Blog by Steve Laug

We finished up around the tree and our Christmas Breakfast so now there is a quiet time before we eat again. I decided that a snowy Christmas day in Vancouver demanded the right pipe to be worked on so I think I chose appropriately. We bought the pipe I chose at an auction from a fellow in Los Angeles, California, USA. Though it is not shiny white and new looking it is a meerschaum ball/apple/ornament with a gold rim cap and shank band that are quite blinged out and beautiful. The bowl had a thick cake and there was a light lava overflow on the rim. The gold coloured rim cap looked good underneath the lava and oils. The exterior of the bowl and shank was smooth and starting to develop some colouring on the shank and sides. The finish had a lot of scratches and some dark spots on the bottom side of the diamond shank near the band. The pipe did not have any stamping on the shank or band. The rim cap had some nicks and dents in it but they did not detract from the beauty of the pipe. The shank band was also scratched but not dented. The Bakelite (Redmanol) stem was in excellent condition with light tooth marks on the surface in front of the button. I expected the stem was screwed onto the shank but that would be revealed soon enough. Jeff took photos of the pipe before he started his cleanup work.

Jeff captured the condition of the bowl and rim top with the next series of photos. You can see the work that is ahead of us in the photos. The cake is very thick and heavy. The rim looked like it might have some damage on the top and inner edge of the cap. The photos of the stem show the shape and the top and underside of the stem. It is dirty and there is some gummed stickiness on the underside where there must have been a price sticker. The tooth marks and chatter was very light on both sides.

Jeff captured the condition of the bowl and rim top with the next series of photos. You can see the work that is ahead of us in the photos. The cake is very thick and heavy. The rim looked like it might have some damage on the top and inner edge of the cap. The photos of the stem show the shape and the top and underside of the stem. It is dirty and there is some gummed stickiness on the underside where there must have been a price sticker. The tooth marks and chatter was very light on both sides.

Jeff took some great photos of the sides of the bowl and heel showing what is underneath the developing patina and the scratches in the surface of the meerschaum. It will be interesting to see what happens as the pipe is cleaned and restored.

Jeff took some great photos of the sides of the bowl and heel showing what is underneath the developing patina and the scratches in the surface of the meerschaum. It will be interesting to see what happens as the pipe is cleaned and restored.

He removed the stem from the shank. You can see the threaded tenon end in the shank of the pipe and the wide open airway in the stem. It looks to me that there is a push tenon in the shank and the threading was for anchoring it in the stem.

