Blog by Dal Stanton

The next pipe on my desk was commissioned by Nathan, a pipe man from St. Louis. Nathan’s multiple trips to my virtual ‘Help Me!’ baskets in the online collection I call, For “Pipe Dreamers” Only!, resulted in 4 very nice pipes being commissioned by Nathan each benefiting the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Nathan’s communications with me indicated that he was happy to help a great cause. Here are the pipes Nathan has in the Pipe Steward queue: a Savinelli Dry System, Pipstar Dublin Sitter, Lorenzo Carnevale Sanremo Italy Rusticated Squat Apple and the Comoy’s Sunrise Volcano H 16 now on the table. The Comoy’s Sunrise Volcano came to me in the acquisition of a large eBay lot I’ve called the ‘Lot of 66’. It came from a non-profit in Georgetown, Texas, called the Caring Place which I was happy to support. Here are some of the original pictures I took when the Lot of 66 arrived.

The Comoy’s Sunrise Volcano came to me in the acquisition of a large eBay lot I’ve called the ‘Lot of 66’. It came from a non-profit in Georgetown, Texas, called the Caring Place which I was happy to support. Here are some of the original pictures I took when the Lot of 66 arrived.

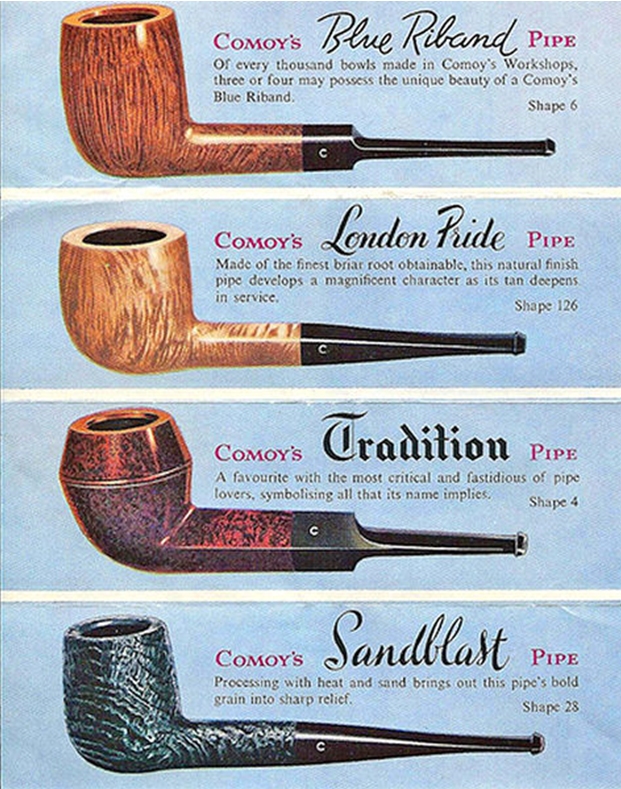

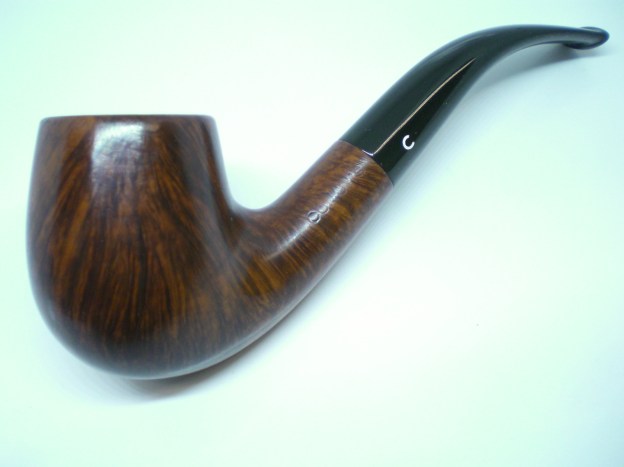

The nomenclature is located on the upper and lower panels of the oval shank. On the upper side is stamped, ‘Comoy’s’ [over] SUNRISE. On the lower shank panel is stamped to the left the rounded, MADE IN LONDON [over] ENGLAND. To the left and above is stamped ‘H’, a random letter. Below and to the right is stamped the shape number, ‘16’ which indicates a number after the Cadogan acquisition of Comoy’s in 1979 when the shape numbers were reduced from 3 to 2 digits. The stamped ‘C’ on the stem also is consistent with a post Cadogan pipe. I looked on Pipedia to see how the shape number, ‘16’ would be described. I discovered that it’s not listed there. I’ve restored other Comoy’s with the ‘H’ stamped on the shank and from what Steve has shared with me, what he has heard is that the random letters indicate a certain parts replacement regimen.

The nomenclature is located on the upper and lower panels of the oval shank. On the upper side is stamped, ‘Comoy’s’ [over] SUNRISE. On the lower shank panel is stamped to the left the rounded, MADE IN LONDON [over] ENGLAND. To the left and above is stamped ‘H’, a random letter. Below and to the right is stamped the shape number, ‘16’ which indicates a number after the Cadogan acquisition of Comoy’s in 1979 when the shape numbers were reduced from 