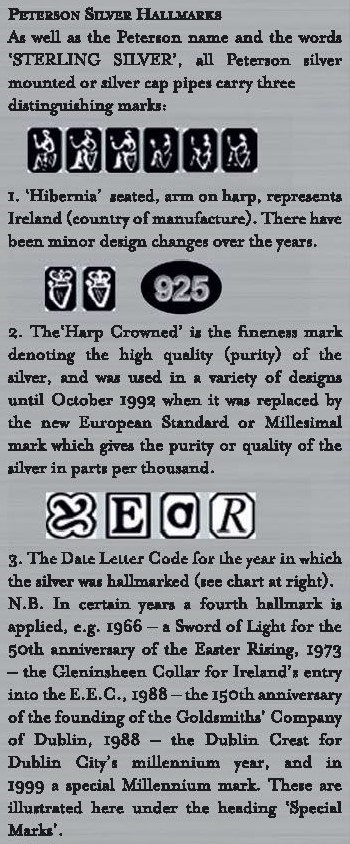

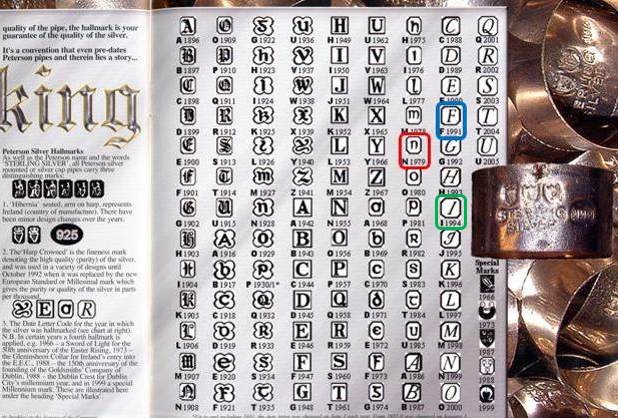

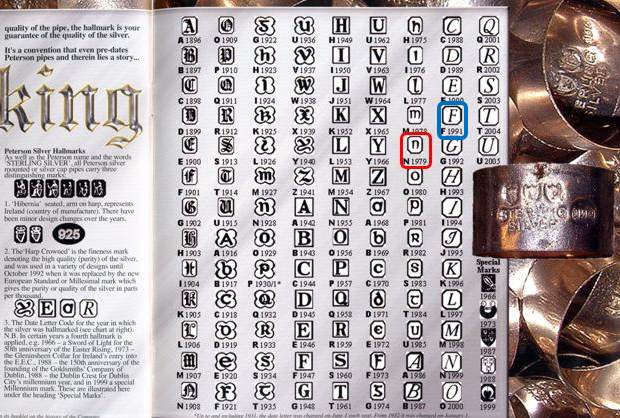

In the last box of pipes Jeff sent me there was a Peterson’s De Luxe that came to us from our contact in Copenhagen, Denmark on 04/11/2023. This one is a Peterson’s De Luxe Bent Billiard. It is stamped on the left side of the shank Peterson’s [over] Deluxe and on the right side it bears the shape number 4S near the bowl shank junction and Made in the Republic of Ireland (three lines). It was a dirty pipe when we received it. The walls of the bowl and shank had tars and oils ground into finish and it was quite grimy. There was a thick coat of lava on the rim top and the inner edge of the rim. There was a thick cake in the bowl that had remnants of tobacco stuck in it. The ferrule on the end of the shank was Sterling Silver. It was stamped Peterson’s [over] Dublin. That is followed by Sterling [over] Silver. Next that there are three silver hallmarks. The first was Hibernia seated, arm on a harp for the country of manufacture. The second was a Crowned Harp designating sterling quality. The third mark was a date stamp and, in this case, a lower-case cursive “n” which dated the pipe as a 1979. Next to that it is engraved RH in script followed by the date 1979. The stem was oxidized and there were tooth marks and chatter on the top and underside ahead of the button. When the stem was removed the tenon had the metal (aluminum) chimney screwed into the end. Jeff took some photos of the pipe before he started his cleanup work.

