Blog by Steve Laug

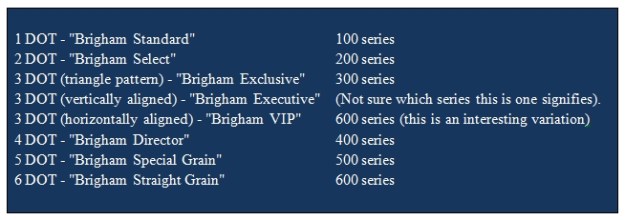

This old Brigham was the next pipe I brought to my work table. I got a message from Greg on Facebook saying he had been reading one of my posts about a box of estate pipes I had received and he was interested in adding this one to his rack. The pipe was a Brigham One Dot Dublin with a slight bend in the stem. It was an older one made before the manufacture of the pipes was moved to Italy. It has the standard aluminum tenon and filter mechanism of the Canadian made pipes. The finish is rusticated with the classic Brigham rustication on the bowl, rim top and shank. It has one smooth patch on the underside of the shank that is stamped Brigham in script over Canada. There is no shape number or other stamping on the shank.

The pipe came to me in a box of pipes that I inherited from a friend in Ontario. He was an old Anglican priest and we had shared a lot about pipes and mutual calling over the 15 years that I knew him. I repaired, restored and sold many pipes for him and have a few of his previous pipes in my current collection. He was a great guy and he is alive in my memory each time I smoke one of his pipes. When the box came I found that there were 70+ pipes in the box and his daughter included a note that said her dad wanted me to restore them pass some of them on to others. This is the first from that lot that I have restored. The finish was very worn and the outer edges of the rim showed wear and damage. The inner edge worn as well but the bowl was still in round. The rim had a thick buildup of tars and oils that filled in the grooves and ridges of the rim top. The rim had some darkening of the finish as well. The stem was oxidized and had a sticky residue left behind by a price sticker. There were no tooth marks on the stem surface on either side next to the button.

The finish was very worn and the outer edges of the rim showed wear and damage. The inner edge worn as well but the bowl was still in round. The rim had a thick buildup of tars and oils that filled in the grooves and ridges of the rim top. The rim had some darkening of the finish as well. The stem was oxidized and had a sticky residue left behind by a price sticker. There were no tooth marks on the stem surface on either side next to the button. The stamping on the underside of the shank was clear but slightly worn. It reads Brigham in script at an angle from left to right and block letters, CANADA underneath. Charles Lemon of Dadspipes has written a helpful blog about dating Brigham Pipes by the style of the stamping on the shank. I turned to that blog to look up information on this particular pipe and see if I could identify the time period. Here is the link; https://dadspipes.com/2016/10/03/brigham-pipes-a-closer-look-at-dots-dates-and-markings//. According to that info this pipe comes from the late Canadian Era 1980-2000. The second close up photo below shows the rim and the cake in the bowl. The end of the Brigham system can be seen poking out of the airway in the photo as well.

