Blog by Paresh Deshpande

As I was winding up my stay at the old duty station, I came across a neatly packed zip-lock pouch that was stowed away in to the deepest part of the cupboard. In that pouch were three pipes; two Comoys and one Drury Lane # 484. I remembered that the Comoy’s had stingers that needed leather gaskets and one needed a top nut for the stinger. Steve had sent me the leather gaskets/ washers while a replacement for the stinger that required top nut, was in post that was delayed for more than a year due to the prevalent worldwide pandemic situation. I completed refurbishing the Drury Lane # 484 (Another Of My Inherited Pipes Restored…. A “Drury Lane # 484” | rebornpipes) and decided to work on the Comoy’s pipe that had an intact top nut but needed a leather gasket.

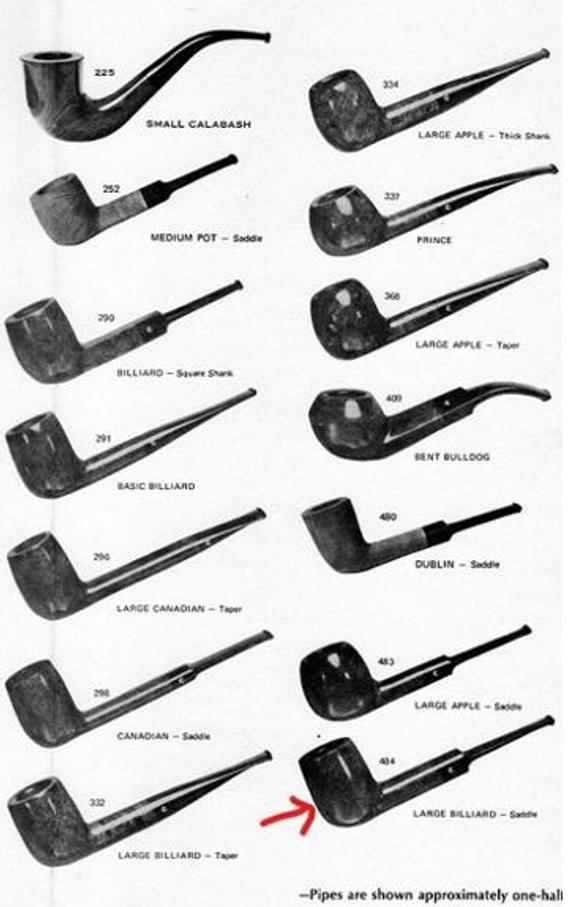

This pipe is a classic Lovat shape and is stamped on the left of the shank towards the shank end as “AIR-O-DRY” in fancy Gothic script. The right side of the shank surface is stamped as “MADE IN ENGLAND” over “BY” over “COMOY’S” and followed by the shape number “212” towards the chamber end. The bottom of the shank is stamped with *5 (this number denotes the leather washer size) over letter “K” (a mystery!!). The high quality vulcanite saddle stem bears the trademark BAR logo that appears to be an aluminum strip embedded in to the vulcanite. All the stampings are crisp and easily readable.

The stampings on the pipe were categorical in pointing out that the pipe is English made and linked with Comoy’s. The shape code # 212 of Comoy’s Shape Number chart also corresponds to LOVAT shape of the pipe on my work table. However, the Air- O- Dry line does not find a mention in the list of seconds from Comoy’s on pipedia.org.

The stampings on the pipe were categorical in pointing out that the pipe is English made and linked with Comoy’s. The shape code # 212 of Comoy’s Shape Number chart also corresponds to LOVAT shape of the pipe on my work table. However, the Air- O- Dry line does not find a mention in the list of seconds from Comoy’s on pipedia.org.

