Blog by Dal Stanton

When I first laid my eyes on this Savinelli, I didn’t realize it was a Savinelli. I was in Athens, Greece, tooling through the Monastiraki market area at the foot of the Acropolis, next door to the Forum. As I explored I found one shop nestled on a tree-covered side street with a table set on the front sidewalk with all kinds of paraphernalia. It drew me like a bee to pollen! Two congenial men were sitting behind the table conversing in Greek. I assumed they chatted about all manner of life, family, politics…, and what is usually the case, as I drew near, their conversation stopped, and the English began. As I perused the table with strategic disinterest, I saw one pipe on the table that did not grab me too much. The shop owner asked me if I was interested in pipes? I said yes, and he said that he had many more that he didn’t know what to do with…. “Oh, my…” – my heart skipped a beat! In his wonderfully, friendly, thick Greek accent and manner of hospitality, he said, ‘Come with me.” As he pulled a chain out of this pocket a full ring of keys followed. He led me down a narrow, alley walkway along the side of the shop. We stopped and he unlocked a side door that led immediately up the stairs to an ‘upper room’ where, as he explained with a subdued, secretive flourish, he seldom brought customers. When we entered the room, I saw why. It was his special place – family pictures were arrayed everywhere, icons of the Greek Orthodox Church were given special deference as they hung from places of honor. Many shelves full of his collections. He pulled my attention away from the array to a slew of pipes displayed in a case hanging on the wall and arranged beneath on a cluttered table.

I took it all in. He explained that his good friend, from Armenia, asked him to sell off his collection of pipes and he gave me a price for everything, including the wall-hanging display case. With gratitude to him for his generous offer, I had to decline as I was flying back to Sofia and would have no room in my luggage for all of it. I suggested to him that his friend could possibly make more money if he sold the pipes and case separately and he confided that he knew little about pricing pipes individually. As we talked, I discovered that he was a board member of a foundation that assisted orphaned children Armenia – the home of his friend. That opened the door for me to share that I too, was a board member of the Daughters of Bulgaria Foundation and I shared with him why I collected pipes – to restore and sell them to benefit the Daughters and their children. He encouraged me to go through the collection and pull out pipes that interested me and make him an offer. In Mediterranean culture, very much like Bulgarian culture – relationship is supreme, and we had talked of things near and dear to our hearts. Pipes became the doorway to a deeper fellowship that we both understood and appreciated. I left the shop owner with a firm handshake, a parting picture, and an appreciation for him and his journey.

I took it all in. He explained that his good friend, from Armenia, asked him to sell off his collection of pipes and he gave me a price for everything, including the wall-hanging display case. With gratitude to him for his generous offer, I had to decline as I was flying back to Sofia and would have no room in my luggage for all of it. I suggested to him that his friend could possibly make more money if he sold the pipes and case separately and he confided that he knew little about pricing pipes individually. As we talked, I discovered that he was a board member of a foundation that assisted orphaned children Armenia – the home of his friend. That opened the door for me to share that I too, was a board member of the Daughters of Bulgaria Foundation and I shared with him why I collected pipes – to restore and sell them to benefit the Daughters and their children. He encouraged me to go through the collection and pull out pipes that interested me and make him an offer. In Mediterranean culture, very much like Bulgarian culture – relationship is supreme, and we had talked of things near and dear to our hearts. Pipes became the doorway to a deeper fellowship that we both understood and appreciated. I left the shop owner with a firm handshake, a parting picture, and an appreciation for him and his journey.  I also left his shop with some special pipes and friendly prices 😊: Lorenzo Carnevale Sanremo of Italy (on top in picture below), a Savinelli Roley Pocket Pipe (bottom, below), and a sorry looking ¾ Bent Billiard (center below) that appeared to have no name – at least in the dim light of the upper room, I could not see any. It appeared the pipe had been left out in a sun-drenched field through a few seasons – showcasing a terribly oxidized stem and a bleached-out bowl, but the old boy had nice form and I liked him. It struck me that this pipe reminded me of a Southern US epithet, ‘Bless his heart, he can’t help how ugly he is!’ The ‘Bless his/her heart’ is the softener or honey before the hard news!

I also left his shop with some special pipes and friendly prices 😊: Lorenzo Carnevale Sanremo of Italy (on top in picture below), a Savinelli Roley Pocket Pipe (bottom, below), and a sorry looking ¾ Bent Billiard (center below) that appeared to have no name – at least in the dim light of the upper room, I could not see any. It appeared the pipe had been left out in a sun-drenched field through a few seasons – showcasing a terribly oxidized stem and a bleached-out bowl, but the old boy had nice form and I liked him. It struck me that this pipe reminded me of a Southern US epithet, ‘Bless his heart, he can’t help how ugly he is!’ The ‘Bless his/her heart’ is the softener or honey before the hard news!  The pipes were unwrapped when I returned home to Sofia. I was anxious to look at them, take some pictures, and to do my normal ‘information intake’ for each pipe I collect so that I can remember later when they emerge from the ‘Help Me! Basket’ heading to The Pipe Steward worktable. With a magnifying glass in hand, I discovered that the ‘Bless his heart’ charity pipe was a hidden prince with great potential – a Savinelli Oscar Aged Briar 614 of Italy. The Oscar is a popular line of the well-known Italian pipe family, Savinelli. I was surprised and happy to see what I could do to help him out! On the left side of the shank was stamped in cursive script, ‘Oscar’ over ‘AGED BRIAR’. The right side of the shank was stamped the Savinelli ‘S’ logo on the left, and to its right was shape number ‘614’ over ‘ITALY’.