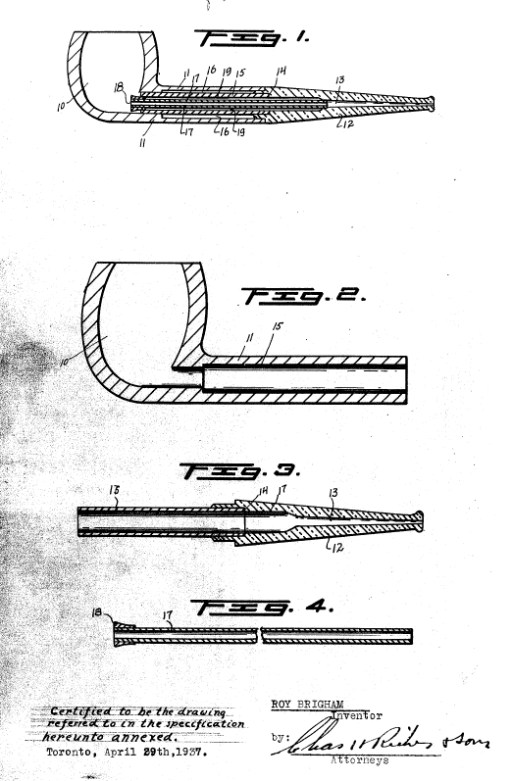

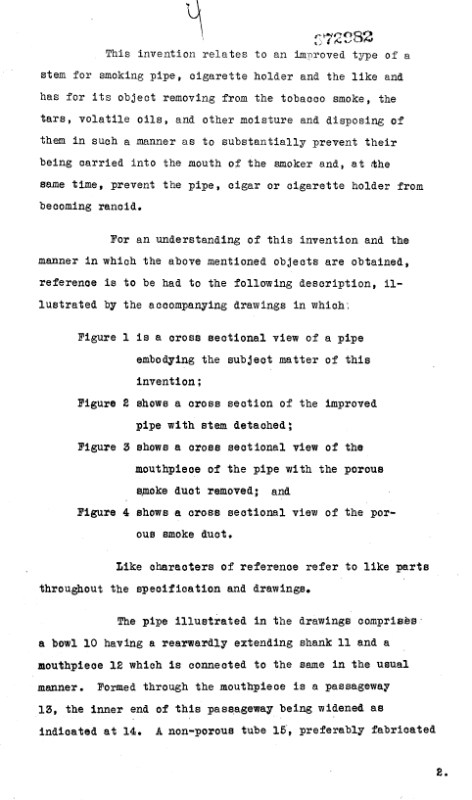

The stamping on the underside of the shank was clear but slightly worn. It reads Brigham in script at an angle from left to right and block letters, CANADA underneath. Charles Lemon of Dadspipes has written a helpful blog about dating Brigham Pipes by the style of the stamping on the shank. I turned to that blog to look up information on this particular pipe and see if I could identify the time period. Here is the link; https://dadspipes.com/2016/10/03/brigham-pipes-a-closer-look-at-dots-dates-and-markings//. According to that info this pipe comes from the late Canadian Era 1980-2000. The second close up photo below shows the rim and the cake in the bowl. The end of the Brigham system can be seen poking out of the airway in the photo as well. The next photo shows the tenon and system tube. It was incredibly dirty with a lot of tar and oil on the inside. The pipe had been smoked a long time without the filter in place and there was a lot of buildup in the tube and stem. The shank was also very dirty.

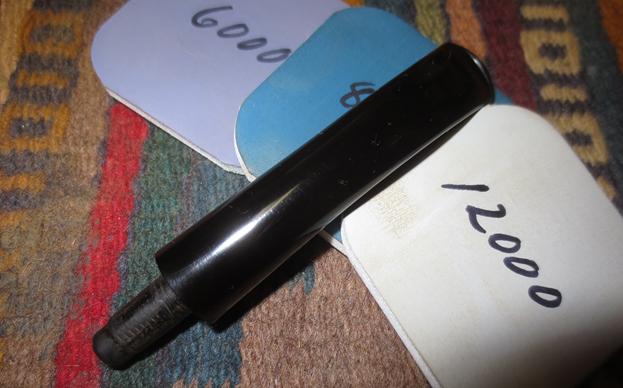

The next photo shows the tenon and system tube. It was incredibly dirty with a lot of tar and oil on the inside. The pipe had been smoked a long time without the filter in place and there was a lot of buildup in the tube and stem. The shank was also very dirty. The next two photos show the condition of the stem. The oxidation pattern and the sticky label gum on the surface are very visible on the stem. The stem is also clear of tooth marks or chatter on the surface near the button.

The next two photos show the condition of the stem. The oxidation pattern and the sticky label gum on the surface are very visible on the stem. The stem is also clear of tooth marks or chatter on the surface near the button. I reamed back the cake with a PipNet reamer and a Savinelli Fitsall pipe knife. I used a brass bristle brush to knock off the tarry buildup on the rim top and clean out the crevices and grooves in the rustication.

I reamed back the cake with a PipNet reamer and a Savinelli Fitsall pipe knife. I used a brass bristle brush to knock off the tarry buildup on the rim top and clean out the crevices and grooves in the rustication. I decided to clean out the interior of the mortise, shank and airway in the shank and stem before going any further with the exterior. I used alcohol, pipe cleaners and cotton swabs to scrub out those areas and scrubbed until the pipe was clean. I wiped down the surface of the stem to remove the sticky gum left behind by a label on the top side of the stem.

I decided to clean out the interior of the mortise, shank and airway in the shank and stem before going any further with the exterior. I used alcohol, pipe cleaners and cotton swabs to scrub out those areas and scrubbed until the pipe was clean. I wiped down the surface of the stem to remove the sticky gum left behind by a label on the top side of the stem. I scrubbed the surface of the briar with Murphy’s Oil Soap, toothbrush and a brass bristle brush to clean out the grooves and cleaning off the dirt, oil and debris on the briar. The bowl and the rim looked significantly better once I had rinsed it off with running water. It was dry and the stain was lightened but it was clean.

