by Steve Laug

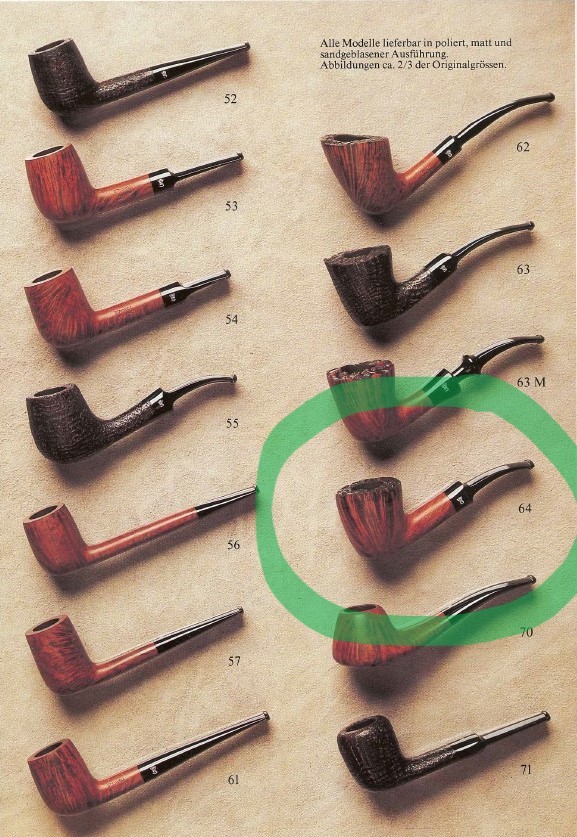

I finally finished the heavy group of pipes that I was working on for the wife of an old pipe man in Ontario. There were some amazing pipes there and with the restoration they came out looking very good. I will be mailing them out to him early in the week ahead. Now it was time to work on other pipes awaiting restoration. The first of those on the table is a Peterson’s of Dublin System Standard 312 with a pineapple style rustication and an acrylic fishtail stem. I received an email before my trip to Idaho to visit my father. In it a friend Matthew wrote about a pipe he had picked up that needed my attention. I have included the email below.

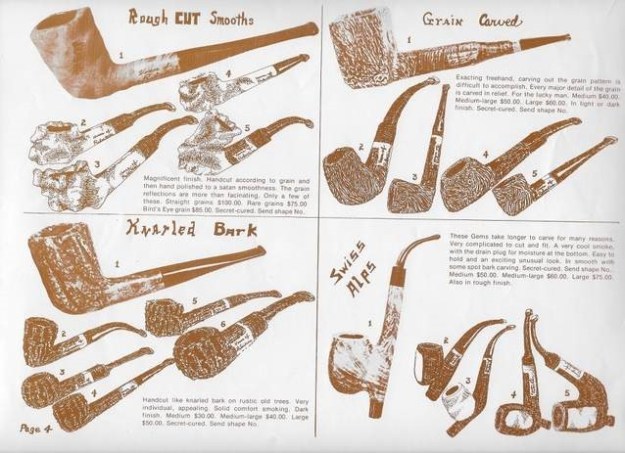

Steve, The Peterson is heading your way. I probably would not have even purchased the Pete, except it is an example of the “pineapple” rustication that Peterson used to employ. They’re getting hard to find and I do not know if it from rarity (not many made) or that Peterson did not sell many because the rustication did not appeal to pipe smokers. Please examine the Pete and give me your diagnosis. Thank you. Matthew

This afternoon I opened the box Matthew shipped the pipe in and found a nice looking green Peterson’s box inside. I opened the box and found a Peterson’s 312 inside and the original green pipe sock it came in. It was a great looking pipe.  The smell in the box was a heavy English/Latakia smell that filled the room when I opened the box. The finish on the pipe was quite clean with just some dust in the rustication grooves. The polished nickel ferrule was in excellent condition with no dents or tarnish. The bowl had a thick cake on the walls of the bowl and the shank had a lot of tar and oil sludge filling the sump, the mortise and the airway in the shank and the stem. The stem was acrylic and was a fishtail style stem. I believe it is a Peterson’s made fishtail stem that came with the pipe but I am not sure. The fir in the shank is perfect which seems to point this direction. There is no P stamp on the saddle portion of the stem but that is not abnormal as many of their stems did not have the stamp. Overall it is a beautiful pipe with a unique finish. I am looking forward to working on it. I took photos of the pipe before I started.