The pipes were unwrapped when I returned home to Sofia. I was anxious to look at them, take some pictures, and to do my normal ‘information intake’ for each pipe I collect so that I can remember later when they emerge from the ‘Help Me! Basket’ heading to The Pipe Steward worktable. With a magnifying glass in hand, I discovered that the ‘Bless his heart’ charity pipe was a hidden prince with great potential – a Savinelli Oscar Aged Briar 614 of Italy. The Oscar is a popular line of the well-known Italian pipe family, Savinelli. I was surprised and happy to see what I could do to help him out! On the left side of the shank was stamped in cursive script, ‘Oscar’ over ‘AGED BRIAR’. The right side of the shank was stamped the Savinelli ‘S’ logo on the left, and to its right was shape number ‘614’ over ‘ITALY’.  I took some other pictures of the Savinelli Oscar on my worktable to catalog his condition when he arrived from Athens.

I took some other pictures of the Savinelli Oscar on my worktable to catalog his condition when he arrived from Athens.

Fast forward now nearly a year. Many of my restoration projects start because a pipe is commissioned, and it is plucked from the ‘Help Me!’ Basket. This often happens when a pipe listed in the “For Pipe Dreamers Only!” on The Pipe Steward site attracts someone. Or, here in Bulgaria, when folks are in our home and know about my pipe restoration work, they often will pour through the many pipes in the ‘Help Me!’ Basket (and boxes 😊) in search of just the right one! That was the case with the Savinelli Oscar. Taylor, a colleague and blooming pipe man, wanted a couple of pipes for himself and one for a friend in the US. The favorite he chose, or did the pipe choose him 😊(?), was the Savinelli Oscar which is now on my worktable.

Fast forward now nearly a year. Many of my restoration projects start because a pipe is commissioned, and it is plucked from the ‘Help Me!’ Basket. This often happens when a pipe listed in the “For Pipe Dreamers Only!” on The Pipe Steward site attracts someone. Or, here in Bulgaria, when folks are in our home and know about my pipe restoration work, they often will pour through the many pipes in the ‘Help Me!’ Basket (and boxes 😊) in search of just the right one! That was the case with the Savinelli Oscar. Taylor, a colleague and blooming pipe man, wanted a couple of pipes for himself and one for a friend in the US. The favorite he chose, or did the pipe choose him 😊(?), was the Savinelli Oscar which is now on my worktable.