3 to 2 digits. The stamped ‘C’ on the stem also is consistent with a post Cadogan pipe. I looked on Pipedia to see how the shape number, ‘16’ would be described. I discovered that it’s not listed there. I’ve restored other Comoy’s with the ‘H’ stamped on the shank and from what Steve has shared with me, what he has heard is that the random letters indicate a certain parts replacement regimen. Even though the shape number is not listed in the Comoy’s listing on Pipedia, I’m calling this a Volcano. The dimensions are: Length: 5 1/4 inches, Height: 1 3/8 inches, Rim width: 1 1/8 inches, Chamber width: 3/4 inches, Chamber depth: 1 1/4 inches – a nice, more diminutive size. The oval shank flowing into the slightly bent stem creates a genuinely nice flow.

Even though the shape number is not listed in the Comoy’s listing on Pipedia, I’m calling this a Volcano. The dimensions are: Length: 5 1/4 inches, Height: 1 3/8 inches, Rim width: 1 1/8 inches, Chamber width: 3/4 inches, Chamber depth: 1 1/4 inches – a nice, more diminutive size. The oval shank flowing into the slightly bent stem creates a genuinely nice flow.  The original color of the stummel leans in the direction of an Oxblood/reddish hue which is now pale. The chamber appears to have been cleaned somewhat with no cake build up. The rim has some lava build up which should clean off with little problem along with the rest of the stummel which bears minor nicks and bumps. The grain looks good – no fills jump out at me. The stem has some chatter but not major. There is oxidation which will be addressed. To begin the recommissioning of this Comoy’s Sunrise Volcano for Nathan, the stem’s airway is cleaned with a pipe cleaner wetted with isopropyl 95%.

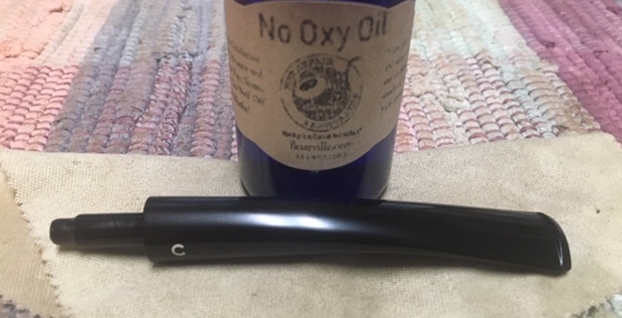

The original color of the stummel leans in the direction of an Oxblood/reddish hue which is now pale. The chamber appears to have been cleaned somewhat with no cake build up. The rim has some lava build up which should clean off with little problem along with the rest of the stummel which bears minor nicks and bumps. The grain looks good – no fills jump out at me. The stem has some chatter but not major. There is oxidation which will be addressed. To begin the recommissioning of this Comoy’s Sunrise Volcano for Nathan, the stem’s airway is cleaned with a pipe cleaner wetted with isopropyl 95%. It then joins other pipes in the queue for a soak in Mark Hoover’s product, Before & After Deoxidizer (www.ibepen.com) which does a good job on stems that are not too heavily oxidized. I allow the stem to soak for a few hours.

