Blog by Steve Laug

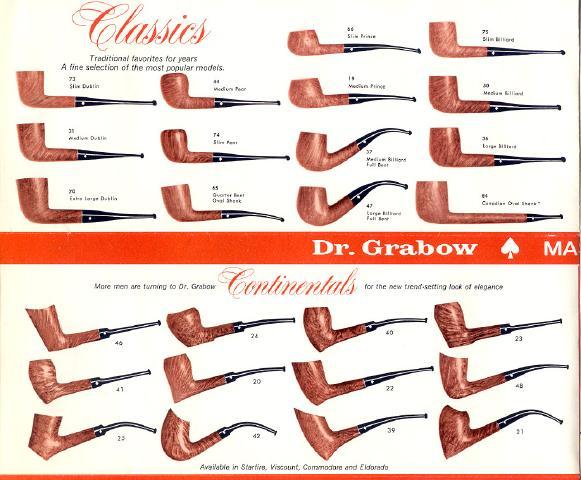

I just finished cleaning up the last of the pipe I picked up from the antique malls while I was in Idaho Falls. It is a little Dr. Grabow bent billiard. It is stamped on the left side of the shank Dr. Grabow over De Luxe over Imported Briar. On the right side near the stem shank union it is stamped with the shape number 9704. From what I can find on the Grabow shape charts the 04 shape is the bent billiard. This one was in rough shape. The finish was basically worn off and the bowl had spots of sticky grime on the sides and shank. There were also spots of paint on the shank and bowl. There were scratches all over the bowl. There were a lot of small fills on the right side of the bowl and the top of the shank as well as a large one on the lower part of the front of the bowl. Because of the missing finish these stood out. The top of the rim had a buildup of tars that looked flaky and hard. The bowl had a thick cake that made it impossible to see if the inside of the rim was in decent shape. I would need to ream it back to be sure. The stem was oxidized and the dirty with light tooth chatter on the underside near the button.

I took a close up photo of the top of the rim to show what I had to work with in cleaning up the bowl and rim.

I took a close up photo of the top of the rim to show what I had to work with in cleaning up the bowl and rim. When I took the stem off the pipe it had the usual Dr. Grabow shovel stinger apparatus. This was a little unique in that it was not inserted into the metal tenon but was an integral part of the tenon. The two were cast together which made removing it impossible. It was covered in tars and in a tobacco coloured lacquer that was rock hard.

When I took the stem off the pipe it had the usual Dr. Grabow shovel stinger apparatus. This was a little unique in that it was not inserted into the metal tenon but was an integral part of the tenon. The two were cast together which made removing it impossible. It was covered in tars and in a tobacco coloured lacquer that was rock hard. The next two photos show the stamping on both sides of the shank. The right side shows the clear shape number stamp and the left side the Dr. Grabow stamping. The Imported Briar stamping is weak but visible.

The next two photos show the stamping on both sides of the shank. The right side shows the clear shape number stamp and the left side the Dr. Grabow stamping. The Imported Briar stamping is weak but visible.

I reamed the bowl back to bare wood with a PipNet reamer. I started with the smallest cutting head and worked my way up to one that was the same diameter as the inside of the bowl. Once the cake was cleaned out I used a pen knife to clean up the small ridge that shows up in the second photo below.

I reamed the bowl back to bare wood with a PipNet reamer. I started with the smallest cutting head and worked my way up to one that was the same diameter as the inside of the bowl. Once the cake was cleaned out I used a pen knife to clean up the small ridge that shows up in the second photo below.

I used a sanding sponge to lightly top the bowl. The tars and lava on the top were hard and this was the way I chose to remove it without damaging the finish to the rim. I worked on it until the rim was clean and smooth. It would still need to be scrubbed to remove the darkening.

I used a sanding sponge to lightly top the bowl. The tars and lava on the top were hard and this was the way I chose to remove it without damaging the finish to the rim. I worked on it until the rim was clean and smooth. It would still need to be scrubbed to remove the darkening.

I scrubbed the rim and the bowl with acetone on a cotton pad to remove the grime and oils left in the finish. I scrubbed until the rim and bowl were clean.

I scrubbed the rim and the bowl with acetone on a cotton pad to remove the grime and oils left in the finish. I scrubbed until the rim and bowl were clean. I scrubbed the shovel stinger with 0000 steel wool to remove the buildup on the aluminum and polish it at the same time.

I scrubbed the shovel stinger with 0000 steel wool to remove the buildup on the aluminum and polish it at the same time.

I cleaned out the shank with alcohol, pipe cleaners and cotton swabs until it was spotless. I then worked on the stem. It was made a bit more difficult with the built in stinger but I was able to get it clean with a bit of effort.