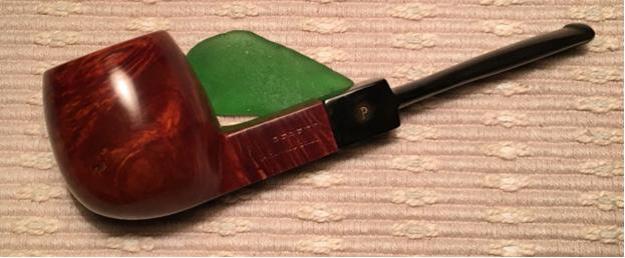

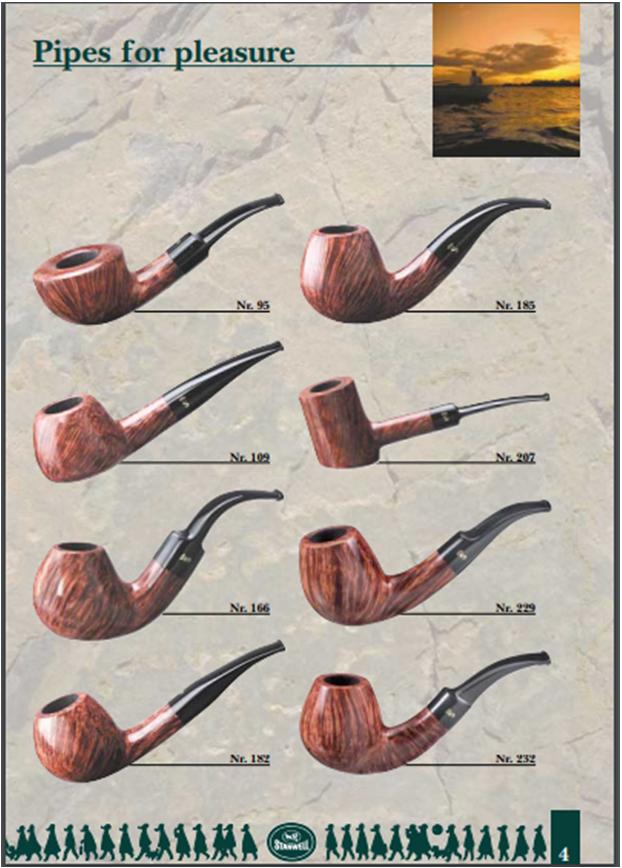

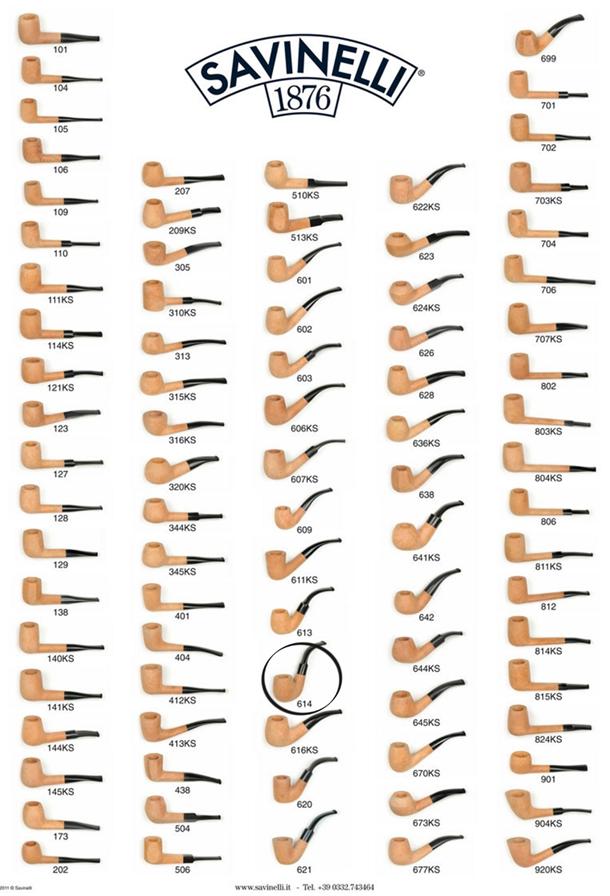

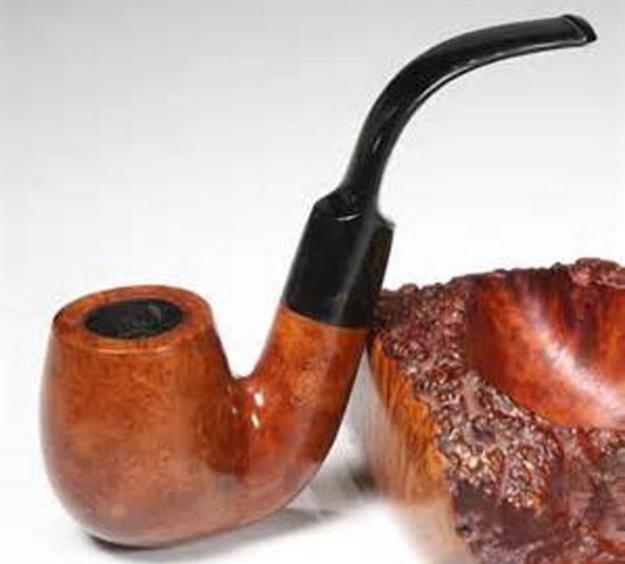

To learn more about the Savinelli Oscar Aged Briar, I look at the Savinelli Pipe Shape guide to identify shape 614. I locate it in the chart and it looks to be a 3/4 Bent Billiard. I circle the 314 in the chart and it’s interesting to see the other Bent Billiards nearby to compare. I’m thinking that the Oscar is a 3/4 Bent but I am surprised to see, that comparing it to all the other Savinelli bent shapes, it seems to be the most fully bent shape that Savinelli offers – at least from this chart. Then, with a simple search on Google using the name and the shape number, 614, I’m hoping for an Oscar 614 in pristine condition to guide the restoration of this sad boy. I find this example of an Oscar Aged Briar 614 formerly on the AntiqueAuctionsNow website – a nice looking classic bent stem Billiard.

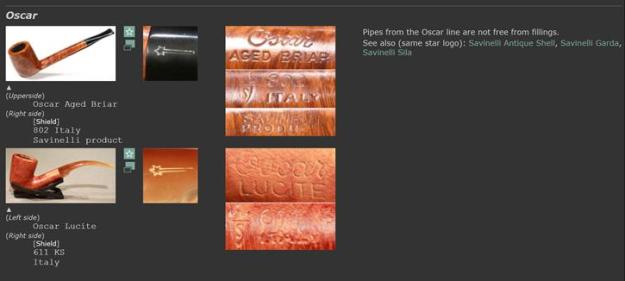

Then, with a simple search on Google using the name and the shape number, 614, I’m hoping for an Oscar 614 in pristine condition to guide the restoration of this sad boy. I find this example of an Oscar Aged Briar 614 formerly on the AntiqueAuctionsNow website – a nice looking classic bent stem Billiard. Ah ha! As I look closely at the picture above, it cues me into the possibility of the Savinelli Shooting Star stem stamp on the Oscar – impossible now to see with the heavy oxidation. I look to another regular place, PipePhil.eu, which gives me more information and understanding. The Savinelli Oscar line, along with three others, is marked with the Shooting Star stamp.