It then joins other pipes in the queue for a soak in Mark Hoover’s product, Before & After Deoxidizer (www.ibepen.com) which does a good job on stems that are not too heavily oxidized. I allow the stem to soak for a few hours. After taking the stem out of the soak, I squeegee off the liquid with my fingers and use cotton pads wetted with alcohol to wipe off the raised oxidation. Another pipe cleaner also wetted with isopropyl 95% clears the airway of remnants of the Deoxidizer.

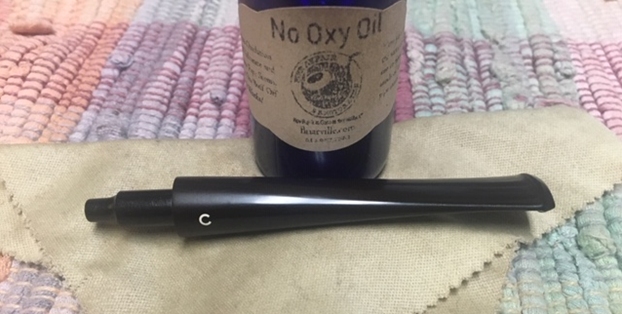

After taking the stem out of the soak, I squeegee off the liquid with my fingers and use cotton pads wetted with alcohol to wipe off the raised oxidation. Another pipe cleaner also wetted with isopropyl 95% clears the airway of remnants of the Deoxidizer. To start the process of conditioning the vulcanite stem, paraffin oil is applied, and the stem is put aside to absorb the oil.

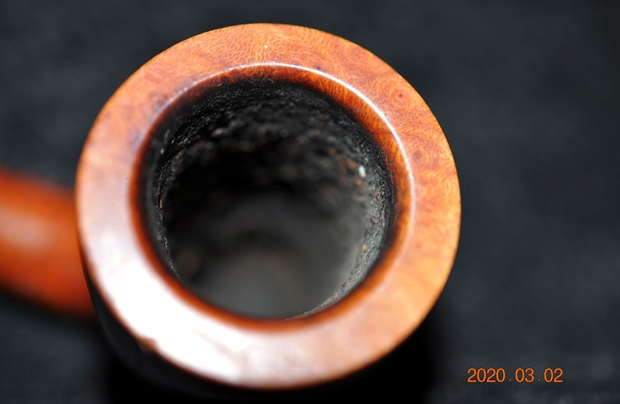

To start the process of conditioning the vulcanite stem, paraffin oil is applied, and the stem is put aside to absorb the oil. Turning now to cleaning the stummel, I start by cleaning the chamber. The cake buildup is almost non-existent, and I give the chamber walls a quick scraping using the Savinelli Fitsall Tool. I then sand the chamber with 240 paper wrapped around a Sharpie Pen. The chamber is in good shape. Little effort to clean is needed – a nice change!

Turning now to cleaning the stummel, I start by cleaning the chamber. The cake buildup is almost non-existent, and I give the chamber walls a quick scraping using the Savinelli Fitsall Tool. I then sand the chamber with 240 paper wrapped around a Sharpie Pen. The chamber is in good shape. Little effort to clean is needed – a nice change! Next, turning to the external surface, undiluted Murphy’s Oil Soap is used to clean with a cotton pad. A brass wire brush, which is not harmful to the briar, is used to help clean the rim along with scraping it very carefully with the edge of my Winchester pocketknife.

