Blog by Al Jones

Followers of this blog are no doubt very familiar with Steve Laug’s wonderful “Father Tom” short stories. For those not familiar with Father Tom, he is fictional well seasoned, pipe smoking minister.

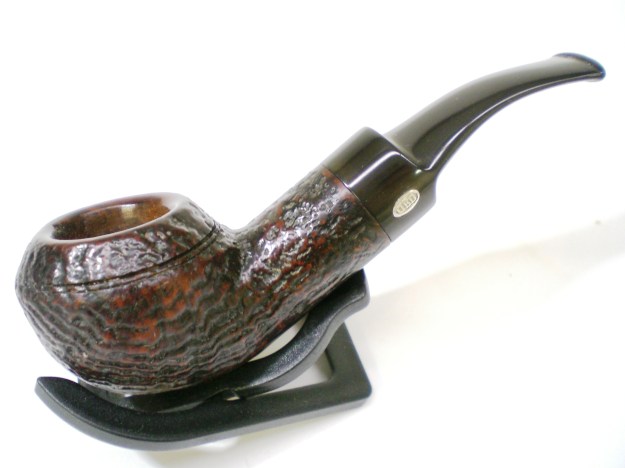

On the “Brothers of Briar” pipe forum and we are fortunate to have a real life “Father Tom” as a member. Father Tom is an Episcopal priest in Northern Indiana. He taught for 32 years before leaving the classroom for full-time parish work. He has been a pipe smoker since college, and most of his college pipes are still in the rotation. The pipe is one he bought in the late 70’s in South Carolina. Tom posted a picture of this pipe earlier this summer on the forum and wondered if the finish could be restored. Tom had recently returned from a church assignment to the Honduras. The pipe was very much well-loved and the varnished finish was worn off in the handling areas. The stem was also heavily oxidized. Tom reported that it smoked Granger quite well. Here is the pipe as it was delivered.

Steve sent me some information on a Wellington brand pipe and this one appears to be a reproduction of that and the Peterson system pipe, including a p-lip military stem. The pipe is stamped “Pietro”. Steve told me that these stems had a reputation of being drilled close to the edge of the stem near the bend. As such, over time, the use of a pipe cleaner wears the stem material thin. Sure enough, after I started to remove the oxidation, there was a small hole and crack on the top of the stem bend. I wasn’t sure the stem could be saved but I thought that perhaps several layers of black superglue blended in would rebuild that area. In total, I applied four light coats of the superglue, raising the surface about 1 mm and covering the hold. The crack still shows thru the material but I think it should hold up to some use. But, I advised Father Tom to be careful clenching that one. At some point a new stem will have to be made for the pipe.

This shows the repair in progress with the black superglue (purchased from Stewart-Mac, a guitar repair supply house).

I finished the stem by removing the heavy oxidation first with 600 grit wet sandpaper, than moving to the 800, 1000, 1500 and 2000 grades. I used 8000 and 12000 grades of micromesh to complete that step. Than, with the stem mounted in the briar, it was buffed with white diamond rouge, than a automotive plastic polish.

I then moved my attention to the briar. I first soaked the briar in an alcohol bath in an attempt to soften the varnished finish. That had some effect, but it was necessary to sand most of the shiny varnish off by hand. I used 600 grit paper and progress up to 1500 grade wet paper. There was one large gash on the bottom of the bowl and one large fill spot, where the putty had fallen out. Not surprisingly, there were other fills on the briar under that finish. I was able to lift out the dent using a heated kitchen knife and steam. I repaired the fill hold with some of the black superglue. Sometimes I think covering the fills looks worse than leaving them and I thought the others lent some character to the pipe that Tom had given the briar (they might have also been handling dings, etc.)

I used a two step process to apply the stain to the briar. First I warmed the bowl with a hair dryer and then brushed on a coat of black stain. I lit the stain with flame to set it into the grain. The black stain was then sanded off with a series of sandpaper, starting again at 800 grit. I then applied a very light, almost neutral brown stain over the black. The bowl was then buffed with white diamond rouge and several coats of carnuba wax. While hand buffing the carnuba wax, I almost had a tragic accident with the pipe – it slipped out of my hands and bounced off my concrete workshop floor. I was horrified but was somewhat relieved to see no visible damage. It was only in the final hand polishing did I notice that the fall had put a dent in the metal cap. Steve shared with me a technique to heat the cap (once removed) and use a wooden dowel shaped into the half-circle to work out dents. Unfortunately, even using heat, I was unable to remove the cap. After discussion with the gracious Father Tom, it was decided to leave well enough alone. I will be picking up a padded piece of carpet to place in front of my work bench.

Below is the finished pipe. My grandfather was also a minister, but didn’t smoke a pipe. I would often watch him in his study poring over notes for his next sermon or wrestling with the day-to-day issues that a pastor faces. While working thru this restoration, I could picture Father Tom thoughtfully puffing on pipe as he completed his pastoral duties. I imagine it has been with him thru many weighty challenges faced by a modern minister. I hope this reborn pipe will be with him for many more years and help work thru the challenges of that endeavor.