Pipedia.org has some information on this line of pipes and I quote:-

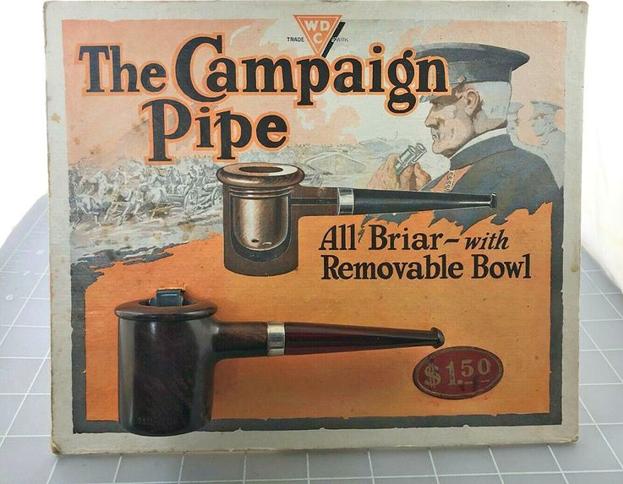

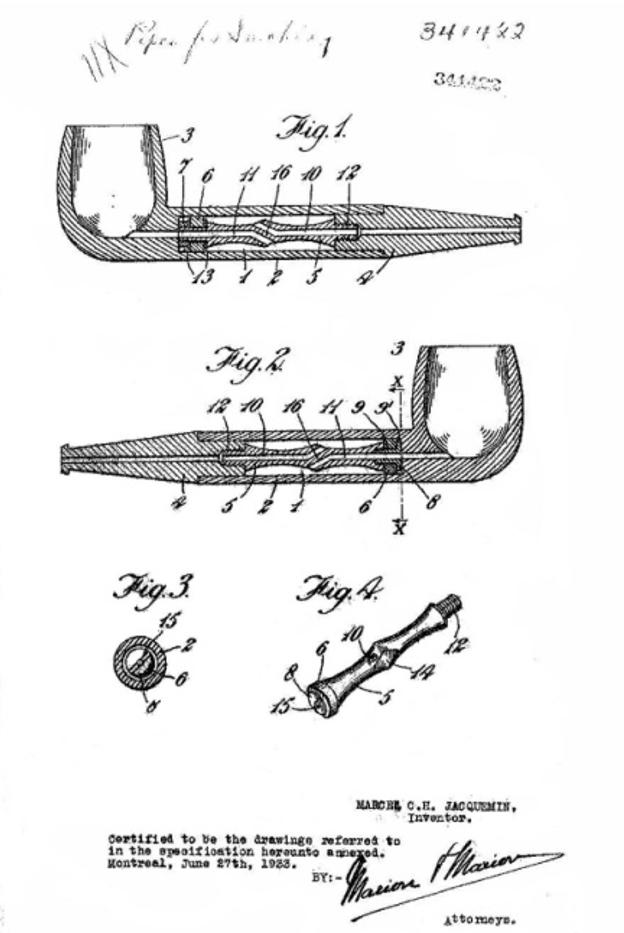

The Air-o-Dry pipe that follows was made by Comoy’s according to the stamp. The patent for the unusual stinger system shows it was invented by Marcel C.H. Jacquemin, as “Annexed” in Montreal, June 27th, 1933.

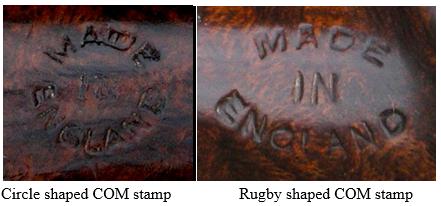

Here are a couple of pictures of the pipe and the patented details of the stinger that were available on pipedia.org, courtesy Dough Valitchka. The three digit shape number, COM stamp and the stinger system make me believe this pipe is from the 1930s to 1950s.

The three digit shape number, COM stamp and the stinger system make me believe this pipe is from the 1930s to 1950s.

