Blog by Steve Laug

The next pipe I chose to work on is a meerschaum Bulldog that Jeff picked up from an antique back in October, 2017 from Bozeman, Montana, USA. It was a classic straight Bulldog with a golden Bakelite taper stem. The finish on the bowl and rim cap were scratched and worn looking but still had a lot of charm. The twin rings separating the bowl from the rim cap are in good condition. There is some damage/chips in the rings and nicks in the bowl. There was a thick cake in the bowl and heavy lava overflow on top the rim. The meerschaum was very dirty and under the grim it seemed to be developing a patina on the shank and lightly on the bowl and rim top. The golden Bakelite stem was threaded to be turned onto the metal tenon that was firmly anchored in the shank of the pipe. The stem had deep tooth marks on the top and underside ahead of the button. I loved the shape but it was in rough condition and needed a lot of work. Jeff took photos of the pipe before he started his work on it.

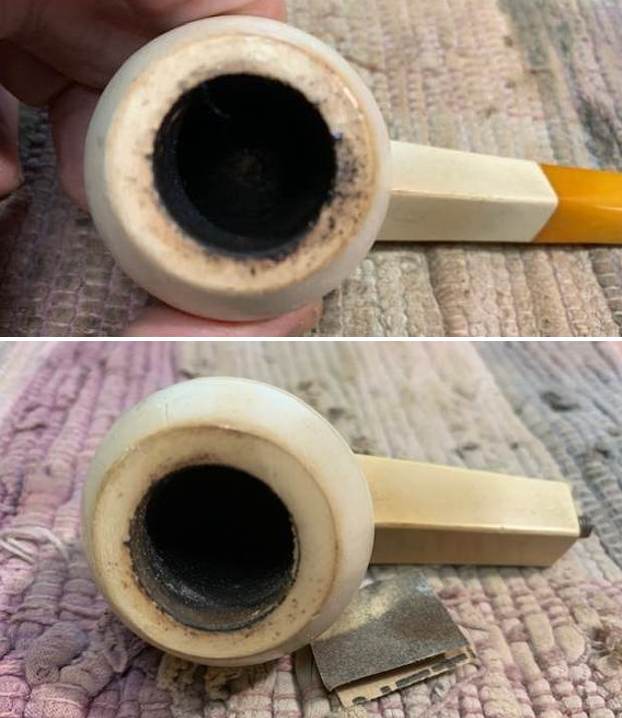

He took photos of the rim top and the stem to show the condition. You can see the issues on the rim top and stem as I noted above. There are also some scratches on the rim top itself that I am hoping will polish out and look much better. You can see the tooth damage on the stem surfaces on both sides ahead of the button.

He took photos of the rim top and the stem to show the condition. You can see the issues on the rim top and stem as I noted above. There are also some scratches on the rim top itself that I am hoping will polish out and look much better. You can see the tooth damage on the stem surfaces on both sides ahead of the button.

Jeff took photos of the side and heel of the bowl. You can see the classic lines and nicely carved bowl of the pipe. It is a great looking Bulldog carved from block meerschaum and is well made. There are a lot of scratches and nicks in the meerschaum around the sides, top and shank of the pipe.

Jeff took photos of the side and heel of the bowl. You can see the classic lines and nicely carved bowl of the pipe. It is a great looking Bulldog carved from block meerschaum and is well made. There are a lot of scratches and nicks in the meerschaum around the sides, top and shank of the pipe.

There was no stamping on the shank or pipe that identified the maker. It was clearly a no name pipe but it was quite nice. Jeff had cleaned up the pipe with his usual thoroughness. He carefully reamed the pipe with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He cleaned the stem Soft Scrub cleanser and rinsed it off with warm water. I took photos of the pipe 3 years later when I finally got around to working on it.

There was no stamping on the shank or pipe that identified the maker. It was clearly a no name pipe but it was quite nice. Jeff had cleaned up the pipe with his usual thoroughness. He carefully reamed the pipe with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He cleaned the stem Soft Scrub cleanser and rinsed it off with warm water. I took photos of the pipe 3 years later when I finally got around to working on it.

