By Steve Laug

The next pipe on the table is an interesting short stemmed, sandblast Dublin that I found in a display cabinet. We purchased it from an Antique Mall in Lincoln City, Oregon, USA on 08/24/2024. The pipe is stamped on the underside of the shank Suhr [over] Kobenhavn. That is followed by Bruyere [over] EXTRA. The band covers some of the next portion of the stamp but it looks like it reads By Hand [over] a shape number beginning with 9. The band is stamped Birmingham Sterling Silver and has a T date stamp. The shank is cracked and I assume that someone put an English band on it that in no way reflects the country of origin. The bowl had a thick cake and lava overflowing on the rim top and inner edge. The sandblast finish was dirty with grime in the sandblast. The stem is worn and has been cut off and a button shaped at the end. There was no bother taken on the slot and it is uneven and rough. It leaves a short snorter of a pipe that does not quite look right. I took photos of the pipe before I started my clean up work. I have included them below.

I took a photo of the rim top, bowl and the surfaces of the stem to give a sense of the condition of the pipe. The bowl is out of round toward the front of the bowl. There was a thick lava coat on the rim edges or top filling in the sandblast. The stem is heavily oxidized, calcified and dirty. It has also been cut off a bit crooked and the button is not clean. The Sterling Silver shank band is dented, scratched and oxidized. It has also been cut at an angle.

I took a photo of the rim top, bowl and the surfaces of the stem to give a sense of the condition of the pipe. The bowl is out of round toward the front of the bowl. There was a thick lava coat on the rim edges or top filling in the sandblast. The stem is heavily oxidized, calcified and dirty. It has also been cut off a bit crooked and the button is not clean. The Sterling Silver shank band is dented, scratched and oxidized. It has also been cut at an angle. I took photos of the stamping on the sides of the shank. It is clear and readable and read as noted above. I took a photo of the pipe with the stem removed. It is definitely dirty and very oxidized on the shank extension and the stem.