The smell in the box was a heavy English/Latakia smell that filled the room when I opened the box. The finish on the pipe was quite clean with just some dust in the rustication grooves. The polished nickel ferrule was in excellent condition with no dents or tarnish. The bowl had a thick cake on the walls of the bowl and the shank had a lot of tar and oil sludge filling the sump, the mortise and the airway in the shank and the stem. The stem was acrylic and was a fishtail style stem. I believe it is a Peterson’s made fishtail stem that came with the pipe but I am not sure. The fir in the shank is perfect which seems to point this direction. There is no P stamp on the saddle portion of the stem but that is not abnormal as many of their stems did not have the stamp. Overall it is a beautiful pipe with a unique finish. I am looking forward to working on it. I took photos of the pipe before I started.

I took a close-up photo of the bowl and rim top to show its condition. The inside of the bowl was heavily caked with debris in the bottom of the bowl. The rim top looked very good with just some grime in the rustication. There was a polished nickel ferrule on the shank end that was in decent condition with no nicks. The acrylic stem was dirty and had some light tooth marks and chatter on the top and underside ahead of the button.

I took a close-up photo of the bowl and rim top to show its condition. The inside of the bowl was heavily caked with debris in the bottom of the bowl. The rim top looked very good with just some grime in the rustication. There was a polished nickel ferrule on the shank end that was in decent condition with no nicks. The acrylic stem was dirty and had some light tooth marks and chatter on the top and underside ahead of the button. I took photos of the stamping on the smooth panel on the underside of the shank. It is faint but readable as noted above. I also took a photo of the stamping on the left side of the nickel ferrule and it is also very clear. I also removed the stem from the shank and took a photo of the pipe.

I took photos of the stamping on the smooth panel on the underside of the shank. It is faint but readable as noted above. I also took a photo of the stamping on the left side of the nickel ferrule and it is also very clear. I also removed the stem from the shank and took a photo of the pipe.

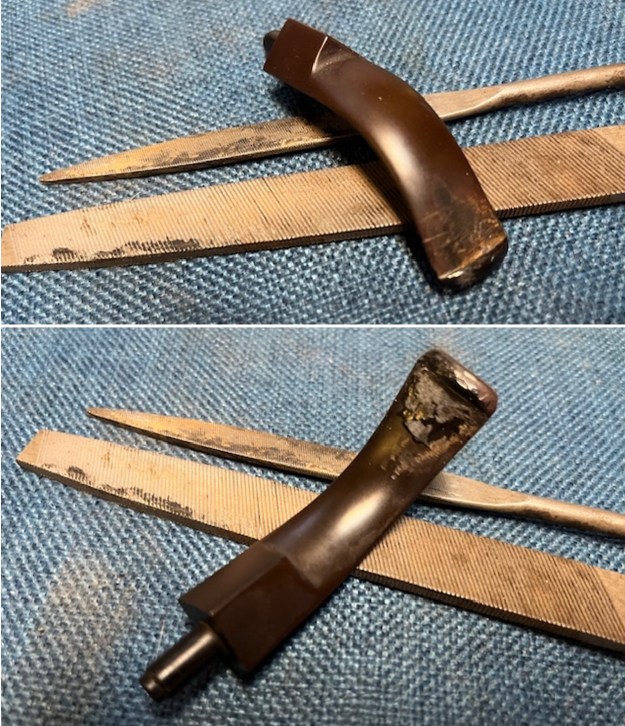

I reamed the bowl with a PipNet reamer to remove the cake. I cleaned up what remained with a Savinelli Fitsall Pipe Knife. I sanded the walls of the bowl to remove any remnants of cake with 220 grit sandpaper wrapped around a piece of dowel. Once finished the inside of the bowl was smooth.

