by Steve Laug

In November I received an email from Mario about working on some of his Dad’s pipes. Here is what he wrote to me.

I am desperately seeking help restoring and repairing some of my dad’s smoking pipes. I have tried reaching out to the only two known pipe repair establishments I could find in the entire country but one is not currently taking repair orders and the other said she didn’t want to try to repair these pipes without having even seen them. Would you be willing to take on the repairs or can you recommend anyone? Thank you much!!!—Mario

I wrote him back and asked him to send me photos of the pipes. He sent some single photos of the meerschaum bowl and stem, several of the leather clad Canadian and the photo of the rack and six pipes shown below. I looked through the photos and this is what I saw. There were two leather clad pipes a Canadian and a Pot. Both of them were cracked on the shanks and had been self-repaired with wire to hold the cracked shank together. The leather cladding was torn and the stitching was rotten and broken around the bowl. To me they were both irreparable. There was a lovely older Meerschaum figural with a horn stem that needed a good cleaning and repairs to the horn stem. There were two Knute Freehand pipes with original stems that were dirty but fixable. The plateau on the smooth one had a large chunk of briar missing. There was a Wilshire Dublin with a chewed and misfit stem. Finally, there was a billiard that had been restemmed with a fancy GBD saddle stem on it. They were a messy lot but I told him to send them on to me. They arrived yesterday and the condition of the pipes in the photos was confirmed. They were a mess and needed much work. I have included Mario’s group photo below to show the lot. I have also included three of the photos of the meerschaum that Mario sent to me as well. The first of the photos show the bowl top and what is either a metal cup lining the bowl or at least a metal rim top/cap. The meerschaum shows some great colour/patina as well as some chips and scratches and perhaps some repaired cracks in the surface. The horn stem also shows some wear and tear on the horn surface and some roughening.

I have also included three of the photos of the meerschaum that Mario sent to me as well. The first of the photos show the bowl top and what is either a metal cup lining the bowl or at least a metal rim top/cap. The meerschaum shows some great colour/patina as well as some chips and scratches and perhaps some repaired cracks in the surface. The horn stem also shows some wear and tear on the horn surface and some roughening.

This afternoon I decided to start working on the fifth of the pipes from Mario – a figural carved freehand. It was a figural with a richly carved bearded man wearing a lion’s head as a cap on his head and a metal rim cap. The stem was made of horn that had lots of tooth marks and chatter on both sides near the button. The stem is dry and some of the striations are separating at the button end. The tenon has been wrapped with waxed thread to soften the fit of the stem in the mortise of the meerschaum. The bowl had a thick cake on the walls and a heavy lava coat the metal insert or the rim top. Which one is true will become clearer as I work on it. It was internally a mess. The finish was dirty and had grime ground into the sides of the bowl. That in many ways obscured the beauty of the patina on the bowl. There were nicks and deep scratches in the beard and in the smooth parts of the bowl but otherwise it seemed sound. The carving and filigree as well as scratches and nicks. There was no stamping or identifying marks on the meerschaum shank. I took photos of the pipe when I unpacked it to examine it. I have included those below.

This afternoon I decided to start working on the fifth of the pipes from Mario – a figural carved freehand. It was a figural with a richly carved bearded man wearing a lion’s head as a cap on his head and a metal rim cap. The stem was made of horn that had lots of tooth marks and chatter on both sides near the button. The stem is dry and some of the striations are separating at the button end. The tenon has been wrapped with waxed thread to soften the fit of the stem in the mortise of the meerschaum. The bowl had a thick cake on the walls and a heavy lava coat the metal insert or the rim top. Which one is true will become clearer as I work on it. It was internally a mess. The finish was dirty and had grime ground into the sides of the bowl. That in many ways obscured the beauty of the patina on the bowl. There were nicks and deep scratches in the beard and in the smooth parts of the bowl but otherwise it seemed sound. The carving and filigree as well as scratches and nicks. There was no stamping or identifying marks on the meerschaum shank. I took photos of the pipe when I unpacked it to examine it. I have included those below.

I took a photo of the bowl and rim top to show the condition of both. You can see the darkening on the metal insert rim top. There was a heavy cake in the bowl. The grooves in the carved meer are very dirty with debris. I also took photos of the stem showing the tooth marks and chatter on both sides ahead of the button.