Initial Visual Inspection

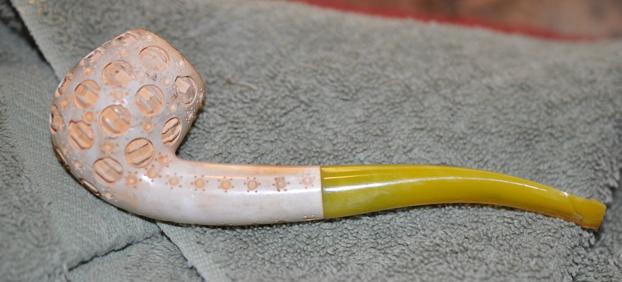

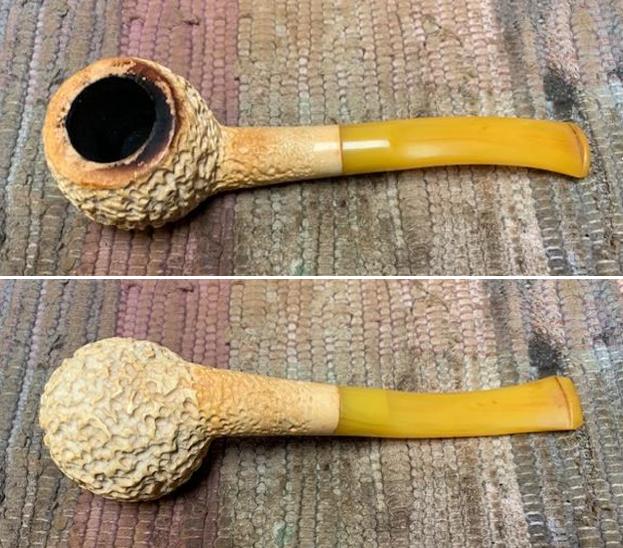

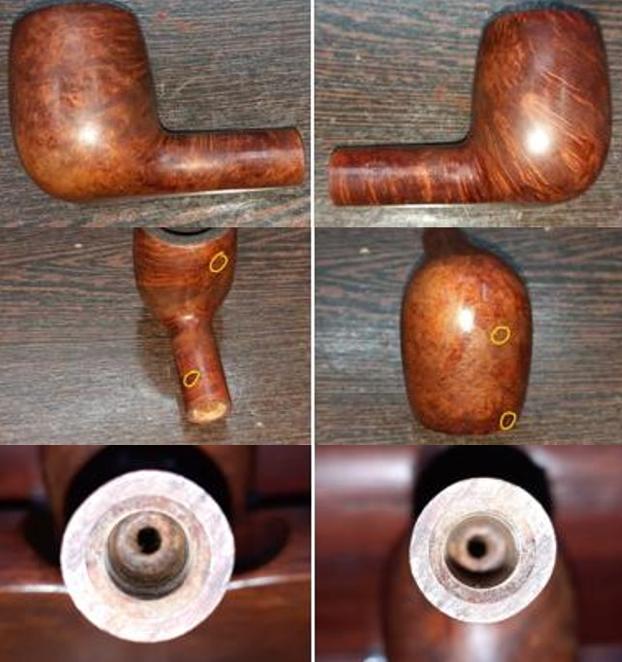

The pipe that is currently on my work table has a classic Lovat shape with a nice hand feel and heft to it. The stummel has rich light brown coloration that has turned dark over the years due to regular use. The stummel has a beautiful mix of cross grains and tightly packed bird’s eye grains peeking out from underneath the dirt and grime. Once the stummel has been cleaned and polished, these beautiful grains should add to the visual appeal of this piece of the briar. There is a thick layer of cake in the chamber with lava overflow over the rim top surface. The beveled inner rim edge has dents and dings and suspected charring in 12 o’clock and 6 o’clock directions. The outer edge has chipped surfaces all around, probably the pipe having being knocked against a hard surface. The vulcanite saddle stem is heavily oxidized with minor calcification and damage to the bite zone on either surface. The buttons on both surfaces have worn out slightly with minor tooth indentations. The following pictures will give the Readers an idea of the overall condition of the pipe as it sits on my work table.