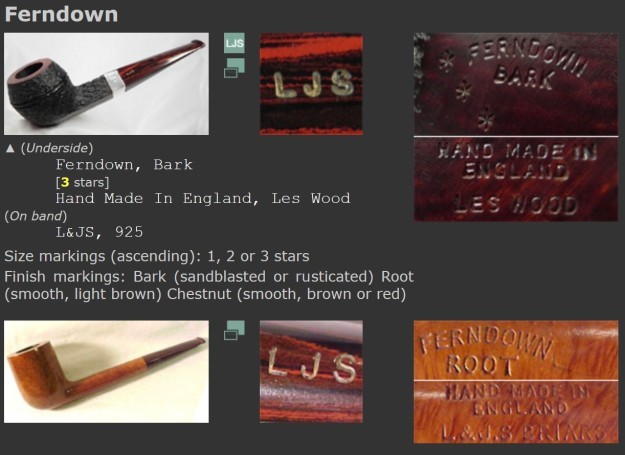

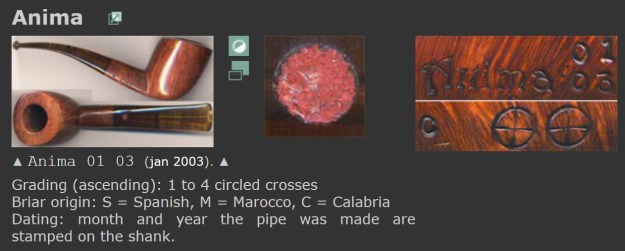

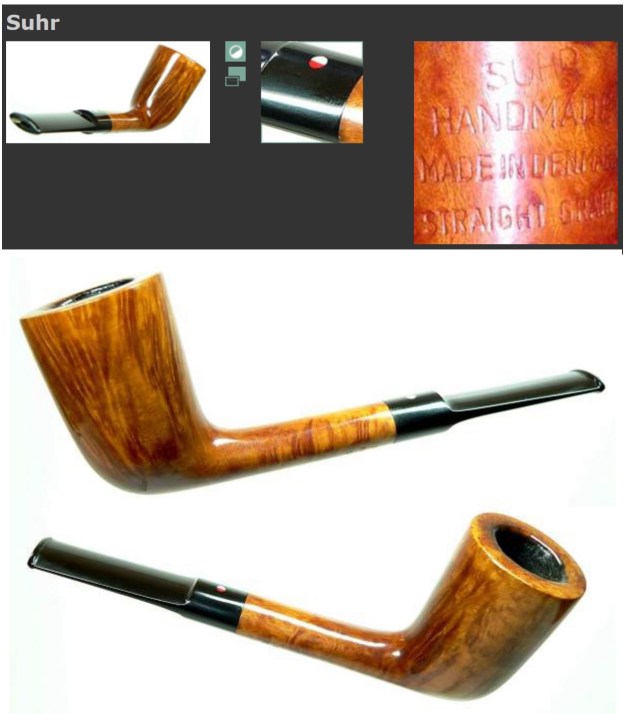

I took photos of the stamping on the sides of the shank. It is clear and readable and read as noted above. I took a photo of the pipe with the stem removed. It is definitely dirty and very oxidized on the shank extension and the stem. While I was looking at the pipe in the Antique Mall I looked up the Suhr brand on Pipephil’s helpful site where he has some great resources on stamping (http://pipephil.eu/logos/en/logo-s13.html). I had a fleeting memory of the name but I could not give it any data. I read about the brand and looked at the shape of the pipe shown on the site which was very similar to the pipe I was looking at. I was pretty convinced that the pipe at the shop was made by the same Suhr as shown on Pipephil’s site. The photos included also gave a clear picture of what the original stem may have looked like on the pipe when it left the maker. I bought it based on that information and added it to the purchase.

While I was looking at the pipe in the Antique Mall I looked up the Suhr brand on Pipephil’s helpful site where he has some great resources on stamping (http://pipephil.eu/logos/en/logo-s13.html). I had a fleeting memory of the name but I could not give it any data. I read about the brand and looked at the shape of the pipe shown on the site which was very similar to the pipe I was looking at. I was pretty convinced that the pipe at the shop was made by the same Suhr as shown on Pipephil’s site. The photos included also gave a clear picture of what the original stem may have looked like on the pipe when it left the maker. I bought it based on that information and added it to the purchase.

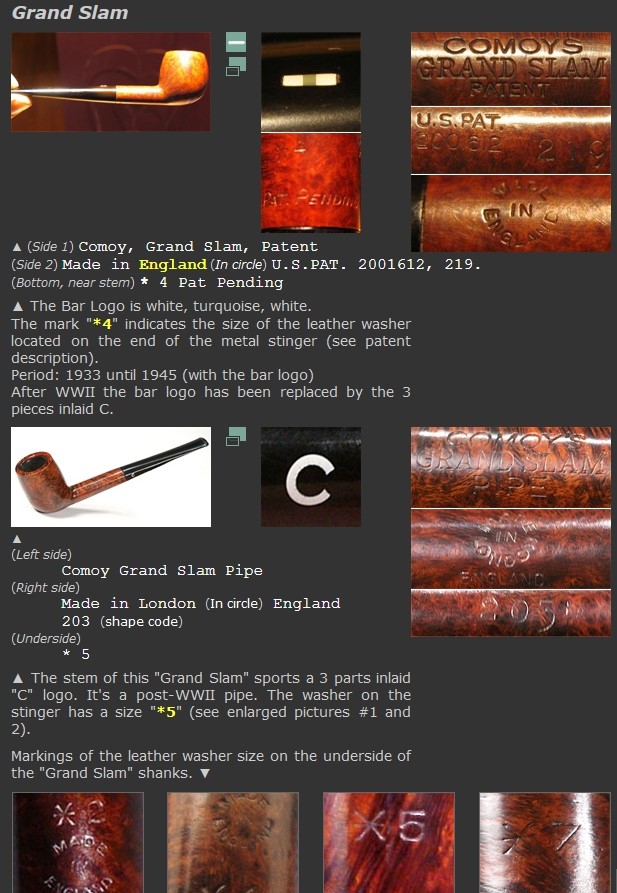

I have added the information, photos and a screen capture of the section below for the purpose of putting the information together with the restoration.

