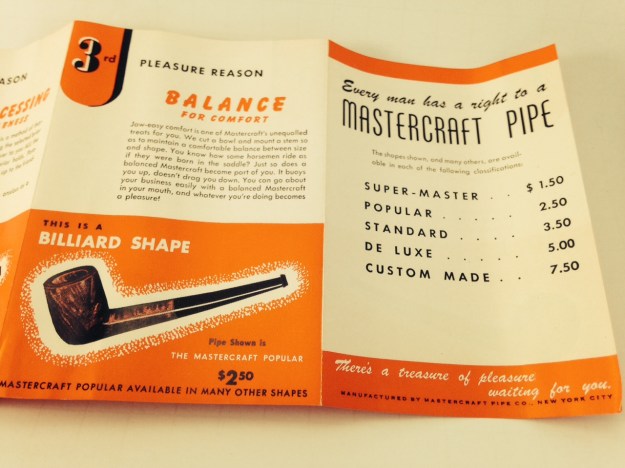

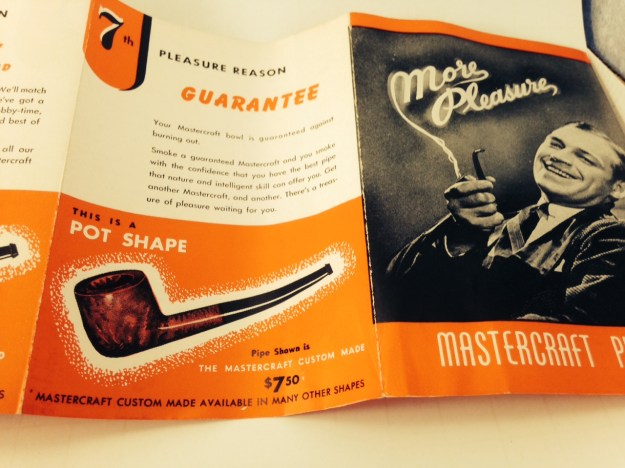

I recently posted a blog about cleaning up a Mastercraft De Luxe billiard and received an email from Andrew Selking telling me that he had a Mastercraft catalogue from the 1930’s and he sent it to me as an attachment. We both thought it would be great to post it here for the ongoing information of refurbishers who like to know a bit of the history of the pipes they are working on. Here is the brochure for your enjoyment. Thanks Andrew.

Tag Archives: Mastercraft Pipes

Breathing New Life into a Mastercraft De Luxe

Blog by Steve Laug

Another one of the gift pipes that caught my eye was one stamped on the left side of the shank Mastercraft De Luxe in the shield like the one on the left. On the right side it is stamped Century Old Mediterranean Briar Israel. I have worked on quite a few Mastercraft pipes and know that the company never made pipes itself but had makers in Italy and other places make the pipes for them. I have written another blog on the lines within the Mastercraft hierarchy and know that the De Luxe was pretty high up the list of their pipes. Here is the link to the hierarchy blog https://rebornpipes.com/2014/06/23/a-mastercraft-pipe-lines-hierarchy/

Another one of the gift pipes that caught my eye was one stamped on the left side of the shank Mastercraft De Luxe in the shield like the one on the left. On the right side it is stamped Century Old Mediterranean Briar Israel. I have worked on quite a few Mastercraft pipes and know that the company never made pipes itself but had makers in Italy and other places make the pipes for them. I have written another blog on the lines within the Mastercraft hierarchy and know that the De Luxe was pretty high up the list of their pipes. Here is the link to the hierarchy blog https://rebornpipes.com/2014/06/23/a-mastercraft-pipe-lines-hierarchy/

When I took the pipe to the worktable my first impressions were that it was in pretty decent shape. But as I looked more closely I could see the issues that were there. The bowl had some fills in the surface on the front, left side and the underside of the shank that had shrunk and were pitted pink putty. The right side of the bowl had a deep scratch in the briar at a diagonal to the bowl that cut through the finish. The varnish coat that was on these older MC pipes was flaking around the damaged rim and around the pitted fills. The rim had some charring and darkening that would need to be addressed. When I took out the stem a previous owner had coated the entire tenon with very soft waxy substance that had gone rancid. It was all over the mortise and inside and outside of the tenon. It was thick and not easily removed. The stem was oxidized and the stamping on the side had been put on at an angle which meant that the whitening only was on one side of the MC oval. The aluminum band on the stem that fit against the end of the shank had marks on it like it had been turned with a pair pliers. It was more of a mess than first met the eye.

The next photo is a close-up of the rim to show some of the damage to the outer edge and the beveled top that would need to be addressed. This would be slightly more complicated than just topping the bowl and resurfacing things. I would have to hand sand the bevel and the edges to minimize the charring and the dents on the back outer edge. I would also need to work on the inner edge of the rim to bring it back into round condition.

The next photo is a close-up of the rim to show some of the damage to the outer edge and the beveled top that would need to be addressed. This would be slightly more complicated than just topping the bowl and resurfacing things. I would have to hand sand the bevel and the edges to minimize the charring and the dents on the back outer edge. I would also need to work on the inner edge of the rim to bring it back into round condition. To facilitate the clean up on the rim I reamed the bowl back with the third cutting head of my PipNet reamer. The bowl is quite large with a diameter of 7/8 inches. I took the cake completely out of the bowl and took it back to bare wood in order to work on the inner edge of the rim.

To facilitate the clean up on the rim I reamed the bowl back with the third cutting head of my PipNet reamer. The bowl is quite large with a diameter of 7/8 inches. I took the cake completely out of the bowl and took it back to bare wood in order to work on the inner edge of the rim. The next photo shows how the reaming with the cutting head smoothed out the surface of the inner rim considerably and made my work simpler.

The next photo shows how the reaming with the cutting head smoothed out the surface of the inner rim considerably and made my work simpler. I decided to try to whiten the stamping on the stem (for a bit of a break from working on the bowl). I wanted to see if I could gain anything from the lighter stamping on the one side of the oval. I used a liquid white-out to fill the stamping and when it dried rubbed off the excess. It looked good initially but the stamping on the topside and the left leg and top of the M was too shallow to hold much of the whitener.

I decided to try to whiten the stamping on the stem (for a bit of a break from working on the bowl). I wanted to see if I could gain anything from the lighter stamping on the one side of the oval. I used a liquid white-out to fill the stamping and when it dried rubbed off the excess. It looked good initially but the stamping on the topside and the left leg and top of the M was too shallow to hold much of the whitener. I scrubbed out some of the mortise and airway in the stem with alcohol, cotton swabs and pipe cleaners to remove the rancid smelling waxy substance (the more I worked with the more it smelled and worked like lard). It took quite a bit of scrubbing to remove the thick coat of this substance. I then used a retort on the bowl and stem and boiled it out three times before I was greeted with clean alcohol. The first boil the alcohol came out black, the second time it came out amber and finally the third time it came out clean. I scrubbed out the airway and the shank a final time with the pipe cleaners and cotton swabs and the shank and stem were finally clean.

I scrubbed out some of the mortise and airway in the stem with alcohol, cotton swabs and pipe cleaners to remove the rancid smelling waxy substance (the more I worked with the more it smelled and worked like lard). It took quite a bit of scrubbing to remove the thick coat of this substance. I then used a retort on the bowl and stem and boiled it out three times before I was greeted with clean alcohol. The first boil the alcohol came out black, the second time it came out amber and finally the third time it came out clean. I scrubbed out the airway and the shank a final time with the pipe cleaners and cotton swabs and the shank and stem were finally clean.

