Blog by Dal Stanton

A few years ago I landed a large lot of pipes on the eBay auction block from a seller in Georgetown, Texas. The seller was actually a charitable organization called the Georgetown Caring Place operating some thrift stores mainly manned by volunteers – elderly. I liked it from the start! The description on the ‘Lot of 66’ said it all:

Huge Lot Of 66 Smoking Pipes, Pre-Owned, Loved, Pre-Smoked, Many different makers styles and Brands, We will not be able to list specifics on these pipes, We are not pipe people, You are buying one person’s collection

Undoubtedly, an estate collection of a pipe man’s collection that the family donated to benefit the Caring Place. My bid won the Lot of 66 and helped a good cause. It also placed the former steward’s pipes in my charge, and it has been a joy for me to discover many treasures in the Lot of 66 and to enable these pipes to continue to serve many new stewards for years to come. Here’s the Lot of 66 that I saw on eBay. Pipe man Todd, who has commissioned and received several pipes from The Pipe Steward before, all benefiting the Daughters of Bulgaria, saw one of the Lot of 66 waiting, an unassuming ‘Heritage Blasted Apple’ listed in my online inventory called For “Pipe Dreamers” Only! and he commissioned it along with 2 others (See: Borge Mortensen of Denmark and Ehrlich Special Chimney of Boston). Todd has a knack for seeing good pipes with ‘Pipe Dreamer’ eyes! Here are the pictures he saw that got his attention despite the cardboard presentation background!

Pipe man Todd, who has commissioned and received several pipes from The Pipe Steward before, all benefiting the Daughters of Bulgaria, saw one of the Lot of 66 waiting, an unassuming ‘Heritage Blasted Apple’ listed in my online inventory called For “Pipe Dreamers” Only! and he commissioned it along with 2 others (See: Borge Mortensen of Denmark and Ehrlich Special Chimney of Boston). Todd has a knack for seeing good pipes with ‘Pipe Dreamer’ eyes! Here are the pictures he saw that got his attention despite the cardboard presentation background!

The nomenclature, what there is, is/would be located on the bottom panel. My initial pictures held little promise of identifying any markings. In this picture, ‘86’ is discernible – a shape number.

The nomenclature, what there is, is/would be located on the bottom panel. My initial pictures held little promise of identifying any markings. In this picture, ‘86’ is discernible – a shape number.  The next picture, which is a picture I recently took to get a better look, ‘ANTIQUE’ is discernible on the lower part of the panel. When I first looked at these pictures, I wanted to see lettering all over the panel, but most would be phantom suggestions. Yet, above ‘ANTIQUE’ I want to see more lettering on a diagonal, but nothing is discernible without question.

The next picture, which is a picture I recently took to get a better look, ‘ANTIQUE’ is discernible on the lower part of the panel. When I first looked at these pictures, I wanted to see lettering all over the panel, but most would be phantom suggestions. Yet, above ‘ANTIQUE’ I want to see more lettering on a diagonal, but nothing is discernible without question. The stem provides the first strong clue of identifying this mystery ‘Antique’ Blasted Apple. A quick trip to Pipephil.eu identifies the double diamond inlay as a ‘Heritage’.

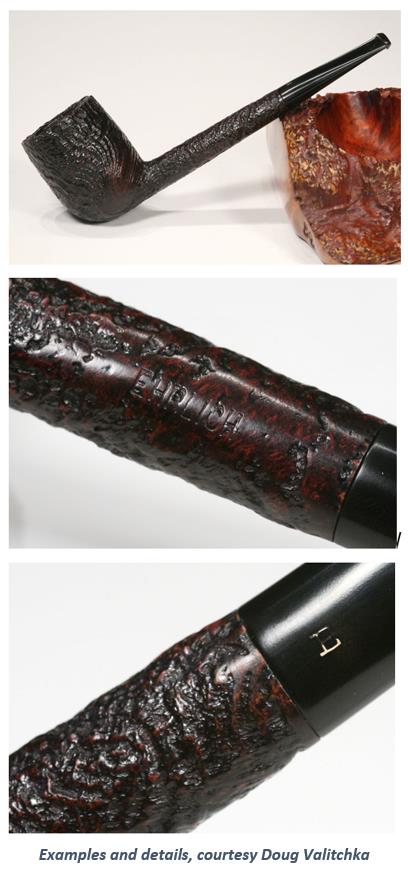

The stem provides the first strong clue of identifying this mystery ‘Antique’ Blasted Apple. A quick trip to Pipephil.eu identifies the double diamond inlay as a ‘Heritage’.  The panel information identified a ‘Heritage Pipe Inc.’ which had closed in 1971 as a submark of the S.M. Frank pipe conglomeration. The double diamond stem inlay was a match.

The panel information identified a ‘Heritage Pipe Inc.’ which had closed in 1971 as a submark of the S.M. Frank pipe conglomeration. The double diamond stem inlay was a match. The next stop at Pipedia brought more clarity to the Heritage name and origins. In the ‘Collector’s Guide to Kaywoodie Pipes’ (LINK) there was a section devoted to “Other” Kaywoodie Pipes which provides great information. I include the introductory paragraph and then the information related directly to the ‘Heritage’ brand.

The next stop at Pipedia brought more clarity to the Heritage name and origins. In the ‘Collector’s Guide to Kaywoodie Pipes’ (LINK) there was a section devoted to “Other” Kaywoodie Pipes which provides great information. I include the introductory paragraph and then the information related directly to the ‘Heritage’ brand.

NOTES ON “OTHER” KAYWOODIE PIPES

Kaywoodie Stembiter and Chinrester, courtesy ChrisKeene.com

The previous sections of this Chapter summarize information taken from eight Kaywoodie Catalogs from the period 1936 to 1969. Because of the gaps in the catalogs, it is highly likely that many “holes” exist in the material presented in this monograph. This section presents a brief overview of some Kaywoodie Pipes that did not appear in any of the catalogs consulted in this research. The information on these pipes was provided by W.R. “Bill” Lowndes (a well-known Kaywoodie Collector from California).

Heritage. Lowndes suggests that the Heritage pipes were introduced in the 1960’s to compete with Dunhill. No fitments. Smooth finish called “Heirloom”, sandblast called “Antique”. Lowndes notes that there was a carved Heritage similar to Barling Quaints. Pipes were not marked “Kaywoodie”, and logo on bit is a double diamond. Lowndes notes that the Heritage pipes in his collection are small to medium-size pipes and have Kaywoodie shape numbers. Lowndes suggests there may have been a special Heritage catalog.