He took photos of the bowl and rim top to show their general condition. You can see the tars on the bevelled inner edge of thick lava coated rim top. The cake in the bowl is quite thick and there is tobacco debris on the walls of the bowl. The finish on the bowl is very dirty with grime and oils ground into the bowl, but still very stunning. This pipe has a classic Peterson’s P-lip stem that has some oxidation, calcification on the surface of the vulcanite. There is chatter and tooth marks on the top and underside.

He took photos of the bowl and rim top to show their general condition. You can see the tars on the bevelled inner edge of thick lava coated rim top. The cake in the bowl is quite thick and there is tobacco debris on the walls of the bowl. The finish on the bowl is very dirty with grime and oils ground into the bowl, but still very stunning. This pipe has a classic Peterson’s P-lip stem that has some oxidation, calcification on the surface of the vulcanite. There is chatter and tooth marks on the top and underside.

Jeff took a photo of the fit of the stem against the shank. It is a part of the De Luxe design that the stem sit slightly above the shank end Sterling Silver ferrule. The second photo below shows the aluminum chimney in the shank end that is a part of the system design by Charles Peterson. It is threaded and turned into the tenon.

Jeff took a photo of the fit of the stem against the shank. It is a part of the De Luxe design that the stem sit slightly above the shank end Sterling Silver ferrule. The second photo below shows the aluminum chimney in the shank end that is a part of the system design by Charles Peterson. It is threaded and turned into the tenon. Jeff took some photos of the sides and heel of the bowl to give an idea of the grain on this particular piece of briar. It is amazing and I cannot wait to see what it looks like once it is polished and waxed.

Jeff took some photos of the sides and heel of the bowl to give an idea of the grain on this particular piece of briar. It is amazing and I cannot wait to see what it looks like once it is polished and waxed.

He took photos of the stamping on both sides of the shank to capture it for me. The first photo shows the left side of the shank and the stamping as noted above. The second shows the right side of the shank with the Made in the Republic of Ireland stamp and shape number 4S.

He took photos of the stamping on both sides of the shank to capture it for me. The first photo shows the left side of the shank and the stamping as noted above. The second shows the right side of the shank with the Made in the Republic of Ireland stamp and shape number 4S. Jeff took photos of the stamping on the silver ferrule. It is oxidized and worn looking but the stamping is very clear and readable. The engraved initials on the silver and the date 1979 are clear and readable.

Jeff took photos of the stamping on the silver ferrule. It is oxidized and worn looking but the stamping is very clear and readable. The engraved initials on the silver and the date 1979 are clear and readable.

I did a bit of work on Google to gather background on the DeLuxe line of pipes. The first information I found was on the Peterson’s website (https://www.peterson.ie/pipes/system/deluxe-system-smooth/). I quote from the description of the line below. I have highlighted several key portions in bold black for emphasis.

I did a bit of work on Google to gather background on the DeLuxe line of pipes. The first information I found was on the Peterson’s website (https://www.peterson.ie/pipes/system/deluxe-system-smooth/). I quote from the description of the line below. I have highlighted several key portions in bold black for emphasis.

While the Deluxe stamp first appeared on our System pipes in 1940, the design itself dates to our 1896 and 1906 catalogues and, with the exception of the Supreme, has always marked our highest tier of System pipe. Like the System Standard and System Spigot lines, the Deluxe System pipe incorporates Charles Peterson’s patented System design, including a deep reservoir to collect excess moisture from the smoke; a graduated-bore mouthpiece that funnels the smoke and allows moisture to collect within the reservoir; a sturdy sterling silver military mount, which allows the pipe to be broken down and cleaned without damage or warping; and our patented P-Lip bit, which draws the smoke upward, thus reducing tongue bite. The Deluxe differs from those aforementioned lines, comprised of bowls with only the finest grain patterns and featuring a sterling silver mount and a push-gap stem, which was never designed to be flush-fitting, the space between the mount and stem base gradually decreasing with prolonged use. The Deluxe also elevates the System pipe by fixing each stem with a traditional chimney, an aluminum fitment that extends the tenon past the chamber’s airway for optimal System performance. Created for Peterson enthusiasts interested in acquiring the finest System pipe on the market, the Deluxe System will serve as the crown of any collection. Seen here in the Smooth finish.

From that information I knew how the De Luxe fit in the hierarchy of Peterson’s pipes. It was always the highest tier of the System pipes. It also was made with the gap in the fit of the stem to the shank on purpose with the idea that the distance would decrease over time with prolonged use. The attachment of a chimney at the end of the tenon to maximize System performance.