I scrubbed the surface of the briar with Murphy’s Oil Soap, toothbrush and a brass bristle brush to clean out the grooves and cleaning off the dirt, oil and debris on the briar. The bowl and the rim looked significantly better once I had rinsed it off with running water. It was dry and the stain was lightened but it was clean.

I decided to work on the stem first so while I did I stuffed the bowl with cotton balls and used an ear syringe to fill the bowl with alcohol. I folded a pipe cleaner and plugged the airway so that the alcohol could draw out the oils in the briar. The second photo shows the cotton after it had been sitting for four hours. When I took the cotton balls out at the 6 hour mark they were exactly as they looked at the 4 hour mark. I was a bit surprised that they were not darker. But then again my old friend smoked primarily Virginias – in fact I don’t think he ever smoked aromatics in the time I knew him.

I decided to work on the stem first so while I did I stuffed the bowl with cotton balls and used an ear syringe to fill the bowl with alcohol. I folded a pipe cleaner and plugged the airway so that the alcohol could draw out the oils in the briar. The second photo shows the cotton after it had been sitting for four hours. When I took the cotton balls out at the 6 hour mark they were exactly as they looked at the 4 hour mark. I was a bit surprised that they were not darker. But then again my old friend smoked primarily Virginias – in fact I don’t think he ever smoked aromatics in the time I knew him. I took out a new maple wood Brigham filter for the system and took a photo of the pipe at this point in the process. I still need to stain the bowl but it was looking better and it smelled and looked clean.

I took out a new maple wood Brigham filter for the system and took a photo of the pipe at this point in the process. I still need to stain the bowl but it was looking better and it smelled and looked clean. I stained the bowl with a dark brown aniline stain and flamed it to set it in the grain. The characteristic blue flame that burns the alcohol out of the stain setting it deep in the grain is a beautiful site to my eyes. I repeated the process several times until the coverage was correct.

I stained the bowl with a dark brown aniline stain and flamed it to set it in the grain. The characteristic blue flame that burns the alcohol out of the stain setting it deep in the grain is a beautiful site to my eyes. I repeated the process several times until the coverage was correct. I wiped the bowl down with alcohol on cotton pads to make a bit more transparent. I wanted the contrast that had originally been on these old Brighams to show through. There was enough dark stain in the deep grooves of the finish to contrast nicely with the new stain coats I gave the pipe.

I wiped the bowl down with alcohol on cotton pads to make a bit more transparent. I wanted the contrast that had originally been on these old Brighams to show through. There was enough dark stain in the deep grooves of the finish to contrast nicely with the new stain coats I gave the pipe.

I rubbed the stem down with Brebbia Pipe and Mouthpiece Polish and some Before & After Pipe Stem Polish to remove the oxidation in the vulcanite. It lifted a lot of the oxidation and what was left behind was minor.

I rubbed the stem down with Brebbia Pipe and Mouthpiece Polish and some Before & After Pipe Stem Polish to remove the oxidation in the vulcanite. It lifted a lot of the oxidation and what was left behind was minor. I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil after each pad and gave it a final coat of oil after the 12000 grit pad. I set the stem aside to dry.

I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil after each pad and gave it a final coat of oil after the 12000 grit pad. I set the stem aside to dry.

When I finished there still appeared to be a little oxidation at the tenon end of the stem. I was not sure if it was the light from the flash or reality so I took it to the buffer and buffed that area with red Tripoli and repeated the last three micromesh pad grits. I buffed the pipe and stem with Blue Diamond to further polish it. I buffed the stem with carnauba wax and gave the bowl multiple coats of Conservator’s Wax. I buffed the pipe with a clean buffing pad to raise the shine and with a microfibre cloth to deepen it. The finished pipe is shown in the photos below. It is a beautiful pipe and even better in person. Thanks for looking.

When I finished there still appeared to be a little oxidation at the tenon end of the stem. I was not sure if it was the light from the flash or reality so I took it to the buffer and buffed that area with red Tripoli and repeated the last three micromesh pad grits. I buffed the pipe and stem with Blue Diamond to further polish it. I buffed the stem with carnauba wax and gave the bowl multiple coats of Conservator’s Wax. I buffed the pipe with a clean buffing pad to raise the shine and with a microfibre cloth to deepen it. The finished pipe is shown in the photos below. It is a beautiful pipe and even better in person. Thanks for looking.