Detailed Visual Inspection

Detailed Visual Inspection

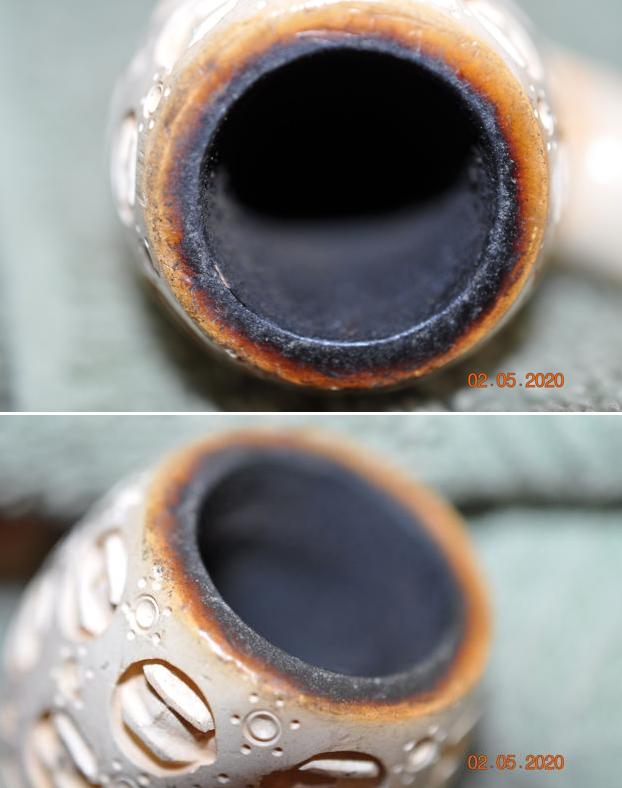

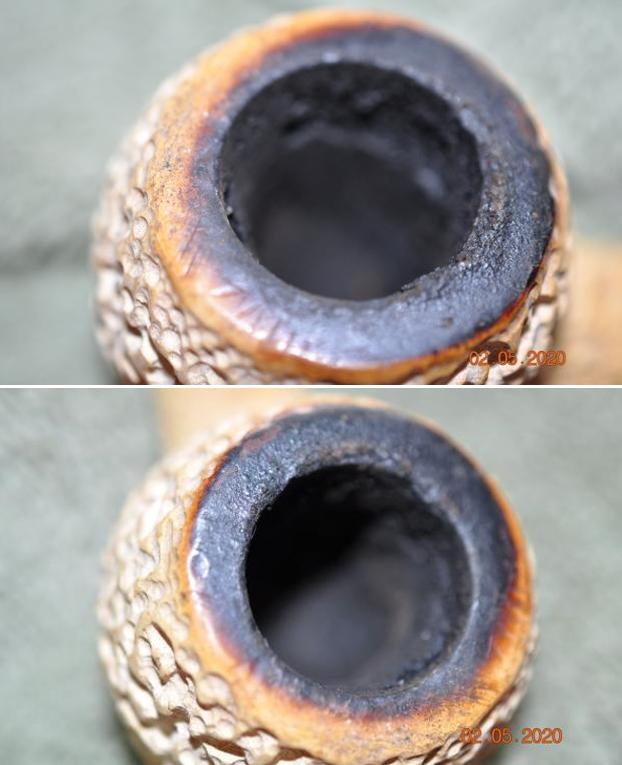

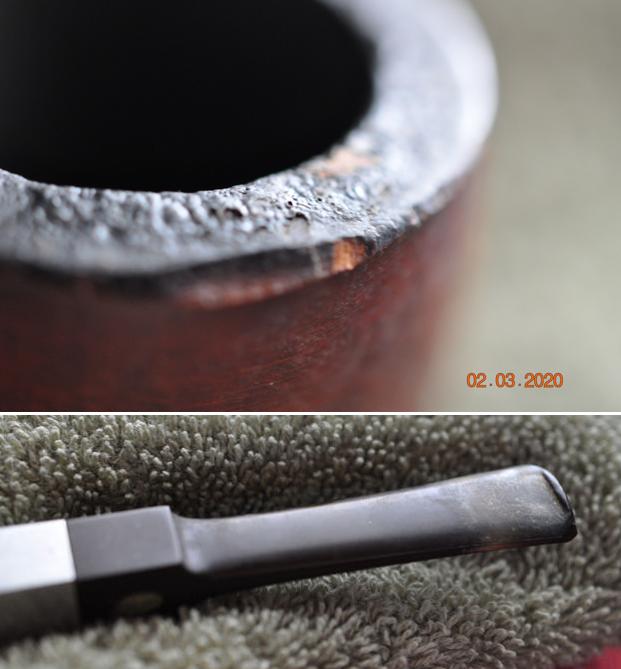

A thick and even layer of cake is seen in the chamber. The rim top surface is covered in overflow of lava, dirt, dust and grime and appears uneven underneath the overflow of lava. The condition of the inner walls of the chamber and rim top surface will be known once the cake has been taken down to the bare briar and the rim top crud has been scraped off completely. The inner rim has suspected burn/ charred surface in 12 o’clock (low probability, I guess) and 6 o’clock directions and is marked in yellow circle. Only once the stummel has been thoroughly cleaned that I can be sure of my initial appreciation. The outer rim edge has chipped surfaces all around (indicated with green arrows) but the most severe damage is in the 3 o’clock direction and is encircled in green. The chamber odor is strong.

Notes: – The stummel feels solid to the touch and I do not foresee any major issues with the condition of the chamber walls. The dents and dings to the rim top surface will necessitate topping. A thin delicate bevel to the outer edge should address the damage to a great extent. The strong ghost smells should be addressed to some extent once the cake has been taken down to the bare briar and the shank internals have been thoroughly cleaned. In case required, more invasive measures like salt and alcohol treatment will be resorted to if the ghosting prevails. Being a seconds pipe from Comoy’s, I had expected to find a few fills and some non-descript grain on the stummel briar. However, I was surprised to note that there is just a single fill in the stummel surface that’s already loosened (encircled in pastel pink). The stummel surface boasts of some beautiful cross grains around the front, back and over the shank surface while tightly packed Bird’s eye adorns the sides and foot of the bowl. The stummel surface is covered in dirt and grime giving the stummel a dull and oily appearance. The surface shows a few scratches, dents and dings (indicated in red). The mortise shows accumulation of old oils and tars which would need to be cleaned.

Being a seconds pipe from Comoy’s, I had expected to find a few fills and some non-descript grain on the stummel briar. However, I was surprised to note that there is just a single fill in the stummel surface that’s already loosened (encircled in pastel pink). The stummel surface boasts of some beautiful cross grains around the front, back and over the shank surface while tightly packed Bird’s eye adorns the sides and foot of the bowl. The stummel surface is covered in dirt and grime giving the stummel a dull and oily appearance. The surface shows a few scratches, dents and dings (indicated in red). The mortise shows accumulation of old oils and tars which would need to be cleaned.

Note: – The loose fill will need to be refreshed with a mix of CA superglue and briar dust. Light sanding of the stummel with a piece of 220 grit sand paper should address the minor scratches and dings over the surface. A nice polish with micromesh grit pads will bring a nice shine to the stummel and highlight the grains. It does have a quality which is seen on vintage pipes in terms of perfection in size, briar material, quality of stem and perfectly centered draught hole drilled right at the bottom of the chamber. And not to forget, this is nearly a 50 plus year old pipe!!

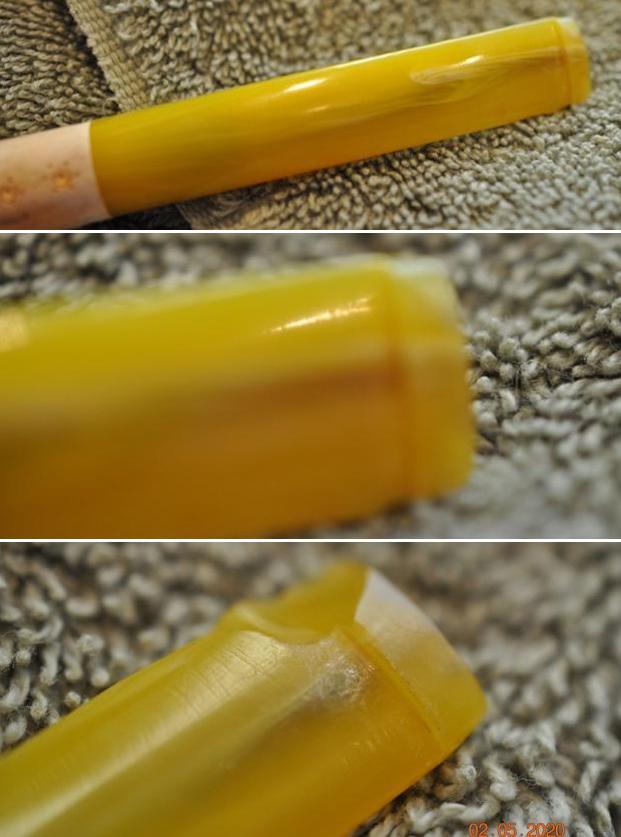

The vulcanite saddle stem is heavily oxidized, but otherwise in a decent condition. The bite zone on either surface shows some minor tooth indentations with a small amount of calcification at the base of the button edge. The button edges on either surface have worn down with minor bite marks. The horizontal slot and stinger openings show accumulation of dried oils and tars. There is a gap at the stinger head, between the top nut and the shoulder of the stinger (indicated by red arrows), where the leather washer is seated.