I reamed the bowl with a PipNet reamer to remove the cake. I cleaned up what remained with a Savinelli Fitsall Pipe Knife. I sanded the walls of the bowl to remove any remnants of cake with 220 grit sandpaper wrapped around a piece of dowel. Once finished the inside of the bowl was smooth.

Once the pipe was reamed and clean I took the opportunity to work on the internals – the sump, mortise and airway in the shank and stem. I cleaned out the airway to the bowl, the mortise and the airway in the stem with pipe cleaners, cotton swabs and alcohol.

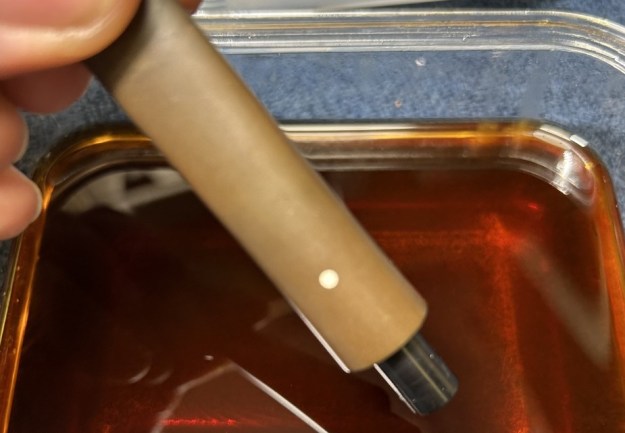

Once the pipe was reamed and clean I took the opportunity to work on the internals – the sump, mortise and airway in the shank and stem. I cleaned out the airway to the bowl, the mortise and the airway in the stem with pipe cleaners, cotton swabs and alcohol.  The stink in the pipe was still strong so I decided to exorcise the stink. I stuffed the bowl with cotton bolls and twisted a cotton boll and stuffed it in the sump and mortise. I used an ear syringe to fill the bowl with 99% isopropyl alcohol and set the bowl aside to let the oils wick out of the briar. I let the pipe sit overnight. In the morning the second and third photos show what I found. The shank plug cotton had wicked out tars, oils and some stain! It smells far better than when I started the process. I will let it dry out and check it again to see if I need to repeat the process.

The stink in the pipe was still strong so I decided to exorcise the stink. I stuffed the bowl with cotton bolls and twisted a cotton boll and stuffed it in the sump and mortise. I used an ear syringe to fill the bowl with 99% isopropyl alcohol and set the bowl aside to let the oils wick out of the briar. I let the pipe sit overnight. In the morning the second and third photos show what I found. The shank plug cotton had wicked out tars, oils and some stain! It smells far better than when I started the process. I will let it dry out and check it again to see if I need to repeat the process.

I cleaned up the rim top a bit with some Before & After Briar Cleaner. I worked it into the rim top surface with a tooth brush and then buffed it off with a cotton pad. It looked much better at this point in the process.

