Blog by Steve Laug

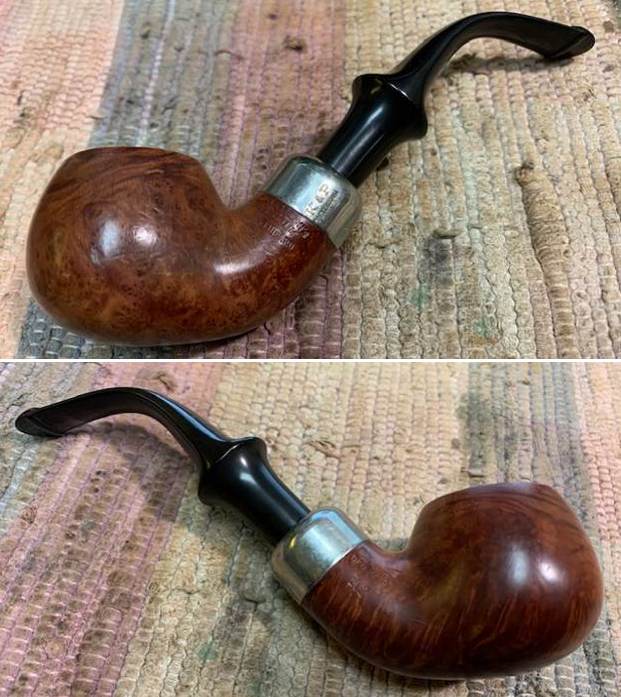

The next pipe is a bit of a mystery to Jeff and me. He keeps a spread sheet and photos of pipes that we pick up and it goes back to 2016 I believe. He has gone through that and cannot find this pipe on the record. However, we both remember finding it. I wonder if it is not on that we found on a trip that Irene and I made to Oregon and met Jeff and Sherry there. We stayed with them and Jeff and I did a bit of pipe hunting. I guess at some level we will never know for sure. I remember that when we saw it we both were struck by the uniqueness of the pipe. It really is a beauty that even the small fills around the bowl do not detract from.