The vulcanite saddle stem is heavily oxidized, but otherwise in a decent condition. The bite zone on either surface shows some minor tooth indentations with a small amount of calcification at the base of the button edge. The button edges on either surface have worn down with minor bite marks. The horizontal slot and stinger openings show accumulation of dried oils and tars. There is a gap at the stinger head, between the top nut and the shoulder of the stinger (indicated by red arrows), where the leather washer is seated.

Note: The button edges will need to be sharpened and reshaped. The gap at the stinger head will be covered with the leather washer. All in all, the stem presents no major damage and should be an easy clean up. The Process

The Process

I started the restoration by reaming the chamber with size 2 followed by size 3 head of the PipNet reamer as I was keen to know the condition of the walls of the chamber. With my sharp fabricated knife, I removed the cake from the chamber where the reamer head could not reach and thereafter, using a folded piece of 180 grit sand paper, I sanded out the last traces of cake and exposed the walls of the chamber. I wiped the chamber with a cotton swab dipped in isopropyl alcohol to remove the carbon dust left behind by all the reaming and sanding process. Once the chamber walls were cleaned out, I was pleased to note a solid chamber. With the same sharp knife, I gently scraped off the lava overflow from the rim top surface. It was a big relief to note that the suspected charring in 6 o’clock and 12 o’clock direction is non-existent and the beveled inner rim edge has just darkened as a result of the lighting habits of my grandfather. However, the damage to the outer rim edge is very much a reality and will need to be addressed. Next, I cleaned out the internals of the shank and mortise. Using my dental tool, I scraped out all the dried oils, tars and gunk that had accumulated in the draught hole and on the walls of the mortise. The amount of crud that was scrapped out is an indicator as to how dirty the shank internal is.

Note: The darkened and uneven beveled inner rim edge and the dents/ dings to the rim top surface are now clearly seen. These issues should be easily addressed by topping and light sanding of the existing inner edge bevel. Similarly, the outer rim edge issue would be reduced after topping and what chipped areas remain will be masked by creating a light delicate bevel. The ghosting is still prevalent and will, in all probability, require invasive methods to completely eliminate it.

I continued the cleaning of the chamber and shank internals with a salt and alcohol bath. I usually use cotton balls which is an at par substitute to Kosher salt as I have realized over the years. I drew out a wick from the cotton and along with a folded regular pipe cleaner; inserted it in to the mortise and through the draught hole into the chamber. Thereafter, I packed the chamber with cotton balls to about quarter of an inch below the inner rim edge and filled it with isopropyl alcohol up to the brim. About half an hour later, the level of alcohol had gone down, having been absorbed by the cotton. I topped it up once again with isopropyl alcohol and set it aside overnight. By next afternoon, the cotton was dark colored and with alcohol, had drawn out all the remaining oils and tars from the chamber and mortise, fulfilling its intended task. I removed the cotton balls from the chamber and the pipe cleaner with cotton from the shank and ran pipe cleaners through the mortise to clean out all the loosened tars and gunk. I further cleaned the mortise and chamber by scarping the walls with a dental tool and knife respectively, to completely remove the gunk. I blew through the draught hole to dislodge the trapped gunk, wiped the bowl clean and dried the shank and bowl with paper napkins and set it aside to dry for an entire day. By next day, the pipe was nice and dry and all the smells were history.

I continued the cleaning of the chamber and shank internals with a salt and alcohol bath. I usually use cotton balls which is an at par substitute to Kosher salt as I have realized over the years. I drew out a wick from the cotton and along with a folded regular pipe cleaner; inserted it in to the mortise and through the draught hole into the chamber. Thereafter, I packed the chamber with cotton balls to about quarter of an inch below the inner rim edge and filled it with isopropyl alcohol up to the brim. About half an hour later, the level of alcohol had gone down, having been absorbed by the cotton. I topped it up once again with isopropyl alcohol and set it aside overnight. By next afternoon, the cotton was dark colored and with alcohol, had drawn out all the remaining oils and tars from the chamber and mortise, fulfilling its intended task. I removed the cotton balls from the chamber and the pipe cleaner with cotton from the shank and ran pipe cleaners through the mortise to clean out all the loosened tars and gunk. I further cleaned the mortise and chamber by scarping the walls with a dental tool and knife respectively, to completely remove the gunk. I blew through the draught hole to dislodge the trapped gunk, wiped the bowl clean and dried the shank and bowl with paper napkins and set it aside to dry for an entire day. By next day, the pipe was nice and dry and all the smells were history.