I love it when research begins to back up the forensics of the pipe on your worktable! “Antique”, which I could barely make out on the lower panel is the sandblasted line of Heritage pipes, a line introduced by Frank to compete with Dunhill. Not a bad aspiration!

The article provided by Pipedia on the S. M. Frank & Co. adds more information:

The history of S. M. Frank & Co. spans nearly a century and half of pipe making, supporting its claim as the “oldest pipe house in America.” S. M. Frank, as it exists today, is a combination of some of the biggest names in pipe making from the early part of the 20th. century. The pipe names Kaywoodie, Yello-Bole, Reiss-Premier, William Demuth Company, Medico, Heritage (Heritage Pipes Inc.), and Frank are familiar to generations of pipe smokers.

In May of 1960, S. M. Frank started a subsidiary company called Heritage Pipes. The Heritage pipes were an upscale line of push bit pipes meant to compliment the Kaywoodie line. Although not hugely successful, Heritage produced some fine pipes that are still in the collections of many pipe smokers. This company was dissolved on December 31, 1971.

In May of 1960, S. M. Frank started a subsidiary company called Heritage Pipes. The Heritage pipes were an upscale line of push bit pipes meant to compliment the Kaywoodie line. Although not hugely successful, Heritage produced some fine pipes that are still in the collections of many pipe smokers. This company was dissolved on December 31, 1971.

The article references an article about Heritage Pipes Inc. does not add new information but has examples of Heritage pipes which give a clue to the nomenclature and the marking design of the Blasted Apple on my table. The picture on the top shows the way ‘Antique’ was below the fancy script ‘Heritage’ above it and diagonal – as I was trying to make out on the panel of the Blasted Apple. The shape number to the left, beneath the bowl proper, is the design which I’m seeing – or, barely seeing. The upscale Heritage pipe subsidiary of Frank was started in May of 1960 and the company closed its doors in December of 1971. The look and feel of the pipe on my table I would guess ranges toward the early of these years. The look and wear it has endured, with much dignity, gives it an older cast to me.

As if frosting were needed on the Heritage Antique cake, the reference to ChrisKeene.com. In the introductory paragraph to the “Collectors Guide to Kaywoodie Pipe” was a reference to Chris Keen’s Pipe Pages. This site has been down for some time and I miss the information that was on this site. Here’s the paragraph:

This is an ongoing effort to adapt information from the Collector’s Guide to Kaywoodie Pipes into Pipedia articles. The Guide was first compiled by Chris Keene for his pipe pages at ChrisKeene.com. Chris used source material from Robert W. Stokes, Ph.D and additional support materials from Bill Feuerbach III, of the S.M. Frank Co.. Many thanks to these dedicated pipemen for their work in compiling this material.

Without expecting too much, I followed the ChrisKeene.com link to see what I might find. What I found appears to be links to ALL the information that was formerly compiled in the now defunk Pipe Pages site. Oh my! There are 100s of links to catalogues and brochures listed. They are not categorized but the links gives some identifying information. I went down the long list of links and pulled out four pictures that had ‘Heritage’ referenced. A brochure of ‘Heritage – Briar Pipes of Rarest Beauty’ emerged with great information about this line of pipes – included is the ‘Antique’ line and the shape number of 86 – a large Apple. I enjoyed the motto given for the ‘Double-Diamond’: “Symbol of FINEST, RAREST PIPES of IMPORTED BRIAR”.

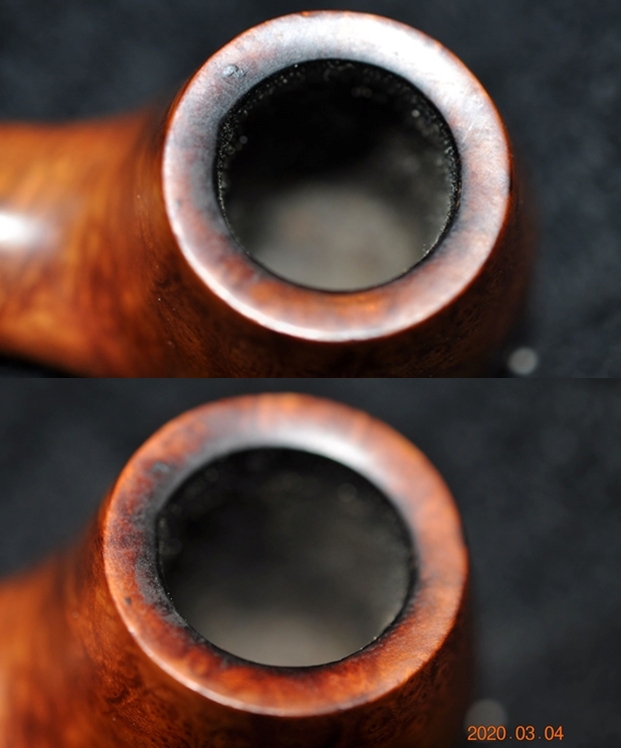

I love historic brochures and catalogs! With a better understanding of the Heritage Antique name and history, I take a closer look at the Blasted Apple on my worktable. The chamber has moderately heavy cake build up which needs to be removed to give the briar a fresh start. The rim has grime as you would expect, but most notable are the divots out of the internal rim lip. The damage to the rim is significant. The left-aft quadrant of the rim is in especially poor shape where it appears that lighting practices caused the chamber wall to deteriorate so that it’s now thinner at this point. The blasted briar surface is dirty and has grime build-up, but the blasted surface has a look of quality about it.

The blasted briar surface is dirty and has grime build-up, but the blasted surface has a look of quality about it.  The stem has oxidation and the bit has biting. There are compressions on the upper and lower bit, but the button appears to be in good shape. Interestingly, the left side of the stem has a cut where a wedge of vulcanite has been removed.

The stem has oxidation and the bit has biting. There are compressions on the upper and lower bit, but the button appears to be in good shape. Interestingly, the left side of the stem has a cut where a wedge of vulcanite has been removed. I start the restoration of this Heritage Antique Blasted Apple by cleaning the stem’s airway using a pipe cleaner wetted with alcohol.

I start the restoration of this Heritage Antique Blasted Apple by cleaning the stem’s airway using a pipe cleaner wetted with alcohol.  To address the oxidation, I use a soak of Before & After Deoxidizer along with the Ehrlich stem. I leave the stems in the soak for a few hours.

To address the oxidation, I use a soak of Before & After Deoxidizer along with the Ehrlich stem. I leave the stems in the soak for a few hours. After fishing out the Heritage stem, I squeegee the liquid off with my fingers and run a pipe cleaner wetted with alcohol through the airway to clean it of the Deoxidizer. I use cotton pads wetted with isopropyl 95% to wipe off the raised oxidation. The Deoxidizer did a good job dealing with the oxidation.