With the interior cleaned out it was time to work on the exterior of the bowl. I scrubbed the surface of the bowl with acetone on cotton pads to remove the varnish topcoat and the grime from the finish. Then I picked out the pink putty fills and replaced them with briar dust and super glue. I put a drop of glue in the pit, tamped in dust and then a bubble of glue on top of the patch. The next two photos show the patches after they had dried and before I sanded them.

With the interior cleaned out it was time to work on the exterior of the bowl. I scrubbed the surface of the bowl with acetone on cotton pads to remove the varnish topcoat and the grime from the finish. Then I picked out the pink putty fills and replaced them with briar dust and super glue. I put a drop of glue in the pit, tamped in dust and then a bubble of glue on top of the patch. The next two photos show the patches after they had dried and before I sanded them.

I sanded the patches with 220 grit sandpaper and followed that with a medium and fine grit sanding sponge to blend it into the surface and remove the scratches. Strangely the briar dust and super glue patch did not turn black this time as I was counting on. It was almost tan coloured. I would have to use a black permanent marker to etch in lines to match the grain around the repair and then sand them lightly to blend them in. I also sanded the horizontal scratch on the right side of the bowl until it was smooth. When I had finished sanding I scrubbed the bowl another time with acetone on the cotton pads.

I sanded the patches with 220 grit sandpaper and followed that with a medium and fine grit sanding sponge to blend it into the surface and remove the scratches. Strangely the briar dust and super glue patch did not turn black this time as I was counting on. It was almost tan coloured. I would have to use a black permanent marker to etch in lines to match the grain around the repair and then sand them lightly to blend them in. I also sanded the horizontal scratch on the right side of the bowl until it was smooth. When I had finished sanding I scrubbed the bowl another time with acetone on the cotton pads.

I sanded the bevel on the rim and the inner and outer edges of the rim with a folded piece of 220 grit sandpaper and then with the sanding sponges to minimize the damage and bring the bowl back into round. I wiped down the rim with the acetone to clean up the dust.

I sanded the bevel on the rim and the inner and outer edges of the rim with a folded piece of 220 grit sandpaper and then with the sanding sponges to minimize the damage and bring the bowl back into round. I wiped down the rim with the acetone to clean up the dust. I decided to stain the pipe with a dark brown aniline stain thinned 3:1 (3 parts stain to 1 part alcohol). I wanted the stain opaque enough to cover the fills and mask them so that they did not stand out but also did not totally hide the bird’s eye and cross cut grain on the shank and bowl. This mixture of stain worked well.

I decided to stain the pipe with a dark brown aniline stain thinned 3:1 (3 parts stain to 1 part alcohol). I wanted the stain opaque enough to cover the fills and mask them so that they did not stand out but also did not totally hide the bird’s eye and cross cut grain on the shank and bowl. This mixture of stain worked well.

After I had flamed the stain to set it I rubbed the bowl and shank down with a coarse cotton cloth to blend the finish and hand buff it. I wanted to remove some of the opaqueness on the sides of the bowl and lighten the finish slightly. Once it was done I set the bowl on a cork to dry while I worked on the stem.

After I had flamed the stain to set it I rubbed the bowl and shank down with a coarse cotton cloth to blend the finish and hand buff it. I wanted to remove some of the opaqueness on the sides of the bowl and lighten the finish slightly. Once it was done I set the bowl on a cork to dry while I worked on the stem. I lightly sanded the stem with 220 grit sandpaper to remove the tooth chatter and some of the oxidation. I used the lighter to paint the flame across the surface of the stem to burn off the oxidation and also heat the tooth marks to lift them. I was able to raise all of the tooth marks using this method. The key is to keep the flame moving across the surface and to not stop in any one place too long. Once I had flamed the stem I wiped it down and sanded it with the medium and fine grit sanding sponges. I also sanded the aluminum ring to smooth out the damage on its surface and prepare it for polishing.

I lightly sanded the stem with 220 grit sandpaper to remove the tooth chatter and some of the oxidation. I used the lighter to paint the flame across the surface of the stem to burn off the oxidation and also heat the tooth marks to lift them. I was able to raise all of the tooth marks using this method. The key is to keep the flame moving across the surface and to not stop in any one place too long. Once I had flamed the stem I wiped it down and sanded it with the medium and fine grit sanding sponges. I also sanded the aluminum ring to smooth out the damage on its surface and prepare it for polishing.

With the oxidation removed I sanded the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12,000 grit pads. In between each set of three pads I rubbed the stem down with Obsidian Oil before moving on to the next set of pads. When I finished sanding with the 12,000 grit pad I rubbed it down a final time with the oil and when it dried put the stem on the pipe and took it to the buffer.

With the oxidation removed I sanded the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12,000 grit pads. In between each set of three pads I rubbed the stem down with Obsidian Oil before moving on to the next set of pads. When I finished sanding with the 12,000 grit pad I rubbed it down a final time with the oil and when it dried put the stem on the pipe and took it to the buffer.

I buffed the pipe with White Diamond and gently buffed around the stamping on the shank and the stem. I gave it multiple coats of carnauba wax and buffed it with a soft flannel buff to raise the shine. The finished pipe is shown in the photos below. The last two photos below show a close-up of the rim to show how the beveling and shaping worked to restore the look of the top of the pipe. It is ready to re-enter a life of usefulness for its next companion. It should be a great smoking pipe for whoever takes on the trust next.

I buffed the pipe with White Diamond and gently buffed around the stamping on the shank and the stem. I gave it multiple coats of carnauba wax and buffed it with a soft flannel buff to raise the shine. The finished pipe is shown in the photos below. The last two photos below show a close-up of the rim to show how the beveling and shaping worked to restore the look of the top of the pipe. It is ready to re-enter a life of usefulness for its next companion. It should be a great smoking pipe for whoever takes on the trust next.

Giving New Life to a MasterCraft Custom De Luxe Bent Billiard

Blog by Steve Laug

Yesterday morning my wife, three of our daughters and I made our after Christmas trek to the US, crossing the border at Blaine, Washington. After a great breakfast I dropped them off at the shopping mall and I made my way down to my favourite hunting grounds for pipes. I made a quick stop at Senate Tobacco Shop and sorted through some of the tins of tobacco he had in stock, though Washington prices are high they are still lower than Canada. I picked up a nice tin of McClellands Black Parrot, a Virginia, Carolina and Perique flake tobacco dated from May of 2010. I went from there to look for pipes. I went through three of my normal stops and found nothing of interested. I stopped at the last spot, figuring I would go home empty handed but the shopkeep had just picked up a few pipes. I was able to get the MasterCraft pipe on the left below and an Algerian Briar pot that had been made in France.

I really liked the shape of the old MasterCraft. The original stem was in excellent shape with no tooth marks or damage and the MC stem logo was intact. The briar had some nice spots but the pipe had a lot of fills on the bowl and shank that had fallen out and left pits in the briar. The finish was shot with peeling varnish on the sides, back and front. The stamping was sharp and read MasterCraft in the usual shield and underneath that it read Custom De Luxe. There was no other stamping on the bowl.