With the stummel set aside for drying, I turned to address the stem issues. I addressed the deeper oxidation by sanding the entire stem with a folded piece of 220 grit sand paper. Once the oxidation was completely removed, I wiped the surface clean with Murphy’s oil soap on a cotton swab. I cleaned up the oils and tars from the surface of the stinger using alcohol on cotton pads followed by Murphy’s Oil soap. I followed it up with cleaning the internals of the stem using hard and normal bristled pipe cleaners and isopropyl alcohol. The gunk that came out with the pipe cleaners tells the sordid tale of the stem condition. To save on to the requirement of number of pipe cleaners, I have resorted to cleaning the stem internals using thin shank brushes with anti-oil dish washing soap and finally rinsing the stem with warm water to clean and freshen up the stem internals. With a pointed dental tool, I scraped out the entire dried gunk from the horizontal slot. I rubbed a little Extra Virgin Olive oil to hydrate the stem and kept it aside.

With the stummel set aside for drying, I turned to address the stem issues. I addressed the deeper oxidation by sanding the entire stem with a folded piece of 220 grit sand paper. Once the oxidation was completely removed, I wiped the surface clean with Murphy’s oil soap on a cotton swab. I cleaned up the oils and tars from the surface of the stinger using alcohol on cotton pads followed by Murphy’s Oil soap. I followed it up with cleaning the internals of the stem using hard and normal bristled pipe cleaners and isopropyl alcohol. The gunk that came out with the pipe cleaners tells the sordid tale of the stem condition. To save on to the requirement of number of pipe cleaners, I have resorted to cleaning the stem internals using thin shank brushes with anti-oil dish washing soap and finally rinsing the stem with warm water to clean and freshen up the stem internals. With a pointed dental tool, I scraped out the entire dried gunk from the horizontal slot. I rubbed a little Extra Virgin Olive oil to hydrate the stem and kept it aside.

Continuing with the stem refurbishing, I heated the bite zone with the flame of a lighter to raise the tooth indentations to the surface. Though the issue was addressed to a great extent, one bite mark on both surfaces (encircled in yellow) along with damage to the button edge (indicated in pastel blue) was still evident. The button edges and deeper tooth indentations on either surface of the stem were filled with a mix of CA superglue and activated charcoal powder and set aside for the fill to cure.

Continuing with the stem refurbishing, I heated the bite zone with the flame of a lighter to raise the tooth indentations to the surface. Though the issue was addressed to a great extent, one bite mark on both surfaces (encircled in yellow) along with damage to the button edge (indicated in pastel blue) was still evident. The button edges and deeper tooth indentations on either surface of the stem were filled with a mix of CA superglue and activated charcoal powder and set aside for the fill to cure. With the stem repairs set aside for curing, I decided to clean the external surface of the stummel. I used a hard bristled tooth brush and Murphy’s Oil Soap to scrub the stummel and rim top. I further scrubbed the rim top surface with a brass bristled brush to completely remove the dirt and grime from the rim surface. I rinsed the stummel under running warm water. I cleaned the stummel with anti oil dish washing detergent till the stummel surface was clean and dried it using paper towels and soft cotton cloth.

With the stem repairs set aside for curing, I decided to clean the external surface of the stummel. I used a hard bristled tooth brush and Murphy’s Oil Soap to scrub the stummel and rim top. I further scrubbed the rim top surface with a brass bristled brush to completely remove the dirt and grime from the rim surface. I rinsed the stummel under running warm water. I cleaned the stummel with anti oil dish washing detergent till the stummel surface was clean and dried it using paper towels and soft cotton cloth.

I simultaneously cleaned the shank internals with the detergent and hard bristled shank brush and set the stummel aside to dry out naturally.

I simultaneously cleaned the shank internals with the detergent and hard bristled shank brush and set the stummel aside to dry out naturally. While the stummel was set aside for drying, I decided to complete the stem repairs and refurbishing. With a flat head needle file, I sanded the stem fills on either surface till I had achieved a rough match with the rest of the stummel surface. I reshaped and sharpened the button edges with the same flat needle file. The filled surface and button edges were worked upon with a piece of 220 grit sand paper to further blend in the repairs. I followed it up by further dry sanding the stem with 400, 600, 800 and wet sanding with 1000 grit sand papers to completely rid the surface of the oxidation and bring out the shine in the vulcanite. I applied a little EVO to stem surface to hydrate it and set it aside.

While the stummel was set aside for drying, I decided to complete the stem repairs and refurbishing. With a flat head needle file, I sanded the stem fills on either surface till I had achieved a rough match with the rest of the stummel surface. I reshaped and sharpened the button edges with the same flat needle file. The filled surface and button edges were worked upon with a piece of 220 grit sand paper to further blend in the repairs. I followed it up by further dry sanding the stem with 400, 600, 800 and wet sanding with 1000 grit sand papers to completely rid the surface of the oxidation and bring out the shine in the vulcanite. I applied a little EVO to stem surface to hydrate it and set it aside.

While the stem was set aside to absorb the EVO, I addressed the issue of one single fill in the entire stummel surface. I removed the old fill from the surface with a sharp dental tool and cleaned the area with isopropyl alcohol in preparation for refreshing the fill. Since the area to be filled was very minute, I decided to fill it with a drop of CA superglue alone. Once that was done, I set the stummel aside for the fill to cure.