Next, turning to the external surface, undiluted Murphy’s Oil Soap is used to clean with a cotton pad. A brass wire brush, which is not harmful to the briar, is used to help clean the rim along with scraping it very carefully with the edge of my Winchester pocketknife.

Then the stummel is taken to the kitchen sink to continue the cleaning with warm water using shank brushes to clean the mortise with anti-oil liquid dishwashing soap. After a thorough rinsing, the stummel is brought back to worktable to continue cleaning the internals with cotton buds and pipe cleaners. A couple buds and a pipe cleaner confirm the cleaned stated of the internals. Moving on.

Then the stummel is taken to the kitchen sink to continue the cleaning with warm water using shank brushes to clean the mortise with anti-oil liquid dishwashing soap. After a thorough rinsing, the stummel is brought back to worktable to continue cleaning the internals with cotton buds and pipe cleaners. A couple buds and a pipe cleaner confirm the cleaned stated of the internals. Moving on.

Taking a closer look at the stummel, the Oxblood/reddish finish is very thin and has disappeared from the edge of the rim which has a nice rounded sloping pitch toward the chamber – a stylistic touch for the volcano shape. The rim cleaned up nicely and along with the rim, the finish is thin but present. I see no fills that need attention.

Taking a closer look at the stummel, the Oxblood/reddish finish is very thin and has disappeared from the edge of the rim which has a nice rounded sloping pitch toward the chamber – a stylistic touch for the volcano shape. The rim cleaned up nicely and along with the rim, the finish is thin but present. I see no fills that need attention.

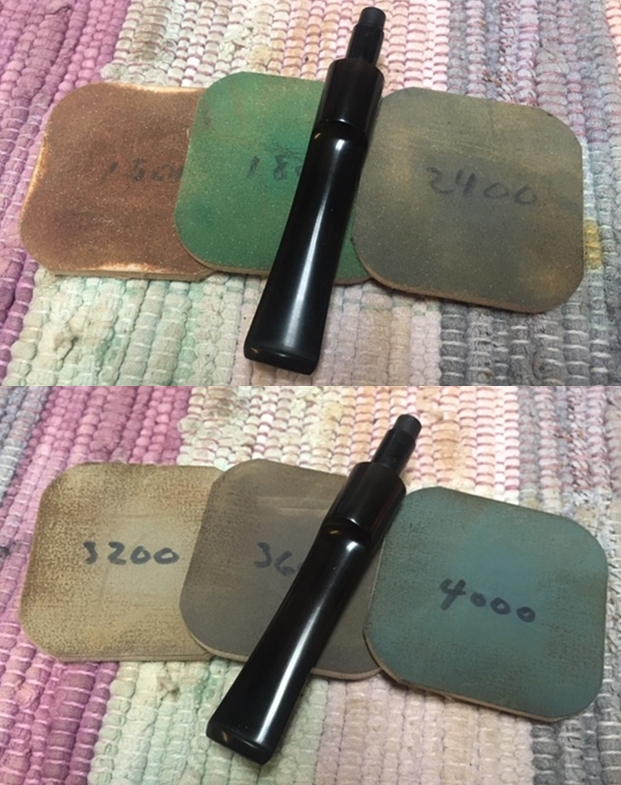

To clean the surface of the minor nicks, I proceed to using the full regimen of micromesh pads on the stummel surface. I begin by wet sanding with pads 1500 to 2400 and then dry sand with pads 3200 to 4000 and 6000 to 12000.

To clean the surface of the minor nicks, I proceed to using the full regimen of micromesh pads on the stummel surface. I begin by wet sanding with pads 1500 to 2400 and then dry sand with pads 3200 to 4000 and 6000 to 12000.

After the micromesh process, it is evident that the finish has lost its original luster and what is left is a pinkish tint that is not attractive. However, the micromesh sanding did bring out the grain very nicely. To make sure the surface is clean of the old finish, acetone on a cotton pad is used to wipe the stummel. The results reveal the former color.