I really liked the shape of the old MasterCraft. The original stem was in excellent shape with no tooth marks or damage and the MC stem logo was intact. The briar had some nice spots but the pipe had a lot of fills on the bowl and shank that had fallen out and left pits in the briar. The finish was shot with peeling varnish on the sides, back and front. The stamping was sharp and read MasterCraft in the usual shield and underneath that it read Custom De Luxe. There was no other stamping on the bowl.

There was one large fill on the rim that went ¾ of the way from the outside of the bowl inward but did not enter the bowl. The putty fill on that one had shrunken and portions of it had fallen out. The bowl had a thick hard cake that was like rock. The band was stamped STERLING and was oxidized and worn. It was also loose on the shank so it was amazing that it still was with the pipe when I found it.

There was one large fill on the rim that went ¾ of the way from the outside of the bowl inward but did not enter the bowl. The putty fill on that one had shrunken and portions of it had fallen out. The bowl had a thick hard cake that was like rock. The band was stamped STERLING and was oxidized and worn. It was also loose on the shank so it was amazing that it still was with the pipe when I found it.

I took the next three photos to show the status of the fills on the bowl and shank. They were broken and loose and would take very little to remove them.

I took the next three photos to show the status of the fills on the bowl and shank. They were broken and loose and would take very little to remove them.

To soften the fills and the cake I took the stem off the bowl and dropped the bowl in an alcohol bath to soak while I cleaned up the stem. It was not in bad shape so I did not need to soak it in oxyclean. There was no oxidation on the stem only dirt and grime build up that would scrub off quite easily.

To soften the fills and the cake I took the stem off the bowl and dropped the bowl in an alcohol bath to soak while I cleaned up the stem. It was not in bad shape so I did not need to soak it in oxyclean. There was no oxidation on the stem only dirt and grime build up that would scrub off quite easily.

I removed the bowl after soaking for 30 minutes and used my PipNet reamer with the number 2 cutting head to ream the cake back to the briar.

I removed the bowl after soaking for 30 minutes and used my PipNet reamer with the number 2 cutting head to ream the cake back to the briar. I used a dental pick to pick out the remaining putty fills from the bowl and shank. The alcohol bath had sufficiently softened them so that removing them was quite simple.

I used a dental pick to pick out the remaining putty fills from the bowl and shank. The alcohol bath had sufficiently softened them so that removing them was quite simple.

I took the band off the shank and wiped the bowl and shank down with acetone on cotton pads to remove the remaining varnish.

I took the band off the shank and wiped the bowl and shank down with acetone on cotton pads to remove the remaining varnish.

With the finish removed I took out my canister of briar dust and used the dental pick to fill each of the pits in the bowl. I put the dust in them one at a time, tamped it down so that the dust was well compacted and then dripped super glue into the repair. I packed in more briar dust and then more glue. Even though the glue hardens and dries dark I find it far better than the white and pink putty fills that had been there before. I always overfill the holes as I have found in the past that to skimp on the process inevitably means that I repeat it.

With the finish removed I took out my canister of briar dust and used the dental pick to fill each of the pits in the bowl. I put the dust in them one at a time, tamped it down so that the dust was well compacted and then dripped super glue into the repair. I packed in more briar dust and then more glue. Even though the glue hardens and dries dark I find it far better than the white and pink putty fills that had been there before. I always overfill the holes as I have found in the past that to skimp on the process inevitably means that I repeat it.

I sanded the bowl and repaired fills with 220 grit sandpaper, medium and fine grit sanding sponges and then wet sanded the bowl and shank with 1500-2400 grit micromesh sanding pads. Once I had the surface of the fills blended into the surface of the briar I stained the bowl with a dark brown aniline stain. I decided to use the stain straight without cutting it to lighten it. I wanted to have the rim and top edges near the fills dark so that they would blend in with the fills well and hide them. I then stained the rest of the bowl and shank, flamed the stain and restained it until I had a good even coverage.

I sanded the bowl and repaired fills with 220 grit sandpaper, medium and fine grit sanding sponges and then wet sanded the bowl and shank with 1500-2400 grit micromesh sanding pads. Once I had the surface of the fills blended into the surface of the briar I stained the bowl with a dark brown aniline stain. I decided to use the stain straight without cutting it to lighten it. I wanted to have the rim and top edges near the fills dark so that they would blend in with the fills well and hide them. I then stained the rest of the bowl and shank, flamed the stain and restained it until I had a good even coverage.

I buffed the bowl and shank with red Tripoli and White Diamond and brought it back to the work table. I glued the silver band on the shank and polished it with a silver polishing cloth and 4000-6000 grit micromesh sanding pads. I rubbed the bowl and shank down with a light coat of olive oil to prepare it for sanding with micromesh sanding pads.

I buffed the bowl and shank with red Tripoli and White Diamond and brought it back to the work table. I glued the silver band on the shank and polished it with a silver polishing cloth and 4000-6000 grit micromesh sanding pads. I rubbed the bowl and shank down with a light coat of olive oil to prepare it for sanding with micromesh sanding pads.

The coverage on the fills was quite good. They were still there but the darker stain coat hid them and made them blend into the briar. I sanded the bowl and shank with micromesh sanding pads to lighten the stain slightly and to bring up the shine. I wanted a bit more of the grain to show through the stain so the sanding would allow that to happen. The oil on the surface helped the micromesh to cut into the briar and really smooth things. Once I had finished sanding the bowl, I set up my retort to clean out the shank and stem. I had to run three tubes of alcohol through the stem and shank before it came out clean. It was one dirty pipe.

The coverage on the fills was quite good. They were still there but the darker stain coat hid them and made them blend into the briar. I sanded the bowl and shank with micromesh sanding pads to lighten the stain slightly and to bring up the shine. I wanted a bit more of the grain to show through the stain so the sanding would allow that to happen. The oil on the surface helped the micromesh to cut into the briar and really smooth things. Once I had finished sanding the bowl, I set up my retort to clean out the shank and stem. I had to run three tubes of alcohol through the stem and shank before it came out clean. It was one dirty pipe.

When I removed the retort I cleaned out the shank and stem with a minimum of pipe cleaners and cotton swabs and with very little effort they were spotless. I sanded the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12,000 grit pads. I rubbed the stem down between each set of three pads with Obsidian Oil. I gave the stem a final coat of oil and once it dried buffed the stem with White Diamond and gave it several coats of carnauba wax to protect.

When I removed the retort I cleaned out the shank and stem with a minimum of pipe cleaners and cotton swabs and with very little effort they were spotless. I sanded the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12,000 grit pads. I rubbed the stem down between each set of three pads with Obsidian Oil. I gave the stem a final coat of oil and once it dried buffed the stem with White Diamond and gave it several coats of carnauba wax to protect.

I put the stem back on the shank and then buffed the entire pipe with White Diamond and gave it multiple coats of carnauba wax. I buffed it with a soft flannel buff to raise the shine. The finished pipe is shown below.

I put the stem back on the shank and then buffed the entire pipe with White Diamond and gave it multiple coats of carnauba wax. I buffed it with a soft flannel buff to raise the shine. The finished pipe is shown below.

For the Canadian Pipe Restorer Who Has Everything – Robert M. Boughton

Guest Blog by Robert M. Boughton

http://www.roadrunnerpipes.com

http://about.me/boughtonrobert

Photos © the Author

“The old pipe gives the sweetest smoke.”