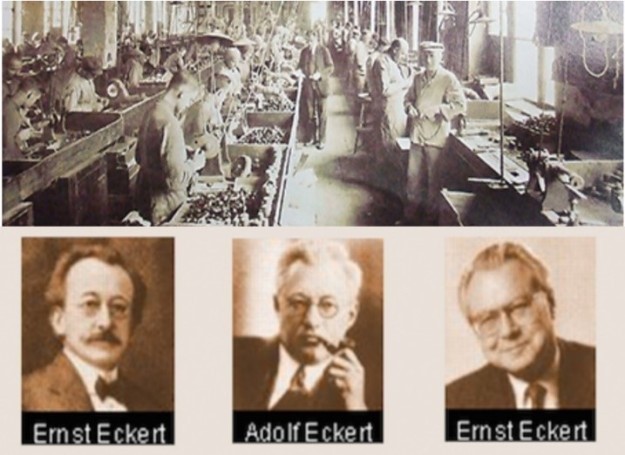

Suhr’s Pibemageri (pipe workshop) was owned by Teophil Suhr. Poul Rasmussen († 1967), Svend Axel Celius or Sven Knudsen used to produce the pipes proposed in the shop.

Suhr’s Pibemageri (pipe workshop) was owned by Teophil Suhr. Poul Rasmussen († 1967), Svend Axel Celius or Sven Knudsen used to produce the pipes proposed in the shop.

It is not established the red-white dot is Suhr’s original logo. it may be the symbol used by Poul Rasmussen himself. See also: Anne Julie (widow of Poul Rasmussen)

When I got home and before I began working on the pipe I reread PipePhil’s info included above and turned to Pipedia for more (https://pipedia.org/wiki/Suhr%27s_Pibemageri). I quote from that site below.

Suhr’s Pibemageri was a pipemaking workshop started by Teofil Suhr in Copenhagen central to the birth of the modern Danish pipe. When Sixten Ivarsson, then a debt collector newly moved to Copenhagen, broke his pipe, it was to Suhr’s he went for a repair, only to find a broken lathe and no pipemaker. Soon after, he was working as the foreman at Suhr’s, where, among others, Peter Micklson got his start and Sven Axel Celius learned pipemaking from Poul Rasmussen and his then foreman Sven Knudsen. Pipes from Suhr’s were stamped with the workshop name Suhr, and on occasion carried the same red and white dot used by Anne Julie to this day.

While it is said to be a disagreement with Suhr’s that led Ivarsson to leave for Stanwell, and all of these names went on to greater fame in later years, it would be impossible to overstate the importance of Suhr’s to the evolution of the modern smoking pipe.

I googled Suhr to find more information. I found some on the Smokingpipes.com web site (https://www.smokingpipes.com/pipes/new/suhr/). I quote the information on the brand there.

Suhr is a venerable name, tracing back to the 1940s in Copenhagen, where it was primarily a pipe repair shop before picking up pipe manufacturing. Sixten Ivarsson served as foreman there in the 1940s before moving on to Stanwell. When he left, Poul Rasmussen became foreman and made Suhr pipes until his death in 1967. His widow, Anne Julie, started making pipes at that time, and eventually trained other carvers, including Tom Eltang.

The grandson of famous pipe makers Poul Rasmussen and Anne Julie, Johannes Rasmussen trained with Tom Eltang for years before carrying on the Suhr name.

When Johannes decided to pursue pipe making, he went full circle in his family history and contacted Tom Eltang for an apprenticeship. While at the Eltang workshop, he learned the basics and began exploring his own creative voice, expanding his artistic reach until confident about breaking out on his own.

It was natural to resurrect the Suhr name for his pipes. Johannes credits his grandparents and Tom Eltang for his inspiration, and they were all part of Suhr history. He maintains a keen understanding of his place in the historical legacy of pipe making, in which he stands on the shoulders of giants.

