by Steve Laug

The next pipe was a mess and one that obviously had been the previous pipe smoker’s favourite pipe. The finish and condition were abysmal. It was definitely a stranger to any cleaning! This one is a smooth Billiard that has a rich coloured finish around the bowl sides and shank under the grit and grime of years. The shank end had a double brass band separating it from the stem. This pipe was purchased on 12/09/2023 from our contact in Copenhagen, Denmark. The finish is shiny but is also so dirty it was hard to know what to expect once it was cleaned. It was stamped on the left side of the shank and read Peterson’s [over] “Kapp-Royal”. It was stamped to the right of the shank and reads MADE IN THE REPUBLIC OF IRELAND (three lines) with the shape number X105 next to the bowl. The underside of the shank was stamped Huber over Munchen. It was filthy when Jeff brought it to the table. There was a thick cake in the bowl and lava on the back of the rim top and the inner edge of the bowl. The outer edge looked good. The Cumberland stem was oxidized and had light tooth marks and chatter on the top and underside on and near the button. Jeff took photos of the pipe before his cleanup work.

Jeff took photos of the rim top and stem to show the general condition of the pipe. The bowl is heavily caked and there was a light lava overflow on the back of the rim top and the inner edge. The stem is oxidized and grimy. It has some light tooth marks on the top and underside near and on the surface of the button itself.

Jeff took photos of the rim top and stem to show the general condition of the pipe. The bowl is heavily caked and there was a light lava overflow on the back of the rim top and the inner edge. The stem is oxidized and grimy. It has some light tooth marks on the top and underside near and on the surface of the button itself.

Jeff took photos of the bowl sides and heel to show the grain that was around this bowl. The grain is quite beautiful around the sides of the bowl and shank. It is a nice looking pipe.

Jeff took photos of the bowl sides and heel to show the grain that was around this bowl. The grain is quite beautiful around the sides of the bowl and shank. It is a nice looking pipe. He took photos of the sides of the shank to show the stamping. The stamping is readable in the photos below and is as noted above. There is a golden “P” inlaid logo on the left side of the taper stem.

He took photos of the sides of the shank to show the stamping. The stamping is readable in the photos below and is as noted above. There is a golden “P” inlaid logo on the left side of the taper stem.

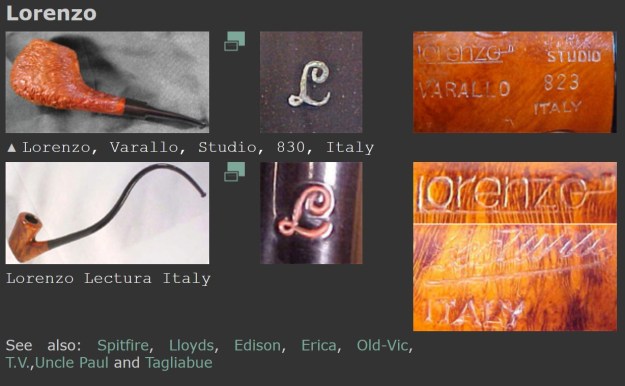

I am including the link to the Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson). There was a short note toward the bottom of the page about the series. It is definitely referring to the newer line that came out later. I quote:

I am including the link to the Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson). There was a short note toward the bottom of the page about the series. It is definitely referring to the newer line that came out later. I quote:

Kapp Royal Series: The Kapp Royal series is a relatively new one, but has a well establish history in Europe. They are a handsome colourful series with a good quality natural stain briar and bright orange Lucite stems and occasionally Cumberland.

I turned to “The Peterson Pipe” by Mark Irwin and Gary Malmberg to get some background on the Peterson’s Kapp-Royal Pipe. On page 306 it had the following information.

Kapp-Royal (1969, 1976-79, c1988, 2004) First appearance as a line introduced 1969. In 1976-79 Iwan Ries catalog offering identical with non-System Dunmore line. Second appearance in the late eighties as a high-grade Italian market line with briar band inset into the mouthpiece. From c.2004, Italian line available in US as high grade, orange finish, sterling band, amber-colored acrylic fishtail stem or sometimes vulcanite, embedded aluminum P.

Judging from the description above, the pipe I am working on is probably one of the first appearing series that came out in 1969. As noted in Red above it came with an occasional Cumberland stem. The Made in the Republic of Ireland stamp on the right side of the stamp puts it in the Republic Era 1950-1989.