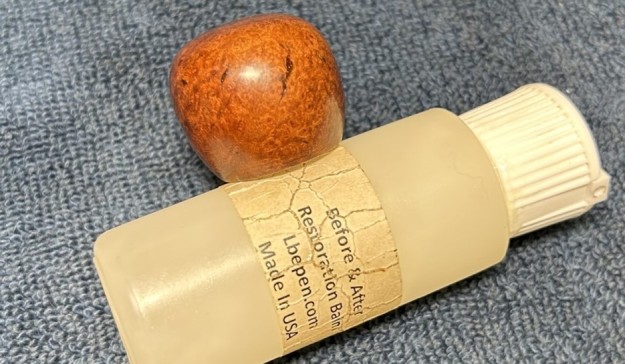

I cleaned up the rim top a bit with some Before & After Briar Cleaner. I worked it into the rim top surface with a tooth brush and then buffed it off with a cotton pad. It looked much better at this point in the process.  I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips and a shoe brush to clean, enliven and protect it. I let the balm sit for ten minutes then buffed with a cotton cloth to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips and a shoe brush to clean, enliven and protect it. I let the balm sit for ten minutes then buffed with a cotton cloth to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on.

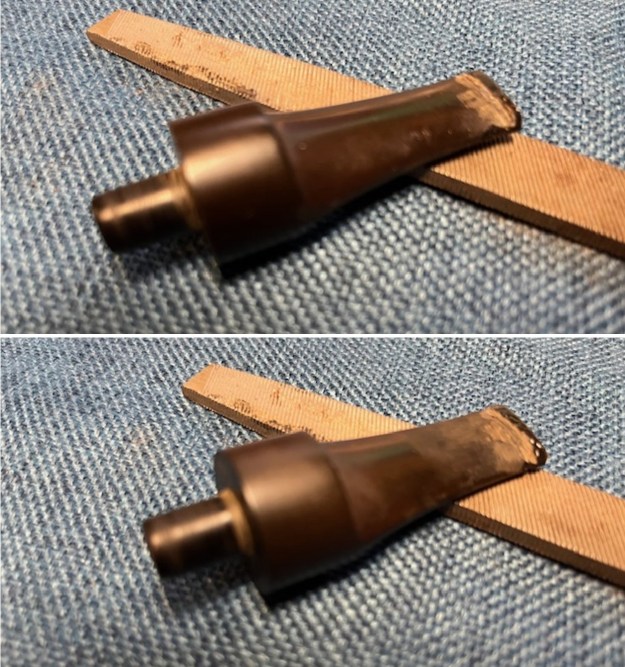

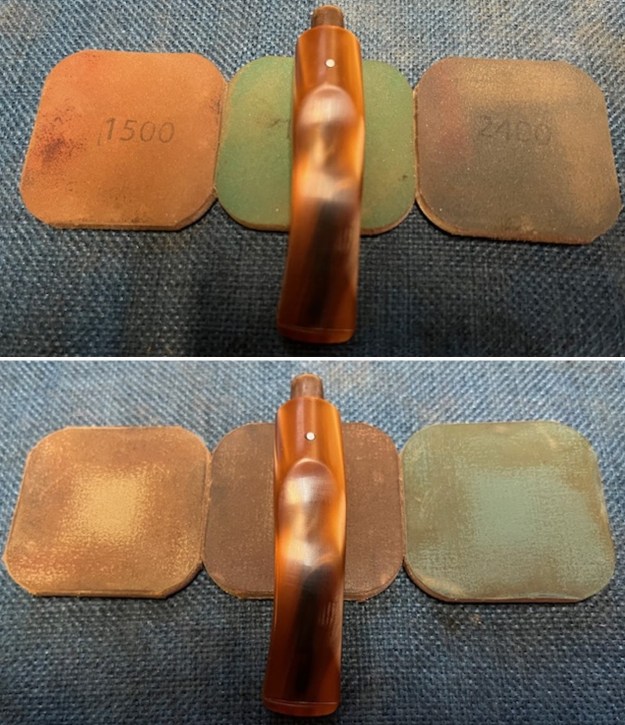

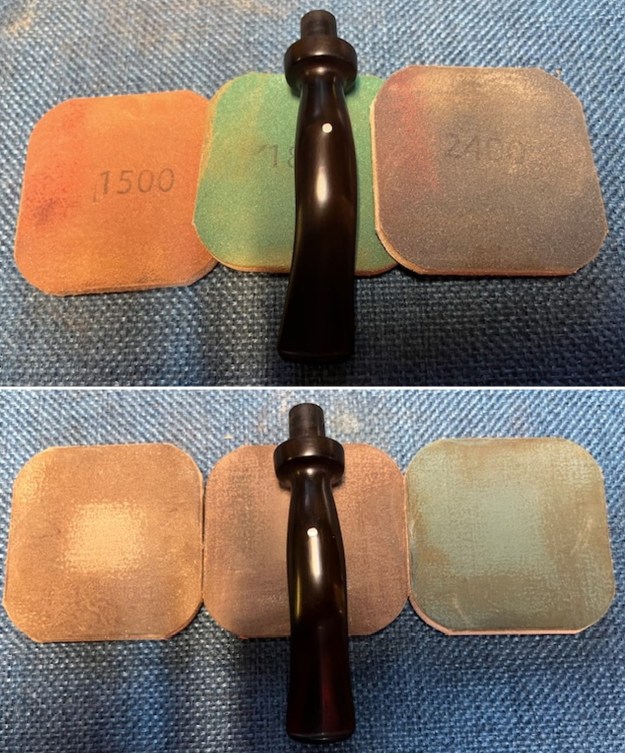

I sanded the stem with 320-3500 grit sanding pads to break up the remaining oxidation. I wiped it down after each sanding pad with a soft cloth. It began to look good.

