Blog by Steve Laug

Once again I want to take you through my process of working on each pipe that we purchase. Jeff has set up a spread sheet to track where the pipe came from, the date of purchase and what we paid for it so that we know what we have invested in the pipe before we even work on it. This takes a lot of the guess work out of the process. This particular pipe was purchased on 10/03/2022 from a seller in Copenhagen, Denmark. I also want you to understand why we take the photos we do. If you have followed for a while then you will see the familiar pattern of the photos we include both in the before and midstream process of working on a pipe. It is not accidental or chance as the photos have been taken to help me make an assessment of the pipe Jeff sees before he starts his clean up work. We do this to record the condition that the pipe was in when received it and to assess what kind of work will need to be done on. When I look at these photos this is what I see.

- The first thing I see is a classic Pickaxe shape with a vulcanite stem. It is well proportioned and well made with a Brakner style rustication and stamping.

- The finish is dirty and there is grime and grit ground into the rustication on the sides of the bowl and shank. The two smooth panels on the sides are also dirty. It is dusty and dull looking but under the grime the pipe looks good.

- The smooth rim top has some lava and debris toward the back of the bowl and the edges. It is dirty looking but cleaning will reveal a real beauty. The bowl is deep and the walls adequate but thinner looking.

- The bowl has a thick cake and debris on the walls that hides the walls and some grime on the inner edge of the bowl but once it is clean we will know what the bowl and edges really look like. The outer edges look good and there does not appear to be any obvious burn damage to the smooth rim top or bowl edges.

- The vulcanite stem is in good condition – dirty and has light tooth chatter and marks on both sides ahead of button. I am pretty certain it is a replacement stem as it is not like original Brakner pipe stems I have worked on. The diameter of the stem was a little larger than the shank and the shoulders rounded. There was a wrinkle in the vulcanite on the left side mid stem. This is also a 6mm filter stem and there was a small chip out of the tenon on the top side.

Overall my impressions of this pipe is that it is a beauty that once cleaned up will be another one that will look pretty amazing. Brakner’s shape and rustication are readily identifiable when you see them so I knew what the pipe was even before looking at it in person. The photos below confirm the assessment above.  Jeff took close up photos so that I could have a clearer picture of the condition of the bowl, rim edges and top. The rim top photos confirm my assessment above. The cake in the bowl is thick with tobacco debris stuck on the walls. The rim top has some lava, grime and debris that is heavier on the back of the bowl. You can also see the condition of the outer and the inner edge. They appear to be in great condition. This is what I look for when assessing a pipe. There is no visible burn damage at this point. The bowl is still round and other than being in a used condition it is in great shape.

Jeff took close up photos so that I could have a clearer picture of the condition of the bowl, rim edges and top. The rim top photos confirm my assessment above. The cake in the bowl is thick with tobacco debris stuck on the walls. The rim top has some lava, grime and debris that is heavier on the back of the bowl. You can also see the condition of the outer and the inner edge. They appear to be in great condition. This is what I look for when assessing a pipe. There is no visible burn damage at this point. The bowl is still round and other than being in a used condition it is in great shape.  The photos of the vulcanite stem surface from various angles confirm my assessment of its condition. You can see the dirty grime and light oxidation on the stem in the first photo below. There is light chatter and tooth marks. The stem is quite dirty but otherwise in good condition. The fit of the stem to the shank is off a bit, the diameter is a little larger on the stem.

The photos of the vulcanite stem surface from various angles confirm my assessment of its condition. You can see the dirty grime and light oxidation on the stem in the first photo below. There is light chatter and tooth marks. The stem is quite dirty but otherwise in good condition. The fit of the stem to the shank is off a bit, the diameter is a little larger on the stem.