From there I also turned to Pipedia. I quote from an article by Jim Lilley and have included much of it below. (https://pipedia.org/wiki/A_Closer_Look_at_The_Peterson_Deluxe_System_Pipe). Once again I have highlighted pertinent sections in bold below.

By Jim Lilley

The version of the system pipe for our closer inspection is one of Peterson’s more recognizable series, the handsome and very distinctive Deluxe system pipes, which include the Darwin and Mark Twain. These pipes are at the top of the ‘system’ series in terms of quality and finish.

Each Peterson Deluxe is made from carefully selected, age mellowed root briar. In matt finish with hallmarked sterling silver mounts and a unique space fitting mouthpiece to allow for years of wear. They are available in a wide range of shapes numbered, as follows 1s,2s,3s,4s,5s,8s,9s,11s,12.5s,20s,XL5s, 20FB and 11FB.

The pipes are well carved, construction, engineering and workmanship, is outstanding. The stems are well drilled and aligned. Silver work is excellent, finish very good, and the often maligned briar is of outstanding quality.

The design is a very typically Peterson classic shape. Apart from the Darwin, the balance can be stem heavy, the bit is thick and chunky, especially in the larger versions. I also enjoy the sense of presence they give to the pipe, particularly if smoking in company with friends or strangers. They have a sophistication about them.

The smoking qualities are excellent, dry and cool. The draw is good, and the flavour is particularly great in new pipes. The Mark Twain’s are outstanding in this department.

As for the aesthetics and ergonomics, I find some shapes much more attractive than others. Favourites for me are the 1s,2s,3s,the Mark Twain’s and the Darwin deluxe. As a clencher most are very good to hang, except the beautiful Darwin which is more of a ‘hand holder.’

The one weakness I find is the modern orange/golden colour, (the so called natural) it is, in my opinion, less attractive than that found in the older Walnut finish of the eighties.

As far as value and cost is concerned, for the excellent quality finish, these are competitively priced at around $135 to $250 depending on size and briar grade.

For what it is worth, I reckon the Deluxe s are probably the best value range of pipes that Peterson produce, both in terms of functionality and value. There is not a thing wrong with these pipes. Those who malign the brand because they’re made by the hundreds using machines, are very wrong, IMHO. I like them a lot and the bang for the buck is the best I’ve ever seen for new pipes of this quality.

The De-luxes are all excellent smokers. The Darwin, of course, is a truly outstanding pipe, its only “flaw” being that it’s not a clencher. One particular aspect of this pipe, that appeals to me most is its physical beauty and presence, they are a pipe like no other. For me, they also offer a bowl capacity that I like and a balance in the hand that I appreciate. They are well named Deluxe s for giving that special experience.