I also turned to another site listed by google called Worthpoint. The site also showed a Suhr pipe and the description is very similar to mine (https://www.worthpoint.com/worthopedia/bruyere-extra-suhr-kobenhavn-hand-1864270360). I quote the site’s description below.

No cracks or rim chips. Reads “2085 BRUYERE EXTRA SUHR KOBENHAVN BY HAND ” on the shank.

The shape number 2085 is the only difference in the stamp. The order of the stamp is slightly different but the data is the same. From that it helped me interpret what is partially hidden under the silver band. I now knew that it read By Hand and the shape number starting 9.

Now it was time to work on the pipe. I started my work by reaming the cake and debris in the bowl. I reamed it with a PipNet pipe reamer using the 1st and 2nd cutting heads to remove the cake. I took it back to bare briar. I followed that by scraping out what remained on the bowl walls with a Savinelli Fitsall Pipe Knife. I sanded the walls smooth with 220 grit sandpaper wrapped around a piece of dowel. The bowl walls looked very good with no burn damage or checking on the walls.

I scraped the rim to with the Fitsall knife to remove the thick lava coat. I went over it with a brass bristle brush to clean out the grooves in the sandblast rim and it was starting to look better.

I scraped the rim to with the Fitsall knife to remove the thick lava coat. I went over it with a brass bristle brush to clean out the grooves in the sandblast rim and it was starting to look better. I cleaned out he internals of the shank, mortise and airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. I hard started shaping the new stem (an older worn Stanwell saddle stem seemed a fitting one to use). I paused to clean it at this point.

I cleaned out he internals of the shank, mortise and airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. I hard started shaping the new stem (an older worn Stanwell saddle stem seemed a fitting one to use). I paused to clean it at this point. I scrubbed the dirty bowl with a tooth brush and undiluted Murphy’s Oil Soap. I rinsed it off with warm water and dried it with a cotton cloth. It did a great job removing the oils and tars and overall the bowl looked much better.

I scrubbed the dirty bowl with a tooth brush and undiluted Murphy’s Oil Soap. I rinsed it off with warm water and dried it with a cotton cloth. It did a great job removing the oils and tars and overall the bowl looked much better.

I touched up the outer edge where it was worn and the top of the rim with a Maple Stain Pen. The colour was a perfect match. The only frustration was the burn damage on the front of the inner edge now really is visible. I think I will need to go back and work on that area.

I touched up the outer edge where it was worn and the top of the rim with a Maple Stain Pen. The colour was a perfect match. The only frustration was the burn damage on the front of the inner edge now really is visible. I think I will need to go back and work on that area.

I worked over the inner edge again with a folded piece of 220 grit sandpaper to give it a bevel and try to minimize the damage. Once finished I restained it with the Maple Stain Pen.

I worked over the inner edge again with a folded piece of 220 grit sandpaper to give it a bevel and try to minimize the damage. Once finished I restained it with the Maple Stain Pen. I rubbed the briar down with Before & After Restoration Balm. I worked it into the sandblast finish with my fingertips and a shoe brush. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes then I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the sandblast finish with my fingertips and a shoe brush. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes then I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

The blog is slightly out chronological order as I worked on the stem fit before I worked on the bowl but I decided to write it this way. Using your imagination walk with me through the stem fitting process. I had to search for a stem in my collection of stems that would work with this pipe. I wanted a saddle stem that had some more length on it and would require a minimum of shaping and contouring. I had a tired older Stanwell saddle stem that I think looked very similar to the Suhr in the photos on PipePhil. I think it is quite appropriate to use a Stanwell stem on this Danish piece of history. I would need to reshape the saddle portion and clean up the tenon but the stem would do the trick.

The blog is slightly out chronological order as I worked on the stem fit before I worked on the bowl but I decided to write it this way. Using your imagination walk with me through the stem fitting process. I had to search for a stem in my collection of stems that would work with this pipe. I wanted a saddle stem that had some more length on it and would require a minimum of shaping and contouring. I had a tired older Stanwell saddle stem that I think looked very similar to the Suhr in the photos on PipePhil. I think it is quite appropriate to use a Stanwell stem on this Danish piece of history. I would need to reshape the saddle portion and clean up the tenon but the stem would do the trick.  Before I cleaned up the pipe I ft the stem to the shank to get a sense of what it looked like. It would take a lot of shaping and sanding to get the fit right but I liked the look. Whoever had banded the pipe in the past had put the band on crooked so the shank end was no longer straight It was off to the left side and the stem would not face against the shank well.