— Irish Proverb

“Never to be underestimated is the value of shielding the water and the wind from the bowl of the pipe.”

— The Author

INTRODUCTION

Well, this isn’t a truly old pipe as was likely envisioned by the proverbial author of the Irish quote above, although it is vintage, having survived our world since the days of the yippies, give or take a few years.Certainly it can’t be ranked among the great brands, either, although its name is well-known to pipe smokers with a grain of salt or more of experience.

But it is still a pipe of note, if not, say,as fast and exotic as a Porsche or as timeless and exquisite as a Paganini violin piece, still unique in its own way. And being both weather- and spark-proof to boot, for the enthusiastic smoker determined to light up and head out into natural elements including high wind and rain, this is the tool he wants. It’s also a peach of an apple, which is uncommon for its brand, and the bowl is crafted (if not by hand) of Algerian briar – other than the Bakelite swivel cover. For briar of that origin, the grain is even very nice.

What sets this wonderful specimen of a pipe apart from all others of its ilk, though, is the absence of the brand’s initials where they once were inlaid in the stem, before the original plastic piece fell out (as I have since gathered through research is common with older pipes of this type), and the way the hole was filled.

By the way, I owe credit for the substitute inlay idea, as opposed to filling the hole with a replacement from a similar pipe or just using black Super Glue, to another restoration guru and my mentor, Chuck Richards. Thanks, Chuck, for the inspired thought, which indeed gives the pipe a definite Southwestern flair, as shall be shown.

By the way, I owe credit for the substitute inlay idea, as opposed to filling the hole with a replacement from a similar pipe or just using black Super Glue, to another restoration guru and my mentor, Chuck Richards. Thanks, Chuck, for the inspired thought, which indeed gives the pipe a definite Southwestern flair, as shall be shown.

So I ask, therefore, what better gift to present to the man who can have his pick from among all the legendary pipes, the man I have come to consider a friend and guide in pipe restoration – Steve Laug – than this simple but utilitarian Mastercraft Weatherproof-Sparkproof, made in France? I mean, Steve has already restored, and in many instances all but re-made, almost every brand and probably every style there is. Besides, he lives in Canada, where such a pipe could really come in handy.

BACKGROUND

I bought two Mastercrafts – the apple described here and its apparent mate, a tall billiard which had its MC inlay intact – among 19 pipes from an estate. I suppose that makes me responsible for the forced separation of what might have been a lifelong companionship between the two pipes, for all I know. Putting aside any such sentimental thoughts and planning on restoring most of the pipes for sale on my new Website but knowing ahead of time that I wanted to give Steve one of the Mastercrafts, I put considerable thought into which one to make the lucky winner, so to speak. I was seriously leaning toward the billiard because of its larger bowl and the fact that it was all there.

I bought two Mastercrafts – the apple described here and its apparent mate, a tall billiard which had its MC inlay intact – among 19 pipes from an estate. I suppose that makes me responsible for the forced separation of what might have been a lifelong companionship between the two pipes, for all I know. Putting aside any such sentimental thoughts and planning on restoring most of the pipes for sale on my new Website but knowing ahead of time that I wanted to give Steve one of the Mastercrafts, I put considerable thought into which one to make the lucky winner, so to speak. I was seriously leaning toward the billiard because of its larger bowl and the fact that it was all there.

Then Chuck made his breakthrough brainstorm when I asked if he knew where, other than eBay, I might find an old Mastercraft stem with which to replace the smaller pipe’s altogether or extract its precious inlay for re-implant in the original. At the time, Chuck had no idea of my intention to give one to Steve; in fact, I’m sure he thought he was helping me sell the pipe online thanks to the unique character it would have.

Of course, my ultimate choice of the right gift for Steve was made for me on the spot. Dooming the poor billiard to an uncertain future, Chuck’s brilliant advice secured for its more weathered (pun intended) but soon to be made-over adorable petite amiea definite safe harbor in this often cruel world.

THE RESTORATION

With a cursory first look at the over-the-hill pipe, it seems to be a relatively easy restoration, except maybe for the missing stem inlay.

In fact, most of the process was indeed standard including the basic mineral water bath and removal of the rim burn. Where the situation escalated somewhat was reaming the bowl, which was crusted with decades of cake buildup that made a huge pile, sanding the inside of the bowl to make it baby-smooth again and cleaning the underside of the Bakelite cover that was difficult to reach given the facts that the only way to remove the thing seemed to be to break it off, and the maximum space to get under the lid was highly limited.

In fact, most of the process was indeed standard including the basic mineral water bath and removal of the rim burn. Where the situation escalated somewhat was reaming the bowl, which was crusted with decades of cake buildup that made a huge pile, sanding the inside of the bowl to make it baby-smooth again and cleaning the underside of the Bakelite cover that was difficult to reach given the facts that the only way to remove the thing seemed to be to break it off, and the maximum space to get under the lid was highly limited.  But I used good old-fashioned elbow grease and ingenuity, and with the reamer and some 150-grit shifting to 400-grit sandpaper, I worked out the three-tiered layers of cake until the bowl was almost down to fresh briar again.

But I used good old-fashioned elbow grease and ingenuity, and with the reamer and some 150-grit shifting to 400-grit sandpaper, I worked out the three-tiered layers of cake until the bowl was almost down to fresh briar again.

Then I used up quite a few bristly stem cleaners soaked in alcohol getting under the cover and many more through the stem and shank before they came out clean. That alone took considerable time and patience.  I completed the cleaning of the bowl, shank and underside of the cover with a simple soaking with alcohol while the lid was closed.

I completed the cleaning of the bowl, shank and underside of the cover with a simple soaking with alcohol while the lid was closed.

The next task was to rub out some scratches and dings in the wood with 600 micromesh, which ended up being most difficult on the sides of the bowl where the Bakelite didn’t prevent me from going, and 1000 micromesh on the Bakelite itself.

Now, for Chuck’s suggestion, which was to insert a piece of genuine New Mexico turquoise into the hole in the stem where the original inlay once was fairly poorly set. The better part of valor being discretion, or good judgment, I was willing to take on the task myself but knew to seize a good opportunity to have it done right. That chance presented itself to me when I bought the desired piece of turquoise at a local gem store (http://www.mamasminerals.com/http://www.mamasminerals.com/).

Consulting the store’s gemologist and jeweler, a gentleman and a scholar named Dennis, on how to cut the small piece of turquoise without shattering it and make it a sturdy new part of the stem, I was surprised when he was intrigued enough by my project to offer to do it himself – for $10.

“I’ve done this kind of thing in just about everything, but never a pipe,” Dennis told me.

And so I accepted his offer, and here are the final results after re-staining the rim, buffing the bowl with White Tripoli and carnauba and doing the same to the stem with Red and White Tripoli before handing it over to Dennis to make his much appreciated contribution:

CONCLUSION

CONCLUSION

To be brief for a change, it was all worth it. Over the past two and a half years, Steve has given me so much help and friendship, in addition to the immense support I receive from Chuck, that this small token of my appreciation hardly seems adequate. Thanks again for everything, Steve. May your days and nights in Canada be windy and rainy often enough to keep enjoying this pipe.