Ah ha! As I look closely at the picture above, it cues me into the possibility of the Savinelli Shooting Star stem stamp on the Oscar – impossible now to see with the heavy oxidation. I look to another regular place, PipePhil.eu, which gives me more information and understanding. The Savinelli Oscar line, along with three others, is marked with the Shooting Star stamp. Looking at the overall condition of the pipe, I have already noted the oxidation and a hope that the Shooting Star stamping can be salvaged. The bit also has very minor tooth chatter with a single dent on the upper button. The bowl almost appears like it has been bleached by the sun and the nomenclature stampings on the sides of the shank are thin and will take some care not to diminish more. The rim has some scorching over the left quadrant and has minor cake build up in the chamber. The internal rim has a smart bevel that I will refresh. I’ll ream the chamber to get down to the briar for a fresh start. A few small fills are detected on the lower shank and a significant divot is evident on the shank end, just below to the left of the Savinelli ‘S’ logo.

Looking at the overall condition of the pipe, I have already noted the oxidation and a hope that the Shooting Star stamping can be salvaged. The bit also has very minor tooth chatter with a single dent on the upper button. The bowl almost appears like it has been bleached by the sun and the nomenclature stampings on the sides of the shank are thin and will take some care not to diminish more. The rim has some scorching over the left quadrant and has minor cake build up in the chamber. The internal rim has a smart bevel that I will refresh. I’ll ream the chamber to get down to the briar for a fresh start. A few small fills are detected on the lower shank and a significant divot is evident on the shank end, just below to the left of the Savinelli ‘S’ logo.

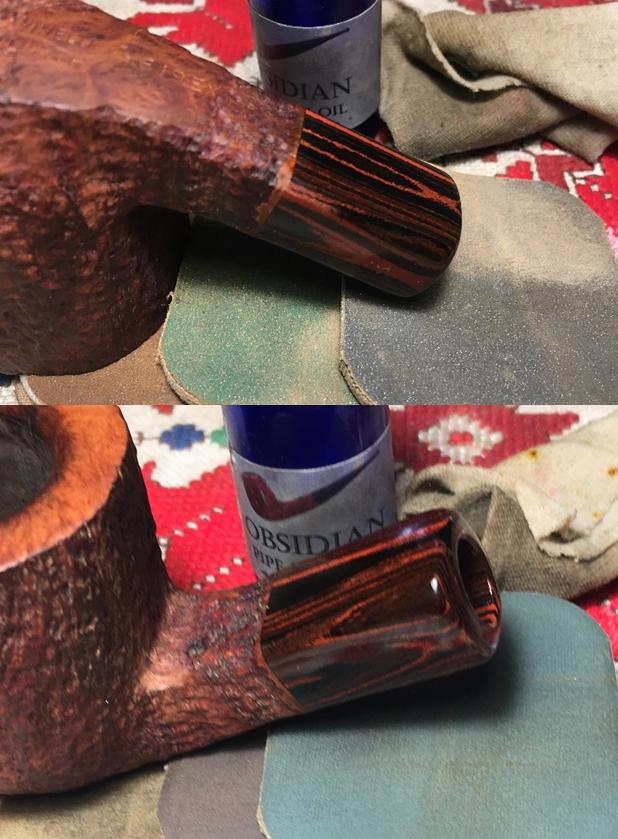

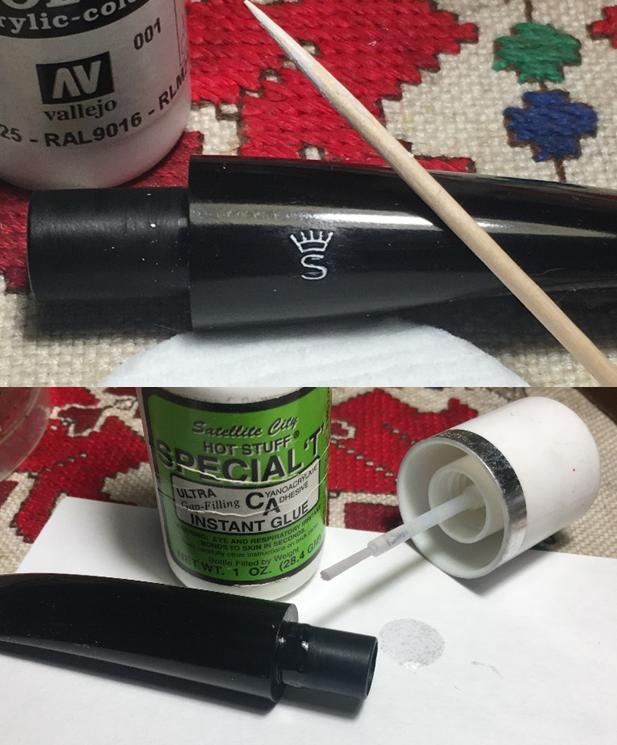

The first thing to address is the stem’s oxidation. I add the Oscar’s deeply oxidized stem with a batch of other stems into a bath of Before and After Deoxidizer to remove the oxidation on the stem. Aligned with each stummel, the stems are put into the solution for a few hours. The Savinelli Oscar is on the left. I’m hopeful that the Before and After Deoxidizer might uncover the Shooting Star stem stamp – hopeful, but doubtful. After a few hours, using a toothpick, I fish out the Oscar’s stem and allow it to drip-drain the Before and After Deoxidizer. I then wipe the stem with cotton pads and mineral spirits (light paraffin oil here in Bulgaria) which removes layers of raised oxidation off the surface. Miraculously, the Savinelli shooting star stamp appears out from underneath the oxidation! It is very thin and I’m not sure there’s enough depth left of the stamp for acrylic paint to find purchase.