After fishing out the Heritage stem, I squeegee the liquid off with my fingers and run a pipe cleaner wetted with alcohol through the airway to clean it of the Deoxidizer. I use cotton pads wetted with isopropyl 95% to wipe off the raised oxidation. The Deoxidizer did a good job dealing with the oxidation. To help rejuvenate the vulcanite stem, paraffin oil is applied with a cloth for that purpose.

To help rejuvenate the vulcanite stem, paraffin oil is applied with a cloth for that purpose. Turning now to the stummel, to ream the chamber I use the Pipnet Reaming Kit. After putting paper towel down for easier cleanup, I use the two smaller blade heads of the four available. I follow the reaming by scraping the chamber wall with the Savinelli Fitsall Tool and then sanding by wrapping 240 grade paper around a Sharpie Pen. Finally, after wiping the bowl with a cotton pad wetted with alcohol, an inspection reveals a healthy chamber.

Turning now to the stummel, to ream the chamber I use the Pipnet Reaming Kit. After putting paper towel down for easier cleanup, I use the two smaller blade heads of the four available. I follow the reaming by scraping the chamber wall with the Savinelli Fitsall Tool and then sanding by wrapping 240 grade paper around a Sharpie Pen. Finally, after wiping the bowl with a cotton pad wetted with alcohol, an inspection reveals a healthy chamber. Continuing with cleaning, using undiluted Murphy’s Oil Soap, the external blasted surface is cleaned using a cotton pad and bristled toothbrush. For the rim, I employ the brass wire brush to clean it of minor lava flow.

Continuing with cleaning, using undiluted Murphy’s Oil Soap, the external blasted surface is cleaned using a cotton pad and bristled toothbrush. For the rim, I employ the brass wire brush to clean it of minor lava flow. Next, taking the stummel to the kitchen sink, I use shank brushes to clean the mortise with anti-oil dish soap. After rinsing well, I return to the worktable.

Next, taking the stummel to the kitchen sink, I use shank brushes to clean the mortise with anti-oil dish soap. After rinsing well, I return to the worktable. Continuing with the internal cleaning, I find that it is clean and pipe cleaner and cotton bud wetted with isopropyl 95% are not soiled indicating that the internals are clean.

Continuing with the internal cleaning, I find that it is clean and pipe cleaner and cotton bud wetted with isopropyl 95% are not soiled indicating that the internals are clean. After the cleaning is completed, I look at the stummel. The old finish has been removed during the cleaning process. I’ll need to give some consideration to how to proceed down the path regarding re-staining the blasted surface. With the original coloring emulating the Dunhill look – S. M. Frank’s marketing strategy, I hope to oblige. I decide to send my fellow restorer and good friend in India, Paresh, an email asking for advice. I know that in his past restorations of Dunhills, he has worked on techniques in restoring the Dunhill hue. With an email written including pictures, I’ll await Paresh’s advice.

After the cleaning is completed, I look at the stummel. The old finish has been removed during the cleaning process. I’ll need to give some consideration to how to proceed down the path regarding re-staining the blasted surface. With the original coloring emulating the Dunhill look – S. M. Frank’s marketing strategy, I hope to oblige. I decide to send my fellow restorer and good friend in India, Paresh, an email asking for advice. I know that in his past restorations of Dunhills, he has worked on techniques in restoring the Dunhill hue. With an email written including pictures, I’ll await Paresh’s advice.

Turning now to the rim, it’s in bad shape. There are some significant divots out of the internal rim edge. In the picture below with 12 o’clock being up, a small divot is at 12 o’clock, and larger divots at 3:30, 4:30 and 5:30. The 2 o’clock region suffers from some burning degradation with a slight compression in the rim plane because of it. The questions in my mind focus on restoring this Heritage close to its original design – a challenge to Dunhill! The coloring is an issue and the remnants of blasting on the rim are evident especially at the 4 o’clock region. I have not done much in the way of rustication processes to emulate the blasting and to repair the rim will undoubtedly mean topping it and therefore, removing the blasting on the rim as a result. The question would then be how to restore it? With this question in my mind, I send an email off to Steve with the full weight of rebornpipes.com experience behind him, to see what light he could shed on an approach.

Turning now to the rim, it’s in bad shape. There are some significant divots out of the internal rim edge. In the picture below with 12 o’clock being up, a small divot is at 12 o’clock, and larger divots at 3:30, 4:30 and 5:30. The 2 o’clock region suffers from some burning degradation with a slight compression in the rim plane because of it. The questions in my mind focus on restoring this Heritage close to its original design – a challenge to Dunhill! The coloring is an issue and the remnants of blasting on the rim are evident especially at the 4 o’clock region. I have not done much in the way of rustication processes to emulate the blasting and to repair the rim will undoubtedly mean topping it and therefore, removing the blasting on the rim as a result. The question would then be how to restore it? With this question in my mind, I send an email off to Steve with the full weight of rebornpipes.com experience behind him, to see what light he could shed on an approach. As I await responses from my fellow restorers, I move forward with the structural issues of the rim that must be addressed either way. As I look at it, there is no way around having to top the bowl to provide a new rim foundation from which to work. Starting with 240 grade paper on the chopping board, I give only a few rotations.

As I await responses from my fellow restorers, I move forward with the structural issues of the rim that must be addressed either way. As I look at it, there is no way around having to top the bowl to provide a new rim foundation from which to work. Starting with 240 grade paper on the chopping board, I give only a few rotations.  The picture below reveals the contouring in the rim with the flat surface of the topping board not touching the areas that are compressed. The upper (in the picture) area that I referenced above is compressed. The divots are more distinctly defined as well.

The picture below reveals the contouring in the rim with the flat surface of the topping board not touching the areas that are compressed. The upper (in the picture) area that I referenced above is compressed. The divots are more distinctly defined as well.  After several more rotations on 240 grade paper, the compression is minimized. The divots from 3:30 to 5:30 are also growing less distinct.

After several more rotations on 240 grade paper, the compression is minimized. The divots from 3:30 to 5:30 are also growing less distinct. I come to the terminal point in using 240 grade paper. I only take off what is needful because we can’t replace briar! My goal was to erase the degraded area at the 1 to 2 o’clock area. That has been done. In the process, the major divots no longer appear as divots but areas of the rim that are thinner.

I come to the terminal point in using 240 grade paper. I only take off what is needful because we can’t replace briar! My goal was to erase the degraded area at the 1 to 2 o’clock area. That has been done. In the process, the major divots no longer appear as divots but areas of the rim that are thinner. After replacing the 240 paper with 600 grade paper, the stummel is rotated several more times to smooth and erase the scratching of the 240 papers.

