Blog by Paresh Deshpande

I had completed the restoration and repairs of an early (probably 1920s) cased pair of meerschaum pipes with Amber stems and had sent this pipe out to its new owner. Though the end results were very satisfying, this pair had proved to be more than handful and had tested all my skills and patience. Well, all’s well that ends well! The feedback I got from my friend as to the smoking qualities and aesthetics was greatly satisfying.

From amongst the pile of 10 odd Meerschaum pipes that awaits restoration, I selected a cased Meerschaum pipe that appeared to be in great condition requiring minimal work. That being one reason for selecting this particular pipe, the second and important reason was the classic Bulldog shape which I am quite fond of (in fact I just love all the classic British shapes). This is a large sized meerschaum pipe with a tortoise shell acrylic stem that is beautifully cut, most likely hand cut. The following picture is of this meerschaum with a group 4 sized Dunhill Bulldog and should give you an idea of the size of this pipe. The only stamping that could be seen on this pipe is on the left shank surface and is stamped as “I. BEKLER”. The stem is devoid of any stampings.

The only stamping that could be seen on this pipe is on the left shank surface and is stamped as “I. BEKLER”. The stem is devoid of any stampings. This is the first time that I have worked on a pipe that is stamped as such. Curious to know more about this pipe maker, I visited pipedia.org and a search on this site lead me to a Turkish pipe company, CAO. (https://pipedia.org/wiki/CAO)

This is the first time that I have worked on a pipe that is stamped as such. Curious to know more about this pipe maker, I visited pipedia.org and a search on this site lead me to a Turkish pipe company, CAO. (https://pipedia.org/wiki/CAO)

It was revealed that Ismet Bekler was a pipe carver who had carved many meerschaum pipes for CAO. I have reproduced certain relevant snippets of information from that article on pipedia.org.

C.A.O International, Inc. is the producer of one of the country’s top lines of premium cigars, cigar accessories, Meerschaum pipes, and pipe tobaccos. CAO’s Meerschaum pipes are smoked by presidents, senators, actors and other dignitaries. CAO was founded in 1964 by Cano A. Ozgener. Using his initials as the company logo.

Cano Ozgener’s interest in tobacco began on the banks of the Bosporus. Born on January 19, 1937, Ozgener was raised in his birthplace of Istanbul, Turkey, by his Armenian parents. His father was a jeweller, his mother a homemaker. He studied at a Jesuit French grammar school before being accepted into the American-run Roberts College in Istanbul, from which he received a bachelor’s degree in mechanical engineering in 1960.

As a student in Turkey, Ozgener enjoyed smoking pipes, especially those made from meerschaum.

Graduating from Columbia in 1964 with a professional engineering degree, Ozgener was recruited by DuPont to work in the firm’s Kinston, North Carolina, plant. It was during his stint in the textile division at the age of 27 that he came across some imperfect Turkish meerschaum pipes. In his spare time, he decided to use his engineering abilities to improve the pipes.

As Cano and the tobacconists were not happy with the quality of Turkish meerschaum, he decided to take the meerschaums and change the stems, make modifications and work with the carvers to improve them,” One day a tobacconist from Wilmington, Delaware, asked him where had he found the meerschaum, that he had never seen such quality. Cano told him that he had modified them. The tobacconist then ordered a dozen or two. That was just the beginning.

Ozgener kept his engineering job as he built his company. He worked constantly; his vacations from DuPont were spent attending tobacco conventions, which left little time to relax with his wife and two young children. Finally, in 1977, he left his engineering position to devote more attention to his growing business and to spend more time with his family.

The preceding article is reprinted here with the permission (forth coming) of Bennington Tobacconist

Ismet Bekler carved many meerschaum pipes, which were signed by him and sold by CAO, beginning in 1977. CAO actually trademarked his last name for use in 2001. Other carvers also provided pipes to CAO, and at least one other, Kural, also signed pipes made for CAO.

I surf the net to know more about the pipe carver Ismet Bekler. I chanced upon a website that had some beautiful pipes on sale and most prominently, had many un-smoked meerschaum pipes carved by Ismet Bekler. Here is the link to the website. I have also noted some information about Ismet Bekler which is given in the introduction on this website.

https://www.therightpipe.com/meerschaum-pipes/ismet-bekler-c382.html

Ismet Bekler was a prolific and popular carver. He began carving in the early 1970’s. Bekler is known as one of the best carvers in the history of Turkish Meerschaum. Master carver Bekler passed away in 2018 at the age of 84.

In 1980, the CAO Meerschaum Company contracted with Bekler to sell all of his carvings to them. CAO wanted to make Bekler a more well-known carver in the US and it was at this time he began signing his pipes.