Instead of telling you what I see in the next photos of the sides of the bowl and the heel I want to hear from you. Tell me what you see? What does the finish look like to you? Are there any visible problems or issues that stand out to you? Are the cracks or scratches in the valleys of the rustication or the high spots? Are there visible flaws or fissures in the briar? How random does the deep rustication look? Is there a pattern to it? Any visible issues on the heel of the bowl? These questions should help you to see what I am looking for when I see these photos.

Instead of telling you what I see in the next photos of the sides of the bowl and the heel I want to hear from you. Tell me what you see? What does the finish look like to you? Are there any visible problems or issues that stand out to you? Are the cracks or scratches in the valleys of the rustication or the high spots? Are there visible flaws or fissures in the briar? How random does the deep rustication look? Is there a pattern to it? Any visible issues on the heel of the bowl? These questions should help you to see what I am looking for when I see these photos.

Jeff took a close up photo of the rustication on the bowl side and the shape of the smooth outer edge of the rim top to give a sense of what he was seeing.

Jeff took a close up photo of the rustication on the bowl side and the shape of the smooth outer edge of the rim top to give a sense of what he was seeing. He took a photo of the stamping on the left side of the shank. It is stamped Brakner Antique. On the right side it is stamped HAND-CUT followed by the shape number 124. What stands out for you in the photos of the stamping? What do you look for in the stamping? It is dirty but what do you see underneath the grime on the surface of the briar?

He took a photo of the stamping on the left side of the shank. It is stamped Brakner Antique. On the right side it is stamped HAND-CUT followed by the shape number 124. What stands out for you in the photos of the stamping? What do you look for in the stamping? It is dirty but what do you see underneath the grime on the surface of the briar?  If you have been following the blog for any length of time you have come to know that when I am working on interesting old pipes (even sometimes those not so interesting) I like to know a bit about the background of the brand. I like to “meet” the carver to get a feel for their work and style. This is the first Brakner I have worked on so I felt compelled to do a bit of reading before I started the cleanup of the pipe.

If you have been following the blog for any length of time you have come to know that when I am working on interesting old pipes (even sometimes those not so interesting) I like to know a bit about the background of the brand. I like to “meet” the carver to get a feel for their work and style. This is the first Brakner I have worked on so I felt compelled to do a bit of reading before I started the cleanup of the pipe.