A Mastercraft Pipe Lines Hierarchy

Blog by Steve Laug

One of the things I am always looking for online is information on the various lines of a brand of pipes. I have been working on one for Marshall Field Pipes and an amended one for other little known American lines. It is just something I do when I clean up pipes. I collect the data until I get a pretty comprehensive list. So when I found the little Mastercraft pot stamped Executive Choice it was a pretty natural thing for me to hunt down information regarding where it stood in the hierarchy of the brand. Not only do I find the information a fun part of the process for me I also find that understanding its place in the list of pipes made by a particular company gives me the desired background colour in the pipes I restore. It can give me much needed details regarding the stains and finishes used in a particular line. Here is the list Mastercraft pipes what I have called the Mastercraft Pipe Lines Hierarchy.

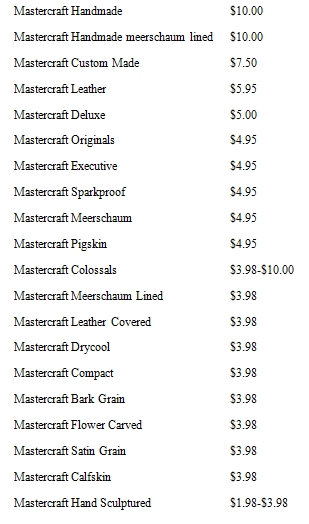

MASTERCRAFT PIPE LINES HIERARCHY (arranged from highest to lowest price)

If you happen to have either examples of any of the pipes on the list or additions or corrections please post them here.

Learned a bit of American Pipe History – Mastercraft Executive Choice Pot Restored

Blog by Steve Laug

Another pipe I picked up along with the two pairs I have written about lately is a nice little Mastercraft Pot. I am generally not taken by the pot shaped bowl but this one has a nice bevel to the rim that shows off the grain on the rim. It has some nice grain on the sides, back and front. It is stamped on the left side of the shank Mastercraft in a shield.  Underneath it is stamped Executive Choice. On the right side it is stamped Imported Briar over Italy. The stem bears the MC silver oval inserted in the side of the stem on the left side.

Underneath it is stamped Executive Choice. On the right side it is stamped Imported Briar over Italy. The stem bears the MC silver oval inserted in the side of the stem on the left side. The bowl was heavily caked and the beveled rim was covered with tars and buildup. The finish was in good shape. There were no deep scratches or dents. There were several fills but they were dark and did not stand out. The bowl was shiny but worn in some places. The stem was not too badly oxidized but it was dirty and seemed to have has a rubber bit guard on it at sometime in its life as it had left a line behind on the stem. There were no tooth marks or chatter on the stem.

The bowl was heavily caked and the beveled rim was covered with tars and buildup. The finish was in good shape. There were no deep scratches or dents. There were several fills but they were dark and did not stand out. The bowl was shiny but worn in some places. The stem was not too badly oxidized but it was dirty and seemed to have has a rubber bit guard on it at sometime in its life as it had left a line behind on the stem. There were no tooth marks or chatter on the stem.

I have cleaned up quite a few Mastercraft pipes over the years but did not really know anything about their history. I assumed that they were American made. I had heard somewhere that Bing Crosby owned stock in the company and smoked their pipes but I was not even sure of that. So I went to work digging into the background on the internet. The first thing I found was this old advertisement for the pipes with the old crooner himself.

I have cleaned up quite a few Mastercraft pipes over the years but did not really know anything about their history. I assumed that they were American made. I had heard somewhere that Bing Crosby owned stock in the company and smoked their pipes but I was not even sure of that. So I went to work digging into the background on the internet. The first thing I found was this old advertisement for the pipes with the old crooner himself.

I continued through the Google list for Mastercraft and one of the next listing was in Pipedia. http://pipedia.org/wiki/Mastercraft

I continued through the Google list for Mastercraft and one of the next listing was in Pipedia. http://pipedia.org/wiki/Mastercraft

In the article the author wrote the following: “Bing Crosby smoked Mastercraft pipes and can be seen in their magazine ads from the fifties. That isn’t a lot of info so I went looking and found a thread with posting by “Ted” — the former Exec VP of Grabow/Mastercraft http://drgrabows.myfreeforum.org/viewtopic.php?t=155&start=0

It doesn’t appear it was ever a manufacturer and bought pipes from multiple factories — mostly French and English. It survived briefly the post war recovery and then was acquired by Grabow.

The following is quoted from the thread: First a confession. From 1974 till 1984 I had several positions with Mastercraft including Executive Vice President. I also worked for Grabow from 66 till 74 and from 84 till I retired in 91. In 91, with retirement, I was President and COO for the corporation that was called “Sparta Industries”. I have seen both sides of the “fence”, and even though I never left the “employ” of Grabow, my loyalties for 10 years were with M/C.

United States Tobacco(UST)(Skoal and Copenhagen) bought Grabow in 69′ from the Lavietes family. In 74′ they bought M/C from Bernard Hochstein and moved it into the EXACT facility Grabow occupied. I was named “operations manager” and we were in the basement of a 4 story building in Sparta, NC.

M/C was STRICTLY an importer of pipes and pipe related merchandise. In 74′ when M/C moved from NYC to NC the inventory of finished goods was stored in a facility in Winston Salem, NC. Lentz Moving and Storage. Stacked 10 feet high the inventory covered 180,000 square feet….FINISHED. In my time at Grabow I had never seen that much finished stock, and the shapes, manufacturers, finishes. Heaven for a pipe smoker…..Damn right. You would have had to slap me really hard to get the grin off my face.

I’ll just list a few Manufacturers/names of the inventory. England ….Parker/Hardcastle(Dunhill) …Orlick…France…Jeantet…Jima…Cherrywoods…Italy…GIGI pipe…Radica…Rossi…Federico Rovera…Emilio Rovera…Santambrogio.Brebbia..Meerschaums from Austria…. Strambach… Lighters from Japan…Pouches and accessories from Hong Kong…and the Israeli pipes from Mr. Hochstein’s sons. Trust me…this is only a small sample of the things M/C had, and bought into inventory.

Now the connection. Since M/C and Grabow shared a building, and I was an employee of Grabow we compared notes. Grabow copied a BUNCH of M/C items fully with my help and some skills I had developed.

First was Omega…A copy of a well pipe made by Federico Rovera (FERO.com)….Freehand by the Alpha/Shalom factory…Meerschaum Lined from M. Gasparini, and later GIGI PIPE. These were originally imported by M/C for Grabow and stamped Grabow, but also stamped ITALY. Later models…better finish were made in the USA. Bucko…copied from M. Gasparini… (Gasparini, to my knowledge is the only maker of leather covered pipes in the world). If you buy a leather covered pipe it was, most assuredly covered by M/G. And you thought the wood in the Grabow COLOR was bad…..oughta unwrap one of these scrappers. There is a lot more. Questions will be answered following the presentation.

Now the other way. Grabow to Mastercraft. M/C never really had a source of continuing supply. The foreign manufacturers would make a line for a while and then quit. Never do it again, no matter how well it sold, no matter the demands we put on em’. Grabow gave M/C a source of stability and a nice profit for both companies. A lot of these you will not have heard of, but maybe….Seville, for M/C all smooth, for Grabow all rustic Hillcrest…. Freehand, For M/C Andersen and (a few Mastersen), for Grabow, Freehand with a DRB tampon. New finishes… New shapes, New bits…..Mastercraft showed Grabow how to use LUCITE for stems… Royalton…Again, these are just examples.