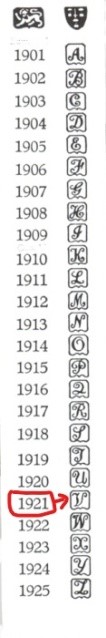

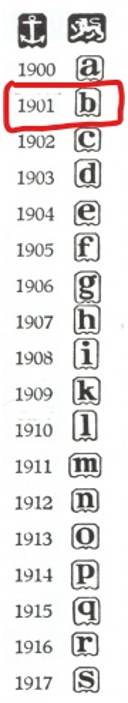

Thus, from the above, my guess would be that this pipe is from the period post 1980 but could be pre- 2001 since it is signed in full. However the lack of CAO in brass logo on the stem makes matters murky. Any inputs on this would definitely help me and other readers to know more about this pipe maker whose demise has left a void in the pipe carver’s community.

Initial Visual Inspection

The pipe, as compared to the many pipes that I have worked on till date, is in excellent condition. The case that housed this pipe and the green velvet inner lining is also in good condition. The chamber has a thick layer of cake with the rim top surface covered in overflowing lava. The stummel is in pristine condition with just a few hand stains and dust covering the stummel. The meerschaum has started coloring at the shank end. The stem too is in pristine condition with just faint traces of accumulation of old oils and tars on the metal tenon. Here are a few pictures of the pipe as it sits on my worktable.

Overall, this pipe is in excellent condition and should be an easy refurbishment project.

Overall, this pipe is in excellent condition and should be an easy refurbishment project.

Detailed Inspection

There is a heavy build up of cake in the chamber with a thicker layer seen at the bottom half of the chamber. The cake has dried and is crumbly due to prolonged storage. The condition of the inner walls of the chamber can be ascertained only after the cake has been removed completely. The rim top has darkened due to thick overflow of lava. This should be a fairly simple cleaning of the chamber. The stummel, likewise, is in good shape. There a few specs of dirt and grime on the surface that have accumulated due to oils on the human palms. These should clean up easily by wiping the stummel with oil soap. There are a couple of very light scrub marks on the base of the stummel. The mortise is not visible due to the small opening in to which fits the brass metal tenon. This would need to be cleaned using bristle and regular pipe cleaners and isopropyl alcohol.

The stummel, likewise, is in good shape. There a few specs of dirt and grime on the surface that have accumulated due to oils on the human palms. These should clean up easily by wiping the stummel with oil soap. There are a couple of very light scrub marks on the base of the stummel. The mortise is not visible due to the small opening in to which fits the brass metal tenon. This would need to be cleaned using bristle and regular pipe cleaners and isopropyl alcohol.

The stem is a beautiful acrylic tortoise shell with beautiful transparency, sharp buttons and a nice slot end. The bite zone in the stem shows slight calcification with no tooth chatter. There is a slight build up of oils and tars in the stem airway that can be seen. The brass tenon too has traces of dried oils and tars. This stem should clean up clean up easily and I just can’t wait to see the stem after all the cleaning and polishing process.

The stem is a beautiful acrylic tortoise shell with beautiful transparency, sharp buttons and a nice slot end. The bite zone in the stem shows slight calcification with no tooth chatter. There is a slight build up of oils and tars in the stem airway that can be seen. The brass tenon too has traces of dried oils and tars. This stem should clean up clean up easily and I just can’t wait to see the stem after all the cleaning and polishing process. The Process