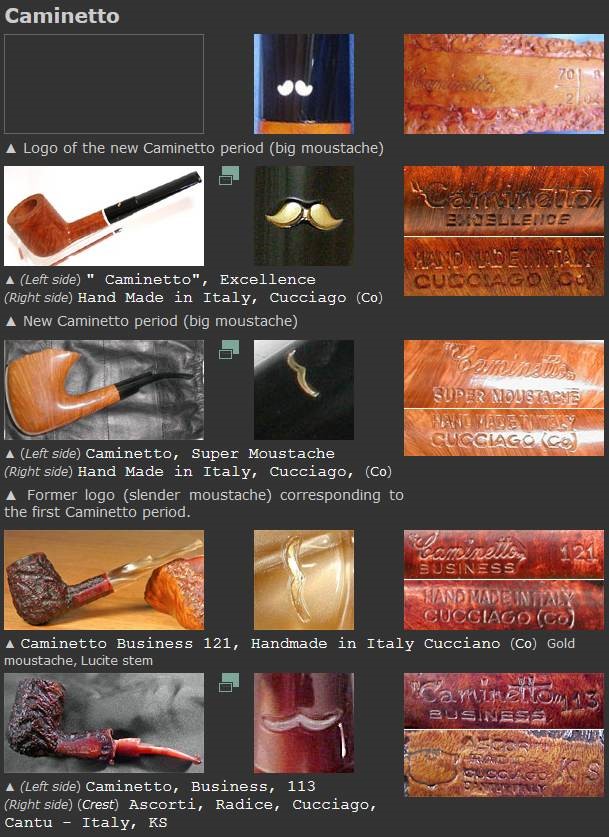

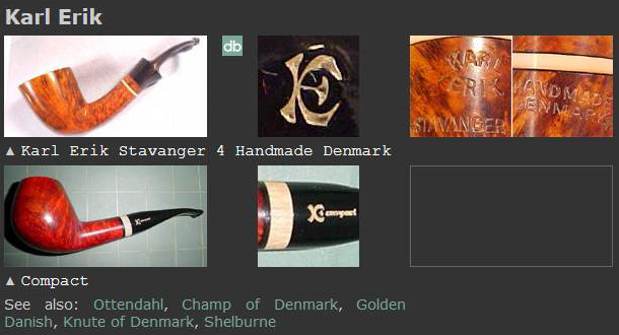

I looked first on the Pipephil website (http://www.pipephil.eu/logos/en/logo-b7.html) to see what I could find. I have found through the years that it gives me a good summary of the information available and some pictures of some of the pipes from the brand. I have included a screen capture of the first pipe in the listing as it shows the logo on the stem and a bit of the stamping that is on the underside of the shank.  There was not much information on the site regarding the history of the maker. It did tell me that most Brakner’s pipes had the carver’s “micro-rustication” finish. He made few smooth pipes. Next I turned to Pipedia for more information and detail (https://pipedia.org/wiki/Brakner). I quote in part:

There was not much information on the site regarding the history of the maker. It did tell me that most Brakner’s pipes had the carver’s “micro-rustication” finish. He made few smooth pipes. Next I turned to Pipedia for more information and detail (https://pipedia.org/wiki/Brakner). I quote in part:

Peter Micklson (†) started his career at the Teofil Suhr workshop, Suhr’s Pibemageri, in Copenhagen, where Sixten Ivarsson was the foreman. He brought in Poul Rasmussen and taught him the two or three important things about pipemaking in a six weeks crash course, before he went off to join Poul Nielsen, the later Mr. Stanwell.

Micklson, who later changed his last name to Brakner, cannot have worked under Rasmussen too long before he felt to be good enough to go off on his own. Indeed he carved himself quite a good name as it was proudly announced 1955’s World Championship of Pipe Smoking was won by a smoker who employed a Peter Brakner pipe. His fame based fairly on developing a unique and very special “micro-rustication” he called Antique. According to Kai Nielsen, Brakner kept this technique as a secret and only once he showed it to one person – Kai’s mother. Both have passed away, so this secret technique is lost. Kent Rasmussen was recently inspired by Brakner’s Antique finish when he created his new technique of rustication. Brakner was a close friend of Ole Larsen, the proprietor of the famous W.Ø. Larsen tobacco shop and sold a lot of his pipes there, before Larsen hired his own indoor carvers…

The pipes came in three different series.

Antique series. Antique finish in tan or black. Smooth pipes also. Each pipe 7.50 $.

Bella Danica series. Antique finish in tan or black. Each pipe 10.00 $.

Royal Danois series. Antique finish in tan or black. Each pipe 12.50 $.\

The latter were named after the Royal Danish Guard Regiment, founded in 1689.

Brakner was one of the first high-end carvers from Denmark to enter the US market and was considerably successful there in the early 1970’s. After his sudden death Peter Brakner’s name faded back from the forefront, but his pipes speak to the injustice of that. His body of work has earned him a place in the important history of Danish pipemaking.

That gives a good picture of the history and development of the Brakner brand and the connection to some of the great carvers of Danish pipe history.

Now I had more information to work with. The Brakner Antique in my hands that probably came out in the early 1970s before his death.

I am sure many of you will shake your head and ask maybe even out loud, “Why is he including this again?” However, please remember that the point of these blogs is not to wow your with the work or make you shake your heads but I want you to know the details of the work we do so you can do your own. Back in 2020 Jeff wrote a blog about his cleaning process. I am including a link to that now so you can see what I mean about his process. Do not skip it! Give it a read (https://rebornpipes.com/2020/01/20/got-a-filthy-estate-pipe-that-you-need-to-clean/). Here is the introduction to that blog and it is very true even to this day.

