Blog by Steve Laug

The next pipe was another surprise to Jeff and me when we bought it from the fellow in Copenhagen, Denmark on November 10, 2022. It is a sandblast Calabash with a smooth rim top and a silver ring around the outer edge of the bowl. The stem is vulcanite and the ring is Sterling Silver. The pipe is stamped S. Bang [over] Copenhagen on a smooth oval on the underside of the shank. Under that is over another smooth patch, a rectangle stamped with Handmade [over] In Denmark. The Sterling Silver around the outer edge of the bowl is not stamped. The bowl had a thick cake with some lava overflow on the rim top and inwardly beveled inner edge of the bowl. There was some damage on the inner edge and bevel. The silver was oxidized and darkened. The finish on the bowl was dirty but also seemed to have a very shiny coat on it. The vulcanite taper stem is oxidized, dirty and had tooth chatter and marks on the top and underside of the stem ahead of the button. It came with a leather bag stamped S. Band over Kobenhavn in gold on the front of it. Jeff took these photos of the pipe before he started his cleanup work.

He took photos of the rim and bowl to show the thick cake and lava coat covering the rim top. It really was filthy and a mess. The photos show the damage to the rim top and beveled inner edge. There are also scratches on the rim top at the front and back of the bowl. He also took photos of the stem surfaces to show its overall condition when it arrived.

He took photos of the rim and bowl to show the thick cake and lava coat covering the rim top. It really was filthy and a mess. The photos show the damage to the rim top and beveled inner edge. There are also scratches on the rim top at the front and back of the bowl. He also took photos of the stem surfaces to show its overall condition when it arrived.

The photos of the sides and heel of the bowls show beautiful blast around the bowl and shank sides. The rich brown stains highlights the grain and adds depth to the finish. It shows some promise.

The photos of the sides and heel of the bowls show beautiful blast around the bowl and shank sides. The rich brown stains highlights the grain and adds depth to the finish. It shows some promise.

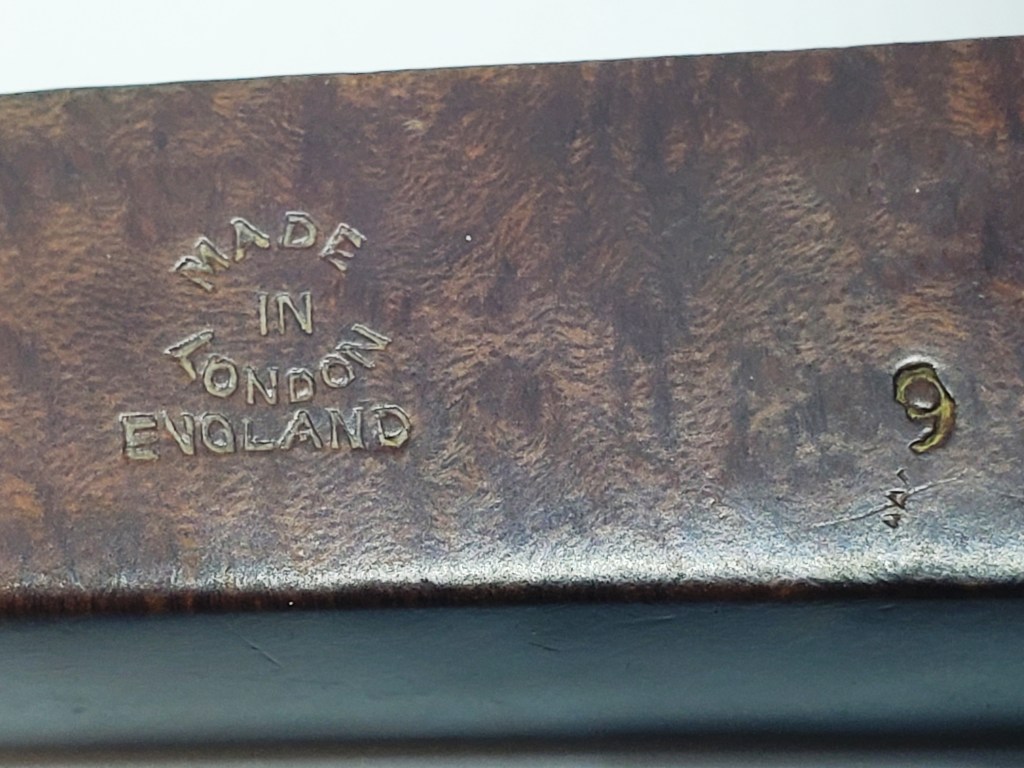

He also took photos of the stamping on the smooth panels on the underside of the shank. It took several photos to capture the stamp on the curve but they were clear and read as noted above.