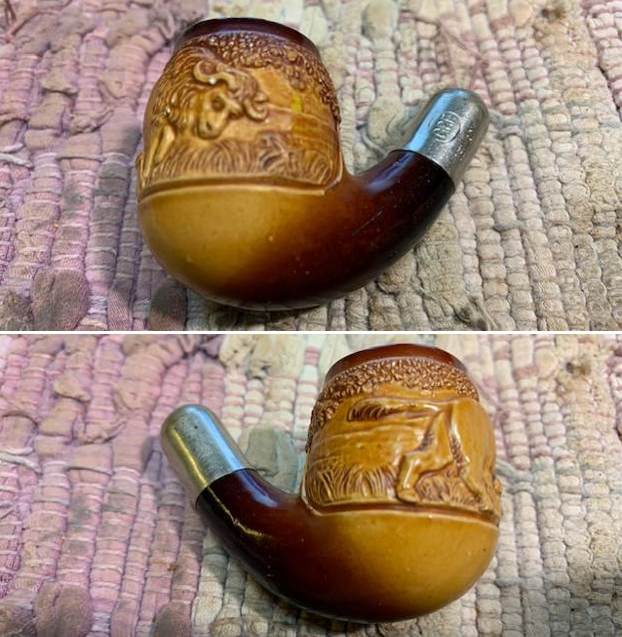

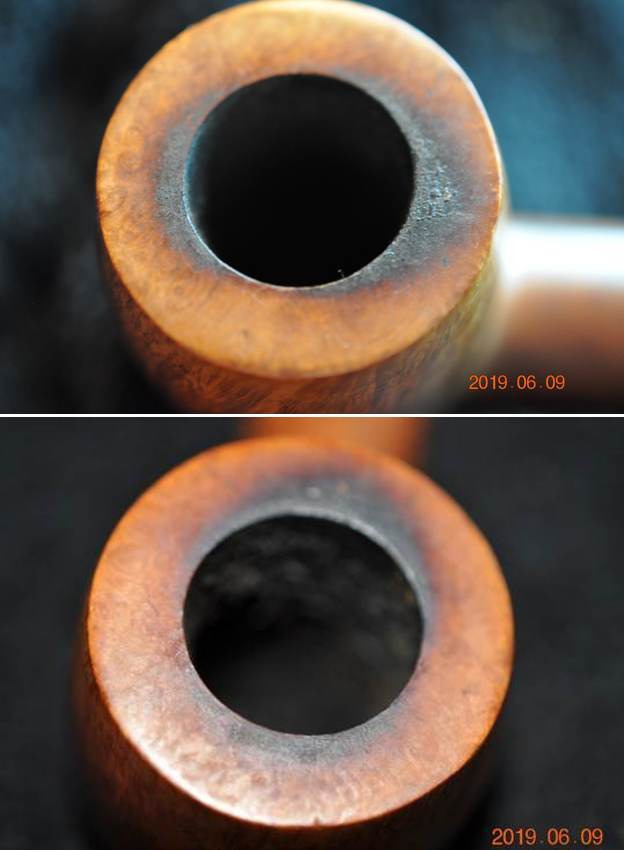

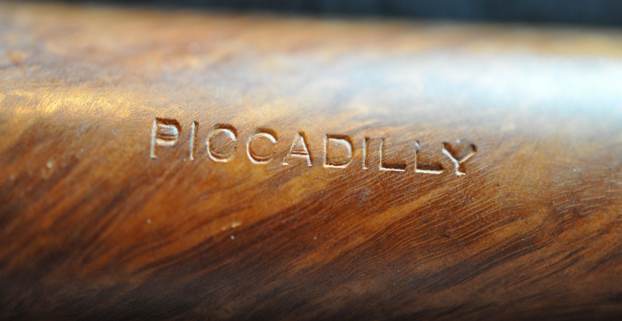

The pipe was quite clean. It has all the marks of Jeff’s clean up work. The bowl is reamed and insides cleaned. The finish is very clean and the rim top and edges look very good. There is no damage on either one. The shank has an interesting joint mid shank. There is a tarnished brass spacer between two sections and each is stained slightly different. The bent saddle stem appears to have been deoxidized as it is also clean and relatively free of oxidation. There are light tooth marks and chatter on both sides at the button. It is stamped with the signature of Nino Rossi on the left side of the shank. Directly under that is the number 1886 which appears to me to be a year. On the left side of the saddle stem it has ROSSI in a oval logo inset. The right side of the shank is stamped Classico. On the underside of the shank it bears the shape number 992 followed by the stamp ITALY stamped vertically at the shank stem joint. It really is an interesting looking pipe. I have included photos of the pipe before I started to work on it.

The rim top and inner and outer edges were in good condition. The stem surface looked very good with some light oxidation remaining and some tooth chatter and marks on both sides ahead of the button.

The rim top and inner and outer edges were in good condition. The stem surface looked very good with some light oxidation remaining and some tooth chatter and marks on both sides ahead of the button.  I took photos of the stamping on the left/right and undersides of the shank. The stamping was clear and readable. The left side of the taper stem had a ROSSI oval logo inset in vulcanite.

I took photos of the stamping on the left/right and undersides of the shank. The stamping was clear and readable. The left side of the taper stem had a ROSSI oval logo inset in vulcanite.

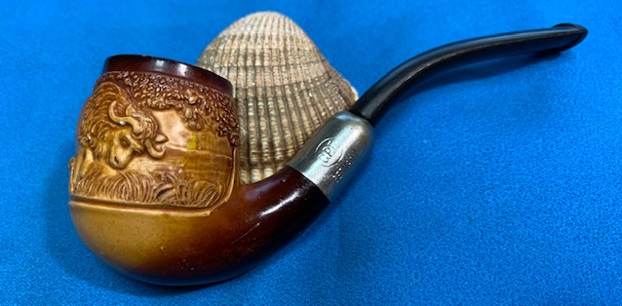

I removed the stem and took a photo of the pipe to give a sense of the beautiful grain on this well shaped Bent Billiard.