I took a photo of the bowl and rim top to show the condition of both. You can see the darkening on the metal insert rim top. There was a heavy cake in the bowl. The grooves in the carved meer are very dirty with debris. I also took photos of the stem showing the tooth marks and chatter on both sides ahead of the button. I took photos of the carving around the bowl. To me it looks like a mountain man wearing a bear’s head hat. The beard and carving are well done. The eyes even have lots of character. The side profile shows the bear’s head hat or head dress.

I took photos of the carving around the bowl. To me it looks like a mountain man wearing a bear’s head hat. The beard and carving are well done. The eyes even have lots of character. The side profile shows the bear’s head hat or head dress.

I removed the stem from the shank and took a photo of the parts. It is a well-proportioned pipe.

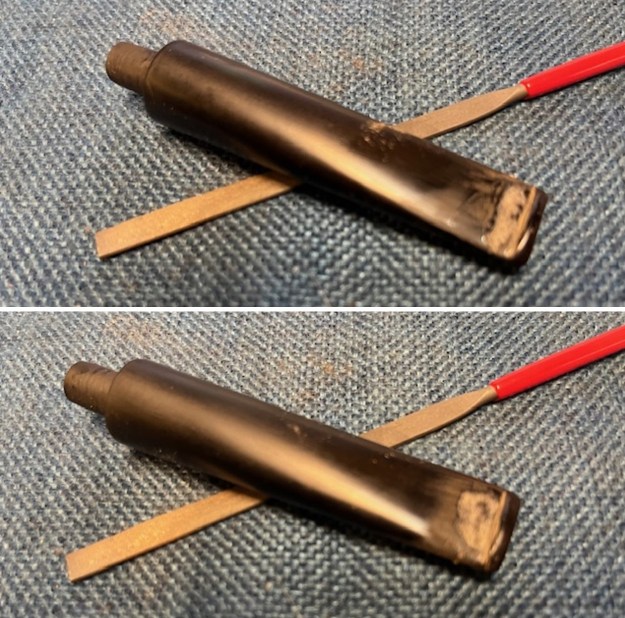

I removed the stem from the shank and took a photo of the parts. It is a well-proportioned pipe. I noted the tenon on the horn stem was wrapped with thread and then waxed. It would need to be cleaned up but it was interesting. It certainly was a self repair of the fit of the stem.

I noted the tenon on the horn stem was wrapped with thread and then waxed. It would need to be cleaned up but it was interesting. It certainly was a self repair of the fit of the stem. It was now time to clean up the pipe. II checked the metal rim cap and found it was not a bowl insert but rather just a rim cap. It was dirty but easily removed.

It was now time to clean up the pipe. II checked the metal rim cap and found it was not a bowl insert but rather just a rim cap. It was dirty but easily removed. I scraped the bowl with a Savinelli Fitsall Pipe Knife to remove the thick cake on the walls. I sanded the bowl walls with 220 grit sandpaper wrapped around a dowel to smooth out the bowl walls. The walls were clear of damage and felt smooth to touch.

I scraped the bowl with a Savinelli Fitsall Pipe Knife to remove the thick cake on the walls. I sanded the bowl walls with 220 grit sandpaper wrapped around a dowel to smooth out the bowl walls. The walls were clear of damage and felt smooth to touch.  I scrubbed the externals of the bowl and shank with undiluted Murphy’s Oil Soap and a tooth brush. I worked over the bowl, shank and rim top with the soap and then lightly rinsed it off warm water. The bowl looked extremely good. The grime was gone and the existing patina looked very rich and variegated. It is a beautifully carved pipe.

I scrubbed the externals of the bowl and shank with undiluted Murphy’s Oil Soap and a tooth brush. I worked over the bowl, shank and rim top with the soap and then lightly rinsed it off warm water. The bowl looked extremely good. The grime was gone and the existing patina looked very rich and variegated. It is a beautifully carved pipe.

I cleaned the metal rim top with 0000 Steel wool and a tooth brush and reset it in the bowl and rim top. It looked much better and smelled cleaned.