He also took photos of the stamping on the smooth panels on the underside of the shank. It took several photos to capture the stamp on the curve but they were clear and read as noted above.  The leather pipe sock is stamped in gold and reads as follows:

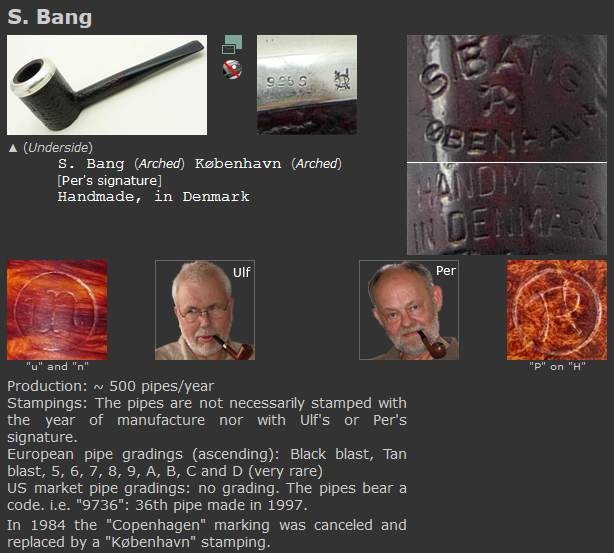

The leather pipe sock is stamped in gold and reads as follows: To help me understand the stamping a bit more I turned to Pipephil’s site and read what it said about S. Bang pipes (http://pipephil.eu/logos/en/logo-s1.html). I have included a screen capture of the section below as well as the side bar information below the capture.

To help me understand the stamping a bit more I turned to Pipephil’s site and read what it said about S. Bang pipes (http://pipephil.eu/logos/en/logo-s1.html). I have included a screen capture of the section below as well as the side bar information below the capture.  Sven Bang opened his tobacco and pipe shop in 1968 in Copenhagen. He was more a business man than a pipe carver and began to hire pipemakers. About half a dozen succeeded each other in his workshop during the 1970’s (Ivan Holst Nielsen, Jan Wideløv, Phil Vigen…). At least Per Hansen and Ulf Noltensmeier stayed and when Sven retired in 1983 they took over the company (in 1984) keeping its name.

Sven Bang opened his tobacco and pipe shop in 1968 in Copenhagen. He was more a business man than a pipe carver and began to hire pipemakers. About half a dozen succeeded each other in his workshop during the 1970’s (Ivan Holst Nielsen, Jan Wideløv, Phil Vigen…). At least Per Hansen and Ulf Noltensmeier stayed and when Sven retired in 1983 they took over the company (in 1984) keeping its name.

I knew from that the pipe I have was made for the European market and was known as a Black Blast. I also knew that it was made before 1984 when the stamp Copenhagen was replaced with Kobenhavn. It is also the time when Ulf and Per took over the company so it was made by one of them.

To close my understanding of the pipe I turned to Pipedia (https://pipedia.org/wiki/S._Bang). I quote the section from the article where the company changed hands from S. Bang to Hansen and Noltensmeier in 1984. It is a great read so I have included it below.

Svend Bang retired in 1984. Evidently he felt a great deal of pride in the product that he initiated throughout his career and retirement and until his death in 1993.

Once Hansen and Noltensmeier took over the company (in 1984) they knew it was best to retain the S. Bang name – the two carvers always shared the same philosophy about that. Noltensmeier and Hansen were determined to maintain top quality at the expense of increased numbers. The only change they made concerns the stamping on the pipes changing from the English version “COPENHAGEN” to the Danish “KOBENHAVN”.