After replacing the 240 paper with 600 grade paper, the stummel is rotated several more times to smooth and erase the scratching of the 240 papers.  With the topping completed, the small divot at the top should be dispatched with sanding. On the lower quadrant, from 3:30 to 7 o’clock, the rim is noticeably thinner.

With the topping completed, the small divot at the top should be dispatched with sanding. On the lower quadrant, from 3:30 to 7 o’clock, the rim is noticeably thinner.  To see the lower quadrant from different angles to demonstrate what I can see, I take a few more pictures looking from the left, then the right. As I see it, I have two options of approach. First, to even out the entire circumference of the rim internal edge and to blend the thinning on the lower quadrant in the pictures, I can sand the entire circumference of the internal rim to smooth to even out the different rim depths. Or, secondly, I can build up the lower quadrant with briar dust putty and sand it down to blend with more balance with the entire rim.

To see the lower quadrant from different angles to demonstrate what I can see, I take a few more pictures looking from the left, then the right. As I see it, I have two options of approach. First, to even out the entire circumference of the rim internal edge and to blend the thinning on the lower quadrant in the pictures, I can sand the entire circumference of the internal rim to smooth to even out the different rim depths. Or, secondly, I can build up the lower quadrant with briar dust putty and sand it down to blend with more balance with the entire rim. I decide to do the latter – seek to build up the thinning area with briar dust putty. Since the application will be only on the very upper part of the chamber, I’m not concerned about issues of heating. I use the plastic disk that serves as a mixing pallet and cover a portion with scotch tape to ease the cleanup. I scoop a small mound of briar dust on the pallet.

I decide to do the latter – seek to build up the thinning area with briar dust putty. Since the application will be only on the very upper part of the chamber, I’m not concerned about issues of heating. I use the plastic disk that serves as a mixing pallet and cover a portion with scotch tape to ease the cleanup. I scoop a small mound of briar dust on the pallet.  Following this, I place next to the briar dust a small puddle of Extra Thick CA glue and with a toothpick, I pull briar dust into the glue.

Following this, I place next to the briar dust a small puddle of Extra Thick CA glue and with a toothpick, I pull briar dust into the glue. As briar dust is pulled into the glue, it is mixed with the developing putty. I aim for the thickness of molasses – not runny and if it gets too thick, it will set up and harden spontaneously – with a little smoke for excitement! The putty needs to be pliable enough to adhere to the chamber/rim edge. When it’s thick enough, I trowel the putty onto the target area.

As briar dust is pulled into the glue, it is mixed with the developing putty. I aim for the thickness of molasses – not runny and if it gets too thick, it will set up and harden spontaneously – with a little smoke for excitement! The putty needs to be pliable enough to adhere to the chamber/rim edge. When it’s thick enough, I trowel the putty onto the target area. I set the bowl aside to allow the briar dust putty to cure thoroughly. It looks good. In the picture below you can see how it adheres to the contours of the damaged area.

I set the bowl aside to allow the briar dust putty to cure thoroughly. It looks good. In the picture below you can see how it adheres to the contours of the damaged area. After a few hours, the briar dust putty is ready to go. The process of removing the excess patch material and shaping starts with a half circle needle file focusing on the center of the patch to shape out the curved pitch of the rim.

After a few hours, the briar dust putty is ready to go. The process of removing the excess patch material and shaping starts with a half circle needle file focusing on the center of the patch to shape out the curved pitch of the rim.  After a few minutes of filing, I remember that I have a Dremel and attach a sanding drum! With the speed set to low, the Dremel quickens the job of removing the excess and shaping the curve. I do go slowly and patiently not to take off too much too quickly.

After a few minutes of filing, I remember that I have a Dremel and attach a sanding drum! With the speed set to low, the Dremel quickens the job of removing the excess and shaping the curve. I do go slowly and patiently not to take off too much too quickly. After the sanding drum does its job, I switch back to filing to fine tune the removal of excess patch and shaping.

After the sanding drum does its job, I switch back to filing to fine tune the removal of excess patch and shaping.

When the needle file brings the patch down near to flush to the briar chamber, I switch and use 240 grade paper wrapped around a Sharpie Pen. This works well to continue a nice curve and to give more leverage to removing excess patch material. My goal is to feel no transition from the patch to the chamber wall.

When the needle file brings the patch down near to flush to the briar chamber, I switch and use 240 grade paper wrapped around a Sharpie Pen. This works well to continue a nice curve and to give more leverage to removing excess patch material. My goal is to feel no transition from the patch to the chamber wall. This is achieved after the sanding. I like what I see.

This is achieved after the sanding. I like what I see. Transitioning now to the rim surface, using a flat needle file the patch excess is removed and smoothed to blend with the rim surface.

Transitioning now to the rim surface, using a flat needle file the patch excess is removed and smoothed to blend with the rim surface. After using the file, I use 240 then 600 grade paper to fine tune. I also sand around the full circumference of the rim to remove other smaller nicks.

After using the file, I use 240 then 600 grade paper to fine tune. I also sand around the full circumference of the rim to remove other smaller nicks. I’m pleased with the progress of the rim’s restoration. The rim rebuild with briar dust putty will be invisible after the rim is dyed and I figure out an approach to introduce an emulated blasted surface on the rim!

I’m pleased with the progress of the rim’s restoration. The rim rebuild with briar dust putty will be invisible after the rim is dyed and I figure out an approach to introduce an emulated blasted surface on the rim! Well, I received Steve’s response regarding his thoughts about how to approach the rim. His counsel was not to top the stummel and to blend repairs and blemishes using burrs from the Dremel. His counsel arrived a bit late but using burrs to emulate a ‘blasted’ rim surface is the direction I’ll take. Since I’ve not had a lot of experience with the use of burrs and what effects they produce, I practice on a discarded stummel destined for the briar dust container.

Well, I received Steve’s response regarding his thoughts about how to approach the rim. His counsel was not to top the stummel and to blend repairs and blemishes using burrs from the Dremel. His counsel arrived a bit late but using burrs to emulate a ‘blasted’ rim surface is the direction I’ll take. Since I’ve not had a lot of experience with the use of burrs and what effects they produce, I practice on a discarded stummel destined for the briar dust container. After testing different burrs and saw what they do, I chose an approach and apply it to the Heritage’s rim. I start with a cylindrical burr and finish with a sharper, cone-like burr to get the effect that I practiced.

After testing different burrs and saw what they do, I chose an approach and apply it to the Heritage’s rim. I start with a cylindrical burr and finish with a sharper, cone-like burr to get the effect that I practiced.