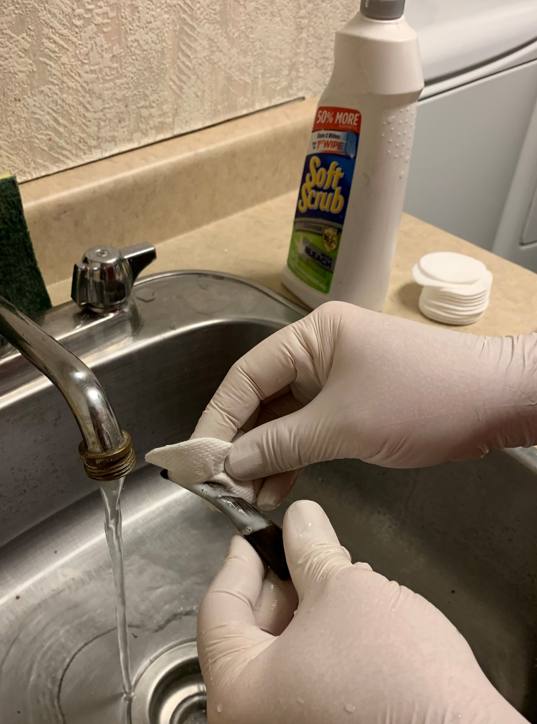

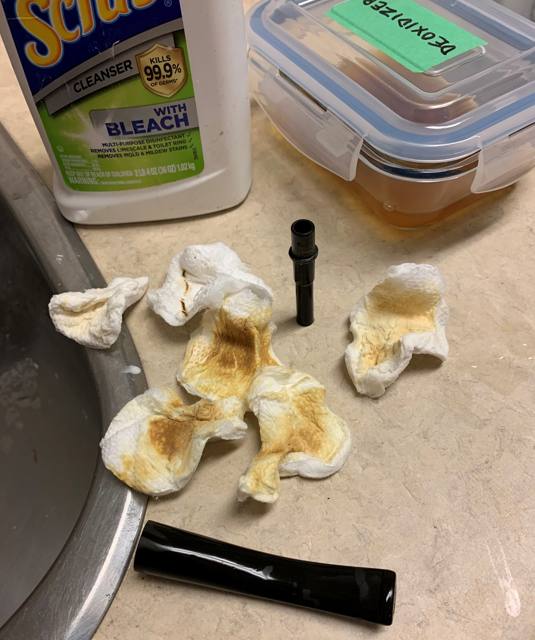

He removed the stem from the shank. You can see the threaded tenon end in the shank of the pipe and the wide open airway in the stem. It looks to me that there is a push tenon in the shank and the threading was for anchoring it in the stem.  I took it out of the box of pipes and looked it over. It was amazingly clean. Jeff carefully reamed it with a PipNet pipe reamer and cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed out the internals with alcohol, pipe cleaners and cotton swabs until the pipe was clean. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and grit on the meerschaum and the lava and oils on the rim top. The bowl looked very good. He scrubbed the stem with Soft Scrub to remove the grime and rinsed it off with warm water. It came out looking far better. Now it was time for me to do my work on the pipe. I took photos before I started my part of the work.

I took it out of the box of pipes and looked it over. It was amazingly clean. Jeff carefully reamed it with a PipNet pipe reamer and cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed out the internals with alcohol, pipe cleaners and cotton swabs until the pipe was clean. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and grit on the meerschaum and the lava and oils on the rim top. The bowl looked very good. He scrubbed the stem with Soft Scrub to remove the grime and rinsed it off with warm water. It came out looking far better. Now it was time for me to do my work on the pipe. I took photos before I started my part of the work.

I took some photos of the rim top and stem. The rim top is clean but you can see some of the dents in the gold cap. I am afraid that they will remain a permanent part of the pipe’s story. The bowl itself looks very clean. The close up photos of the stem shows that is it very clean and the tooth marks are visible.

I took some photos of the rim top and stem. The rim top is clean but you can see some of the dents in the gold cap. I am afraid that they will remain a permanent part of the pipe’s story. The bowl itself looks very clean. The close up photos of the stem shows that is it very clean and the tooth marks are visible. The way the stem lined up with the shank made me wonder about the tenon system that was used. From Jeff’s photos it looked like the threaded portion sticking out of the shank was part of a push tenon system. If that was true then I truly believe that someone had replace the original bone tenon on what I think is actually an older pipe with a new push tenon system. The stem has an orific opening on the end and it is definitely made of Bakelite. I unscrewed the stem from the shank and then pulled the tenon free from the shank end. It was indeed a push tenon. I took a photo of the bowl and stem to give a sense of the proportion of the pipe. It is a classic looking apple for sure.

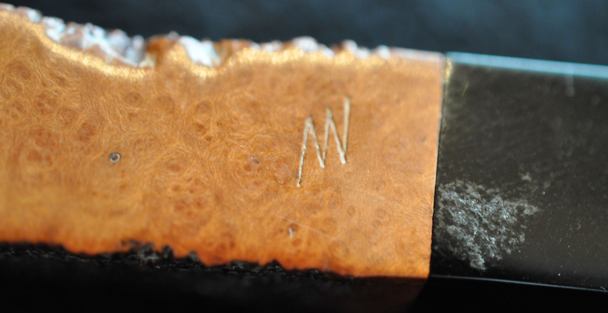

The way the stem lined up with the shank made me wonder about the tenon system that was used. From Jeff’s photos it looked like the threaded portion sticking out of the shank was part of a push tenon system. If that was true then I truly believe that someone had replace the original bone tenon on what I think is actually an older pipe with a new push tenon system. The stem has an orific opening on the end and it is definitely made of Bakelite. I unscrewed the stem from the shank and then pulled the tenon free from the shank end. It was indeed a push tenon. I took a photo of the bowl and stem to give a sense of the proportion of the pipe. It is a classic looking apple for sure. I polished the briar and the shank with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I worked on the two dark spots on the underside of the shank and was able to determine they were not burn marks but rather spots that had taken on a dark patina.I figured that once I heated it to rewax they would look significantly different (Time will tell). I wiped the bowl down after each pad with a damp cloth. The meerschaum began to shine and the scratches were less intrusive. The photos tell the story!

I polished the briar and the shank with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I worked on the two dark spots on the underside of the shank and was able to determine they were not burn marks but rather spots that had taken on a dark patina.I figured that once I heated it to rewax they would look significantly different (Time will tell). I wiped the bowl down after each pad with a damp cloth. The meerschaum began to shine and the scratches were less intrusive. The photos tell the story!