Still, they are two separate carvers, with their own styles and preferences. Each makes his own pipes – there is no “assembly line” construction at S. Bang. They bounce ideas off of each other, of course, and admit that when problems arise in a pipe, it is nice to have a partner to discuss them with.

Though they carve pipes as individuals, there are similarities in their work. All Bang pipes are made with black, hand-cut vulcanite stems.

The same engineering is used by both carvers as well. The shape and size of the tobacco chambers vary according to size and design of the pipe, but each carver follows the same design guidelines for choosing the proper chamber dimensions. The smoke channel is always engineered for optimum performance.

Bang pipes are noted for the high definition and fine contrast in the grain. They undergo a double staining process to achieve that effect. The technique makes the grain leap from the bowl of the pipe, making well-grained wood become extra ordinary. The same coloring, however, will produce different results in different pieces of briar, making each pipe truly individual.

Per Hansen is the designated sandblasting artist for the team. He personally takes those pieces that are to be sandblasted to Stanwell, and is permitted to use the sandblasting equipment himself. That is the only S. Bang process, though, that is not executed by the individual carver of each pipe. Everything else, including the famous S. Bang silverwork, is done in the shop by each of the carvers on his own pipes.

Jeff cleaned up the pipe for me. He reamed the bowl with a PipNet pipe reamer and cleaned it up with a Savinelli Fitsall Pipe Knife. He scrubbed the exterior with Murphy’s Oil Soap and a tooth brush to clean off the grime off the finish and the overflow of lava on the rim top. The cleaning had removed the debris on the rim top. He cleaned up the internals of the shank, mortise and stem with pipe cleaners, cotton swabs and alcohol to remove all of the oils and tars in the pipe. He soaked the stem in Before & After Deoxidizer and was able to remove much of the oxidation, calcification. When it arrived here in Vancouver it was a clean pipe and I knew what I had to work with. I took photos of it before I started my part of the restoration.

I took a photo of the rim top and the stem to show their condition once it arrived in Canada. Jeff was able to clean up the cake and the lava overflow that was shown in the rim and bowl photos above. The rim top and the inner edge of the bowl showed some damage to the inner edge and top toward the front of the bowl. He was also able to get rid of the grime and grit in the surface of the briar. The stem looked better, though there were tooth marks and chatter on both sides near the button.

I took a photo of the rim top and the stem to show their condition once it arrived in Canada. Jeff was able to clean up the cake and the lava overflow that was shown in the rim and bowl photos above. The rim top and the inner edge of the bowl showed some damage to the inner edge and top toward the front of the bowl. He was also able to get rid of the grime and grit in the surface of the briar. The stem looked better, though there were tooth marks and chatter on both sides near the button. I took a photo of the stamping on the underside of the shank. It reads as noted above.

I took a photo of the stamping on the underside of the shank. It reads as noted above. I removed the stem from the shank and took a photo of the parts to give a sense of what the pipe looks like.

I removed the stem from the shank and took a photo of the parts to give a sense of what the pipe looks like. I started my work on the bowl by dealing with the burn damage on the inner edge and rim top. I followed the bevel on the inner edge and removed the burn damage while cleaning the bevel using 220 grit sandpaper. Once I got the bevel cleaned up and the rim damage removed I burn and the scratches on the rim top with 220 grit sandpaper. I smoothed out the repairs with a 1500 grit micromesh sanding pad.

I started my work on the bowl by dealing with the burn damage on the inner edge and rim top. I followed the bevel on the inner edge and removed the burn damage while cleaning the bevel using 220 grit sandpaper. Once I got the bevel cleaned up and the rim damage removed I burn and the scratches on the rim top with 220 grit sandpaper. I smoothed out the repairs with a 1500 grit micromesh sanding pad.

I polished the rim top and silver rim edge with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped it down after each sanding pad with a damp cloth to remove the sanding debris.

I polished the rim top and silver rim edge with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped it down after each sanding pad with a damp cloth to remove the sanding debris.

I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean them. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. While I was rubbing it down with the Balm a chunk of the shank fell out in my hand. There must have been cracks in the shank as the stem was loose before. It is frustrating when that happens. I repaired the cracks with clear CA glue and pressed the piece back into the shank.