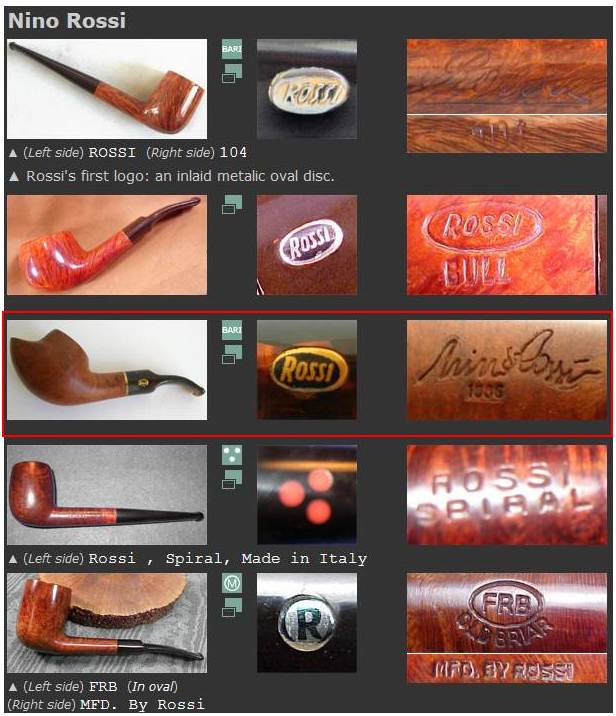

I removed the stem and took a photo of the pipe to give a sense of the beautiful grain on this well shaped Bent Billiard.  I turned first to Pipephil’s site to see what I could learn about the brand as generally the site gives a good summary (http://pipephil.eu/logos/en/logo-n1.html#ninorossi). I quote the information from the side bar below and did a screen capture of the pertinent section on the site. I have also outlined a picture on the screen capture that is stamped like the pipe I am working on.

I turned first to Pipephil’s site to see what I could learn about the brand as generally the site gives a good summary (http://pipephil.eu/logos/en/logo-n1.html#ninorossi). I quote the information from the side bar below and did a screen capture of the pertinent section on the site. I have also outlined a picture on the screen capture that is stamped like the pipe I am working on.

Brand founded in 1886 by Ferdinando Rossi senior. He estabished a factory in Barasso, 5 miles away from Varese. The pipes production by the 850 employees reached 50,000 pipes/day in 1936. Ferdinando Rossi junior headed the company from 1946 until close down in 1985.  I turned to Pipedia to read the more complete history of the brand and learn what I could about a possible date for this pipe (https://pipedia.org/wiki/Rossi). First I wanted to understand the 1886 stamp on the shank under the signature stamp. I found that it was the year that the company acquired land and opened Fabbrica di Pipe di Radica Rossi.

I turned to Pipedia to read the more complete history of the brand and learn what I could about a possible date for this pipe (https://pipedia.org/wiki/Rossi). First I wanted to understand the 1886 stamp on the shank under the signature stamp. I found that it was the year that the company acquired land and opened Fabbrica di Pipe di Radica Rossi.

He acquired a large area of land in Barasso in the province of Varese and founded the Fabbrica di Pipe di Radica Rossi in 1886. For sure there was no lack of skilled workers and Rossi personally recruited 30 craftsmen of different occupations from the environment to get started. After a few years the enterprise had developed well and entered into export trades. In 1892 e.g. the ledgers registered the first pipes shipped to Brazil.

I quote a summary section of the article below.

From, approximately, Twenties, Rossi pipes were marked with “FRB” (Fratelli Rossi Barasso) or “MFRB” (Manifattura Fratelli Rossi Barasso), into an oval and above “OLD BRIAR” (or similar – sometimes, there was also “MFD. BY ROSSI”, as “Manufactured by Rossi”); on the stem, there was generally the “R” letter in circle. However, “FRB OLD BRIAR” was mantained for the “traditional pipes” (for cheap models – see below), surely, to Sixties.

From, approximately, the fiftieth anniverary (1936), pipes were marked with “Rossi” (in cursive font), with model name just under it; on the stem, there was “ROSSI” (for expensive models like “extra”, which had the best quality; “racine”, which was rusticated by hand; “extra grain”, which was accurately sandblasted; “super”, which had the best briar selection, and a limited production; “fiamma”, which was the best selection of Sardinia and Greece briar, and a very limited production) or “R” in circle (for unexpensive models like “standard”, “grana” and “FRB”).