While the stem was set aside to absorb the EVO, I addressed the issue of one single fill in the entire stummel surface. I removed the old fill from the surface with a sharp dental tool and cleaned the area with isopropyl alcohol in preparation for refreshing the fill. Since the area to be filled was very minute, I decided to fill it with a drop of CA superglue alone. Once that was done, I set the stummel aside for the fill to cure. Once the stummel fill had cured, I sanded it first with a flat needle file and followed it up with a piece of 220 grit sand paper. Simultaneously, I sanded the entire stummel surface with the 220 grit paper to eliminate the minor scratches and dings from the surface.

Once the stummel fill had cured, I sanded it first with a flat needle file and followed it up with a piece of 220 grit sand paper. Simultaneously, I sanded the entire stummel surface with the 220 grit paper to eliminate the minor scratches and dings from the surface. The next stummel issue that I addressed was of uneven rim top and damages to the rim edges. I decided to address the issue of uneven and darkened rim top surface by topping the rim surface on a piece of 220 grit sand paper. The progress being made was frequently checked as I had no desire to lose any briar estate than was absolutely necessary. Once satisfied with the result, I wiped the rim top surface with a moist cloth. The darkened rim top had been addressed completely, however, the beveled inner rim edge was still dark and uneven (though greatly reduced) with slight charred edges. I addressed these issues by simply running a piece of 220 grit sand paper along the inner rim edge bevel, till the darkening was eliminated. I created a delicate but sharp bevel to the outer edge for a smooth and an evenly rounded outer edge. However, I was extremely careful that the profile of the stummel was not altered with the creation of the bevel.

The next stummel issue that I addressed was of uneven rim top and damages to the rim edges. I decided to address the issue of uneven and darkened rim top surface by topping the rim surface on a piece of 220 grit sand paper. The progress being made was frequently checked as I had no desire to lose any briar estate than was absolutely necessary. Once satisfied with the result, I wiped the rim top surface with a moist cloth. The darkened rim top had been addressed completely, however, the beveled inner rim edge was still dark and uneven (though greatly reduced) with slight charred edges. I addressed these issues by simply running a piece of 220 grit sand paper along the inner rim edge bevel, till the darkening was eliminated. I created a delicate but sharp bevel to the outer edge for a smooth and an evenly rounded outer edge. However, I was extremely careful that the profile of the stummel was not altered with the creation of the bevel.

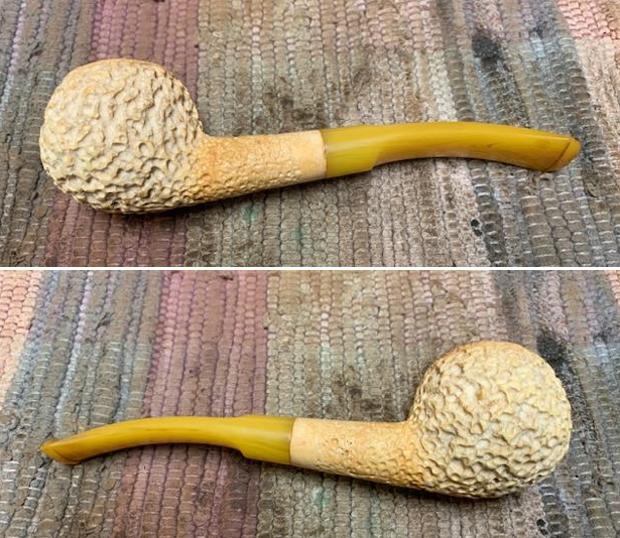

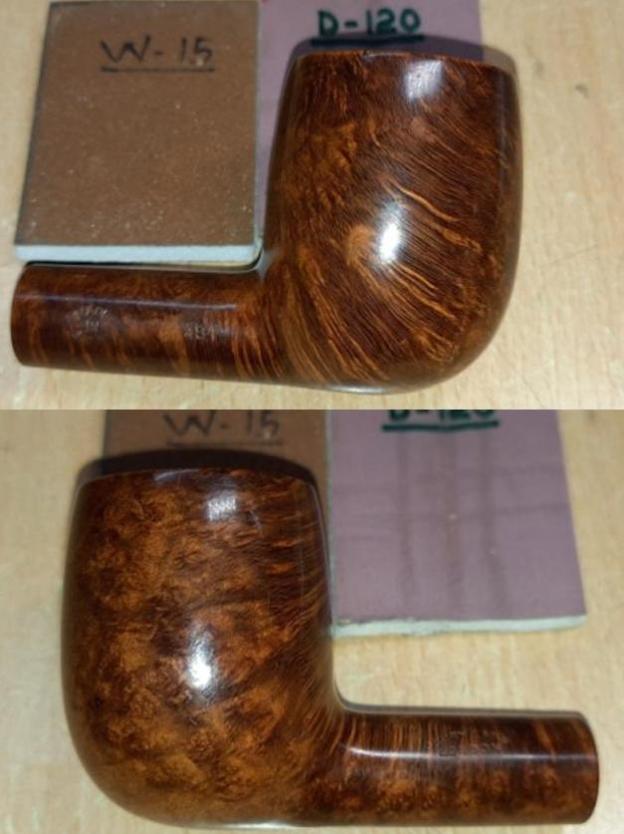

I subjected the stummel to a complete cycle of micromesh polish, dry sanding with 1500 to 12000 grit pads. I paid greater attention to polish the rim top surface and the bevel created on the inner and outer rim edge. I wiped the stummel with a moist cloth after every grit pad to remove the sanding dust left behind by the pads. This also helps in monitoring the progress being made and provides an opportunity to take early corrective action, if required. I was happy with the progress being made till now. The briar had taken on a nice deep shine with the original natural brown of the stummel and the darker brown stains to the grains contrasting beautifully. I really liked the dark brown coloration and the patina that was seen over the stummel surface.