Still not sure if I will stain or leave the stummel as it is, I decide to hydrate the stummel as well as get a sneak peek at what the stummel would look like more in a finished state. I apply paraffin oil to the stummel, not the rim. The stummel darkens nicely, but the finish is uneven – patches of lighter on the lower side which darkens going up. Still thinking….

Still not sure if I will stain or leave the stummel as it is, I decide to hydrate the stummel as well as get a sneak peek at what the stummel would look like more in a finished state. I apply paraffin oil to the stummel, not the rim. The stummel darkens nicely, but the finish is uneven – patches of lighter on the lower side which darkens going up. Still thinking…. With the stummel darkened, I need to darken the raw rim briar to match where the stummel is.

With the stummel darkened, I need to darken the raw rim briar to match where the stummel is.  I use two dye sticks to do the job. The under coat is with a walnut stain, then over that, a mahogany. Then, in order to give the new fresh rim surface a more weathered look, I use three mid-range micromesh pads and lightly sand the rim.

I use two dye sticks to do the job. The under coat is with a walnut stain, then over that, a mahogany. Then, in order to give the new fresh rim surface a more weathered look, I use three mid-range micromesh pads and lightly sand the rim. I heard back from my good friend, Paresh in India, about his approach to achieving a Dunhill color tone. His basic approach is to apply a dark brown undercoat in the normal way – flamed and then ‘unwrap’ after several hours. Then, the key part of the process is when Paresh stain washes with a cherry red dye, applying with cotton pad and immediately wiping until the hue that is wanted is reached. He also sent a link to his great write up on rebornpipes describing the process: A Project Close to My Hear: Restoring a Dunhill From Farida’s Dad’s Collection. With Paresh’s encouragement, I decide to give Paresh’s approach a try with this Dunhill minded Heritage Antique Blasted Apple. Not long ago, thankfully, I acquired some red concentrated dye solution that I’ll be able to employ for the first time. To start, I assemble my desktop staining ensemble.

I heard back from my good friend, Paresh in India, about his approach to achieving a Dunhill color tone. His basic approach is to apply a dark brown undercoat in the normal way – flamed and then ‘unwrap’ after several hours. Then, the key part of the process is when Paresh stain washes with a cherry red dye, applying with cotton pad and immediately wiping until the hue that is wanted is reached. He also sent a link to his great write up on rebornpipes describing the process: A Project Close to My Hear: Restoring a Dunhill From Farida’s Dad’s Collection. With Paresh’s encouragement, I decide to give Paresh’s approach a try with this Dunhill minded Heritage Antique Blasted Apple. Not long ago, thankfully, I acquired some red concentrated dye solution that I’ll be able to employ for the first time. To start, I assemble my desktop staining ensemble.  After wiping the bowl with a cotton pad wetted with alcohol to clean, I warm the stummel using a hot air gun. This has the effect of expanding the briar and helping it to be more receptive to the dye.

After wiping the bowl with a cotton pad wetted with alcohol to clean, I warm the stummel using a hot air gun. This has the effect of expanding the briar and helping it to be more receptive to the dye.  Using a fashioned cork as a handle, I then apply Fiebing’s Dark Brown Leather Dye, per Paresh’s directions. I use a folded over pipe cleaner to do this. After ‘painting’ a section, I immediately ‘flame’ the alcohol-based dye with a lit candle. The combustion burns off the alcohol leaving behind the embedded hue absorbed into the briar.

Using a fashioned cork as a handle, I then apply Fiebing’s Dark Brown Leather Dye, per Paresh’s directions. I use a folded over pipe cleaner to do this. After ‘painting’ a section, I immediately ‘flame’ the alcohol-based dye with a lit candle. The combustion burns off the alcohol leaving behind the embedded hue absorbed into the briar.  After completing this process with a thorough painting and flaming of the entire stummel, I put it aside for several hours for the new dye to rest. This helps to solidify the new dye.

After completing this process with a thorough painting and flaming of the entire stummel, I put it aside for several hours for the new dye to rest. This helps to solidify the new dye. With the newly dyed stummel resting, I turn my attention to the stem. Taking a closer look, the compressions on the upper bit and lower bit are significant. There is also a divot of vulcanite sliced off the left side of the stem. I’m not sure how something like this would happen – perhaps a lit match? I’ll work on blending this in by sanding. First, using the heating method, I paint the compressions with the flame of a Bic lighter. This heats and expands the rubber helping it to regain its original disposition – or closer to it. The goal is to raise the compressions sufficiently enough so that simple sanding will then be all that is needed to erase them – hopefully avoiding patching. Before and after pictures of upper and then lower show the results. First, the upper:

With the newly dyed stummel resting, I turn my attention to the stem. Taking a closer look, the compressions on the upper bit and lower bit are significant. There is also a divot of vulcanite sliced off the left side of the stem. I’m not sure how something like this would happen – perhaps a lit match? I’ll work on blending this in by sanding. First, using the heating method, I paint the compressions with the flame of a Bic lighter. This heats and expands the rubber helping it to regain its original disposition – or closer to it. The goal is to raise the compressions sufficiently enough so that simple sanding will then be all that is needed to erase them – hopefully avoiding patching. Before and after pictures of upper and then lower show the results. First, the upper:  And the lower:

And the lower: I believe that the lower bit may now be sanded out. I’m not so sure about the upper bit – the compression next to the button is still significantly deep. Before sanding, I fill this compression with black CA glue to be on the safe side and fill up against the button. When the patch cures, this will make sure that the compression is addressed in conjunction with the button lip edge.

I believe that the lower bit may now be sanded out. I’m not so sure about the upper bit – the compression next to the button is still significantly deep. Before sanding, I fill this compression with black CA glue to be on the safe side and fill up against the button. When the patch cures, this will make sure that the compression is addressed in conjunction with the button lip edge. After the patch cures, a flat needle file goes to work on bringing the excess CA glue down to the stem’s surface level on both the upper and lower sides. The change in the background is explained by me moving out onto my 10th floor balcony ‘Man Cave’ to enjoy the warmth of the day!

After the patch cures, a flat needle file goes to work on bringing the excess CA glue down to the stem’s surface level on both the upper and lower sides. The change in the background is explained by me moving out onto my 10th floor balcony ‘Man Cave’ to enjoy the warmth of the day! As I was filing the lower side, it became apparent that the compression was too pronounced for filing and sanding to remove. It would require too much to dig that deep. Switching gears, I decide to detour a bit and fill the compression with black CA glue.