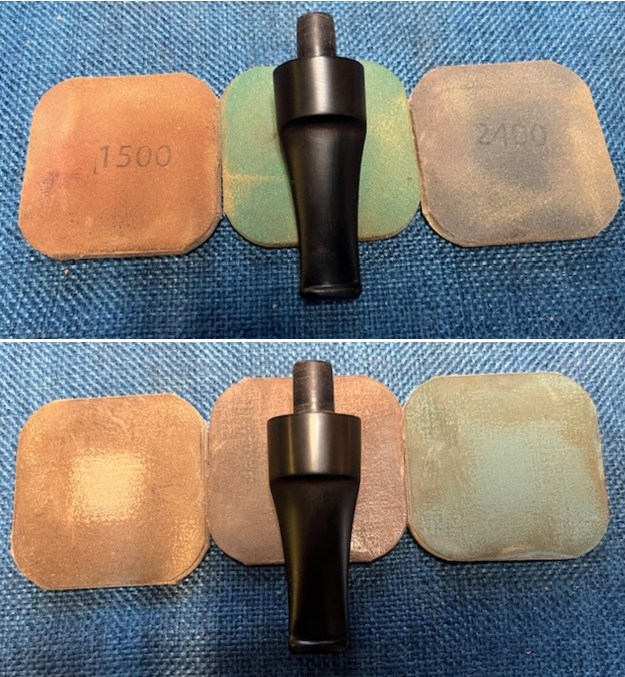

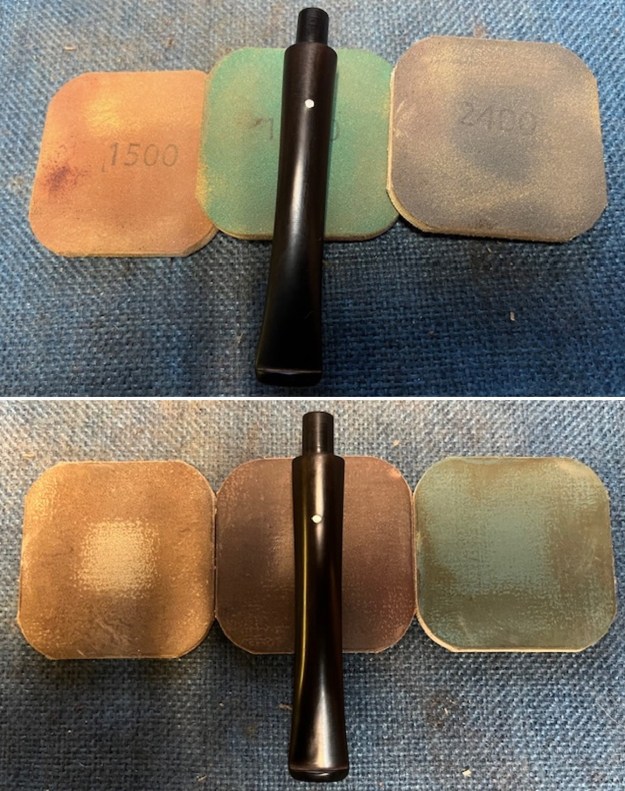

I sanded the stem with 320-3500 grit sanding pads to break up the remaining oxidation. I wiped it down after each sanding pad with a soft cloth. It began to look good.  I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of Obsidian Oil and set it aside to dry.

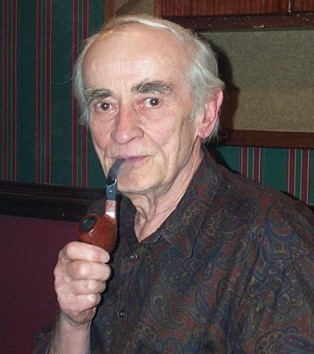

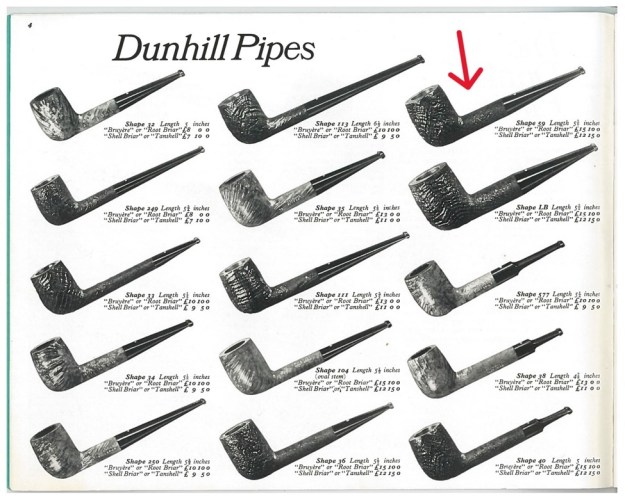

Matthew’s beautifully shaped K&P Peterson’s of Dublin System Standard 312 was a fun one to work on. It has unique Pineapple Rustication beauty that the Peterson’s System Pipes have ceased to use. I put the bowl and stem back together. I polished the bowl and stem with Blue Diamond to blend in the stain and to polish out the scratches in the briar and the vulcanite. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The rusticated finish is well done and the polished smooth finish on the shank end and rim top look really good with the black vulcanite stem. This Peterson’s of Dublin System Standard 312 was a fun pipe to clean up. It is a comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 51 grams/1.80 ounces. Thanks for reading this blog and my reflections on the pipe while I worked on it. This interesting Peterson will be going back to Matthew to fire up and enjoy! Thanks for reading this blog and walking through the restoration with me.

Matthew’s beautifully shaped K&P Peterson’s of Dublin System Standard 312 was a fun one to work on. It has unique Pineapple Rustication beauty that the Peterson’s System Pipes have ceased to use. I put the bowl and stem back together. I polished the bowl and stem with Blue Diamond to blend in the stain and to polish out the scratches in the briar and the vulcanite. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The rusticated finish is well done and the polished smooth finish on the shank end and rim top look really good with the black vulcanite stem. This Peterson’s of Dublin System Standard 312 was a fun pipe to clean up. It is a comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 51 grams/1.80 ounces. Thanks for reading this blog and my reflections on the pipe while I worked on it. This interesting Peterson will be going back to Matthew to fire up and enjoy! Thanks for reading this blog and walking through the restoration with me.