After a few hours, using a toothpick, I fish out the Oscar’s stem and allow it to drip-drain the Before and After Deoxidizer. I then wipe the stem with cotton pads and mineral spirits (light paraffin oil here in Bulgaria) which removes layers of raised oxidation off the surface. Miraculously, the Savinelli shooting star stamp appears out from underneath the oxidation! It is very thin and I’m not sure there’s enough depth left of the stamp for acrylic paint to find purchase.

Continuing with the stem, I use Before and After Fine Polish then Extra Fine Polish to further condition the stem. With both, I place some polish on my finger and work it in on the vulcanite surface until it is absorbed. After each, I buff it further with cotton pads. The stem looks great – though the Shooting Star stamp doesn’t look like there’s much I can do with it but save what’s left of it!

Continuing with the stem, I use Before and After Fine Polish then Extra Fine Polish to further condition the stem. With both, I place some polish on my finger and work it in on the vulcanite surface until it is absorbed. After each, I buff it further with cotton pads. The stem looks great – though the Shooting Star stamp doesn’t look like there’s much I can do with it but save what’s left of it! Turning to the stummel, I use undiluted Murphy’s Oil Soap to scrub the surface and rim with a cotton pad. Whoops! Usually, I do the reaming before this – I’ll need to back track. I rinse the stummel with cool tap water and it cleaned up very well – the rim gunk is gone. I decide to apply a coat of light paraffin oil (mineral oil) to the surface to rehydrate the briar. I set it aside for a while for the paraffin oil to absorb fully. The grain looks good.

Turning to the stummel, I use undiluted Murphy’s Oil Soap to scrub the surface and rim with a cotton pad. Whoops! Usually, I do the reaming before this – I’ll need to back track. I rinse the stummel with cool tap water and it cleaned up very well – the rim gunk is gone. I decide to apply a coat of light paraffin oil (mineral oil) to the surface to rehydrate the briar. I set it aside for a while for the paraffin oil to absorb fully. The grain looks good.

Now, back to the chamber cleaning that I missed. I use the Pipnet Reaming Kit to ream the light cake out of the chamber. I use only the two smaller blades. I then fine tune the reaming with the Savinelli Fitsall Tool. Finally, I wrap 240 grade paper around a Sharpie Pen and sand the chamber down to the fresh briar. I finish the chamber cleaning by wiping it with a cotton pad wetted with isopropyl 95%. The pictures show the progress.

Now, back to the chamber cleaning that I missed. I use the Pipnet Reaming Kit to ream the light cake out of the chamber. I use only the two smaller blades. I then fine tune the reaming with the Savinelli Fitsall Tool. Finally, I wrap 240 grade paper around a Sharpie Pen and sand the chamber down to the fresh briar. I finish the chamber cleaning by wiping it with a cotton pad wetted with isopropyl 95%. The pictures show the progress.

To the internal cleaning – using cotton buds, pipe cleaners and a shank brush I clean the mortise. I also use a dental spatula to scrape the mortise walls to remove gunk. With my day ending, to give a more thorough cleaning, I use a kosher salt and alcohol soak to penetrate the tars and oils left in the bowl and mortise overnight. I fill the bowl with kosher salt – not iodized that leaves a taste. I give the bowl a shake with my hand covering the top to disperse the salt. I then form a wick to stuff down the mortise to draw out the oils and tars. I stretch and twist a cotton ball to do this. With the cotton wick in place, I place the stummel in an egg crate to keep it steady. I then use a large eyedropper to fill the chamber with isopropyl 95%. I wait a few minutes and top it again. Time to call it a day.

To the internal cleaning – using cotton buds, pipe cleaners and a shank brush I clean the mortise. I also use a dental spatula to scrape the mortise walls to remove gunk. With my day ending, to give a more thorough cleaning, I use a kosher salt and alcohol soak to penetrate the tars and oils left in the bowl and mortise overnight. I fill the bowl with kosher salt – not iodized that leaves a taste. I give the bowl a shake with my hand covering the top to disperse the salt. I then form a wick to stuff down the mortise to draw out the oils and tars. I stretch and twist a cotton ball to do this. With the cotton wick in place, I place the stummel in an egg crate to keep it steady. I then use a large eyedropper to fill the chamber with isopropyl 95%. I wait a few minutes and top it again. Time to call it a day.  The next morning, the soak has done the job of pulling even more oils and tar out of the internals. I dump the used salt in the waste and use a paper towel and shank brush to wipe out the expended salt left in the bowl and mortise. I also blow through the stummel to make sure there’s no old salt left.

The next morning, the soak has done the job of pulling even more oils and tar out of the internals. I dump the used salt in the waste and use a paper towel and shank brush to wipe out the expended salt left in the bowl and mortise. I also blow through the stummel to make sure there’s no old salt left. While I’m inspecting the stummel after removing the salt, looking at the scratch by the nomenclature and small chip on the shank end, I notice what I didn’t see before. A stamp on the lower side of the shank that is nearly invisible. I can make out only some of the stamping with a magnifying glass – Sav… over Produ…. I look again at the examples of the Oscar from Pipephil.eu (above) and sure enough, it shows a lower stamp as well – Savinelli over Product. I take a picture to show what I found.