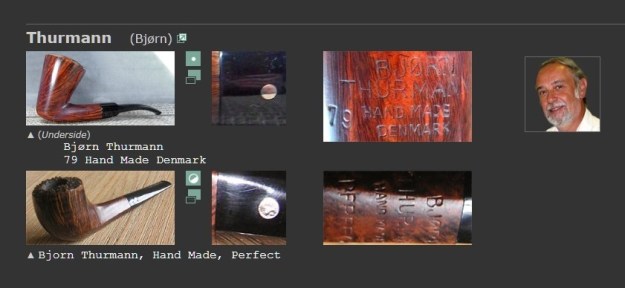

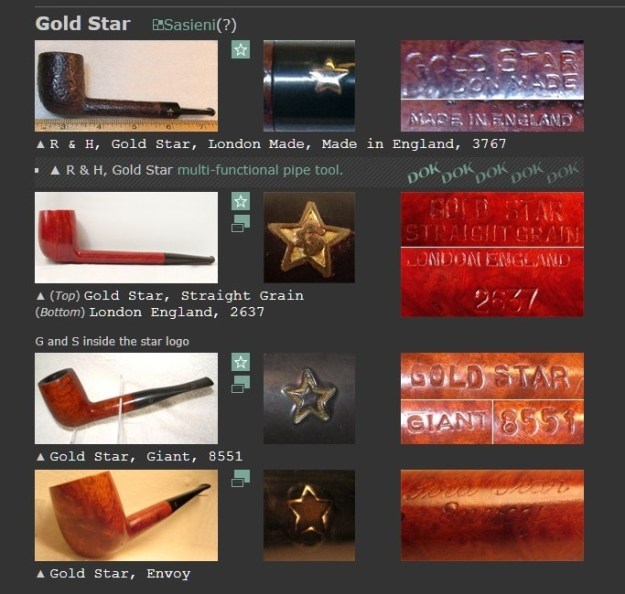

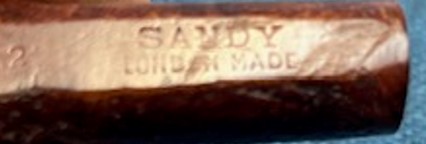

On the underside of the shank it is stamped Huber [over] Munchen. From a past restoration (I have included the link) [https://rebornpipes.com/2023/10/14/petersons-kildare-special-hg-republic-of-ireland-10-canadian/]. I turned to page 300 of “The Peterson’s Pipe” by Mark Irwin and Gary Malmberg as noted by him in the previous blog and found a great paragraph on the stamping. I quote in full.

GH Retailer’s Monogram (c. 1960s) George Huber of Munich, Germany, a Peterson distributor and retailer for decades, stamped their monogram on pipes sold in their store, G overlaid on H. Peterson shared in the 1988 commemoration of Huber’s 125th year in business by producing a special pipe with a sterling rim cap, stamped HUBER over CELEBRATION.

The pipe I have is one that does not bear that monogram and does not appear to have ever had the sterling rim cap and was not stamped HUBER over CELEBRATION. It was however, stamped Huber and Munchen – the city where the shop was located. With that information I turned my attention to working on the pipe.

I was utterly surprised when I took this pipe out of the box and compared it to the before photos. Jeff had done a great job cleaning up the pipe as usual. He reamed the pipe with a PipNet reamer and cut back the cake back to the bare briar. He cleaned up the walls with a Savinelli Fitsall Pipe Knife. Surprisingly the walls looked unscathed from the heavy cake. He scrubbed the interior of the bowl and shank with pipe cleaners, cotton swabs and alcohol to remove the tars and oils. He scrubbed the exterior of the pipe with Murphy’s Oil Soap and a tooth brush to remove the grime from the finish. He worked on the rim top lava and darkening with the soap and tooth brush. He scrubbed the inside of the stem with alcohol and pipe cleaners. He scrubbed the exterior of the stem with Soft Scrub and then soaked it in Briarville’s Deoxidizer. He washed it off with warm water to remove the Deoxidizer. The pipe looked far better when it arrived.

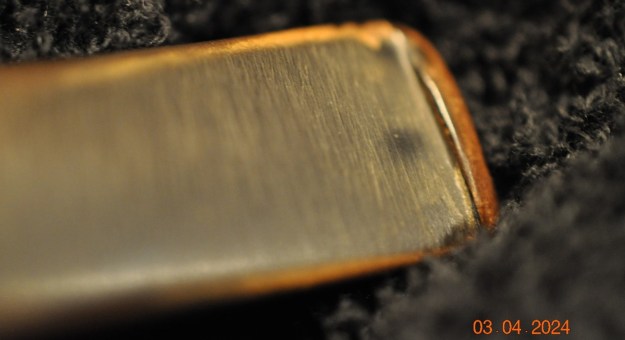

The cleaned up rim top looked very good around the edges and the top. I took a closeup photo of the rim top and edges to show how well it had cleaned up. I also took close up photos of the stem to show the light tooth marks on the surface near and on the button itself.

The cleaned up rim top looked very good around the edges and the top. I took a closeup photo of the rim top and edges to show how well it had cleaned up. I also took close up photos of the stem to show the light tooth marks on the surface near and on the button itself. I took photos of the stamping on the sides of the shank. It is clear and reads as noted above. I also captured the gold insert P on the left side of the Cumberland stem. It looked great. I removed the stem and took a photo of the pipe to have a look at the parts and overall look.

