Blog by Greg Wolford

A week or so ago I went into a local antique shop that houses a variety of vendors. In the past I have found a few decent pipes here so I always have high hopes when I go there. This trip yielded a nice little haul of four pipes which I plan to restore over the next few weeks as i have time. The first two have already been started one: one completed and one still in the process. This post will mainly focus on a Dublin shape that is stamped on the shank Handmade over Denmark, with no other information on the pipe or stem. This is the pipe as it looked when I got it home:

As you can see, it was heavily caked and had what I thought were some deep scratches on it, the rim was charred and damaged from knocking out the dottle, the finish was gone, and the stem was oxidized but had little chatter on it. I decided to start with reaming the back the cake. This bowl is a tapered one, as many Dublins are, and required the use of all four of the bits on my Castleford reamer. After reaming the cake back considerably, to an even, thin layer, I decided to sanitize it with my retort. And since one of the other of the lot I picked up needed very little work other than cleaning (or so I thought at the time) I decided to go ahead and retort it (no reaming needed on this one) while I had the equipment out and also do both stems at this time, too. The Dublin took several “runs” with the retort to produce a clean tube of alcohol at the end; the cherrywood that I was also doing only took two tubes, but I knew it hadn’t been used much and wouldn’t be very dirty.

After I finished the work with the retort I dropped the stems in a OxyClean bath and left them to soak while I cleaned the shanks out. The retort had done a nice job of taking out most of the gunk in the shank of the Dublin; it took comparatively fewer pipe cleaners and cotton swabs than most restorations. I expected the shank from the cherrywood to be all but clean with one or two passes and it sort of was; instead of tar I found the alcohol had “raised” a mahogany-like stain inside the shank – and a lot of it. I then noticed that there was some of this same color on the outside, bottom edge of the shank. The pipe itself wasn’t a reddish color but a more maple, orange-ish one and I hadn’t planned on refinishing it since the color was nice and I didn’t really see a need – until now. Once I noticed the red color it had to come off the outside and out of the shank. Now the entire finish was going to have to be removed so both pipes got wiped down several time with acetone and then put into the alcohol bath overnight.

Several hours later I removed the stems from their soak to begin to make them look new again. I was disappointed to see that the thin layer of petroleum jelly I’d put over the logo on the cherrywood’s stem had washed away and the “white” which had been there was now gone; the stem logo had only been about 60% colored and I’d have had to apply more white anyway so I suppose it wasn’t that big of a deal. I washed the stem well with dish soap and then sprayed them with some liquid Bar Keeper’s Friend, a new product to me (I’ve tried the powdered form before but not the spray). I scrubbed them off with a Miracle Eraser hoping for the good results I had gotten last time I used the eraser but they weren’t as good, though a lot of the oxidation had softened and been removed.

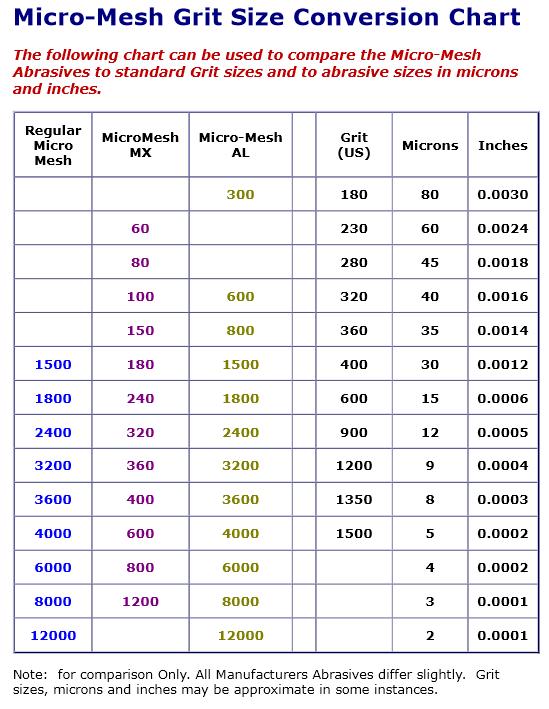

I now moved onto using the micro mesh pads, wet sanding them with 1500 & 1800 grit. At this point I noticed there was some oxidation that hadn’t come out well so I took some 400 grit wet/dry paper to the stems, then “painted” them with a Bic lighter, and then back to the 400 grit paper until the oxidation spots were gone. I then went back to wet sanding with the micro mesh 1500-3200 grits. After the 3200 grit I polished the stems with plastic polish and then dry sanded with the remaining grits through 12,000. Here are a few photos of the shine progression:

I now set the stems aside until the next day when the stummels would come out of their bath.

After removing the stummels from the alcohol bath I wiped them down and them dry a bit. Then I began cleaning the shanks again to make sure all the tar, gunk, and stain were gone. I also cleaned as much gunk off the rims as I could so I could see what their condition really was; fair on the cherrywood and poor on the Dublin. I decided to top the bowl of the Dublin and set the cherrywood aside to finish later. This what the Dublin looked like at this point:

You can see much better the condition of the rim here. You can also see that the “scratches” I referred to earlier are in reality fills that have fallen out; I scraped them with my dental pick to be 100% certain. These would have to be dealt with after I topped the bowl.

I used 400 girt wet.dry paper to top the bowl, checking it often to see how it progressed. The char marks wouldn’t come out completely but were reduced substantially. And the dings in the rim were nearly sanded out, in good enough shape that I was happy with them; the one on the outside edge would require me to sand at least another 1/16″ off the entire bowl and I didn’t want to remove anymore material than I already had.

Now I turned my attention back to the fills. Taking the dental pick, I picked out the remaining fill material. I recently picked up a new product that I wanted to try on fills made by DAP and I thought this would be a good opportunity.

These sticks are a wax-like substance that softens with heat/friction. I chose the darkest of the four sticks and rubbed it into the two largest fill areas. The sticks worked easily into the areas that needed filled:

I buffed the excess off lightly with an old cotton rag, getting it into the fill well and just below the surface. I then put a bit of super glue over the new fills and let it dry. After it dried I sanded the fills back down to flush. There were also some areas that needed small scratches/marks sanded out on the bottom of the stummel so I did that at this time, too.

I avoided sanding around the nomenclature and the shank in general. As you can see, the spot sanding left some obvious differences in the finish. But I didn’t want to sand any more than I needed to and knew that as it was I’d have to blend the stain. I decided to use the new-to-me wood stain markers for this job as well as the bowl’s rim. I applied the stain from the marker in small sections and blended it immediately with my finger after I put it on; I did this with all of the fills, spot sanding and the rim. The stain from the markers is very easy to apply in just the area you want it and blending by “finger” was very smooth and didn’t take long at all. I think that the pens did a great job and they have earned a permanent place in my restoration arsenal!

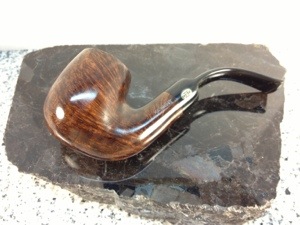

I know took the entire pipe to the buffer and buffed the stummel with Tripoli and then the pipe with white diamond and carnauba wax, finishing with a few passes on a clean soft buff. This is the finished pipe:

The DAP fill sticks did a pretty good job I think. In retrospect, I should have, perhaps, used a lighter color; the fills were so near the grain I thought darker would be better. I do think that they are something that I will explore using further and believe they have potential for some good results.