The Process

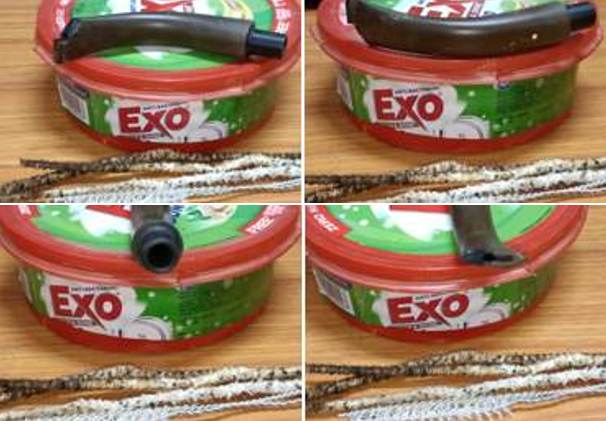

I started the refurbishing of this gorgeous pipe by cleaning the stem first. I cleaned the brass tenon and stem surface with isopropyl alcohol and cotton swabs. I ran a few bristled and regular pipe cleaners, also dipped in alcohol, through the stem airway till it was clean and transparent. I followed this cleaning up with internal cleaning of the chamber. Using my fabricated knife, I carefully scraped the accumulated cake from the walls of the chamber. I avoid using a pipe reamer while cleaning the chamber as the rotational movements of the reamer head exerts outward longitudinal forces on the walls of the chamber and may damage the walls of the chamber. Next, I used a 220 grit sand paper, pinched between my thumb and forefinger, to sand the inner walls of the chamber of the pipe. Once I had reached the bare walls, I wiped the chamber with a cotton pad dipped in isopropyl alcohol. This removed all the residual carbon dust and also rid the chamber of all ghost smells. The walls of the chamber are nice and solid with no signs of cracks. Using a sharp knife, I gently scraped out the overflow of lava from the rim top. Though the lava flow over the rim top surface had been scraped out, the darkening persisted. I would further clean out the rim surface while I cleaned the stummel surface using oil soap.

I followed this cleaning up with internal cleaning of the chamber. Using my fabricated knife, I carefully scraped the accumulated cake from the walls of the chamber. I avoid using a pipe reamer while cleaning the chamber as the rotational movements of the reamer head exerts outward longitudinal forces on the walls of the chamber and may damage the walls of the chamber. Next, I used a 220 grit sand paper, pinched between my thumb and forefinger, to sand the inner walls of the chamber of the pipe. Once I had reached the bare walls, I wiped the chamber with a cotton pad dipped in isopropyl alcohol. This removed all the residual carbon dust and also rid the chamber of all ghost smells. The walls of the chamber are nice and solid with no signs of cracks. Using a sharp knife, I gently scraped out the overflow of lava from the rim top. Though the lava flow over the rim top surface had been scraped out, the darkening persisted. I would further clean out the rim surface while I cleaned the stummel surface using oil soap. Next, I cleaned out the mortise and shank airway using shank brush and pipe cleaners. I started the process with cleaning the shank internals using shank brush dipped in isopropyl alcohol (I use only 99.9% pure alcohol). I ran this shank brush wetted with alcohol through the shank a few time and thereafter ran a couple of bristled pipe cleaners through the shank to draw out the loosened gunk. I continued the cleaning of the shank internals with pipe cleaners and alcohol till the pipe cleaners came out clean.

Next, I cleaned out the mortise and shank airway using shank brush and pipe cleaners. I started the process with cleaning the shank internals using shank brush dipped in isopropyl alcohol (I use only 99.9% pure alcohol). I ran this shank brush wetted with alcohol through the shank a few time and thereafter ran a couple of bristled pipe cleaners through the shank to draw out the loosened gunk. I continued the cleaning of the shank internals with pipe cleaners and alcohol till the pipe cleaners came out clean. I cleaned the surface of the stummel with cotton swab and Murphy’s oil soap. I also cleaned the rim top with the soap on a cotton swab. I further wiped the surface with a moist soft cotton cloth till all the traces of the soap were removed from the stummel surface. Thereafter I dried the stummel with a soft dry cotton cloth and set it aside to dry out naturally. The dark areas on the rim surface are still visible and would need to be addressed using higher invasive methods.

I cleaned the surface of the stummel with cotton swab and Murphy’s oil soap. I also cleaned the rim top with the soap on a cotton swab. I further wiped the surface with a moist soft cotton cloth till all the traces of the soap were removed from the stummel surface. Thereafter I dried the stummel with a soft dry cotton cloth and set it aside to dry out naturally. The dark areas on the rim surface are still visible and would need to be addressed using higher invasive methods.

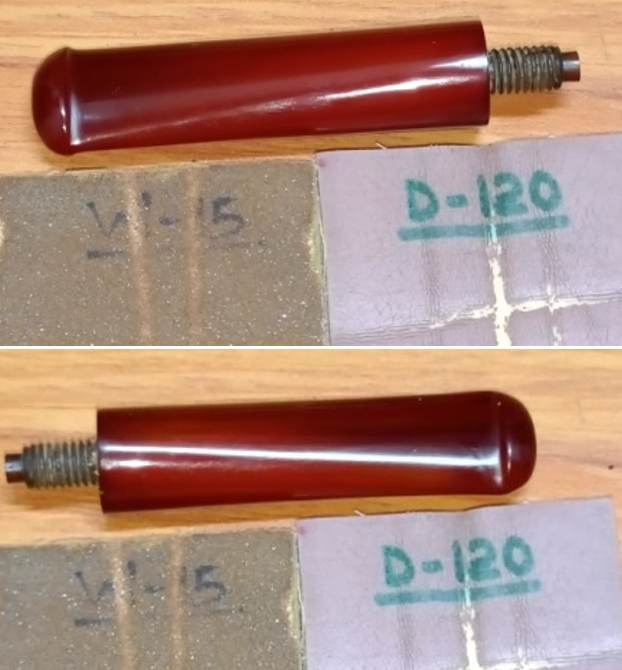

While the stem was drying out naturally, I worked the stem. I began the process of polishing the stem by wet sanding the stem surface with 600, 800, 1000, 1500 and 2000 grit sandpapers. I wiped the surface with a moist cloth and wiped the surface with a little EVO just to clean and bring a shine to the stem surface.