The rim top and inner edge of the rim were in rough condition. The rim top was chipped and nicked. There was darkening on the top and both the inner and outer edges of the bowl along with some dark chips in the surface of the meerschaum.The stem surface looked very good with some tooth marks and chatter on both sides near the button.

The rim top and inner edge of the rim were in rough condition. The rim top was chipped and nicked. There was darkening on the top and both the inner and outer edges of the bowl along with some dark chips in the surface of the meerschaum.The stem surface looked very good with some tooth marks and chatter on both sides near the button.  I removed the stem and took several photos of the pipe to give a sense of the whole. The tenon is anchored in the shank and is threaded metal. The golden Bakelite diamond shaped taper stem is also threaded and screws onto the tenon.

I removed the stem and took several photos of the pipe to give a sense of the whole. The tenon is anchored in the shank and is threaded metal. The golden Bakelite diamond shaped taper stem is also threaded and screws onto the tenon. I worked on the rim top and inner edge of the bowl with a folded piece of 220 grit sandpaper to remove the damage and as many of the pits and nicks as possible. It looked much better at this point in the process.

I worked on the rim top and inner edge of the bowl with a folded piece of 220 grit sandpaper to remove the damage and as many of the pits and nicks as possible. It looked much better at this point in the process. I polished the smooth meerschaum with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I worked on the darkening of the rim top at the same time. I wiped the bowl down after each pad with a damp cloth. The longer I polished it the more the patina came to the surface. The pipe became more beautiful with each grit of polishing pad. While I was not able to remove all of the scratching around the rim top and bowl I was able to minimize them a bit. The remainder are a part of the story of the pipe’s journey and will remain.

I polished the smooth meerschaum with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I worked on the darkening of the rim top at the same time. I wiped the bowl down after each pad with a damp cloth. The longer I polished it the more the patina came to the surface. The pipe became more beautiful with each grit of polishing pad. While I was not able to remove all of the scratching around the rim top and bowl I was able to minimize them a bit. The remainder are a part of the story of the pipe’s journey and will remain.

I set the bowl aside and turned my attention to the stem. I filled in the deep tooth marks on the stem surface on both sides with clear CA glue. Once the repairs cured I sanded them smooth with 220 grit sandpaper. I started polishing the stem with 400 grit wet dry sandpaper.

I set the bowl aside and turned my attention to the stem. I filled in the deep tooth marks on the stem surface on both sides with clear CA glue. Once the repairs cured I sanded them smooth with 220 grit sandpaper. I started polishing the stem with 400 grit wet dry sandpaper.

I polished the stem with micromesh sanding pads. I dry sanded it with 1500-12000 pads and wiped the bowl down after each pad with a cloth and Obsidian Oil. I finished polished it with Before & After Fine and Extra Fine stem polish. I wiped it down with the cloth and Obsidian Oil one final time and set aside to dry.

I polished the stem with micromesh sanding pads. I dry sanded it with 1500-12000 pads and wiped the bowl down after each pad with a cloth and Obsidian Oil. I finished polished it with Before & After Fine and Extra Fine stem polish. I wiped it down with the cloth and Obsidian Oil one final time and set aside to dry.

This Classic No Name Meerschaum Straight Bulldog with a golden Bakelite stem really is a beautiful pipe. The polished meerschaum has a stunning shape. I put the stem back on the bowl and carefully buffed the pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Meerschaum Bulldog is another pipe that fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 59 grams/ 2.08 oz. This Meerschaum Bulldog is a real beauty and the rich amber coloured Bakelite stem just highlights the beauty. Jeff made another great find when he picked this up in Bozeman. I will be putting on the rebornpipes store in the Ceramic and Meerschaum Pipe Section. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This Classic No Name Meerschaum Straight Bulldog with a golden Bakelite stem really is a beautiful pipe. The polished meerschaum has a stunning shape. I put the stem back on the bowl and carefully buffed the pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Meerschaum Bulldog is another pipe that fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 59 grams/ 2.08 oz. This Meerschaum Bulldog is a real beauty and the rich amber coloured Bakelite stem just highlights the beauty. Jeff made another great find when he picked this up in Bozeman. I will be putting on the rebornpipes store in the Ceramic and Meerschaum Pipe Section. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!