I cleaned the metal rim top with 0000 Steel wool and a tooth brush and reset it in the bowl and rim top. It looked much better and smelled cleaned. I cleaned out the internals of the shank and the airway in the stem with pipe cleaners, cotton swabs and alcohol. The shank was quite dirty but the airway in the stem was surprisingly clean.

I cleaned out the internals of the shank and the airway in the stem with pipe cleaners, cotton swabs and alcohol. The shank was quite dirty but the airway in the stem was surprisingly clean.  For awhile now I have been using Clapham’s Beeswax Salad bowl finish for waxing meerschaums. It is a combination of Beeswax and Carnauba. I worked it into the grooves with a shoe brush and into the deep grooves with cotton swabs. I let it harden then buffed it with a soft cloth to raise the shine. The patina looked very good.

For awhile now I have been using Clapham’s Beeswax Salad bowl finish for waxing meerschaums. It is a combination of Beeswax and Carnauba. I worked it into the grooves with a shoe brush and into the deep grooves with cotton swabs. I let it harden then buffed it with a soft cloth to raise the shine. The patina looked very good.

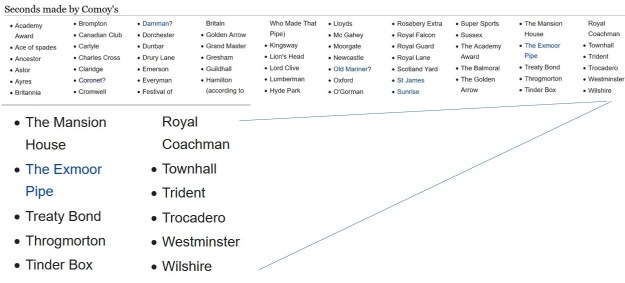

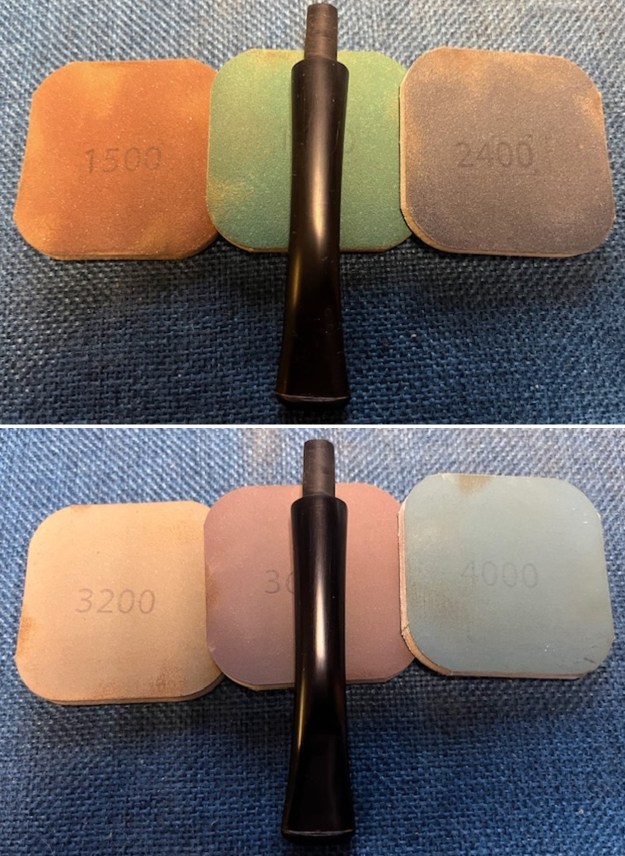

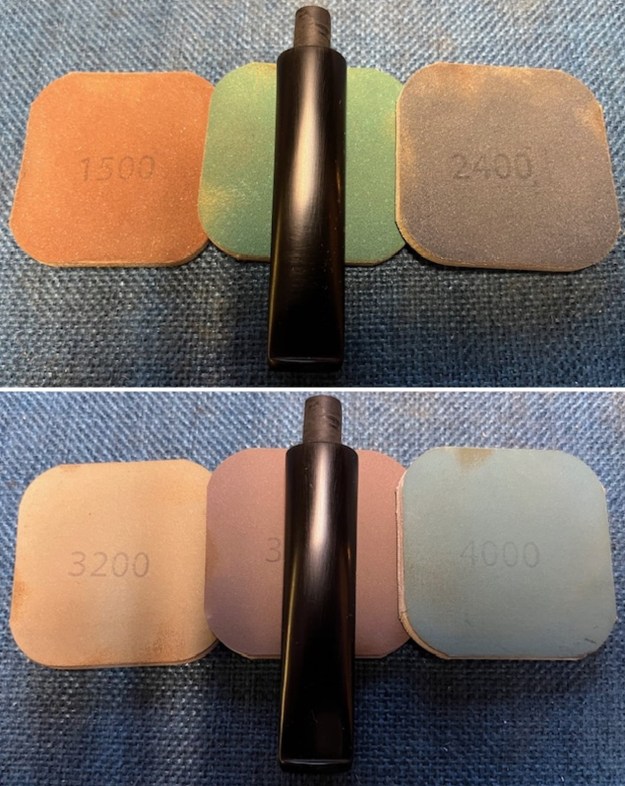

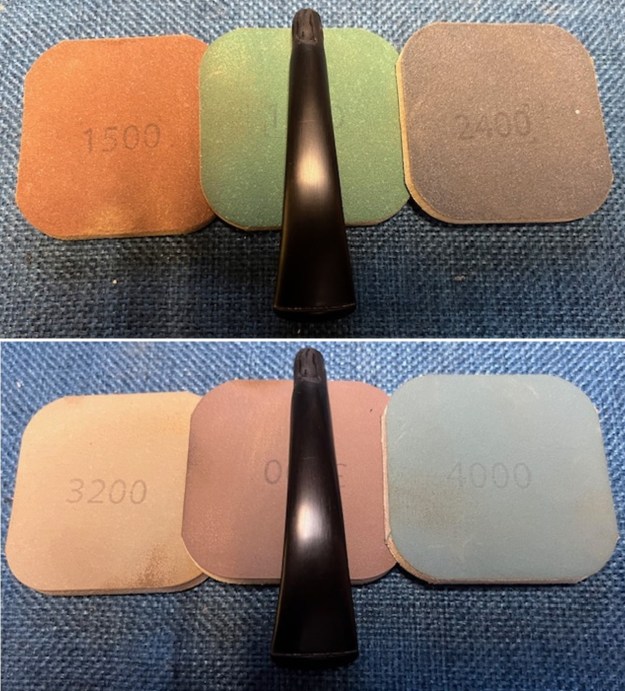

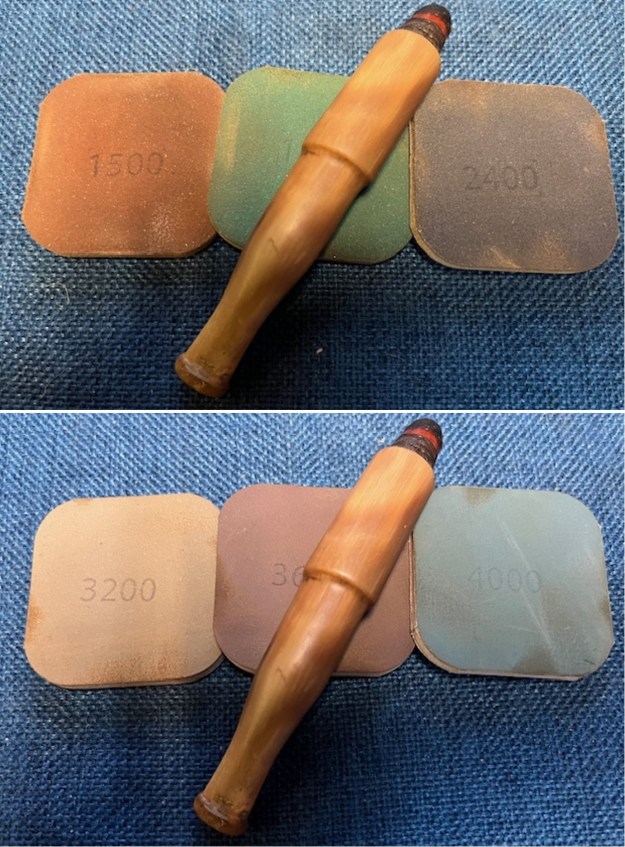

I set the bowl aside and turned my attention to the horn stem. I sanded it with 320-3500 grit sanding pads. I wiped it off between pads with an Obsidian Oil impregnated cloth to remove the debris of the sanding.