Before I cleaned up the pipe I ft the stem to the shank to get a sense of what it looked like. It would take a lot of shaping and sanding to get the fit right but I liked the look. Whoever had banded the pipe in the past had put the band on crooked so the shank end was no longer straight It was off to the left side and the stem would not face against the shank well.

Since I was going to make a mess with the stem I decided to do the fitting work before I cleaned up the pipe. I used a Dremel and a Sanding drum to shape the saddle portion to fit the follow of the shank. It took a bit of work but I was able to get a rough fit.

Since I was going to make a mess with the stem I decided to do the fitting work before I cleaned up the pipe. I used a Dremel and a Sanding drum to shape the saddle portion to fit the follow of the shank. It took a bit of work but I was able to get a rough fit.  I heated the band with my heat gun to loosen the band. It was tightly in place. I used some acetone to try and it to failed. It seemed that the band had been glued in place on the shank with epoxy during the repair. It refused to move! So, the Danish Pipe would be permanently joined with a British Sterling band from Birmingham made in either 1943 or 1968. The stamping on the band was not altogether clear though it was a T. The only I am sure of is that it was added after market as a repair using a band that was handy. Left with that unmovable nature I had to work with what I had. I used a topping board with 220 grit sandpaper and hand sanding to flatten the shank end and square it up for a better stem fit. The stem fit better against the shank. Now I needed to sand the sides to shape them to match the shank curves.

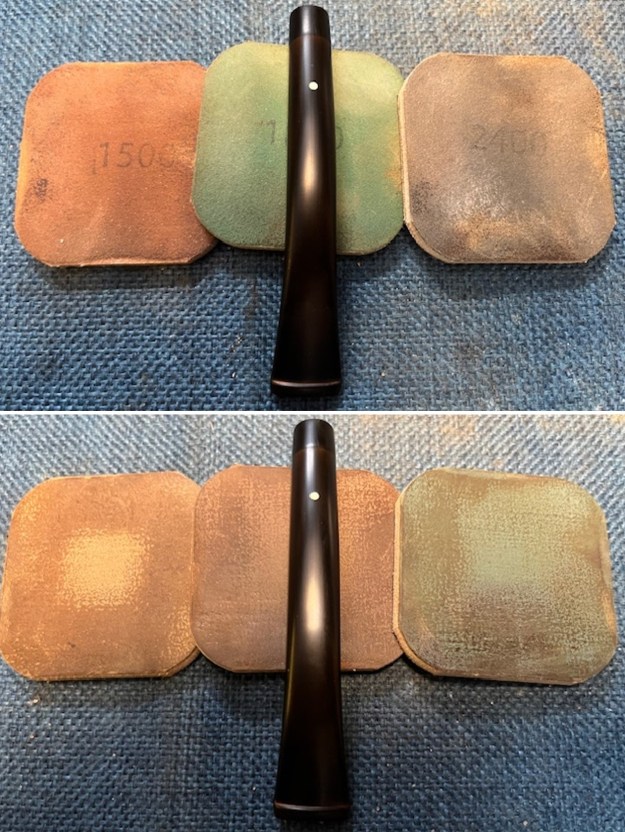

I heated the band with my heat gun to loosen the band. It was tightly in place. I used some acetone to try and it to failed. It seemed that the band had been glued in place on the shank with epoxy during the repair. It refused to move! So, the Danish Pipe would be permanently joined with a British Sterling band from Birmingham made in either 1943 or 1968. The stamping on the band was not altogether clear though it was a T. The only I am sure of is that it was added after market as a repair using a band that was handy. Left with that unmovable nature I had to work with what I had. I used a topping board with 220 grit sandpaper and hand sanding to flatten the shank end and square it up for a better stem fit. The stem fit better against the shank. Now I needed to sand the sides to shape them to match the shank curves.  I worked over the stem with 220 grit sandpaper while I sat on my front porch. I shaped it in place on the shank just to make sure the fit was right. The shape of the shank appears to be oval but it is flat on the bottom and domed on the top. It took a lot of sanding and shaping to get the fit right but the photos show where it is after much sanding.