Ted also said: Several years before UST bought Mastercraft, M/C had acquired Marxman Pipes. A wonderful kind man, Bob Marx was still working as a salesman in NYC, and I was fortunate to make a few sales calls with him. You all remember Charles Atlas? Bob Marx was about 76 and had just been awarded the (I think) Atlas Award for being the finest specimen of manhood over 70 years old in NYC, or maybe the state.

M/C had some inventory of Marxman stuff, but not a lot. I know very little about Marxman. Did they make, import, or both?

M/C was included in all the major Christmas catalogues…Sears… Spiegel… Penney… Ward… Aldens. This was from about 70′ till 80′. We usually would have a 2 pc. Massa (pressed) Meerschaum sets from Robert Strambach, A water pipe from Brebbia, a huge Well pipe (saw one on e-bay a few days ago), and various odds and ends to fill about 6 – 8 spaces.

Let me also say one more thing about the 180,000 sq. ft. That wasn’t all pipes. It included display cases for our sets, which were made in England, and took up lots of space. Regular boxes, bags, and display material were a part, and pouches and accessories took up quite a bit.

In about 78′ UST put together a “premium products” sales force. They sold, mostly to pipe shops, products that UST owned. Tobacco from a plant in Richmond, Don Tomas cigars from Honduras, House of Windsor cigars from Red Lion PA., and M/C pipes. I think the force was 11 or 12 men and this was the heyday for M/C. What we had what EVERYONE in the pipe business wanted.

After the sales force was disbanded, M/C struggled some. This is about the time that Grabow and M/C realized what an asset we were to each other. Sales stayed pretty good for a while because of the relationships Judy Weinberger (NYC sales office and VP Mastercraft) and I had developed with the pipe shop owners.

Most of the Mastercraft pipes I have seen/bought at the bid place have an Algerian Briar stamping which makes them an attractive buy in this era. They are very reasonable and everyone has been well made with a nice draw and fine centering.”

I continued to look through various links on the web and followed this link to Pipesmokers Forum. http://pipesmokersforum.com/community/threads/mastercraft-pipes.3773/

This post from the same Ted as above appeared there. In it he confirmed some of the same information as he did in the extended post on Pipedia. He wrote: “To most pipe smokers Mastercraft Pipes are small cheap pipes, signified by the oval aluminum “MC” on the shank. Absolutely nothing special.

But Mastercraft was much more. As an importer of finished pipes M/C worked with many of the world’s foremost pipe makers and had in inventory finished product from the likes of… England, Hardcastle and Orlik. France, Ropp, Jeantet, Jean LaCroix. Italy, Lorenzo, Gasparini, Federico Rovera, Emilio Rovera, GIGI Pipe, Brebbia, Santambrogio, Fratelli Rossi. Israel, Shalom and Alpha. Plus all the tools, pouches and lighters from Hong Kong and Japan. The list of suppliers is enormous, but these are the ones I can remember after 30 years, and very few of these great pipes were ever stamped Mastercraft (some from Rossi).

Please don’t discount the importance of Mastercraft in this wonderful hobby we enjoy. Mastercraft, like Grabow, made many of our fathers pipe smokers. We all carry on the tradition…Thanks…Ted”

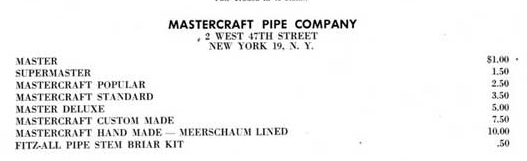

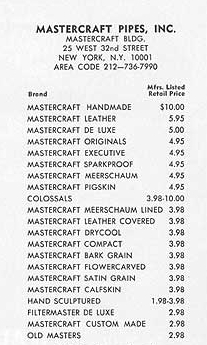

I also found some older RTDA Almanac pages on Chris’ Pipe Pages site. http://pipepages.com/index.html The first of these shows the address of the Mastercraft Pipe Company in New York before the move and purchase that Ted mentions above. It is a listing of different brands sold by the pipe company. I clipped this image from the 1949 RTDA Almanac. It is an early catalogue listing since the brand was created in 1941.

The next two photos were clipped from the 1969 RTDA Almanac. I included these as they show a list of various MC pipe lines. Note the inclusion in this list of the Executive line. It is the fifth pipe in the list below and sold for $4.95. I am assuming that the Executive Choice could be a subset of this line. The one I have is Italian made and imported to the US. The time frame fits the pipe that I refurbished so it may well be a 1969 pipe. The Italian pipes were made for Mastercraft by such Italian pipe makers as: Lorenzo, Gasparini, Federico Rovera, Emilio Rovera, GIGI Pipe, Brebbia, Santambrogio, Fratelli Rossi.

The next two photos were clipped from the 1969 RTDA Almanac. I included these as they show a list of various MC pipe lines. Note the inclusion in this list of the Executive line. It is the fifth pipe in the list below and sold for $4.95. I am assuming that the Executive Choice could be a subset of this line. The one I have is Italian made and imported to the US. The time frame fits the pipe that I refurbished so it may well be a 1969 pipe. The Italian pipes were made for Mastercraft by such Italian pipe makers as: Lorenzo, Gasparini, Federico Rovera, Emilio Rovera, GIGI Pipe, Brebbia, Santambrogio, Fratelli Rossi.

Now that I had found out some of the history of the Mastercraft brand I was intrigued. I went to work on the pipe with a new interest. I find that often a bit of history of the brand fuels my clean up and restoration work. The photo below shows the cake and the tars buildup on the rim. The rim itself was beveled inward and appeared to be unharmed under the tars. The grain was quite nice on the bevel.

I reamed the bowl with a PipNet reamer. For this bowl I used three of the reaming heads to take the cake back to bare briar so that I can build up a hard and even cake.

I reamed the bowl with a PipNet reamer. For this bowl I used three of the reaming heads to take the cake back to bare briar so that I can build up a hard and even cake.

I scrubbed the tar on the rim with Murphy’s Oil Soap to soften and remove it. It took a lot of scrubbing to break through the tar and hard carbon buildup. I put the oil soap on cotton pads and worked them against the bevel of the rim. After much scrubbing the rim was finally clean. The photo below shows the finished rim. I scrubbed down the rest of the bowl to remove the grime on the surface.

I cleaned out the shank and the bowl with pipe cleaners, cotton swabs and isopropyl alcohol. I scrubbed out the stem at the same time. Once the pipe was clean inside and out I found that the finish was covered with a thick varnish coat in a rather surprising way.

I decided to do a bit of touching up the rim edges and bevel with a dark brown aniline stain. It went on spotty and when I flamed and hand buffed it things did not feel or look right with the rim. I wasn’t sure what the issue was, the bowl had been quite shiny when I started but with the oil soap it had dulled slightly.

I found that the finish was covered with a thick varnish coat. I did not figure that out until I did a touch up stain on the rim and took it to the buffer to polish the rim. I gave the entire bowl a buff with red Tripoli. As I buffed it the finish began to bubble and peel. I have to tell you this was very frustrating and irritating at the same time. The photo below shows the bubbling of the finish on the back side of the bowl. It appears almost white in the photo.