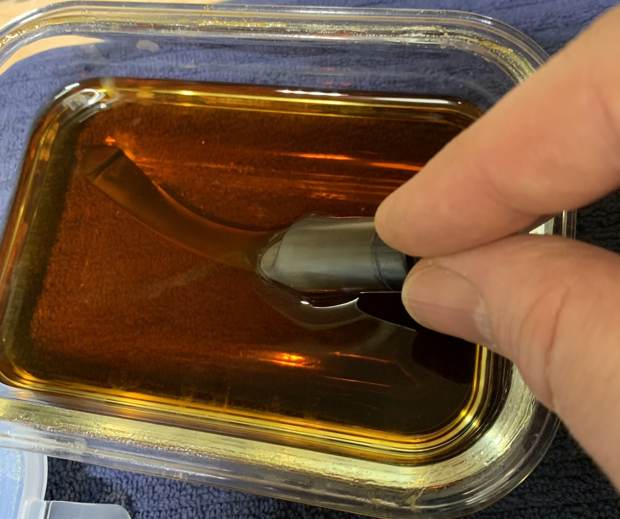

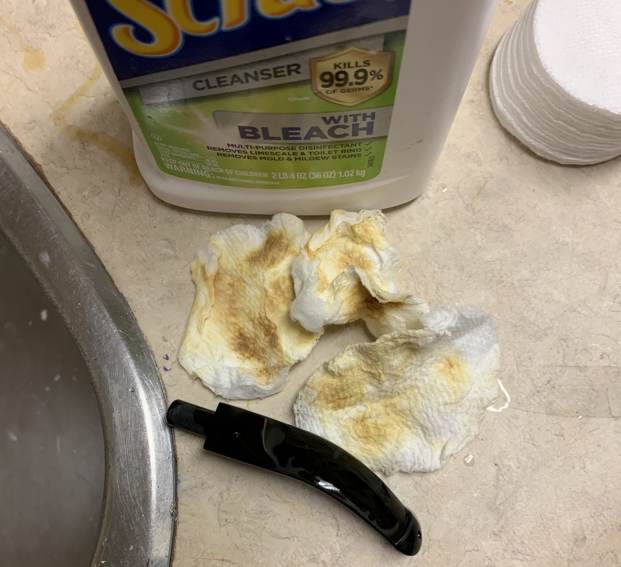

With that information at hand I turned to work on the pipe itself. Jeff had thoroughly cleaned up the pipe. He reamed the pipe with a PipNet Pipe Reamer and cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the stem with Soft Scrub to remove as much of the oxidation and calcification as possible. He soaked the stem in Briarville’s Pipe Stem Deoxidizer and rinsed it off with warm water. I took photos of the pipe once I started to work on it.

I took some photos of the rim top and stem. The rim top and bowl looked very good. The cake and lava overflow were gone and the inward bevelled rim was very clean. There was also some darkening on the back bevelled rim edge. Jeff had been able to get rid of most of the darkening and lava and tars. The rim top looked very good with no marks or nicks on the surface or edges. The closeup photos of the stem shows that it is a much cleaner and better looking stem. The light tooth chatter was still present but faint and the stem looked really good.

I took some photos of the rim top and stem. The rim top and bowl looked very good. The cake and lava overflow were gone and the inward bevelled rim was very clean. There was also some darkening on the back bevelled rim edge. Jeff had been able to get rid of most of the darkening and lava and tars. The rim top looked very good with no marks or nicks on the surface or edges. The closeup photos of the stem shows that it is a much cleaner and better looking stem. The light tooth chatter was still present but faint and the stem looked really good. I took some photos of the stamping on the shank sides and the silver on the ferrule to show the condition after the cleanup. Often the stamping takes a hit with the cleaning and is lessened in its clarity. Jeff does a great job in leaving the stamping looking very good.

I took some photos of the stamping on the shank sides and the silver on the ferrule to show the condition after the cleanup. Often the stamping takes a hit with the cleaning and is lessened in its clarity. Jeff does a great job in leaving the stamping looking very good.

I removed the stem from the shank and took a photo of the pipe at this point. Like other Peterson’s Deluxe pipes that I have worked on this stem had an aluminum chimney threaded into the tenon to extend into the lower part of the mortise and provides a funnel for drawing the smoke into the mouth of the smoker.

I removed the stem from the shank and took a photo of the pipe at this point. Like other Peterson’s Deluxe pipes that I have worked on this stem had an aluminum chimney threaded into the tenon to extend into the lower part of the mortise and provides a funnel for drawing the smoke into the mouth of the smoker. I started my restoration work on this pipe by addressing the darkening around the inner edge of the bowl. I used a folded piece of 220 grit sandpaper to clean up the bevelled inner edge and the rim top with the same sandpaper. The finish rim top looked very good. All that remained was to polish it with micromesh.