After the micromesh process, it is evident that the finish has lost its original luster and what is left is a pinkish tint that is not attractive. However, the micromesh sanding did bring out the grain very nicely. To make sure the surface is clean of the old finish, acetone on a cotton pad is used to wipe the stummel. The results reveal the former color.

I will apply a new dye to the stummel, and I will begin with an undercoat of Oxblood and if needed, follow with a dye wash of red aniline dye. I’ll see how the first phase goes before deciding on the second. After assembling the staining module on my desk, I begin by warming the stummel with the hot air gun to open the briar helping the grain to be more receptive to the dye. After warm, I use a folded pipe cleaner to apply Fiebing’s Oxblood Leather Dye to the stummel. After painting a section with the pipe cleaner, the dye is this ‘flamed’ using a lit candle combusting the wet aniline dye. When lit, the alcohol in the dye combusts and leaves behind the pigment set in the briar grain.

I will apply a new dye to the stummel, and I will begin with an undercoat of Oxblood and if needed, follow with a dye wash of red aniline dye. I’ll see how the first phase goes before deciding on the second. After assembling the staining module on my desk, I begin by warming the stummel with the hot air gun to open the briar helping the grain to be more receptive to the dye. After warm, I use a folded pipe cleaner to apply Fiebing’s Oxblood Leather Dye to the stummel. After painting a section with the pipe cleaner, the dye is this ‘flamed’ using a lit candle combusting the wet aniline dye. When lit, the alcohol in the dye combusts and leaves behind the pigment set in the briar grain. After a thorough covering a few times over, the flamed stummel is set aside for several hours to allow the new dye to settle in.

After a thorough covering a few times over, the flamed stummel is set aside for several hours to allow the new dye to settle in. With the stummel resting, I turn to the Comoy’s stem. There is minor damage to the bit.

With the stummel resting, I turn to the Comoy’s stem. There is minor damage to the bit.  Using a needle file, I refresh the lines of the button. Afterwards, using 240 grade paper, the minor chatter is sanded out on the upper and lower bit.

Using a needle file, I refresh the lines of the button. Afterwards, using 240 grade paper, the minor chatter is sanded out on the upper and lower bit. To address any residual oxidation, the remainder of the stem is sanded with 240 grade paper. A plastic disk helps to guard against shouldering the stem facing.

To address any residual oxidation, the remainder of the stem is sanded with 240 grade paper. A plastic disk helps to guard against shouldering the stem facing. Transitioning now to 600 grade paper, the entire stem is wet sanded. This is followed by applying 000 steel wool.

Transitioning now to 600 grade paper, the entire stem is wet sanded. This is followed by applying 000 steel wool. Ugh! During this sanding phase, the Comoy’s ‘C’ factory stamping was damaged. This I don’t like. This mishap will not be easy to restore as thin as the factory stamping is. Unlike the older inlaid Comoy’s ‘C’, this stamping is more of a painting of a ‘C’ as there is no impression in the vulcanite for new paint to hold.

Ugh! During this sanding phase, the Comoy’s ‘C’ factory stamping was damaged. This I don’t like. This mishap will not be easy to restore as thin as the factory stamping is. Unlike the older inlaid Comoy’s ‘C’, this stamping is more of a painting of a ‘C’ as there is no impression in the vulcanite for new paint to hold. Avoiding the ‘C’, I continue with the full regimen of micromesh pads is applied beginning with wet sanding with pads 1500 to 2400. Following this, pads 3200 to 4000 and 6000 to 12000 are used to dry sand. Between each set of 3 pads, Obsidian Oil is applied to continue conditioning the stem and protect it from future oxidation.