From, approximately, Seventies, until 1985, Rossi pipes were marked with “ROSSI”, into an oval (sometimes there was also “ITALY” on the shank); on the stem, there was “ROSSI”. In these years, appeared the signature “Nino Rossi” (in cursive font): he was the last heir of the factory.

When Savinelli took back the production, it is said that first pipes had a twinbore mouthpiece, with “ROSSI” on the stem, and they were marked with “ROSSI” on the shank. Today most of them had 6 mm or 9 mm adapter (also, for the most part, the stem was made by methacrylate, always with “Rossi” on the side).

The section I have highlighted in Blue above gave me what I was looking for regarding this pipe. It is one that was clearly made between the 70s and 1985 when the company closed. It is stamped as described in the highlighted paragraph. Now it was time to work on the pipe.

As I examined the spacer between the two parts of the shank it became clear that it was oxidized brass. I started there with my work on this pipe. I lightly sanded it with a 1500 grit micromesh sanding pad to break up the oxidation and then polished it with a jewelers cloth that removes oxidation and preserves against further oxidation. It is a pretty neat looking addition with the polished brass. I took some photos of the pipe to show the spacer.

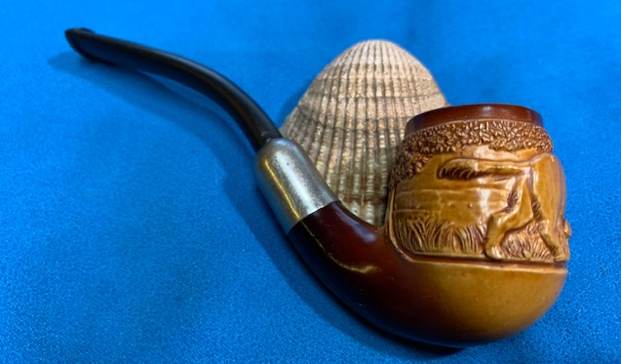

I polished the bowl and the rim top, sides and shank with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping it down after each pad with a damp cloth. I carefully avoided the stamping on the sides of the shank so as not to damage it. The fills on the side of the bowl and shank are visible but oddly do not bother me too much. It is still a nice looking pipe.

I polished the bowl and the rim top, sides and shank with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping it down after each pad with a damp cloth. I carefully avoided the stamping on the sides of the shank so as not to damage it. The fills on the side of the bowl and shank are visible but oddly do not bother me too much. It is still a nice looking pipe.

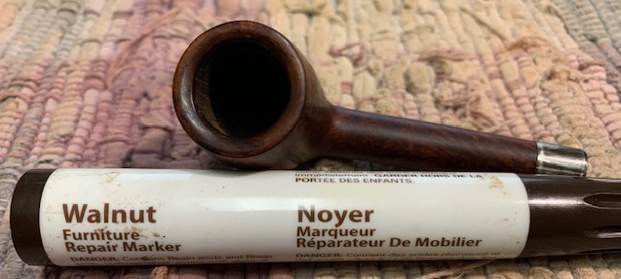

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides, rim top and shank end with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The grain really stood out clearly. While the fills are still evident they seem to blend in better at this point in the process.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides, rim top and shank end with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The grain really stood out clearly. While the fills are still evident they seem to blend in better at this point in the process.