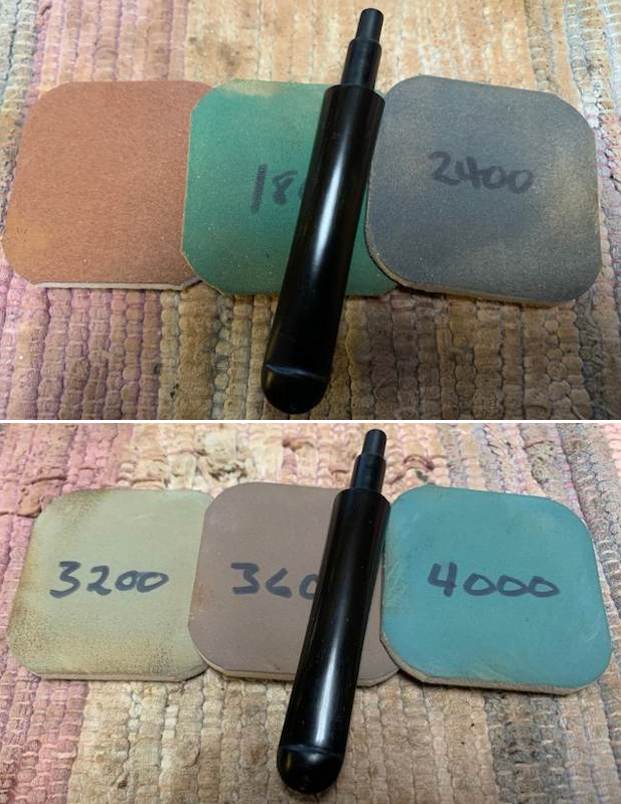

I started my restoration work on this pipe by addressing the darkening around the inner edge of the bowl. I used a folded piece of 220 grit sandpaper to clean up the bevelled inner edge and the rim top with the same sandpaper. The finish rim top looked very good. All that remained was to polish it with micromesh. I started my polishing regimen on the bowl. I used nine micromesh sanding pads and dry sanded the bowl with 1500-12000 grit pads. I wiped the bowl down with a damp cloth after each pad. The bowl really shines by the final three pads.

I started my polishing regimen on the bowl. I used nine micromesh sanding pads and dry sanded the bowl with 1500-12000 grit pads. I wiped the bowl down with a damp cloth after each pad. The bowl really shines by the final three pads.

I polished the Sterling Silver ferrule with a jewellers polishing cloth to remove the tarnish and protect it from further tarnishing. I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I polished the Sterling Silver ferrule with a jewellers polishing cloth to remove the tarnish and protect it from further tarnishing. I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I set the bowl aside and turned my attention to the stem. I filled in the deep tooth marks with black CA glue and set it aside to let the repairs cure. I smoothed them out and blended in the repairs with 220 grit sandpaper and started to polish it with a folded piece of 600 wet dry sandpaper. Once it was finished it was smooth.

I set the bowl aside and turned my attention to the stem. I filled in the deep tooth marks with black CA glue and set it aside to let the repairs cure. I smoothed them out and blended in the repairs with 220 grit sandpaper and started to polish it with a folded piece of 600 wet dry sandpaper. Once it was finished it was smooth.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with a cloth containing some Obsidian Oil.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with a cloth containing some Obsidian Oil.

I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth. I gave it a coat of Obsidian Oil to preserve and protect the stem.

I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth. I gave it a coat of Obsidian Oil to preserve and protect the stem. I don’t know how many times I have said this but I love it when I come to the end of a restoration and all of the parts come together and the pipe looks better than when we started the cleanup process. I put the stem back on the Peterson’s DeLuxe 4S System and buffed the pipe with Blue Diamond on the buffing wheel. I carefully avoided the stamping on the shank sides during the process. I gave the bowl and stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad on the buffer. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished pipe is a real stunning example of an Republic Era Peterson’s Deluxe 4S Bent Billiard. Once again, the grain and the way the shape follows the grain is amazing. Give the finish pipe a look in the photos below. I can only tell you that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 2.36 ounces/67 grams. This Peterson’s Deluxe 4S is a great piece of pipe history that is in exceptional condition. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will be putting this one on the rebornpipes store in the Irish Pipemakers Section. Let me know if you are interested in adding it to your collection. Thanks for your time.

I don’t know how many times I have said this but I love it when I come to the end of a restoration and all of the parts come together and the pipe looks better than when we started the cleanup process. I put the stem back on the Peterson’s DeLuxe 4S System and buffed the pipe with Blue Diamond on the buffing wheel. I carefully avoided the stamping on the shank sides during the process. I gave the bowl and stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad on the buffer. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished pipe is a real stunning example of an Republic Era Peterson’s Deluxe 4S Bent Billiard. Once again, the grain and the way the shape follows the grain is amazing. Give the finish pipe a look in the photos below. I can only tell you that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 2.36 ounces/67 grams. This Peterson’s Deluxe 4S is a great piece of pipe history that is in exceptional condition. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will be putting this one on the rebornpipes store in the Irish Pipemakers Section. Let me know if you are interested in adding it to your collection. Thanks for your time.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.