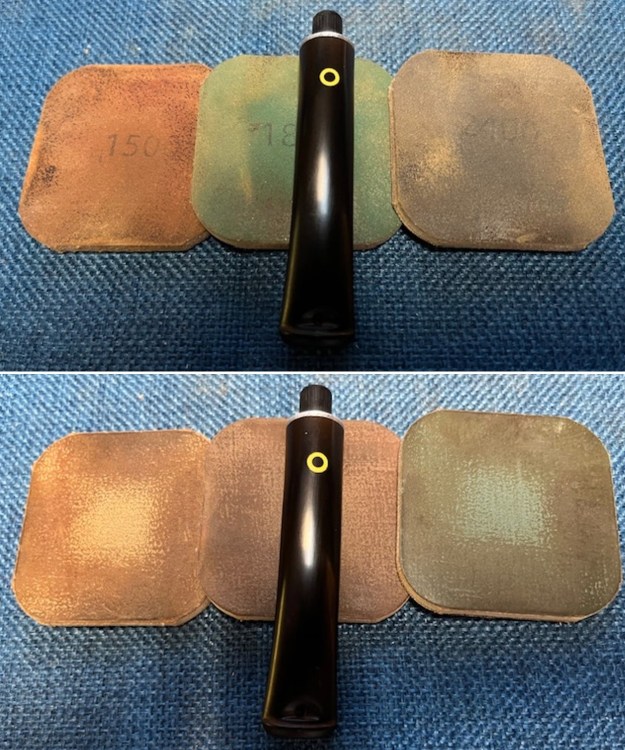

I worked over the stem with 220 grit sandpaper while I sat on my front porch. I shaped it in place on the shank just to make sure the fit was right. The shape of the shank appears to be oval but it is flat on the bottom and domed on the top. It took a lot of sanding and shaping to get the fit right but the photos show where it is after much sanding.