As I was filing the lower side, it became apparent that the compression was too pronounced for filing and sanding to remove. It would require too much to dig that deep. Switching gears, I decide to detour a bit and fill the compression with black CA glue. After cleaning it with alcohol, I place a drop of black CA glue on the lower side compression.

After cleaning it with alcohol, I place a drop of black CA glue on the lower side compression. What I missed taking a picture of was that during the detour, I also decided to apply some black CA glue to the wedge on the left side of the stem. I used an accelerator to hold the glue in place and to quicken the curing time.

What I missed taking a picture of was that during the detour, I also decided to apply some black CA glue to the wedge on the left side of the stem. I used an accelerator to hold the glue in place and to quicken the curing time. After both of the ‘tour patches’ cure, I used the flat needle file on both to remove excess and to bring the patches down to stem level.

After both of the ‘tour patches’ cure, I used the flat needle file on both to remove excess and to bring the patches down to stem level. After filing, the sanding continues with 240 grade paper on the upper and lower.

After filing, the sanding continues with 240 grade paper on the upper and lower. Sanding is continued after the 240 grade paper with wet sanding using 600 grade paper on the entire stem along with applying 000 grade steel wool.

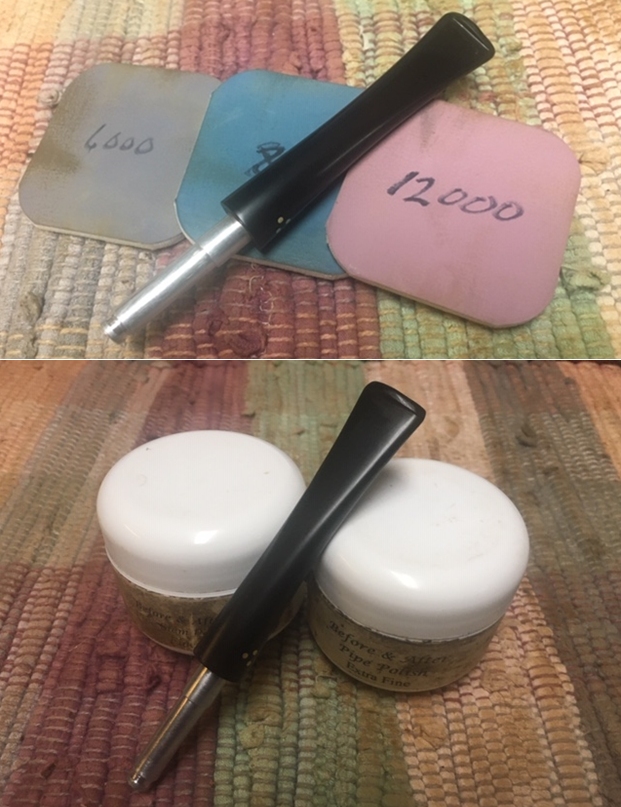

Sanding is continued after the 240 grade paper with wet sanding using 600 grade paper on the entire stem along with applying 000 grade steel wool. Continuing to the micromesh process, I wet sand with pad 1500 to 2400 and dry sand with pads 3200 to 4000 and 6000 to 12000. Between each set of three pads Obsidian Oil is applied to freshen as well as to protect the vulcanite against oxidation. I’m pleased with the repairs. The large fill on the upper side is solid but still visible. We still live in an imperfect world!

Continuing to the micromesh process, I wet sand with pad 1500 to 2400 and dry sand with pads 3200 to 4000 and 6000 to 12000. Between each set of three pads Obsidian Oil is applied to freshen as well as to protect the vulcanite against oxidation. I’m pleased with the repairs. The large fill on the upper side is solid but still visible. We still live in an imperfect world!

Turning back to the newly stained stummel, it has been resting now for several hours and it’s time to ‘unwrap’ the flame crusted surface.

Turning back to the newly stained stummel, it has been resting now for several hours and it’s time to ‘unwrap’ the flame crusted surface.  To remove the crusted surface, a felt buffing wheel is mounted onto the Dremel with the speed set almost to the slowest to avoid excess heating with the friction created by the felt on the briar surface. With the felt wheel, the coarser Tripoli compound is applied to the blasted briar surface. With my wife’s help taking some pictures while my hands are full, it shows the ‘unwrapping’ process. The second close-up shows the line between the crusted part and the unwrapped part.

To remove the crusted surface, a felt buffing wheel is mounted onto the Dremel with the speed set almost to the slowest to avoid excess heating with the friction created by the felt on the briar surface. With the felt wheel, the coarser Tripoli compound is applied to the blasted briar surface. With my wife’s help taking some pictures while my hands are full, it shows the ‘unwrapping’ process. The second close-up shows the line between the crusted part and the unwrapped part. The stummel has been unwrapped revealing the dark brown undercoat. Next, the stain wash with a red dye applied until the desired hue is reached – hopefully!

The stummel has been unwrapped revealing the dark brown undercoat. Next, the stain wash with a red dye applied until the desired hue is reached – hopefully! The red dye concentrate I acquired not long ago prescribes a ratio of 1 fluid ounce per quart of either water or alcohol. For my smaller purposes of application, I pour some isopropyl 95% in a small jar – about 1/3 filled and add several drops of the red tint concentrate until it looks good.

The red dye concentrate I acquired not long ago prescribes a ratio of 1 fluid ounce per quart of either water or alcohol. For my smaller purposes of application, I pour some isopropyl 95% in a small jar – about 1/3 filled and add several drops of the red tint concentrate until it looks good.  Then, using a folded pipe cleaner, I wash the stummel with the red dye and wipe it with a cotton pad. Since I haven’t done this before, I’m going by the ‘seat of my pants’ to see how the briar takes the wash and what the effect will be.

Then, using a folded pipe cleaner, I wash the stummel with the red dye and wipe it with a cotton pad. Since I haven’t done this before, I’m going by the ‘seat of my pants’ to see how the briar takes the wash and what the effect will be. Satisfied at this point, not sure whether I’m achieving the ‘Dunhill’ look, I set the stummel aside to rest for several hours through the night.

Satisfied at this point, not sure whether I’m achieving the ‘Dunhill’ look, I set the stummel aside to rest for several hours through the night. The next morning, the red dye wash has had time to settle. The next step to unwrap the stummel a second time. For this, I mount the Dremel with a softer cotton cloth buffing wheel, set at the normal 40% speed, and apply the lesser abrasive compound, Blue Diamond. Again, my wife assists with a picture of this process.