I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean them. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. While I was rubbing it down with the Balm a chunk of the shank fell out in my hand. There must have been cracks in the shank as the stem was loose before. It is frustrating when that happens. I repaired the cracks with clear CA glue and pressed the piece back into the shank. Once the repair cured I sanded the shank end smooth to hold a silver band. I sanded the depth of the band and removed half of the depth of the band. It would look good once it was pressed in place on the shank end. I coated the shank end with all purpose glue and heated and pressed the band on to the shank end.

Once the repair cured I sanded the shank end smooth to hold a silver band. I sanded the depth of the band and removed half of the depth of the band. It would look good once it was pressed in place on the shank end. I coated the shank end with all purpose glue and heated and pressed the band on to the shank end.

I stained the sanded areas on the shank just ahead of the band with a Walnut stain pen to blend them into the surrounding briar. It looks very good.

I stained the sanded areas on the shank just ahead of the band with a Walnut stain pen to blend them into the surrounding briar. It looks very good.

I rubbed the bowl and shank down once again with Before & After Restoration Balm to deep clean them. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine.

I rubbed the bowl and shank down once again with Before & After Restoration Balm to deep clean them. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine.

I set aside the bowl and turned my attention to the damage on the stem. I painted the stem surface with the flame of a lighter to lift the tooth marks. I lifted them some. I filled in what remained of the marks on both sides with black CA glue. I set it aside to cure.

I set aside the bowl and turned my attention to the damage on the stem. I painted the stem surface with the flame of a lighter to lift the tooth marks. I lifted them some. I filled in what remained of the marks on both sides with black CA glue. I set it aside to cure.  Once the repairs cured I flattened them out with a small file. I sanded the repairs with 220 grit sandpaper to blend them into the stem surface. I started polishing it with 400 grit wet dry sandpaper.

Once the repairs cured I flattened them out with a small file. I sanded the repairs with 220 grit sandpaper to blend them into the stem surface. I started polishing it with 400 grit wet dry sandpaper.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with a damp cloth to remove the sanding dust. I gave it a further polish with Before & After Stem Polish – both Fine and Extra Fine. I finished by wiping the stem down with a final coat of Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with a damp cloth to remove the sanding dust. I gave it a further polish with Before & After Stem Polish – both Fine and Extra Fine. I finished by wiping the stem down with a final coat of Obsidian Oil and set it aside to dry.

I put the stem back on the S. Bang Black Sandblast Calabash and took the pipe to the buffer. I buffed the bowl and stem with Blue Diamond to polish the briar and the vulcanite. Blue Diamond does a great job on the smaller scratches that remain in both. I gave the bowl and the stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. Considering the mess the pipe was when we received it and the surprise of a cracked shank that appeared in the cleanup, I am amazed at how well it turned out. The finished pipe is shown in the photos below. This is a beautiful S. Bang Sandblast Calabash – the vulcanite taper stem and rim top and sandblast finish combine to give the pipe a great look. The newly fitted silver band and the polished black, vulcanite stem looks really good with the rich grain standing out on the bowl and shank. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¾ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.48 ounces/43 grams. This beautiful S. Bang will be staying with me for awhile. Thanks for walking through the restoration with me on this beauty!

I put the stem back on the S. Bang Black Sandblast Calabash and took the pipe to the buffer. I buffed the bowl and stem with Blue Diamond to polish the briar and the vulcanite. Blue Diamond does a great job on the smaller scratches that remain in both. I gave the bowl and the stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. Considering the mess the pipe was when we received it and the surprise of a cracked shank that appeared in the cleanup, I am amazed at how well it turned out. The finished pipe is shown in the photos below. This is a beautiful S. Bang Sandblast Calabash – the vulcanite taper stem and rim top and sandblast finish combine to give the pipe a great look. The newly fitted silver band and the polished black, vulcanite stem looks really good with the rich grain standing out on the bowl and shank. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¾ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.48 ounces/43 grams. This beautiful S. Bang will be staying with me for awhile. Thanks for walking through the restoration with me on this beauty!