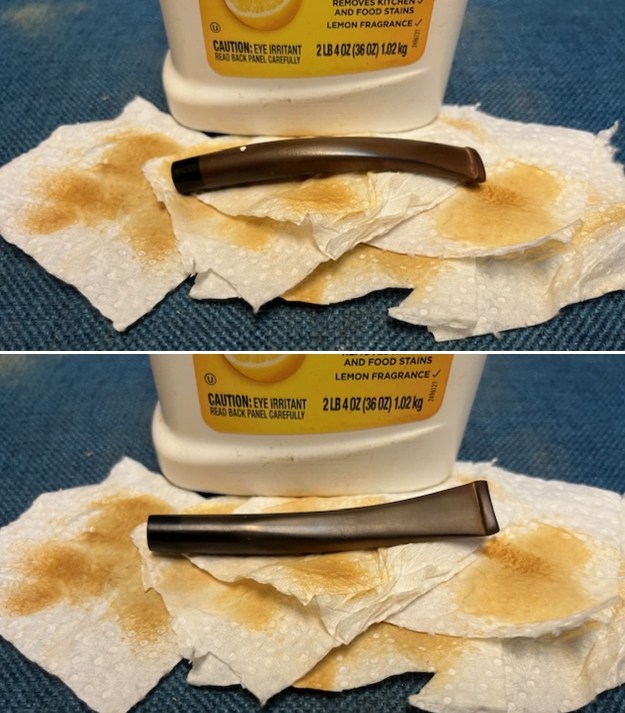

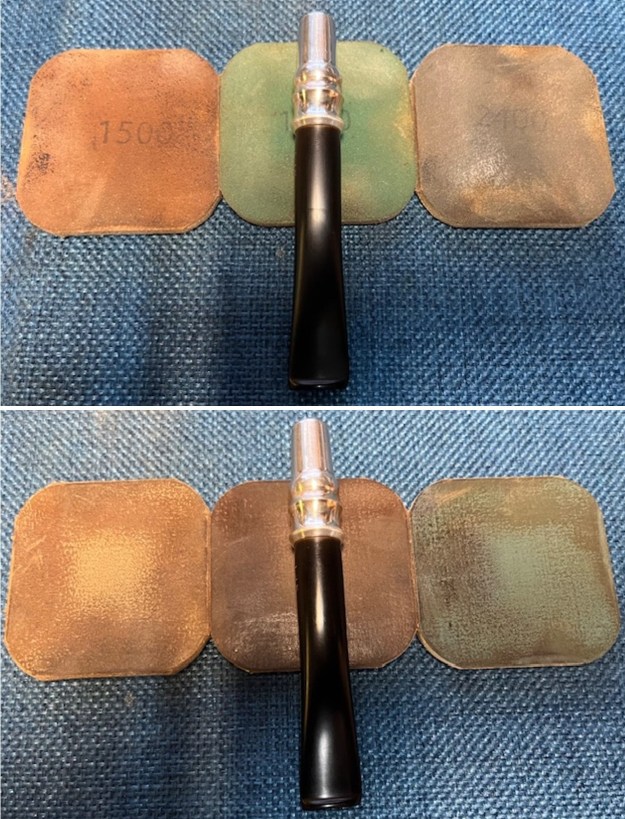

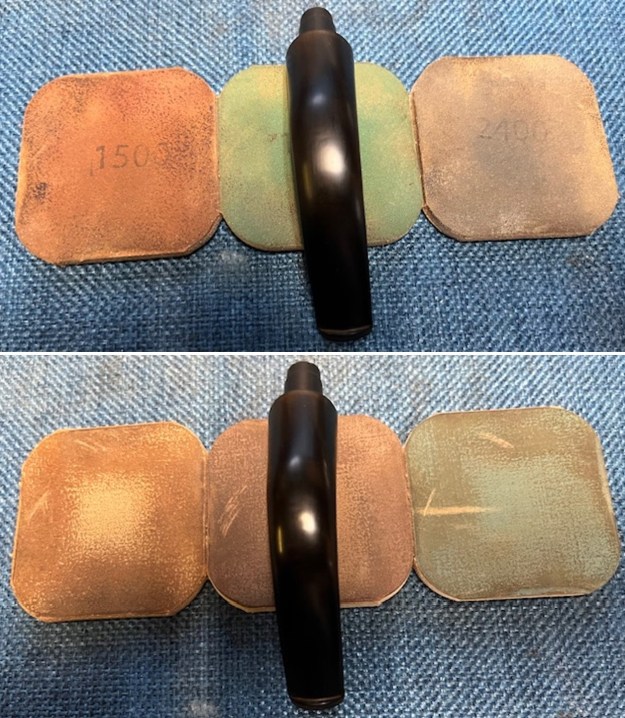

Chronologically it was at this point in the process that I removed the stem and went back and scrubbed the bowl to clean up the mess. I cleaned it and used the Balm on it. While it sat doing its magic I started the polishing process on the stem. I sanded it with 320-3500 grit sanding pads. I wiped it down after each sanding pad with an Obsidian Oil impregnated cloth. It really began to take on a finished look.