I cleaned out the shank with alcohol, pipe cleaners and cotton swabs until it was spotless. I then worked on the stem. It was made a bit more difficult with the built in stinger but I was able to get it clean with a bit of effort. With the inside clean I sanded the bowl and rim with 220 grit sandpaper and a medium and fine grit sanding sponge to clean up the finish. I was able to remove the darkening on the rim and also the dark spots on the sides of the bowl.

With the inside clean I sanded the bowl and rim with 220 grit sandpaper and a medium and fine grit sanding sponge to clean up the finish. I was able to remove the darkening on the rim and also the dark spots on the sides of the bowl.

I screwed the stem back on the shank and then sanded the stem with the same sandpapers as I had sanded the bowl. I removed tooth chatter and the calcification on the first inch of the stem. I worked on the slight tooth marks on the button itself and cleaned them up. The pipe was beginning to take shape. Much more sanding would need to be done to the bowl to remove all of the scratches left behind by the sandpaper and a lot of polishing would need to be done on the stem before the pipe was finished.

I screwed the stem back on the shank and then sanded the stem with the same sandpapers as I had sanded the bowl. I removed tooth chatter and the calcification on the first inch of the stem. I worked on the slight tooth marks on the button itself and cleaned them up. The pipe was beginning to take shape. Much more sanding would need to be done to the bowl to remove all of the scratches left behind by the sandpaper and a lot of polishing would need to be done on the stem before the pipe was finished.

I rubbed the bowl down with olive oil so that I could wet sand the finish and work out the scratches.

I rubbed the bowl down with olive oil so that I could wet sand the finish and work out the scratches.

I sanded the bowl with micromesh sanding pads and the olive oil until I was able to remove the scratches. I started with 1500-2400 grit pads and sanded until the scratches were minimized and then rubbed it down with olive oil once again before sanding with 3200-4000 grit pads. Each successive micromesh pad brought more of a shine to the briar. The fills became smooth and blended into the briar better and began to disappear into the briar as the scratches around the edges were smoothed out.

I sanded the bowl with micromesh sanding pads and the olive oil until I was able to remove the scratches. I started with 1500-2400 grit pads and sanded until the scratches were minimized and then rubbed it down with olive oil once again before sanding with 3200-4000 grit pads. Each successive micromesh pad brought more of a shine to the briar. The fills became smooth and blended into the briar better and began to disappear into the briar as the scratches around the edges were smoothed out.

I gave it a final rub down with oil and then finished sanding it with the last three grits of micromesh – 6000-12000. The bowl was smooth to the touch and had a shine to it that once was buffed and waxed would glow.

I gave it a final rub down with oil and then finished sanding it with the last three grits of micromesh – 6000-12000. The bowl was smooth to the touch and had a shine to it that once was buffed and waxed would glow.

I sanded the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and then rubbing it down with Obsidian Oil. I continued to dry sand with 3200-4000 grit pads and gave it another coat of the oil. I finished by sanding it with 6000-12000 grit pads and then gave it a final coat of oil and let it dry.

I sanded the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and then rubbing it down with Obsidian Oil. I continued to dry sand with 3200-4000 grit pads and gave it another coat of the oil. I finished by sanding it with 6000-12000 grit pads and then gave it a final coat of oil and let it dry.

I buffed the pipe on the wheel with Blue Diamond polish and then gave the bowl and stem multiple coats of carnauba wax. I buffed it with a clean flannel wheel to give it a shine and finished by buffing it with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. It is a beautiful old Grabow that has a lot of life left in it. Whether I keep it or pass it on to someone else it should last much longer than I will. It should continue to give companionship to whoever’s rack it graces. Thanks for looking.

I buffed the pipe on the wheel with Blue Diamond polish and then gave the bowl and stem multiple coats of carnauba wax. I buffed it with a clean flannel wheel to give it a shine and finished by buffing it with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. It is a beautiful old Grabow that has a lot of life left in it. Whether I keep it or pass it on to someone else it should last much longer than I will. It should continue to give companionship to whoever’s rack it graces. Thanks for looking.

ADDENDUM: I received the following message on FaceBook from Christopher Chopin. It adds much to the information on this pipe so I add it here:

A favorite shape. Nice job as always Steve. And yes, 04 is the shape code, 97 was the finish code for deluxe. Also 92 and 98, there was more than one De Luxe, and 97 was the natural variegated finish. Dating on that if I’m not mistaken is between 1944 and 1953, at which point the spade was rotated so that the tip pointed to the bowl instead of the mouthpiece, after the company was purchased by HL&T. That is a true Linkman’s grabow, they just discontinued the Linkman’s stamp in ’44. I suspect it’ll find a place in your regular rotation.