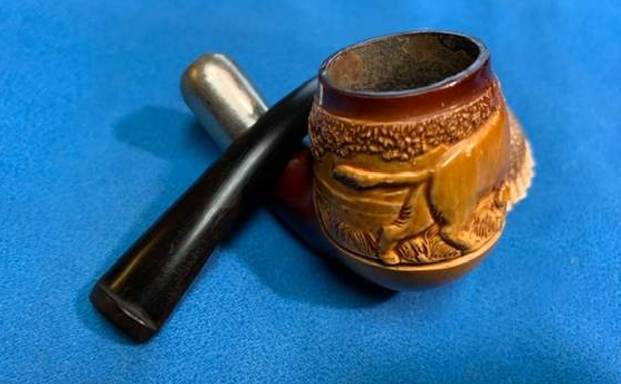

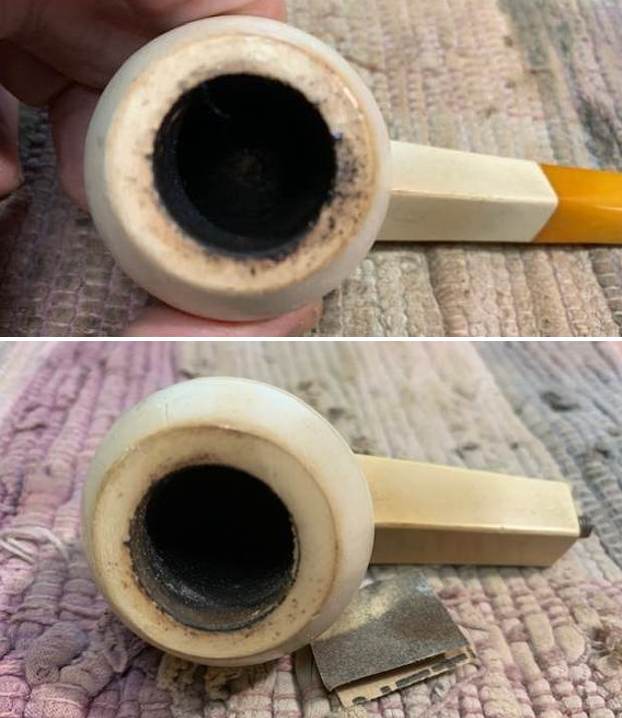

I set the bowl aside and turned my attention to the stem. I heated the stem with a lighter flame to lift out the tooth marks (forgot to take photos). They were too sharp and essentially were cuts so they did not lift at all. I filled them in with clear CA glue and set them aside to cure. Once they cured I flattened the repairs out with a small flat file.

I set the bowl aside and turned my attention to the stem. I heated the stem with a lighter flame to lift out the tooth marks (forgot to take photos). They were too sharp and essentially were cuts so they did not lift at all. I filled them in with clear CA glue and set them aside to cure. Once they cured I flattened the repairs out with a small flat file.

Once the repairs had cured I sanded them smooth with 220 grit sandpaper to blend them into the surrounding vulcanite. I started the polishing with 400 grit wet dry sandpaper.

Once the repairs had cured I sanded them smooth with 220 grit sandpaper to blend them into the surrounding vulcanite. I started the polishing with 400 grit wet dry sandpaper.  I worked over the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped the stem down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I worked over the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped the stem down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This well made Nino Rossi 1886 Classico 992 Bent Billiard with a briar shank extension and a vulcanite saddle stem is a great looking pipe now that it has been restored. The rich reddish, brown finish that was used came alive with the polishing and waxing. The brass spacer was a great touch in the middle of the shank. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Nino Rossi Classico is a beauty with combination of great grain and rich stain. Even the fills do not detract from its appearance. It fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: 5/8 of an inch. The weight of the pipe is 58 grams/ 2.01 ounces. If you are interested in adding this pipe to your collection I will be adding it to the rebornpipes store shortly. It will be in the Italian Pipe Makers section. Send me a message or an email if you are interested in purchasing it. Thanks for reading this blog and my reflections on the pipe while I worked on it. As always there are more to come.

This well made Nino Rossi 1886 Classico 992 Bent Billiard with a briar shank extension and a vulcanite saddle stem is a great looking pipe now that it has been restored. The rich reddish, brown finish that was used came alive with the polishing and waxing. The brass spacer was a great touch in the middle of the shank. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Nino Rossi Classico is a beauty with combination of great grain and rich stain. Even the fills do not detract from its appearance. It fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: 5/8 of an inch. The weight of the pipe is 58 grams/ 2.01 ounces. If you are interested in adding this pipe to your collection I will be adding it to the rebornpipes store shortly. It will be in the Italian Pipe Makers section. Send me a message or an email if you are interested in purchasing it. Thanks for reading this blog and my reflections on the pipe while I worked on it. As always there are more to come.