Avoiding the ‘C’, I continue with the full regimen of micromesh pads is applied beginning with wet sanding with pads 1500 to 2400. Following this, pads 3200 to 4000 and 6000 to 12000 are used to dry sand. Between each set of 3 pads, Obsidian Oil is applied to continue conditioning the stem and protect it from future oxidation.

Restoring the Comoy’s ‘C’ stamping has no good options as my regretful pining has produced. Simply to paint a ‘C’ on the surface is not easy to do and it is resting on the surface and will be easily wiped away without too much effort. I considered attempting to engrave a ‘C’ but without machine shop precision, I’m left to freehand and that leaves no room for errors. My hand is not that steady! In the end, the only option open to me is to paint a ‘C’ building on the remnant of the original. I apply white acrylic paint several times and then carefully shape the lettering with a toothpick. It’s slow work. I’ve done the best I could. I move on.

Restoring the Comoy’s ‘C’ stamping has no good options as my regretful pining has produced. Simply to paint a ‘C’ on the surface is not easy to do and it is resting on the surface and will be easily wiped away without too much effort. I considered attempting to engrave a ‘C’ but without machine shop precision, I’m left to freehand and that leaves no room for errors. My hand is not that steady! In the end, the only option open to me is to paint a ‘C’ building on the remnant of the original. I apply white acrylic paint several times and then carefully shape the lettering with a toothpick. It’s slow work. I’ve done the best I could. I move on.

With the fired stummel ready to unwrap after applying Oxblood dye to the briar grain surface, a felt buffing wheel is mounted to the Dremel set at the lowest speed. Tripoli compound, a coarser abrasive compound, is then used to ‘unwrap’ the flamed crust of dye – removing the excess dye leaving the dyed grain that has absorbed the pigment.

With the fired stummel ready to unwrap after applying Oxblood dye to the briar grain surface, a felt buffing wheel is mounted to the Dremel set at the lowest speed. Tripoli compound, a coarser abrasive compound, is then used to ‘unwrap’ the flamed crust of dye – removing the excess dye leaving the dyed grain that has absorbed the pigment.

I pause to take a picture showing the contrast of the unwrapping process.

I pause to take a picture showing the contrast of the unwrapping process. I mentioned earlier that I anticipated doing a ‘dye wash’ using a red aniline dye over the Oxblood. This I decide to do using a pipe cleaner. I simply paint the dye on the stummel and after covering it thoroughly, I put the stummel aside for several hours for the dye to settle in.

I mentioned earlier that I anticipated doing a ‘dye wash’ using a red aniline dye over the Oxblood. This I decide to do using a pipe cleaner. I simply paint the dye on the stummel and after covering it thoroughly, I put the stummel aside for several hours for the dye to settle in. After the dye had dried enough to handle the stummel, I rejoin the stem and stummel to examine the fit. I notice a gapping on one side of the oval shank/stem fitting which I’ve pictured below.

After the dye had dried enough to handle the stummel, I rejoin the stem and stummel to examine the fit. I notice a gapping on one side of the oval shank/stem fitting which I’ve pictured below. Attempting to remedy this gap, I use a folded piece of 240 grade sanding paper wedged between the stem and shank on the opposite side of the stem from the gapping – the tight side. After gently compressing the shank and stem against the sanding paper, I move the paper back and forth in a sawing motion to sand down the tight side resulting in closing the gap on the other side of the stem/shank – hopefully! After a few attempts, checking and repositioning the paper, the gap is reduced and the seating of the stem into mortise is now much better.

Attempting to remedy this gap, I use a folded piece of 240 grade sanding paper wedged between the stem and shank on the opposite side of the stem from the gapping – the tight side. After gently compressing the shank and stem against the sanding paper, I move the paper back and forth in a sawing motion to sand down the tight side resulting in closing the gap on the other side of the stem/shank – hopefully! After a few attempts, checking and repositioning the paper, the gap is reduced and the seating of the stem into mortise is now much better. After several hours, the red dye has seasoned long enough. With a cotton cloth buffing wheel mounted on the Dremel and set at about 40% full power, Blue Diamond compound, a finer abrasive compound, is applied to the surface to remove excess dye and to smooth the briar surface.