Several have asked about Jeff’s cleaning regimen as I generally summarize it in the blogs that I post rather than give a detailed procedure. I have had the question asked enough that I asked Jeff to put together this blog so that you can get a clear picture of the process he uses. Like everything else in our hobby, people have different methods they swear by. Some may question the method and that is fine. But it works very well for us and has for many years. Some of his steps may surprise you but I know that when I get the pipes from him for my part of the restoration they are impeccably clean and sanitized. I have come to appreciate the thoroughness of the process he has developed because I really like working on clean pipe!

For the benefit of some of you who may be unfamiliar with some of the products he uses I have included photos of three of the items that Jeff mentions in his list. This will make it easier for recognition. These three are definitely North American Products so you will need to find suitable replacements or order these directly on Amazon. The makeup pads are fairly universal as we were able to pick some up in India when we were with Paresh and his family.

In the blog itself he breaks his process down into two parts – cleaning the stem and cleaning the bowl. Each one has a large number of steps that he methodically does every time. I know because I have watched him do the work and I have seen the pipes after his work on them. He followed this process step by step and when the pipe got to me it was spotlessly clean and ready for my work. The inside of the stem, shank and bowl were clean and to me that is an amazing gift as it means that my work on this end is with a clean pipe! I cannot tell you how much difference that makes for my work.

When the pipe arrives here in Vancouver I have a clean pipe and I go over it keeping in mind my assessment shared in the opening paragraph above. Now that I have it in hand I am looking for confirmation of what I saw in the photos as well as any significant structural changes in the bowl and finish as I go over it.

- The first thing I see is a classic rusticated Pickaxe with a vulcanite taper stem. It is well proportioned and well made with a Brakner style micro rustication and stamping.

- The finish is clean and the grime and grit have been removed from the finish on the bowl. The rustication and the smooth finish both have come alive around the bowl sides.

- The lava, grime and dust on the rim top has been removed and it looks to be in good condition on the top and edges of the bowl.

- The walls of the bowl are clean and I do not see any checking or burn damage. The inner edge of the bowl looks good. The outer edges look good and there does not appear to be any obvious burn damage there.

- The vulcanite stem is clean and has very light tooth chatter and marks on both sides. The stem is definitely a replacement. This is also a 6mm filter stem what has a chip out of the tenon on the top side.

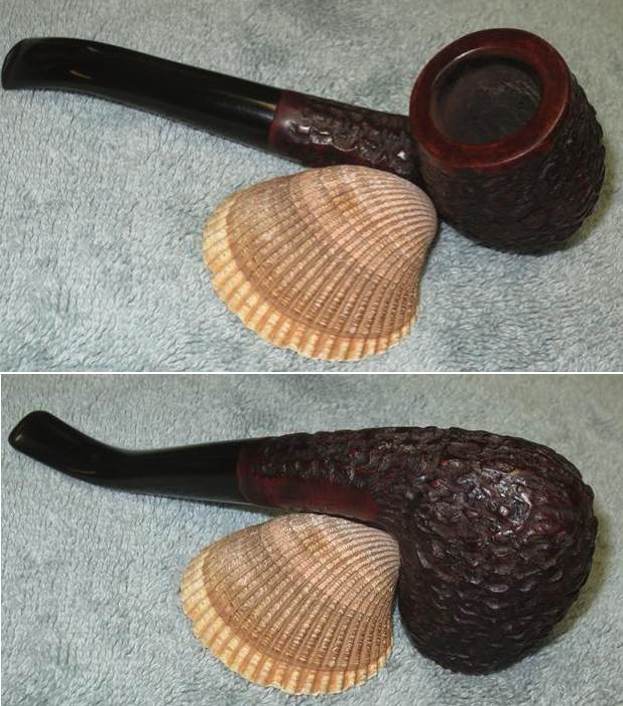

Hopefully the steps above show you both what I look for when I go over the pipe when I bring it to the work table and also what I see when I look at the pipe in my hands. They also clearly spell out a restoration plan in short form. My work is clear and addressing it will be the next steps. I took photos of the whole pipe to give you a picture of what I see when I have it on the table. This is important to me in that it also shows that there was no damage done during the clean up work or the transit of the pipe from Idaho to here in Vancouver.