While I’m inspecting the stummel after removing the salt, looking at the scratch by the nomenclature and small chip on the shank end, I notice what I didn’t see before. A stamp on the lower side of the shank that is nearly invisible. I can make out only some of the stamping with a magnifying glass – Sav… over Produ…. I look again at the examples of the Oscar from Pipephil.eu (above) and sure enough, it shows a lower stamp as well – Savinelli over Product. I take a picture to show what I found. I take a few shots of some problem areas – a cut or possibly a hairline crack, just above the shape number, the internal bevel of the rim is worn from lighting practices. I want to refresh the bevel and rim, which is already in good shape. I begin with the divot on the shank.

I take a few shots of some problem areas – a cut or possibly a hairline crack, just above the shape number, the internal bevel of the rim is worn from lighting practices. I want to refresh the bevel and rim, which is already in good shape. I begin with the divot on the shank.

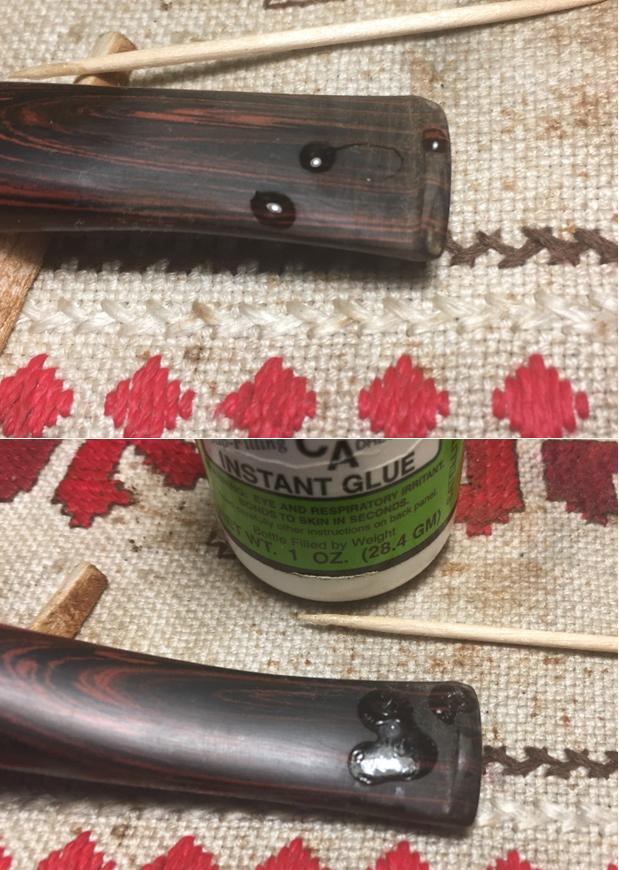

I decide to apply a drop of regular, clear super at the divot to build it out. I’ll let it cure a few hours before sanding and blending it. After a couple of hours, the shank end divot has set up enough for me to work on the cut/crack. I’m not convinced it is a crack – a cut is more likely I think. I decide to lay a very small line of regular super glue over the cut using a toothpick to guide the glue. It will be close quarters with the shape number when I sand it down, but I think it will look better.

I decide to apply a drop of regular, clear super at the divot to build it out. I’ll let it cure a few hours before sanding and blending it. After a couple of hours, the shank end divot has set up enough for me to work on the cut/crack. I’m not convinced it is a crack – a cut is more likely I think. I decide to lay a very small line of regular super glue over the cut using a toothpick to guide the glue. It will be close quarters with the shape number when I sand it down, but I think it will look better. After the glue cures, I first use 240 grit paper to sand both the divot and the cut down to the briar. I stay on top of the glue mound as much as possible to not impact the briar surface. I then use 600 grit paper to smooth and blend. These were small issues, but I feel better for addressing them – the Savinelli Oscar will look good.

After the glue cures, I first use 240 grit paper to sand both the divot and the cut down to the briar. I stay on top of the glue mound as much as possible to not impact the briar surface. I then use 600 grit paper to smooth and blend. These were small issues, but I feel better for addressing them – the Savinelli Oscar will look good.

Now, I turn to the rim. It’s in good condition but there are some nicks and dents on the edge of the rim. There is also a darkened area from minor scorching from lighting the tobacco. (11 o’clock in the first picture). In this area, the internal bevel has also eroded. I decide to give the stummel a very light topping using 600 grade paper to reestablish the lines of the rim and bevel. After this, I wrap first a 120 grade paper around a tapered wooden disk to provide a hard surface behind the paper to cut a more distinct bevel. I work the 120 paper around the damaged bevel area to shape the bevel. I then follow in the same manner with the wooden disk, 240 then 600 paper to finish the rim and bevel repair. The rim now looks fresher – I like it.

Now, I turn to the rim. It’s in good condition but there are some nicks and dents on the edge of the rim. There is also a darkened area from minor scorching from lighting the tobacco. (11 o’clock in the first picture). In this area, the internal bevel has also eroded. I decide to give the stummel a very light topping using 600 grade paper to reestablish the lines of the rim and bevel. After this, I wrap first a 120 grade paper around a tapered wooden disk to provide a hard surface behind the paper to cut a more distinct bevel. I work the 120 paper around the damaged bevel area to shape the bevel. I then follow in the same manner with the wooden disk, 240 then 600 paper to finish the rim and bevel repair. The rim now looks fresher – I like it.