I took the pipe back to the work table to remove the varnish coat. I wiped the bowl down with acetone on cotton pads to remove the finish. Thankfully it was a varnish and not a urethane based finish. It came off quite easily with a little scrubbing of the bowl, rim and shank. The next series of four photos show the bowl after the finish was removed. I decided I liked the colour of the bowl at this point so I did not restain it once it was clean. The rim and the bowl matched so it became unnecessary.

I sanded the stem with 220 grit sandpaper, medium and fine grit sanding sponges to remove the buildup on the stem. I then went on to sand it with micromesh sanding pads. I wet sanded it with the 1500-2400 grit pads and dry sanded with the 3200-12,000 grit pads.

I rubbed the stem down with Obsidian Oil and when it had dried I took it to the buffer and buffed the bowl and stem with White Diamond. I was careful in the buffing on the shank as I did not want to damage the stamping. When the bowl and stem shone I gave them multiple coats of carnauba wax. I gave it a final buff with a soft flannel buffing pad. The finished pipe is shown in the photos below. The first photo is a close of the beveled rim. I find that feature of this pipe to be one of its most beautiful features. The final series of four photos show various views of the finished pipe. It turned out to be a beautiful pipe with interesting grain and once the varnish was removed a more natural finish. The pipe is now ready to enter the next phase of its journey in time and be smoked by me until I pass it on to whoever comes next in its life.

Reworking a Mastercraft Custom Deluxe Billiard and Removing Mold

Blog by Steve Laug

This old Mastercraft billiard is the second pipe of the threesome that was sent to me last week as a gift. In his email asking if I wanted them he said they were either going to the rubbish bin or to me so I was not surprised when I opened the box and unpacked them. It had some nice looking grain underneath all of the grime and peeling varnish. But this one was in very rough shape. The stem was chewed in half so there was not enough to save. The inner tube apparatus inserted into the stem looked like it had been destroyed and then somebody bent it close to shape and cut a X cut in the end of the tenon so that it would fit into the stem. The shank was grimy and dark with a white mold residing inside both the bowl and the shank. The pipe reeked of mold. The bowl itself had a heavy but broken cake underneath the mold. It had a coat of varnish that was spotty and peeling where it was worn off the briar. In those worn spots the briar was almost black. The rim was also in very bad shape. The front was burned down from repeatedly lighting the pipe in the same spot with a torch. The back side of the rim looked like it had been scraped on concrete or hammered out on concrete because it was worn and broken down. The three photos below (I apologize for the poor quality – still getting used to this new camera!) show the state of the bowl and stem.

I sorted through my stems and found two options that I thought might work on the pipe. The first one was an acrylic saddle stem that I thought might look good with the bowl (pictured in the first photo below). I turned the tenon and fit it to the pipe but did not like the proportion of the stem and shank length. I then took the second stem – a shorter, straight tapered stem and fit it to the pipe (pictured in the second – fourth photo below). It looked like it belonged on the pipe so my choice was made. It was an old previously used vulcanite stem from my collection of old pre-used stems that I collect. This one would take some work as it was oxidized and had a calcified buildup around the button area. It was also clogged and the slot was plugged to a small pin hole. But it had the right look so it would be worth cleaning up.

I set the stem aside and worked on the bowl. I reamed the pipe with a PipNet reamer to get rid of the cake and the mold. I cleaned the reamer with alcohol before putting it away. I cleaned the bowl and the shank with cotton swabs, pipe cleaners and Everclear to remove as much of the tars and oils and moldy smell as possible.

When I finished it still smelled moldy, but I had several plans in mind for addressing that. But first I topped the bowl with my usual flat board and 220 grit sandpaper. I place the bowl rim down flat against the sandpaper and work in it a circle to remove the damage on the rim. This one took quite a bit of work to even out the top and get rid of the damage from the burn on the front side of the rim and the roughened back edge done by beating the pipe against concrete. I sanded it, repeatedly checking to see if I was removing enough of the damage to get a sharp edge on the bowl. On the outer rim next to the shank there was a chunk of briar missing that I would try to minimize after topping the bowl. I was able to remove all of the damage of the burned area and most of the damage of the battering the old pipe had taken. The rim looked good. I used a folded piece of sand paper to work on the inside edge of the rim and clean up the damage that was done there and keep the bowl in round.

I wiped the exterior of the bowl down with acetone on a cotton pad to remove the grime and the finish that remained. I repeated this until I could not remove any more finish or grime. The next two photos show the wipe downed bowl.

I placed the bowl in an alcohol bath for several hours while I worked on the stem and worked on several other old pipes that I have on the go. When I took it out of the bath, I dried it off with a cotton cloth and scrubbed it with a tooth-brush dipped in alcohol from the bath. I dried it again to check on the finish. There were still several spots where the varnish remained – the shank and the bottom of the bowl. One benefit of the bath was that the glue softened on the over pressed band and I was able to remove it from the shank. I sanded and scrubbed the old glue off the shank and sanded the bowl with a fine grit sanding sponge. I wiped it down with another acetone cotton pad. It still needed to soak a bit longer to finish breaking down the varnish that remained. While it soaked I cleaned up the silver band with silver polish and the jeweler’s polishing cloth. Under all the tarnish I found that the band was stamped Sterling.

I removed the bowl from the alcohol soak and dried it off. I used a lighter to burn off the alcohol from inside the bowl and the shank. I then recleaned the inside of the bowl and the shank with Everclear and many more pipe cleaners and cotton swabs. The amount of tars and sticky oils and grit that came out of the shank was incredible. It was no wonder that the pipe still reeked like mold. The next series of three photos show the pipe after soaking and sanding.

I scoured the shank until it was fairly clean and then set up a retort to do a more thorough clean. The retort sends vaporized alcohol into the bowl and shank and in essence boils out the grime with hot alcohol. As the alcohol cools it returns to the tube and with it the grime and oils from the pipe. I repeated the retort three times on the pipe until the alcohol came out clean. I then took apart the pipe and cleaned out the shank with pipe cleaners and cotton swabs a third time. There was even more oil and grime that came out of the shank. I cleaned off the surface with an acetone wipe and then reset the silver band with Weldbond glue. I turned it so that the Sterling stamp was on the top of the shank and pressed it on to the shank until it was even with the edge of the shank. Weldbond dries fairly quickly to touch so that the band would not be loosened when I went on to the next step in my cleaning process.

After removing the retort I cleaned the bowl and shank. Yet even more grime came out. I put the stem back on and took the four photos below to show the state of the pipe at this point. I did this more for an encouragement to me as this one was proving a difficult rework. The photos gave me a picture of what I was aiming for in cleaning this one up. If I lose sight of that it will end up in the bin as rubbish.

When the alcohol dried in the bowl and the visual showed a clean bowl and shank I took a sniff of the bowl. After all of this work the moldy smell still was present in the bowl and shank. This called for more drastic measures. I used the Dremel with a sanding drum on it and sanded the inside of the bowl until the briar was bare and clean. Then I filled the bowl with salt and alcohol to leach out the oil from the inside of the bowl and shank. My hope was that in doing this I would also kill the stench. I plugged the shank with a cork, filled the bowl with kosher rock salt (I was out of my normal cotton bolls) and set it up on an old ice-cube tray. I used an ear syringe to fill the bowl with 99% isopropyl alcohol. I set it aside and went to bed to let the treatment do its work while I was sleeping. The two photos below show the bowl after filling with alcohol.