I carefully went over the bowl and rim top to get a sense of what is happening there. In this case once the rim top and edges were cleaned, they looked very good. There was no damage on the edges or the top of the rim. The rim edge and top are clean and should polish up well. I also go over the stem carefully. The stem had some issues as noted. The diameter of the stem was larger than the shank and the end had been rounded giving it shoulders. That would need to be addressed. There were some faint tooth marks chatter on the surface of the stem. I took photos of the rim top and stem sides to show as best as I can what I see when I look at them.

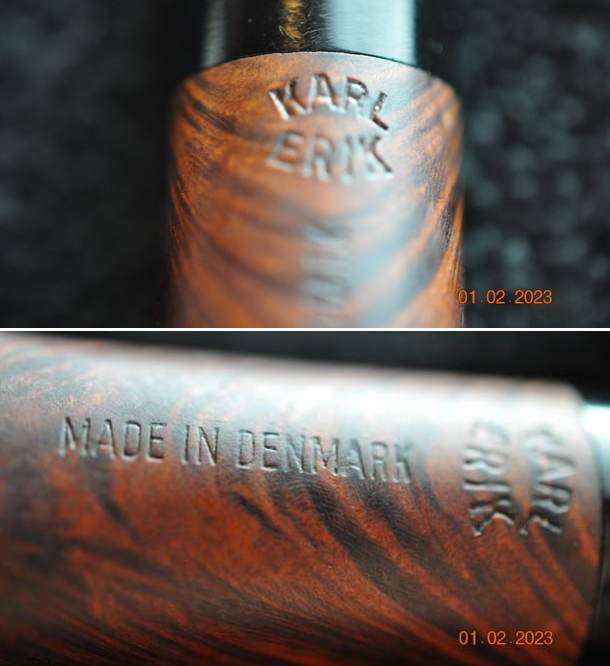

I carefully went over the bowl and rim top to get a sense of what is happening there. In this case once the rim top and edges were cleaned, they looked very good. There was no damage on the edges or the top of the rim. The rim edge and top are clean and should polish up well. I also go over the stem carefully. The stem had some issues as noted. The diameter of the stem was larger than the shank and the end had been rounded giving it shoulders. That would need to be addressed. There were some faint tooth marks chatter on the surface of the stem. I took photos of the rim top and stem sides to show as best as I can what I see when I look at them.  I always check to make sure that the clean up work did not damage the stamping on the shank in any way. It is in excellent condition and is very clear and readable. Brakner’s micro rustication is unique and readily recognizable. To me it different and I like the feel of it. I love just looking at the beauty of the lay of the pipe and the proportion of the hand made pipes. I like to remove the stem from the shank to get a sense of what was in the mind of the pipe maker when he crafted the pipe. The photo shows its beauty in flow and shape.

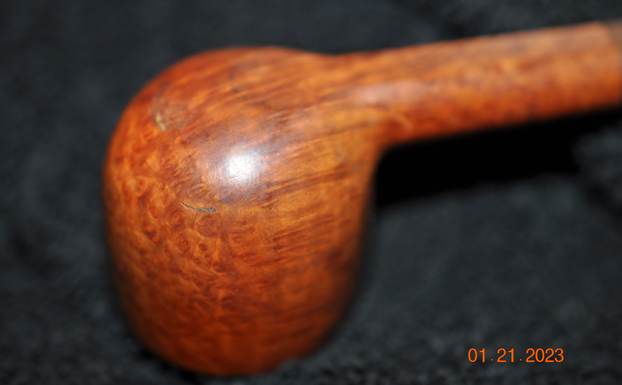

I always check to make sure that the clean up work did not damage the stamping on the shank in any way. It is in excellent condition and is very clear and readable. Brakner’s micro rustication is unique and readily recognizable. To me it different and I like the feel of it. I love just looking at the beauty of the lay of the pipe and the proportion of the hand made pipes. I like to remove the stem from the shank to get a sense of what was in the mind of the pipe maker when he crafted the pipe. The photo shows its beauty in flow and shape.