The next morning, the red dye wash has had time to settle. The next step to unwrap the stummel a second time. For this, I mount the Dremel with a softer cotton cloth buffing wheel, set at the normal 40% speed, and apply the lesser abrasive compound, Blue Diamond. Again, my wife assists with a picture of this process. DISASTER AVOIDED! When I reached for the stem to rejoin it to the stummel to apply Blue Diamond to it, I noticed that the double diamond inlay was missing! Oh my! Miracle of miracles, I looked down and amazingly saw the diamonds. To remedy this near disaster, using a toothpick, I dab a bit of CA glue in the diamond cavities on the stem and with tweezers replace the double diamond inlay. The process was not as easy as it sounds as small as the double diamonds are and not getting excess CA glue on the finished stem surface….

DISASTER AVOIDED! When I reached for the stem to rejoin it to the stummel to apply Blue Diamond to it, I noticed that the double diamond inlay was missing! Oh my! Miracle of miracles, I looked down and amazingly saw the diamonds. To remedy this near disaster, using a toothpick, I dab a bit of CA glue in the diamond cavities on the stem and with tweezers replace the double diamond inlay. The process was not as easy as it sounds as small as the double diamonds are and not getting excess CA glue on the finished stem surface….

With Double Diamonds reattached, and the stem and stummel reunited, I continue the application of Blue Diamond compound to the stem. I do change buffing wheels because of the dye unwrapping.

With Double Diamonds reattached, and the stem and stummel reunited, I continue the application of Blue Diamond compound to the stem. I do change buffing wheels because of the dye unwrapping. Before applying wax, I do a ‘heat’ buffing. To help minimize dye leaching off on the hands of the new steward, I use the heat gun to warm the stummel, emulating the heating of a pipe in service, and use a cotton cloth to wipe it during the heated state. This helps to stabilize the new dyed briar surface.

Before applying wax, I do a ‘heat’ buffing. To help minimize dye leaching off on the hands of the new steward, I use the heat gun to warm the stummel, emulating the heating of a pipe in service, and use a cotton cloth to wipe it during the heated state. This helps to stabilize the new dyed briar surface. After reuniting stem and stummel, I mount another cotton cloth buffing wheel to the Dremel, set at 40% full power, and apply carnauba wax to the pipe. When completed, a microfiber cloth provides a rigorous hand buffing to raise the shine.

After reuniting stem and stummel, I mount another cotton cloth buffing wheel to the Dremel, set at 40% full power, and apply carnauba wax to the pipe. When completed, a microfiber cloth provides a rigorous hand buffing to raise the shine.

Wow! With Paresh’s help, I think I nailed it! The depth and richness of this blasted finish has that ‘Dunhill’ look to it I believe. Thanks, Paresh! The blasted landscape of this Heritage Antique Blasted Apple jumps out with the 3-dimensional contours of the briar grain contours. I can’t get over the red notes in the finish – it gives it a depth and richness that is something to enjoy. The technical challenges with the rim repairs and stem patches turned out great. I’m pleased with this restoration and Todd, who commissioned it, will have the first opportunity in The Pipe Steward Store to acquire the Heritage Antique benefiting the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Thanks for joining me!

He took some photos of the rim top and bowl from various angles to give me a clear picture of the condition of the rim top and bowl. You can see the cake in the bowl and the darkening around the inner edge of the rim.

He took some photos of the rim top and bowl from various angles to give me a clear picture of the condition of the rim top and bowl. You can see the cake in the bowl and the darkening around the inner edge of the rim.

Jeff took some photos of the sides and heel of the bowl to show the condition of the finish on the pipe. The photos show the beautiful grain around the bowl. Under the oils and grime it was a nice looking bowl. I think it will be a really nice looking pipe once it is restored.

Jeff took some photos of the sides and heel of the bowl to show the condition of the finish on the pipe. The photos show the beautiful grain around the bowl. Under the oils and grime it was a nice looking bowl. I think it will be a really nice looking pipe once it is restored.

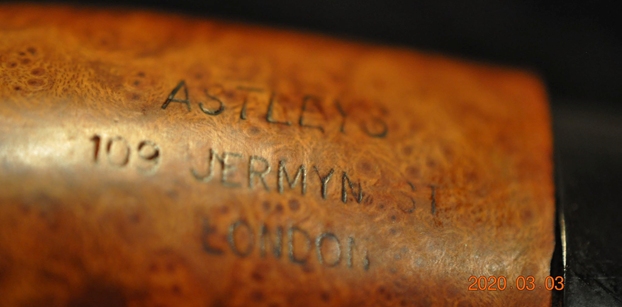

He took a photo of the stamping on the underside of the shank. On the shank it was stamped Astley’s over 109 Jermyn St over London. As noted there was not a shape number.

He took a photo of the stamping on the underside of the shank. On the shank it was stamped Astley’s over 109 Jermyn St over London. As noted there was not a shape number. The next two photos show the top and underside of the stem. It is dirty and has calcification on both sides at the button. There is also some tooth chatter and some light tooth marks. The third photo shows the condition of the slot while the final photo shows the curve of the full stem.

The next two photos show the top and underside of the stem. It is dirty and has calcification on both sides at the button. There is also some tooth chatter and some light tooth marks. The third photo shows the condition of the slot while the final photo shows the curve of the full stem.

Jeff once again did an amazing job cleaning the pipe. He reamed it with a PipNet pipe reamer and got rid of the cake. He cleaned up the reaming with a Savinelli Fitsall Pipe Knife so that we could see the walls of the bowl and assess for damage. He cleaned the internals of the shank and stem with alcohol, pipe cleaners and alcohol. He scrubbed the exterior with undiluted Murphy’s Oil Soap and a tooth brush. He rinsed the pipe under warm water. He dried it off with a cloth and then let it air dry. The stem was scrubbed with Soft Scrub and it came out looking very good. The finish on the bowl and the rim top cleaned up nicely. I took pictures of the pipe to show how it looked when I unpacked it.

Jeff once again did an amazing job cleaning the pipe. He reamed it with a PipNet pipe reamer and got rid of the cake. He cleaned up the reaming with a Savinelli Fitsall Pipe Knife so that we could see the walls of the bowl and assess for damage. He cleaned the internals of the shank and stem with alcohol, pipe cleaners and alcohol. He scrubbed the exterior with undiluted Murphy’s Oil Soap and a tooth brush. He rinsed the pipe under warm water. He dried it off with a cloth and then let it air dry. The stem was scrubbed with Soft Scrub and it came out looking very good. The finish on the bowl and the rim top cleaned up nicely. I took pictures of the pipe to show how it looked when I unpacked it.

I took a close up photo of the rim top to show how clean it was. There was some damage and darkening on the inner edge of the rim. It was slightly out of round from the damage. You can also see the crack on the top of the shank (Jeff had mentioned this to me in our conversations today). I have circled it in red in the photo below. The stem looked good just some light tooth chatter and several deeper tooth marks near the button.