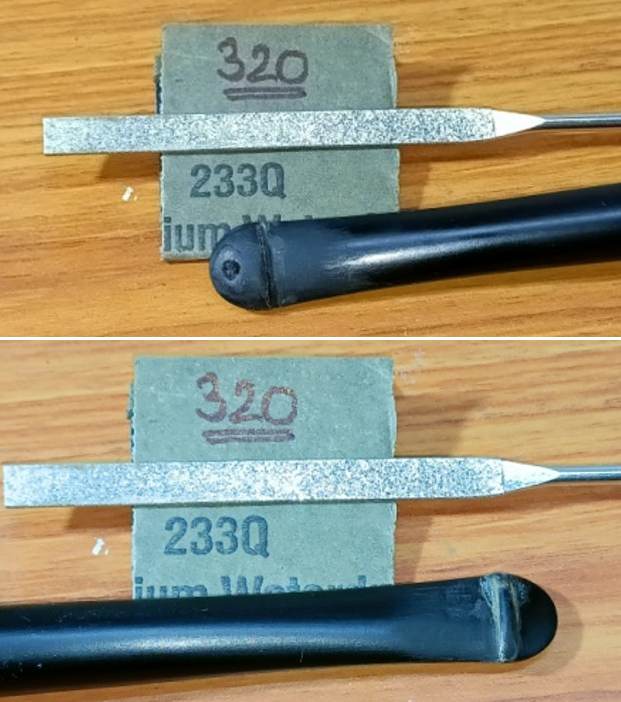

While the stem was drying out naturally, I worked the stem. I began the process of polishing the stem by wet sanding the stem surface with 600, 800, 1000, 1500 and 2000 grit sandpapers. I wiped the surface with a moist cloth and wiped the surface with a little EVO just to clean and bring a shine to the stem surface. I addressed the darkening over the rim surface by sanding the rim with a folded piece of 320 grit sandpaper. I sand the rim surface with minimum force as my intent was only to remove the dark stains and not removal of any meerschaum material from the surface. The rim looks much better now at this stage in restoration.

I addressed the darkening over the rim surface by sanding the rim with a folded piece of 320 grit sandpaper. I sand the rim surface with minimum force as my intent was only to remove the dark stains and not removal of any meerschaum material from the surface. The rim looks much better now at this stage in restoration.  I polished the stummel and specifically the rim, dry sanding with 1500 to 12000 grit micromesh pads. I wiped the stummel regularly with a dry soft cloth. I like the pristine look of the stummel after this polishing.

I polished the stummel and specifically the rim, dry sanding with 1500 to 12000 grit micromesh pads. I wiped the stummel regularly with a dry soft cloth. I like the pristine look of the stummel after this polishing.

Thereafter, I polished the stem by wet sanding the surface with 1500 to 12000 grit micromesh pads.

Thereafter, I polished the stem by wet sanding the surface with 1500 to 12000 grit micromesh pads.  The last item that required cleaning was the leather covered case that housed this pipe. Using a hard bristled toothbrush and soap water, I cleaned the velvet lining on the inside of the case. I dried the lining with paper napkins. Next, I cleaned the external surface with a moist cloth and polished the surface with a neutral color shoe polish. Once the wax was absorbed, I polished the surface with a horse hair shoe brush.

The last item that required cleaning was the leather covered case that housed this pipe. Using a hard bristled toothbrush and soap water, I cleaned the velvet lining on the inside of the case. I dried the lining with paper napkins. Next, I cleaned the external surface with a moist cloth and polished the surface with a neutral color shoe polish. Once the wax was absorbed, I polished the surface with a horse hair shoe brush. Since this Meerschaum pipe is now looking fresh and the coloration is not too developed, I decided to forego the step of polishing the stummel with beeswax. I gave a final rub down to the entire pipe with a microfiber cloth to deepen the shine. This is one gorgeous looking pipe which I am happy to include in my personal collection. Here are a few pictures of the finished pipe.

Since this Meerschaum pipe is now looking fresh and the coloration is not too developed, I decided to forego the step of polishing the stummel with beeswax. I gave a final rub down to the entire pipe with a microfiber cloth to deepen the shine. This is one gorgeous looking pipe which I am happy to include in my personal collection. Here are a few pictures of the finished pipe.