I put the stummel aside for a time to address the stem. After deoxidizing the stem, discovering the Shooting Star stamp hanging on by threads, I look closely at the stem and the bit is in good shape. There are only shadows of tooth chatter and one small dent on the upper button lip. To bring up the button dent, I try painting it with a flame from a Bic lighter to expand the vulcanite enabling me to sand out the dent. After several attempts, I was still left with a dent. I decide to apply a drop of Black Medium KE-150 CA glue to the dent. I put the stem aside to let the patch cure.

I put the stummel aside for a time to address the stem. After deoxidizing the stem, discovering the Shooting Star stamp hanging on by threads, I look closely at the stem and the bit is in good shape. There are only shadows of tooth chatter and one small dent on the upper button lip. To bring up the button dent, I try painting it with a flame from a Bic lighter to expand the vulcanite enabling me to sand out the dent. After several attempts, I was still left with a dent. I decide to apply a drop of Black Medium KE-150 CA glue to the dent. I put the stem aside to let the patch cure.

While I wait for the stem patch to cure, I pick up the stummel and start the external finishing process by first using a light grade sanding sponge to work the surface – addressing minor nicks. I then wet sand the stummel using micromesh pads 1500 to 2400. I follow this by dry sanding using pads 3200 to 4000, then 6000 to 12000. I take pictures after each set of 3 to show the progress. I enjoy this part of the restoration process! With each cycle of micromesh pads, the beauty of the grain emerges. This Oscar has attractive grain. I am drawn to the knot pattern on the heel as it gravitates outwardly and up the stummel with lateral grain having a feathered texture – bird’s eye grain as well on the upper bowl. Very nice!

While I wait for the stem patch to cure, I pick up the stummel and start the external finishing process by first using a light grade sanding sponge to work the surface – addressing minor nicks. I then wet sand the stummel using micromesh pads 1500 to 2400. I follow this by dry sanding using pads 3200 to 4000, then 6000 to 12000. I take pictures after each set of 3 to show the progress. I enjoy this part of the restoration process! With each cycle of micromesh pads, the beauty of the grain emerges. This Oscar has attractive grain. I am drawn to the knot pattern on the heel as it gravitates outwardly and up the stummel with lateral grain having a feathered texture – bird’s eye grain as well on the upper bowl. Very nice!

With the black CA glue cured, I now return to the stem. Using a flat, needle file, I remove the patch area above the vulcanite and redefine the button. I follow with 240 grade paper to erase the tracks left by the file. I then use 320 grade paper followed by 600 grade to smooth the area further. I flip the stem and sand the lower bit with 600 grade paper to remove the light tooth chatter. Finally, I buff the entire stem, watchful of the Shooting Star stamp, using 0000 steel wool. The pictures show the progress.

With the black CA glue cured, I now return to the stem. Using a flat, needle file, I remove the patch area above the vulcanite and redefine the button. I follow with 240 grade paper to erase the tracks left by the file. I then use 320 grade paper followed by 600 grade to smooth the area further. I flip the stem and sand the lower bit with 600 grade paper to remove the light tooth chatter. Finally, I buff the entire stem, watchful of the Shooting Star stamp, using 0000 steel wool. The pictures show the progress.

Following the steel wool buff, I now wet sand the stem with micromesh pads 1500 to 2400. After finishing with this first wet sand cycle, I was bushwhacked by oxidation resurfacing on the Oscar’s stem! Ugh!! After all the sanding and roughing up the surface, sometimes it’s difficult to see the oxidation left behind until the fine tuning with the micromesh pads. The first picture below doesn’t show what I can see with the eye – a deep shadow of oxidation. I take another picture adjusting the aperture, so you can see the source of my frustrations! I send a note to Steve with questions and his response was good news and bad. The good news was that it wasn’t my process but that Savinelli stems are notoriously difficult to exorcise oxidation. The bad news is that I simply will go back to work, sanding with 240 grit, 320, 600, then again steel wool buff and application of Before and After polishes…. I did all these, including a few times going through the first set of 1500 to 2400 micromesh pads, so that I am finally satisfied with the Savinelli Oscar’s stem. Yet, I haven’t rid the oxidation 100%, but time to move on!

Following the steel wool buff, I now wet sand the stem with micromesh pads 1500 to 2400. After finishing with this first wet sand cycle, I was bushwhacked by oxidation resurfacing on the Oscar’s stem! Ugh!! After all the sanding and roughing up the surface, sometimes it’s difficult to see the oxidation left behind until the fine tuning with the micromesh pads. The first picture below doesn’t show what I can see with the eye – a deep shadow of oxidation. I take another picture adjusting the aperture, so you can see the source of my frustrations! I send a note to Steve with questions and his response was good news and bad. The good news was that it wasn’t my process but that Savinelli stems are notoriously difficult to exorcise oxidation. The bad news is that I simply will go back to work, sanding with 240 grit, 320, 600, then again steel wool buff and application of Before and After polishes…. I did all these, including a few times going through the first set of 1500 to 2400 micromesh pads, so that I am finally satisfied with the Savinelli Oscar’s stem. Yet, I haven’t rid the oxidation 100%, but time to move on! Again, at the end of the first cycle of 3, wet sanding with micromesh pads, 1500 to 2400, I then dry sand with pads 3200 to 4000, then 6000 to 12000. After each cycle I apply Obsidian Oil to the (almost!) exorcised vulcanite. When I look at the stem now, it looks pretty good!