I polished the smooth briar on the rim top and the panels on the bowl sides with micromesh sanding pads. I choose to dry sand the briar rather than wet sand it. Again it is a matter of personal preference. I prefer to use the pads dry and find they work very well on the briar. I sand with each pad (9 in total) and group them by threes for ease of reference. I wipe the bowl down after each pad with a damp cloth to remove the sanding debris and check the briar. I love seeing the developing shine on the briar as I move through the pads which is why I include so many photos of this step.

I polished the smooth briar on the rim top and the panels on the bowl sides with micromesh sanding pads. I choose to dry sand the briar rather than wet sand it. Again it is a matter of personal preference. I prefer to use the pads dry and find they work very well on the briar. I sand with each pad (9 in total) and group them by threes for ease of reference. I wipe the bowl down after each pad with a damp cloth to remove the sanding debris and check the briar. I love seeing the developing shine on the briar as I move through the pads which is why I include so many photos of this step.

I applied some Before & After Restoration Balm to the briar. It is a paste/balm that is rubbed into the surface of the briar – both smooth and rusticated finishes. The product works to deep clean the nooks and crannies of finish, enliven and protect the briar. I worked it into the briar with my finger tips and a horse hair shoe brush. I let it sit for 10 minutes to do its work. I wiped it off with a soft cloth then buffed it with a cotton cloth. The briar really began to have a deep shine in the briar and the grain shone through. The photos I took of the bowl at this point mark the progress in the restoration. It is a gorgeous pipe.

I applied some Before & After Restoration Balm to the briar. It is a paste/balm that is rubbed into the surface of the briar – both smooth and rusticated finishes. The product works to deep clean the nooks and crannies of finish, enliven and protect the briar. I worked it into the briar with my finger tips and a horse hair shoe brush. I let it sit for 10 minutes to do its work. I wiped it off with a soft cloth then buffed it with a cotton cloth. The briar really began to have a deep shine in the briar and the grain shone through. The photos I took of the bowl at this point mark the progress in the restoration. It is a gorgeous pipe.

I set the bowl aside and turn to work on the stem. I decided to address the chipped 6mm filter tenon. I decided to fit it with an adapter/converter to remove the filter aspect of the stem. I had a long thin piece of Delrin tubing that I had saved from a previous project. It fit perfectly in the 6mm tenon and was snug.

I set the bowl aside and turn to work on the stem. I decided to address the chipped 6mm filter tenon. I decided to fit it with an adapter/converter to remove the filter aspect of the stem. I had a long thin piece of Delrin tubing that I had saved from a previous project. It fit perfectly in the 6mm tenon and was snug.  I glued the converter in place in the filter tenon and built up the chipped area on the end of the tenon. I used clear CA glue to hold it in place. I set the stem aside to allow the glue to cure.

I glued the converter in place in the filter tenon and built up the chipped area on the end of the tenon. I used clear CA glue to hold it in place. I set the stem aside to allow the glue to cure. I used my Dremel and a sanding drum to cut foo the tenon to the length of a normal tenon. I sanded the built up area on the tenon with 220 grit sandpaper. It fit the shank well and the airflow through the stem is perfect.

I used my Dremel and a sanding drum to cut foo the tenon to the length of a normal tenon. I sanded the built up area on the tenon with 220 grit sandpaper. It fit the shank well and the airflow through the stem is perfect. I smoothed out the tooth marks on the stem surface on both sides ahead of the button with 220 grit sandpaper. I also reduced the diameter on the stem at the shank and removed the shoulders on the shank end of the stem. It looked much better. I started the polishing of the stem with 600 grit wet dry sandpaper.