After several hours, the red dye has seasoned long enough. With a cotton cloth buffing wheel mounted on the Dremel and set at about 40% full power, Blue Diamond compound, a finer abrasive compound, is applied to the surface to remove excess dye and to smooth the briar surface. Next, to help avoid dye leaching onto the hands of the new steward when the pipe is initially put into service, I heat the stummel with the hot gun to emulate the initial use of the chamber. After heating the stummel, I give the stummel a vigorous hand buffing with a cotton cloth to remove the dye loosened by the heating. I forgot to picture this, but the old t-shirt cotton cloth used had red residue.

Next, to help avoid dye leaching onto the hands of the new steward when the pipe is initially put into service, I heat the stummel with the hot gun to emulate the initial use of the chamber. After heating the stummel, I give the stummel a vigorous hand buffing with a cotton cloth to remove the dye loosened by the heating. I forgot to picture this, but the old t-shirt cotton cloth used had red residue. The final step is to apply carnauba wax to the stem and stummel. After mounting another cotton cloth wheel onto the Dremel with the speed the same, the wax is applied to the pipe. Following applying a few coats of wax, the pipe is given a hearty hand buffing to raise the shine.

The final step is to apply carnauba wax to the stem and stummel. After mounting another cotton cloth wheel onto the Dremel with the speed the same, the wax is applied to the pipe. Following applying a few coats of wax, the pipe is given a hearty hand buffing to raise the shine. The Comoy’s Sunrise turned out well. The grain pops now and the Volcano shape, with the wide heel, fits well in the hand ready for a new steward. The only disappointment was the ‘friendly fire’ damage done to the Comoy’s ‘C’ stem stamping – ugh! Nathan commissioned this Comoy’s Sunrise and will have the first opportunity to acquire it in The Pipe Steward Store benefitting the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Thanks for joining me!

The Comoy’s Sunrise turned out well. The grain pops now and the Volcano shape, with the wide heel, fits well in the hand ready for a new steward. The only disappointment was the ‘friendly fire’ damage done to the Comoy’s ‘C’ stem stamping – ugh! Nathan commissioned this Comoy’s Sunrise and will have the first opportunity to acquire it in The Pipe Steward Store benefitting the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Thanks for joining me!

I took photos of the rim top and stem to show the condition of the bowl, rim top and edges and stem. The bowl looks clean and the rim top and beveled inner edge look very good. I was hopeful that the pipe was actually as clean as it was shiny! The next photos show the condition of the stem. It is also clean and has no remaining oxidation. There are tooth marks and chatter under the shine on both sides near the button.

I took photos of the rim top and stem to show the condition of the bowl, rim top and edges and stem. The bowl looks clean and the rim top and beveled inner edge look very good. I was hopeful that the pipe was actually as clean as it was shiny! The next photos show the condition of the stem. It is also clean and has no remaining oxidation. There are tooth marks and chatter under the shine on both sides near the button. I took photos of the stamping on both sides of the shank. You can see that it is clear and readable on the left side and a little more blurry on the right side. There is also the inset C on the saddle stem – a new one piece inlaid C rather than the earlier version with the circles.

I took photos of the stamping on both sides of the shank. You can see that it is clear and readable on the left side and a little more blurry on the right side. There is also the inset C on the saddle stem – a new one piece inlaid C rather than the earlier version with the circles. I took the stem off the shank and took a photo of the pipe.