I took photos of the stamping on the sides of the shank. It is clear and reads as noted above. I also captured the gold insert P on the left side of the Cumberland stem. It looked great. I removed the stem and took a photo of the pipe to have a look at the parts and overall look.

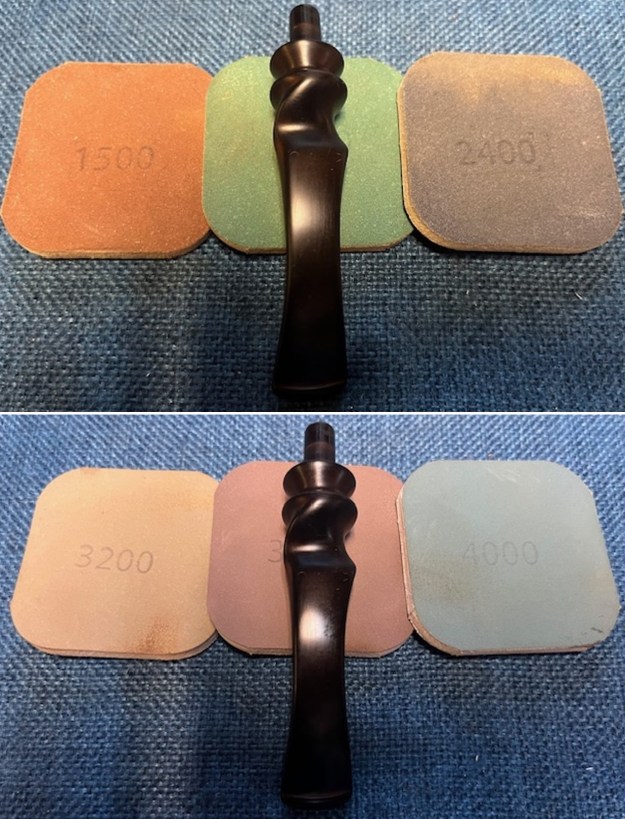

I started my work on this pipe polishing the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad.

I started my work on this pipe polishing the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I set the bowl aside and worked on the stem. The stem was clean and the light tooth marks were minimal. There was pitting on the topside of the stem that left it feeling rough. I sanded the stem with 320-3500 grit sanding pads to smooth out the pitting and marks in the Cumberland. Once finished it was greatly improved.

I set the bowl aside and worked on the stem. The stem was clean and the light tooth marks were minimal. There was pitting on the topside of the stem that left it feeling rough. I sanded the stem with 320-3500 grit sanding pads to smooth out the pitting and marks in the Cumberland. Once finished it was greatly improved. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I wiped it down with another coat of Obsidian Oil.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I wiped it down with another coat of Obsidian Oil.

I put a new 9mm filter in the tenon on the stem. It fit well and looked great. I used Vauen filters as they are easily accessible here and on Amazon.com.

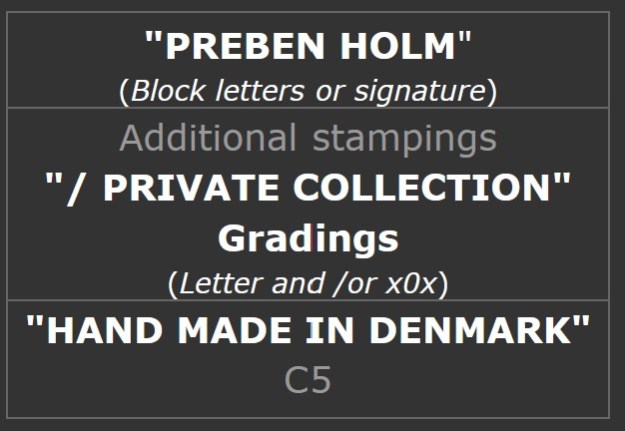

I put a new 9mm filter in the tenon on the stem. It fit well and looked great. I used Vauen filters as they are easily accessible here and on Amazon.com. I am excited to finish this beautifully grained Peterson’s Kapp-Royal X105 Billiard. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful mixed grain all around it. I polished the twin golden bands on the shank with a jeweller’s cloth. This smooth Classic Peterson’s Kapp-Royal X105 Billiard is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 45 grams/1.59 ounces. It turned out to be a beautiful pipe. I will be putting on the rebornpipes store in the Irish Pipe Makers Section. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for walking with me through this restoration.

I am excited to finish this beautifully grained Peterson’s Kapp-Royal X105 Billiard. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful mixed grain all around it. I polished the twin golden bands on the shank with a jeweller’s cloth. This smooth Classic Peterson’s Kapp-Royal X105 Billiard is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 45 grams/1.59 ounces. It turned out to be a beautiful pipe. I will be putting on the rebornpipes store in the Irish Pipe Makers Section. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for walking with me through this restoration.