I smoothed out the tooth marks on the stem surface on both sides ahead of the button with 220 grit sandpaper. I also reduced the diameter on the stem at the shank and removed the shoulders on the shank end of the stem. It looked much better. I started the polishing of the stem with 600 grit wet dry sandpaper. I continued polishing the stem with micromesh sanding pads – 1500-12000 grit sanding pads and water to wet sand the stem. I wiped it down after each sanding pad with Obsidian Oil on a cotton rag after each sanding pads. But I find it does two things – first it gives some protection to the stem from oxidation and second it give the sanding pads bite in the polishing process.

I continued polishing the stem with micromesh sanding pads – 1500-12000 grit sanding pads and water to wet sand the stem. I wiped it down after each sanding pad with Obsidian Oil on a cotton rag after each sanding pads. But I find it does two things – first it gives some protection to the stem from oxidation and second it give the sanding pads bite in the polishing process.

After finishing with the micromesh pads I rub the stem down with Before & After Fine and Extra Fine stem polish as it seems to really remove the fine scratches in the vulcanite. I rub the Fine Polish on the stem and wipe it off with a paper towel and then repeat the process with the Extra Fine polish. I finish the polishing of the stem down with a final coat of Obsidian Oil and set the stem aside to let the oil absorb. This process gives the stem a shine and also a bit of protection.

After finishing with the micromesh pads I rub the stem down with Before & After Fine and Extra Fine stem polish as it seems to really remove the fine scratches in the vulcanite. I rub the Fine Polish on the stem and wipe it off with a paper towel and then repeat the process with the Extra Fine polish. I finish the polishing of the stem down with a final coat of Obsidian Oil and set the stem aside to let the oil absorb. This process gives the stem a shine and also a bit of protection.  The final steps in my process involve using the buffer. I don’t buff a rusticated pipe with Blue Diamond as it can build up in the deep grooves of the finish. I used it on the stem and find that it works very well to polish out the light scratches in the vulcanite. I moved on to buffing the pipe – I gave the bowl multiple coats of Conservator’s Wax by hand and the stem multiple coats of carnauba wax on the wheel. I have found that I can get a deeper shine if I follow up the wax buff with a clean buffing pad. It works to raise the shine and then I hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished vulcanite stem. It really is a nice pipe. The micro rusticated finish around the bowl sides and shank looks great with the rich black and dark brown stains. The Brakner Antique 124 Pickaxe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.20 ounces/34 grams. It is a beautiful pipe that I will soon be adding to the rebornpipes store in the Danish Pipemakers section. If you would like to add it to your collection let me know. It should be a great smoking pipe.

The final steps in my process involve using the buffer. I don’t buff a rusticated pipe with Blue Diamond as it can build up in the deep grooves of the finish. I used it on the stem and find that it works very well to polish out the light scratches in the vulcanite. I moved on to buffing the pipe – I gave the bowl multiple coats of Conservator’s Wax by hand and the stem multiple coats of carnauba wax on the wheel. I have found that I can get a deeper shine if I follow up the wax buff with a clean buffing pad. It works to raise the shine and then I hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished vulcanite stem. It really is a nice pipe. The micro rusticated finish around the bowl sides and shank looks great with the rich black and dark brown stains. The Brakner Antique 124 Pickaxe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.20 ounces/34 grams. It is a beautiful pipe that I will soon be adding to the rebornpipes store in the Danish Pipemakers section. If you would like to add it to your collection let me know. It should be a great smoking pipe.

Hopefully the style of writing of this blog is helpful to you in some way. In it I wanted to show both what I am looking for and how I move forward in addressing what I see when work on a pipe. Let me know if it is helpful to you. It is probably the most straightforward detailed description of my work process that I have written. As always I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.