In the morning the salt was a dark brown as pictured below. I emptied the now darkened salt and dried out the inside of the bowl by flaming the alcohol with my lighter. It still smelled like mold though the smell was definitely losing strength.

I cleaned out the button area of the stem with the dental pick and then ran several bristle pipe cleaners through it and then followed up with regular pipe cleaners. I soak both in Everclear to clean out the stem. I then sanded the stem with 220 grit sandpaper to remove the calcification that was all over the stem. I also gave the stem a quick sand all over with the 220 grit to remove the top oxidation. I ran the flame from the Bic lighter over the surface to burn off the oxidation. It did a great job of removing what I had loosened with the sandpaper. I continued sanding it with a fine grit sanding sponge to remove the remaining oxidation. I rubbed down with Obsidian Oil and set it aside with the bowl while I went off to work. The Obsidian Oil sat on the stem and soaked in for the 9 hours I was at work.

I refilled the bowl with salt and put a cork in the shank. I again used the ear syringe to fill the bowl with alcohol and set it aside to work on the stem. It too sat for the nine hours I was at work.

When I got home from work the stem looked quite good. It was significantly more black and the oxidation was gone except around the stem shank union. More work to do there. The salt was a dark brown, but slightly lighter than the first treatment. I dumped out the salt and cleaned out the bowl and shank with cotton swabs again. When I finished the smell was better but present nonetheless. I cleaned out the bowl with alcohol and cotton swabs again.

I needed another bit of encouragement at this point so I decided to stain the pipe with a dark brown aniline stain cut 2:1 with isopropyl alcohol. I applied the stain, flamed it and then buffed it on with Tripoli and White Diamond (photos 1-4 below). The brown did a fair job of coverage but I would need to give it a second coat of stain using a oxblood colour to do some blending with the dark areas on the bowl.

I worked on the stem with fine grit sanding sponges and 1500-2400 grit micromesh sanding pads. There were some minor tooth dents that still showed up so I passed over them with a Bic lighter and was able to raise them. More sanding was needed and I repeated the sanding described above.

Once the bowl dried out it still smelled so I decided to repeat the salt and alcohol treatment a third time. I filled the bowl with salt and isopropyl and set it aside over night (photo 1 below). In the morning the salt was little lighter brown this time (photos 2-3 below). I dumped the salt out and cleaned the bowl and shank again. This time the cotton swabs came out fairly clean. I flamed the inside of the bowl. Once the bowl dried out it still smelled so I decided to repeat the salt and alcohol treatment again. I filled the bowl with salt and isopropyl and set it aside over night. In the morning the salt was once again a dark brown. I dumped the salt out and cleaned the bowl and shank again. This time the cotton swabs came out fairly clean. I flamed the inside of the bowl. Though the inside of the bowl and the shank was very clean the musty smell still remained, though less prevalent. This was one stubborn pipe bowl to clean.

While the inside of the bowl dried out I decided to restain the bowl. For the second/top coat I used a oxblood stain. I applied it and wiped it off (first photo below). The coverage this time was much better. The dark reddish stain blended well and covered the dark areas of the bowl. The finished colour is a nice older deep reddish brown look (second-fourth photos below).

I decided to sand back the inside of the bowl yet again. I used the Dremel with the sanding drum a second time. When I was finished the inside of the bowl was very clean and fresh looking. The smell was still there. I stuffed the bowl with cotton bolls and then used an ear syringe to fill it with white vinegar and set it in the ice-cube tray to let it work. I have used that in the past to remove stubborn ghosts so I thought I would give it a try on this one.

While the bowl soaked I worked on the stem with the remaining grits of micromesh sanding pads – 3200-12,000 to bring back the deep shine on the stem. Sanding them with the higher grits of micromesh really gives a deep shine to the stem. It is amazing to see the difference between each of the successive grits of micromesh. I did not take photos of the steps as almost all of my refurbishing posts have shown the polishing process with the micromesh. The next two photos show the finished stem. Once the bowl is finished I will buff the bowl and stem with White Diamond and then give the whole a buff with multiple coats of carnauba wax to polish.

Once the vinegar had soaked in the bowl for several hours I removed the cotton boll and dried out the bowl. I then used a Dremel with a sanding drum to sand back the sides of the bowl yet again. This time I extended the diameter of the bowl to get rid of the surface area of the bowl interior. Once I was finished with the Dremel I hand sanded the bowl with 220 grit sandpaper to smooth out the small ridges left behind by the drum sanding. The last two photos in this sequence show the newly sanded bowl.

I took the bowl outside and put it in the bright sun on my patio. I wanted to let the heat and the UV rays from the sun do more work on the potential mold in the bowl. The evening is cooling down and the sun is no longer as warm. I brought in the bowl and wiped down the inside of the bowl and shank with an alcohol based anti bacterial wipe. I took it to the buffer and gave the whole pipe a buff with White Diamond. I then gave it several coats of carnauba wax and buffed it with a clean flannel buff. The pipe is like new and it SMELLS GREAT. I finally beat the moldy smell. The final four photos show the finished pipe.

Refurbished Mastercraft Bulldog

Another old timer, a Mastercraft Bulldog was in my box of bowls without stems. The squat shape of this little bulldog caught my eye.

The bowl pretty rough looking. The finish was gone and the top had been used as a hammer so it was badly dented and the roughening of the wood left a lot of splintering edges. It was also badly caked and still had a remnant of tobacco left in the bowl. Since it was missing its stem I have no idea when the bowl and tobacco got separated from the stem. I have a coffee can in which I keep a wide range of stems that I have picked up and another can of stem blanks that need to be shaped and fit to the new pipe. For this pipe I found an old stem in the can that was a perfect fit once I removed the old stinger type insert. The stem was badly oxidized virtually brown. There were no tooth marks on the stem and no dents that needed to be repaired.

I reamed and cleaned the bowl and shank until the pipe cleaners came white. I use 99% isopropyl alcohol for doing this as I find that it works well and evaporates quickly leaving no residual tastse. The top had been hammered so much that the bowl had to be topped so that it would be smooth again. The trick with this one was not to remove too much of the top and thus change the angles of the bulldog shape. So I removed enough to give me a smooth surface to work with but not enough to change the shape. Once it was topped and sanded I put it in the alcohol bath and left it while I worked on cleaning up the stem.

I had soaked the stem in a mixture of Oxyclean to soften the oxidation and prepare it for the sanding that would be necessary to clean it. Once I remove it from the soak I buffed it with Tripoli to remove the oxidation that had softened and then sanded it with 240 grit sandpaper. Once I had removed the brown surface I used 400 and 600 grit wet dry sandpaper to continue the smoothing and polishing process. I finished the stem with the micromesh pads from 1500 – 6000 grit. Then I set it aside to wait until I had finished bowl and polish the entirety on the buffer.

I took the bowl out of the alcohol bath and sanded it with the micromesh pads to remove the surface scratches and remaining marks in the bowl surface. I steamed out the dents with a damp cloth and a hot knife and then sanded them smooth again. I restained this bowl with a Medium Brown stain. I flamed it to set the stain, inserted the stem and then took it to the buffer and buffed it with White Diamond to polish it. The entirety was then given several coats of carnauba wax. This one found a new home with someone who loved the shape and it is providing a great smoke for them.