I took a close up photo of the rim top to show how clean it was. There was some damage and darkening on the inner edge of the rim. It was slightly out of round from the damage. You can also see the crack on the top of the shank (Jeff had mentioned this to me in our conversations today). I have circled it in red in the photo below. The stem looked good just some light tooth chatter and several deeper tooth marks near the button. I decided to address the hairline crack in the top of the shank. It was not a deep crack and it did not go all the way around the shank. It was only on the top of the shank. You can see the totality of it in the first photo below. I used a microdrill bit on my Dremel to drill a small hole at each end of the crack to stop it from spreading further. I located the end of the crack with lens and marked it. I drilled a hole at each end (photos 2 and 3). The fourth photo shows both ends of the crack with the pilot holes.

I decided to address the hairline crack in the top of the shank. It was not a deep crack and it did not go all the way around the shank. It was only on the top of the shank. You can see the totality of it in the first photo below. I used a microdrill bit on my Dremel to drill a small hole at each end of the crack to stop it from spreading further. I located the end of the crack with lens and marked it. I drilled a hole at each end (photos 2 and 3). The fourth photo shows both ends of the crack with the pilot holes.

I wiped down the surface of the crack. I cleaned it out with a dental pick to open it slightly. I filled in the crack and the pilot holes with clear super glue. I used a dental spatula to spread briar dust over the pilot holes and the crack.

I wiped down the surface of the crack. I cleaned it out with a dental pick to open it slightly. I filled in the crack and the pilot holes with clear super glue. I used a dental spatula to spread briar dust over the pilot holes and the crack. Once the repair had cured I sanded the surface of the shank around and over the crack with a folded piece of 220 grit sandpaper and smoothed the repair out and blended it into the surface of the surrounding briar. I was able to blend it in fairly well. While it is still visible in the photo below it is solid and repaired.

Once the repair had cured I sanded the surface of the shank around and over the crack with a folded piece of 220 grit sandpaper and smoothed the repair out and blended it into the surface of the surrounding briar. I was able to blend it in fairly well. While it is still visible in the photo below it is solid and repaired. When I examined the end of the shank, the angled drilling of the airway into the bowl left a thin area at the bottom of the mortise opening. I put a few drops of super glue in the airway and put some briar dust on top of the glue to build up the mortise in that area. Once it was cured I sanded it smooth with a small sanding stick.

When I examined the end of the shank, the angled drilling of the airway into the bowl left a thin area at the bottom of the mortise opening. I put a few drops of super glue in the airway and put some briar dust on top of the glue to build up the mortise in that area. Once it was cured I sanded it smooth with a small sanding stick. I decided to address the damage to the inner edge of the rim. I used a folded piece of 220 grit sandpaper to smooth out the rim edge and give it a bevel to minimize the damage to the edge.. I was able to remove the damage and bring the bowl back into round.

I decided to address the damage to the inner edge of the rim. I used a folded piece of 220 grit sandpaper to smooth out the rim edge and give it a bevel to minimize the damage to the edge.. I was able to remove the damage and bring the bowl back into round. I polished the briar with micromesh sanding pads – wet sanding with 1500-12000 grit pads and wiping down the briar after each sanding pad with a damp cloth. The briar began to shine.

I polished the briar with micromesh sanding pads – wet sanding with 1500-12000 grit pads and wiping down the briar after each sanding pad with a damp cloth. The briar began to shine.

I touched up the stain around the sanded area of the repair with a Cherry stain pen and blended the repair into the surrounding briar. The result looks very good.

I touched up the stain around the sanded area of the repair with a Cherry stain pen and blended the repair into the surrounding briar. The result looks very good. I worked some Before & After Restoration Balm into the briar with my fingertips. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. I appreciate Mark Hoover’s work in developing this product.

I worked some Before & After Restoration Balm into the briar with my fingertips. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. I appreciate Mark Hoover’s work in developing this product.

I set the bowl aside and turned my attention to the stem. I “painted” the tooth marks with the flame of a Bic lighter to try and raise them a bit. Remember vulcanite has “memory” and if the marks are not sharp edge the heat well raise them. In this case while they came up some there was still significant damage.

I set the bowl aside and turned my attention to the stem. I “painted” the tooth marks with the flame of a Bic lighter to try and raise them a bit. Remember vulcanite has “memory” and if the marks are not sharp edge the heat well raise them. In this case while they came up some there was still significant damage. I filled in the remaining tooth marks with clear CA glue and set the stem aside to dry.

I filled in the remaining tooth marks with clear CA glue and set the stem aside to dry. Once the repairs cured I used a needle file to flatten them out and recut the sharp edge of the button.

Once the repairs cured I used a needle file to flatten them out and recut the sharp edge of the button. I sanded the surface of the stem with 220 grit sandpaper to further blend in the repairs. I started the polishing process with 400 grit wet dry sandpaper.

I sanded the surface of the stem with 220 grit sandpaper to further blend in the repairs. I started the polishing process with 400 grit wet dry sandpaper. I polished the stem with Denicare Mouthpiece Polish from a tin of it I have in the drawer here. It is a gritty red paste that I rub on with my finger tips and work it into the surface of the stem and button and buff it off with a cotton pad. It gives me a bit of a head start on the polishing work.

I polished the stem with Denicare Mouthpiece Polish from a tin of it I have in the drawer here. It is a gritty red paste that I rub on with my finger tips and work it into the surface of the stem and button and buff it off with a cotton pad. It gives me a bit of a head start on the polishing work. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I buffed the stem with a soft cloth to raise the shine. I wiped the stem down with Briarville’s No Oxy Oil to preserve and protect the stem surface.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I buffed the stem with a soft cloth to raise the shine. I wiped the stem down with Briarville’s No Oxy Oil to preserve and protect the stem surface.

As always I am excited to finish a pipe that I am working on. I put the Astley’s pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad and hand buffed it to raise the shine. It is fun to see what the polished bowl looks like along with the polished vulcanite stem. This is nice looking pipe and I am sure that it will be comfortable in hand when smoking as it is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. It is another beautiful pipe and one that will be on the rebornpipes store soon. You can find it in the section of Pipes by English Pipe Makers. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

As always I am excited to finish a pipe that I am working on. I put the Astley’s pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad and hand buffed it to raise the shine. It is fun to see what the polished bowl looks like along with the polished vulcanite stem. This is nice looking pipe and I am sure that it will be comfortable in hand when smoking as it is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. It is another beautiful pipe and one that will be on the rebornpipes store soon. You can find it in the section of Pipes by English Pipe Makers. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.