I subjected the stummel to a complete cycle of micromesh polish, dry sanding with 1500 to 12000 grit pads. I paid greater attention to polish the rim top surface and the bevel created on the inner and outer rim edge. I wiped the stummel with a moist cloth after every grit pad to remove the sanding dust left behind by the pads. This also helps in monitoring the progress being made and provides an opportunity to take early corrective action, if required. I was happy with the progress being made till now. The briar had taken on a nice deep shine with the original natural brown of the stummel and the darker brown stains to the grains contrasting beautifully. I really liked the dark brown coloration and the patina that was seen over the stummel surface.

Next, I rubbed a small quantity of “Before and After Restoration Balm” into the briar with my finger tips and worked it deep in to the surface and let the balm be absorbed by the briar for a few minutes. The balm almost immediately works its magic and the briar now has a nice vibrant appearance with the beautiful straight and Bird’s eye grain patterns on full display. The contrast of the dark browns of the grain with the light brown hues of the rest of the stummel adds an interesting dimension to the appearance of the stummel. I further buffed it with a horse hair brush to further deepen the shine.

Next, I rubbed a small quantity of “Before and After Restoration Balm” into the briar with my finger tips and worked it deep in to the surface and let the balm be absorbed by the briar for a few minutes. The balm almost immediately works its magic and the briar now has a nice vibrant appearance with the beautiful straight and Bird’s eye grain patterns on full display. The contrast of the dark browns of the grain with the light brown hues of the rest of the stummel adds an interesting dimension to the appearance of the stummel. I further buffed it with a horse hair brush to further deepen the shine.

Using micromesh pads, I completed the polishing of the stem by wet sanding the stem surface with 1500 to 12000 girt pads. I gave a final rub with “Before and After Extra Fine” stem polish compound from Mark Hoover to remove fine scratches from the stem surface. I rubbed a little quantity of Extra Virgin Olive oil in to the stem surface and set it aside to be absorbed by the vulcanite. The stem polished up nicely and appears as good as when new.

Using micromesh pads, I completed the polishing of the stem by wet sanding the stem surface with 1500 to 12000 girt pads. I gave a final rub with “Before and After Extra Fine” stem polish compound from Mark Hoover to remove fine scratches from the stem surface. I rubbed a little quantity of Extra Virgin Olive oil in to the stem surface and set it aside to be absorbed by the vulcanite. The stem polished up nicely and appears as good as when new. The only repair aspect that remained was replacing the leather washer in the stinger head. Steve, my Guru/ Mentor/ Friend, had spared me two size 5 leather washers, for this pipe and other for Comoy’s “Grand Slam”. These leather washers will be put to good use, I assure you Steve!!

The only repair aspect that remained was replacing the leather washer in the stinger head. Steve, my Guru/ Mentor/ Friend, had spared me two size 5 leather washers, for this pipe and other for Comoy’s “Grand Slam”. These leather washers will be put to good use, I assure you Steve!!

I soaked one leather washer in water to make it soft and more pliable. Carefully unscrewing the top nut (I had broken the top nut on the stinger of Grand Slam while trying to unscrew and the memory of the pain is still vivid), I fixed the leather washer and gently tightened the top nut. With a piece of 220 grit sand paper, I sanded off the excess leather material from the washer, frequently checking for the seating of the stinger into the mortise (remember my mantra… SAND ONCE, CHECK TWICE!). Once the seating was snug and just perfect, I stopped any further sanding and applied petroleum jelly to the washer to keep it moist and pliable. To put the finishing touches, I mounted a cotton cloth buffing wheel onto my hand held rotary tool and polished the stummel and stem with Blue Diamond compound. This compound helps to remove the minor scratch marks that remain from the sanding. Next, I mounted another cotton buffing wheel that I have earmarked for carnauba wax and applied several coats of the wax. I mounted a clean cotton cloth buffing wheel and gave the entire pipe a once over buff. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. The finished pipe with the aged patina to the briar looks amazingly beautiful and now all that remains for me is to load it with some Regent’s Flake and get transported back in time when things were a bit more contemplative and people had time for each other… time to share!!

To put the finishing touches, I mounted a cotton cloth buffing wheel onto my hand held rotary tool and polished the stummel and stem with Blue Diamond compound. This compound helps to remove the minor scratch marks that remain from the sanding. Next, I mounted another cotton buffing wheel that I have earmarked for carnauba wax and applied several coats of the wax. I mounted a clean cotton cloth buffing wheel and gave the entire pipe a once over buff. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. The finished pipe with the aged patina to the briar looks amazingly beautiful and now all that remains for me is to load it with some Regent’s Flake and get transported back in time when things were a bit more contemplative and people had time for each other… time to share!!

P.S. The completion of this project would not have been possible without the help that was extended by Steve and I am really thankful to him.

P.S. The completion of this project would not have been possible without the help that was extended by Steve and I am really thankful to him.

Praying for the health and safety of all the readers and their loved ones in these troubled times…