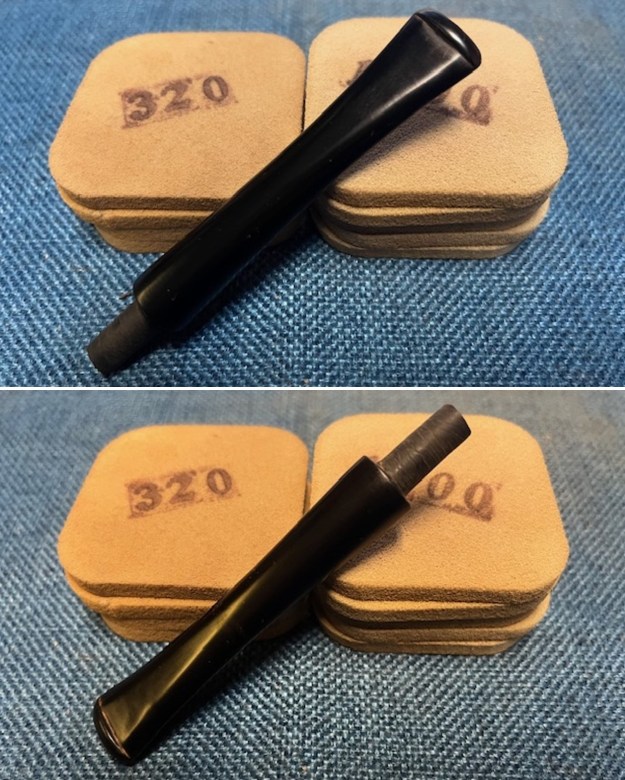

I set the bowl aside and turned my attention to the horn stem. I sanded it with 320-3500 grit sanding pads. I wiped it off between pads with an Obsidian Oil impregnated cloth to remove the debris of the sanding. I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with an Obsidian Oil cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I gave it a final coat of Obsidian Oil.

I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with an Obsidian Oil cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I gave it a final coat of Obsidian Oil.

I put the horn stem back on the Figural Carved Mountain Man Meerschaum pipe and buffed the pipe. I gently buffed waxed bowl with a clean microfibre cloth to raise the shine. I gave the stem several coats of carnauba wax and buffed it with a clean buffing pad to raise the shine. I hand buffed the stem with a microfiber cloth to deepen the shine. The pipe polished up really nicely and the patina gave depth to the carving. The finished pipe is shown in the photos below. This is a beautiful Figural Carved Mountain Man Meerschaum – the horn saddle stem and patinaed meer combine to give the pipe a great look. The dimensions of the pipe are Length: 6 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ¾ inches wide x 2 inches long, Chamber diameter: ¾ of an inch. The weight of the pipe is 3.56 ounces/101 grams. This is the fifth of six pipes that am restoring for Mario from his Dad’s collection. I look forward to hearing what he thinks of this newly restored pipe. One more to go then the lot will go back to him. Thanks for reading this blog and my reflections on the pipe while I worked on it!

I put the horn stem back on the Figural Carved Mountain Man Meerschaum pipe and buffed the pipe. I gently buffed waxed bowl with a clean microfibre cloth to raise the shine. I gave the stem several coats of carnauba wax and buffed it with a clean buffing pad to raise the shine. I hand buffed the stem with a microfiber cloth to deepen the shine. The pipe polished up really nicely and the patina gave depth to the carving. The finished pipe is shown in the photos below. This is a beautiful Figural Carved Mountain Man Meerschaum – the horn saddle stem and patinaed meer combine to give the pipe a great look. The dimensions of the pipe are Length: 6 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ¾ inches wide x 2 inches long, Chamber diameter: ¾ of an inch. The weight of the pipe is 3.56 ounces/101 grams. This is the fifth of six pipes that am restoring for Mario from his Dad’s collection. I look forward to hearing what he thinks of this newly restored pipe. One more to go then the lot will go back to him. Thanks for reading this blog and my reflections on the pipe while I worked on it!