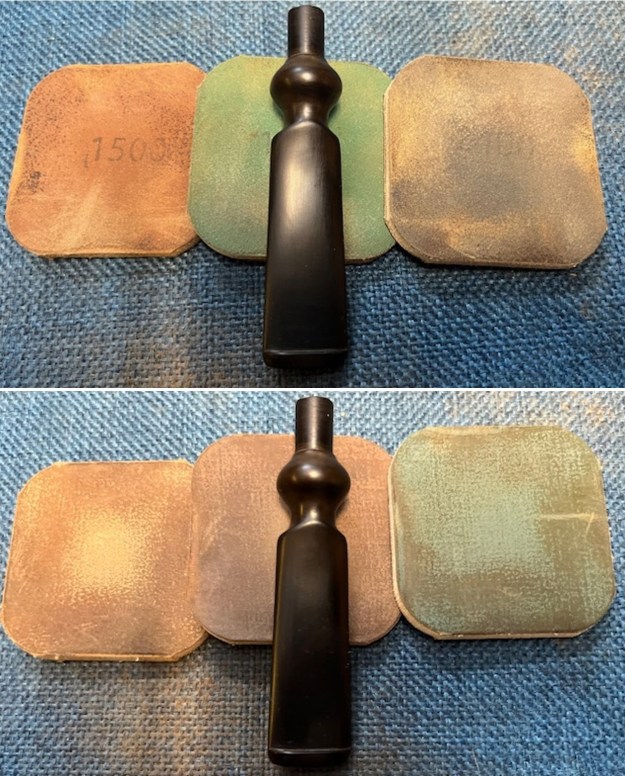

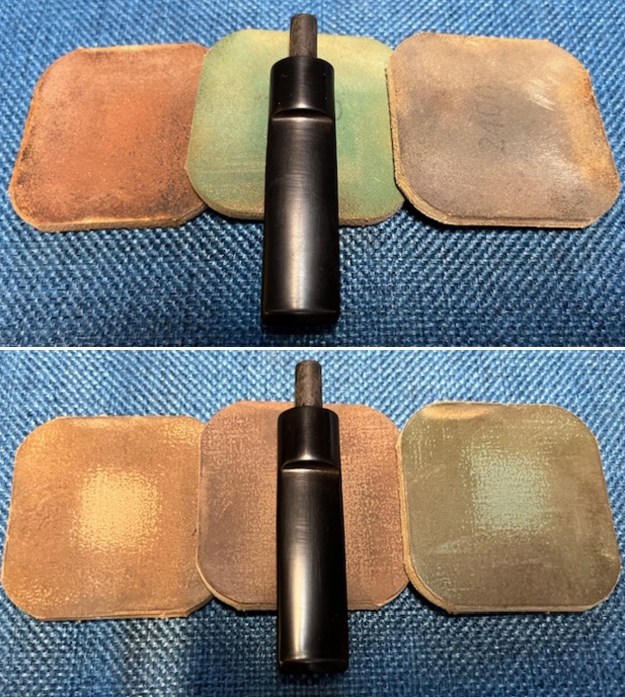

Chronologically it was at this point in the process that I removed the stem and went back and scrubbed the bowl to clean up the mess. I cleaned it and used the Balm on it. While it sat doing its magic I started the polishing process on the stem. I sanded it with 320-3500 grit sanding pads. I wiped it down after each sanding pad with an Obsidian Oil impregnated cloth. It really began to take on a finished look. I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Stem Polish – both Fine and Extra Fine to further polish the stem. I gave it a final coat of Obsidian Oil and let it dry.

I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Stem Polish – both Fine and Extra Fine to further polish the stem. I gave it a final coat of Obsidian Oil and let it dry.

This beautiful Suhr Kobenhvn Bruyere Extra Zulu with a newly fit saddle looks amazing. The briar is clean and the finish really came alive. The rich brown stains gave the finish a sense of depth with the polishing and waxing. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Suhr Kobenhvn Zule really is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¼ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 28 grams/.95 ounces. This beautiful pipe will reside in my collection at least for a while as I enjoy this piece of Danish Pipe History. If the condition of the pipe when it was found is any indicator, the pipe should be a great smoker. Thanks for reading this blog and my reflections on the pipe while I worked on it. It was a fun one to work on.

This beautiful Suhr Kobenhvn Bruyere Extra Zulu with a newly fit saddle looks amazing. The briar is clean and the finish really came alive. The rich brown stains gave the finish a sense of depth with the polishing and waxing. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Suhr Kobenhvn Zule really is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¼ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 28 grams/.95 ounces. This beautiful pipe will reside in my collection at least for a while as I enjoy this piece of Danish Pipe History. If the condition of the pipe when it was found is any indicator, the pipe should be a great smoker. Thanks for reading this blog and my reflections on the pipe while I worked on it. It was a fun one to work on.