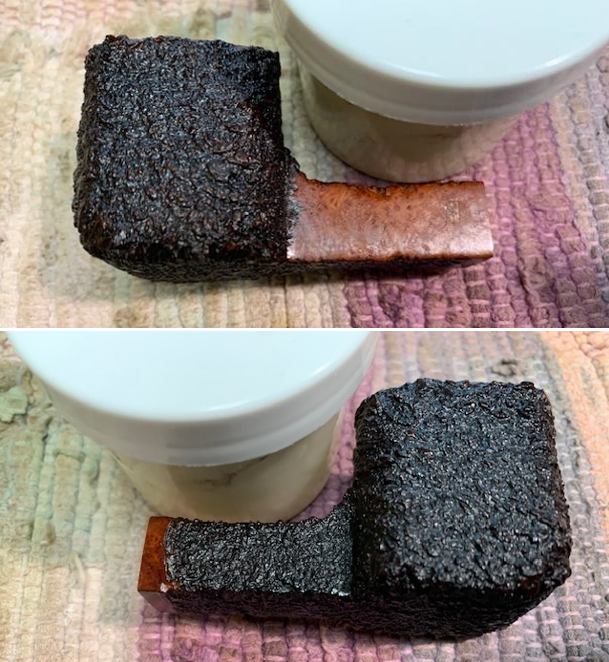

Now it was time to wax the meerschaum bowl. I melted a block of beeswax and dipped the pipe I in the mix and painted the wax with a brush into the hard to reach spots on the shank corners. I heavily coated the bowl with the liquid wax.

Now it was time to wax the meerschaum bowl. I melted a block of beeswax and dipped the pipe I in the mix and painted the wax with a brush into the hard to reach spots on the shank corners. I heavily coated the bowl with the liquid wax.

I let the wax harden dry then I put a cork in the bowl to provide a handle while I heated it with a heat gun. As the wax melted I wiped it off with a paper towel. I let the excess drip back into the container. The bowl began to really take on some patina and the dark spots changed in colour.

I let the wax harden dry then I put a cork in the bowl to provide a handle while I heated it with a heat gun. As the wax melted I wiped it off with a paper towel. I let the excess drip back into the container. The bowl began to really take on some patina and the dark spots changed in colour.

I buffed it with a soft cloth and took pictures of the pipe at this point in the process of the restoration. The wax did its magic and the patina was rich and deep. Even the scratches looked better to me!

I buffed it with a soft cloth and took pictures of the pipe at this point in the process of the restoration. The wax did its magic and the patina was rich and deep. Even the scratches looked better to me!

I set the bowl aside and turned to deal with the stem. I polished the Bakelite stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with a cloth containing some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth. I gave it a final coat of obsidian Oil and set it aside to dry. It is a beautiful looking ruby coloured stem.

I set the bowl aside and turned to deal with the stem. I polished the Bakelite stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with a cloth containing some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth. I gave it a final coat of obsidian Oil and set it aside to dry. It is a beautiful looking ruby coloured stem.

This beautiful no name Bent Apple shaped Meerschaum with a Bakelite stem was another fun pipe to work on and I really was looking forward to seeing it come back together again. With the grime and debris gone from the finish it was a beauty and after the waxing with Beeswax the patina was quite nice. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel. I buffing it with a clean buffing pad on the buffer to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The rich polished meerschaum on the bowl looks really good with the polished ruby Bakelite stem. It is very well done. Give the finished pipe a look in the photos below. I can only tell you that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 4 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 35grams/1.23oz. This is truly a great looking blinged out Meerschaum Bent Apple. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will be adding it to rebornpipes store in the Ceramic and Meerschaum Pipes section if are interested in adding it to you collection. Let me know by email or message. Thanks for your time.

This beautiful no name Bent Apple shaped Meerschaum with a Bakelite stem was another fun pipe to work on and I really was looking forward to seeing it come back together again. With the grime and debris gone from the finish it was a beauty and after the waxing with Beeswax the patina was quite nice. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel. I buffing it with a clean buffing pad on the buffer to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The rich polished meerschaum on the bowl looks really good with the polished ruby Bakelite stem. It is very well done. Give the finished pipe a look in the photos below. I can only tell you that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 4 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 35grams/1.23oz. This is truly a great looking blinged out Meerschaum Bent Apple. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will be adding it to rebornpipes store in the Ceramic and Meerschaum Pipes section if are interested in adding it to you collection. Let me know by email or message. Thanks for your time.