Again, at the end of the first cycle of 3, wet sanding with micromesh pads, 1500 to 2400, I then dry sand with pads 3200 to 4000, then 6000 to 12000. After each cycle I apply Obsidian Oil to the (almost!) exorcised vulcanite. When I look at the stem now, it looks pretty good!

With the Savinelli Oscar’s bowl back in front of me, I begin the final sanding and waxing process. I first mount the felt buffing wheel on the Dremel and apply Tripoli compound to the briar’s surface. I first set the speed at the slowest speed, purge the wheel with the Dremel’s tightening wrench’s sharp edge, and I apply the compound. I apply compounds, which are abrasives, not waxes, in a methodical, circular motion, not applying too much downward pressure on the wheel but allowing the compound, speed and the wheel to do the work. Following the Tripoli, I apply Blue Diamond compound in the same manner, with a cotton cloth buffing wheel mounted on the Dremel, set at about 40% speed. During the application of the compounds, I love to watch the natural shine of the briar start reflecting like glass. The beauty of this Savinelli’s grain is popping. With the help of my wife, the picture below shows the application of Tripoli compound. You can see how I use the sheen of the lamp to ‘steer’ the compound around the briar surface allowing the action to buff out the microscopic lines and nicks.

With the Savinelli Oscar’s bowl back in front of me, I begin the final sanding and waxing process. I first mount the felt buffing wheel on the Dremel and apply Tripoli compound to the briar’s surface. I first set the speed at the slowest speed, purge the wheel with the Dremel’s tightening wrench’s sharp edge, and I apply the compound. I apply compounds, which are abrasives, not waxes, in a methodical, circular motion, not applying too much downward pressure on the wheel but allowing the compound, speed and the wheel to do the work. Following the Tripoli, I apply Blue Diamond compound in the same manner, with a cotton cloth buffing wheel mounted on the Dremel, set at about 40% speed. During the application of the compounds, I love to watch the natural shine of the briar start reflecting like glass. The beauty of this Savinelli’s grain is popping. With the help of my wife, the picture below shows the application of Tripoli compound. You can see how I use the sheen of the lamp to ‘steer’ the compound around the briar surface allowing the action to buff out the microscopic lines and nicks.

With the compounds finished, I buff the stummel with a clean felt cloth to remove the compound dust left behind. The last restoration I did of the L. J. Peretti Oom Paul (see LINK) which I added to my own collection, I utilized for the first time the Before and After Restoration Balm. I liked the results a lot. The Restoration Balm maintains the lighter hues of the natural grain but enriches the patina. I use the Balm with the Savinelli Oscar as well. I reunite the stem and stummel and I put some Balm on my fingertips and I work it into the briar surface as well as the stem. As I rub, the Balm thickens until it has almost a stickiness. After application, I lay it aside for a while to allow the Balm to do its thing – while it’s doing its thing, I take a picture. I then wipe it down and buff it with a cotton cloth pad. I like the rich luster that the balm brings up from the briar. The vulcanite stem also responds very well.

With the compounds finished, I buff the stummel with a clean felt cloth to remove the compound dust left behind. The last restoration I did of the L. J. Peretti Oom Paul (see LINK) which I added to my own collection, I utilized for the first time the Before and After Restoration Balm. I liked the results a lot. The Restoration Balm maintains the lighter hues of the natural grain but enriches the patina. I use the Balm with the Savinelli Oscar as well. I reunite the stem and stummel and I put some Balm on my fingertips and I work it into the briar surface as well as the stem. As I rub, the Balm thickens until it has almost a stickiness. After application, I lay it aside for a while to allow the Balm to do its thing – while it’s doing its thing, I take a picture. I then wipe it down and buff it with a cotton cloth pad. I like the rich luster that the balm brings up from the briar. The vulcanite stem also responds very well. I follow the Restoration Balm by applying carnauba wax to the stem and stubble. I mount the Dremel with a cotton cloth buffing wheel dedicated to applying wax. With the Dremel speed still at 40% I apply several coats to the pipe and follow the wax with a hearty hand buffing using a micromesh cloth that bring up the shine even more.

I follow the Restoration Balm by applying carnauba wax to the stem and stubble. I mount the Dremel with a cotton cloth buffing wheel dedicated to applying wax. With the Dremel speed still at 40% I apply several coats to the pipe and follow the wax with a hearty hand buffing using a micromesh cloth that bring up the shine even more.

This surprising Savinelli Oscar find in Athens turned out better than I expected. The grain is eye-catching, with plentiful bird’s eye captured around the bowl. The knot on the heel though, grabs my attention. The deep briar that I see now is a far cry from the sun-bleached conditioned that I found it in. This Savinelli Oscar will go into the Pipe Steward Store and since Taylor commissioned this pipe as his first pipe, he will have first dibs. The restoration of this Italian Savinelli Oscar Aged Grain 614 will benefit the Daughters of Bulgaria – helping women, girls, and their children, who have been trafficked and sexually exploited. The first picture is a reminder of before and after. Thanks for joining me!