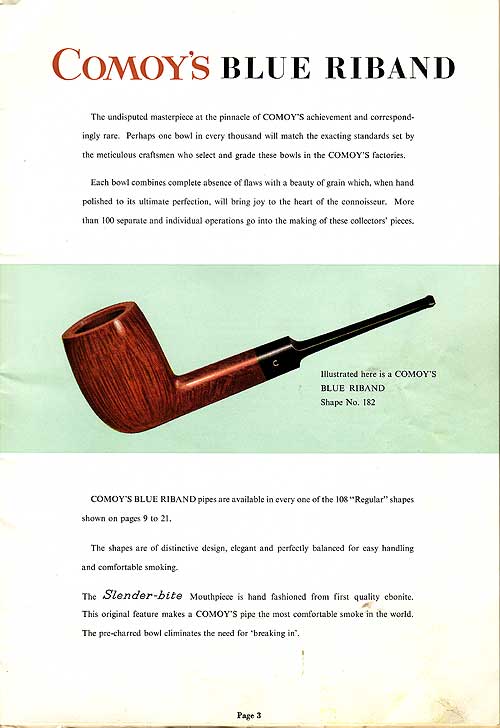

I took the stem off the shank and took a photo of the pipe. The “C” stem logo on Comoy’s pipes was the “three-piece C” insert until the Cadogan era in the 1980s. That helped me with a potential date on this pipe – 1980s or later. Knowing that this was a newer Comoy’s pipe from the Cadogan time period did not deter me as the shape on this one fascinated me. I turned to work on the pipe on my work table. The pipe was externally quite clean and I wanted to make sure that the internals were also clean. I scrubbed the interior of the bowl and shank with pipe cleaners, cotton swabs and alcohol to remove the tars and oils. I scrubbed the inside of the stem with alcohol and pipe cleaners. The shank was very dirty and appeared to not have been cleaned. The stem was much better.

The “C” stem logo on Comoy’s pipes was the “three-piece C” insert until the Cadogan era in the 1980s. That helped me with a potential date on this pipe – 1980s or later. Knowing that this was a newer Comoy’s pipe from the Cadogan time period did not deter me as the shape on this one fascinated me. I turned to work on the pipe on my work table. The pipe was externally quite clean and I wanted to make sure that the internals were also clean. I scrubbed the interior of the bowl and shank with pipe cleaners, cotton swabs and alcohol to remove the tars and oils. I scrubbed the inside of the stem with alcohol and pipe cleaners. The shank was very dirty and appeared to not have been cleaned. The stem was much better. I polished the briar with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the briar down with a damp cloth after each sanding pad.

I polished the briar with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the briar down with a damp cloth after each sanding pad.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes while I worked on the stem. After the time passed I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes while I worked on the stem. After the time passed I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

I worked over the light tooth marks and blended them into the stem surface with 220 grit sandpaper. I started polishing the stem with 400 grit wet dry sandpaper. At this point it is starting to look much better.

I worked over the light tooth marks and blended them into the stem surface with 220 grit sandpaper. I started polishing the stem with 400 grit wet dry sandpaper. At this point it is starting to look much better.  I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This Comoy’s Tradition 496 Pot turned out to be a great looking pipe. The mix of brown stains highlights the mix of grain around the bowl sides, top and bottom. The finish on the pipe is in excellent condition and the contrasting stains work well with the polished vulcanite saddle stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Comoy’s Tradition fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. Thanks for walking through the restoration with me as I worked over another beautiful pipe. This pipe will be going back into the box of finished pipes that I have done for Alex so he can pick them up when COVID-19 allows. Looking forward to hearing what Alex thinks of this one. Thanks for your time.

This Comoy’s Tradition 496 Pot turned out to be a great looking pipe. The mix of brown stains highlights the mix of grain around the bowl sides, top and bottom. The finish on the pipe is in excellent condition and the contrasting stains work well with the polished vulcanite saddle stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Comoy’s Tradition fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. Thanks for walking through the restoration with me as I worked over another beautiful pipe. This pipe will be going back into the box of finished pipes that I have done for Alex so he can pick them up when COVID-19 allows. Looking forward to hearing what Alex thinks of this one. Thanks for your time.