by Steve Laug

A while back I was asked by a customer and friend, Jack to take on some projects for him. I have worked on a few pipes for him over the years so we seem to have a standing agreement that I will clean up his pipes. This time he sent a batch containing 11 pipes – six Bertrams, an Arlington, a GBD, an old WDC Triangle Bakelite and one marked Texaco. All of them were in various conditions and would need different types of work. I took a photo of the pipes before I started working on them.

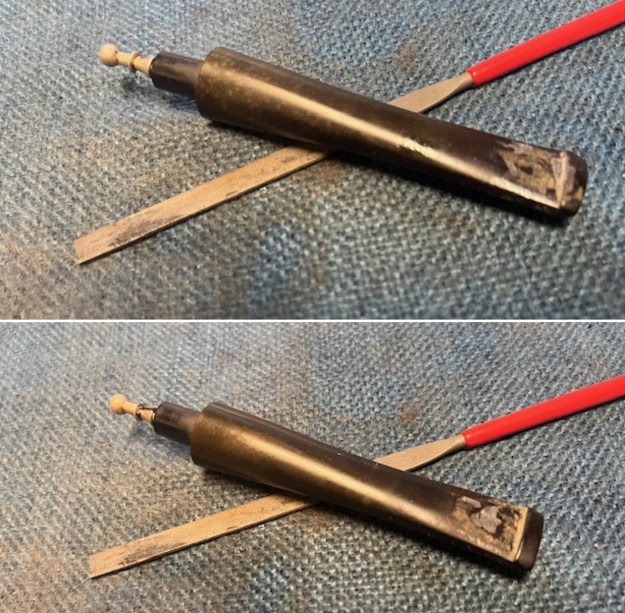

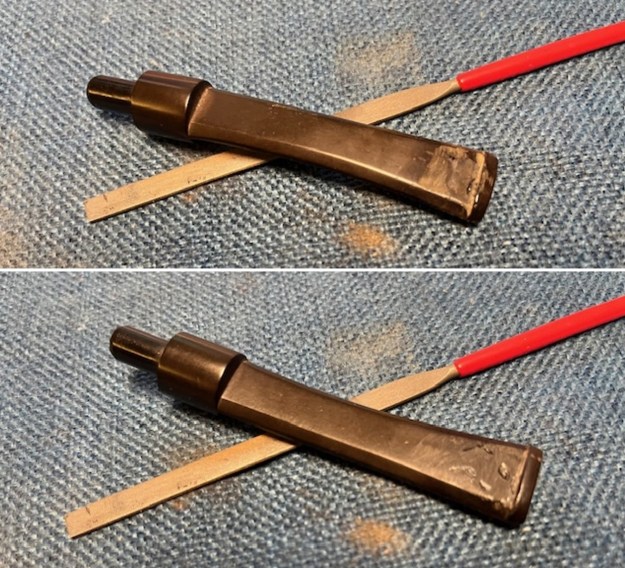

I chose to work on the Bertram 30 Bent Billiard that needed to be restemmed next. This next one is from Jack’s 11 pipes – a dirty, dull Grade 30 Bertram with a ruined tapered vulcanite bite proof stem. The pipe is stamped on the underside side near the stem with the Grade 30 number. On the left side it is stamped Bertram [over] Washington D.C. centered on the shank. The finish had a lot of grime ground into the smooth finish on the bowl and some darkening around the sides of the bowl. The bowl was moderately caked with an overflowing lava coat on the top of the rim, heavier toward the back of the bowl. The edges looked okay other than some potential damage on the back inner edge. The ruined replacement twin bore, or bite proof stem was calcified, oxidized, dirty and had tooth chatter and many bite throughs and chips on the top and underside near the button. The photos show the condition of the stem surface. It will need to be replaced. There were not markings or a logo on the taper stem. Like the rest of the Bertrams that Jack sent, this one had promise but it was very dirty. I took photos of the pipe before I started his cleanup work.

I chose to work on the Bertram 30 Bent Billiard that needed to be restemmed next. This next one is from Jack’s 11 pipes – a dirty, dull Grade 30 Bertram with a ruined tapered vulcanite bite proof stem. The pipe is stamped on the underside side near the stem with the Grade 30 number. On the left side it is stamped Bertram [over] Washington D.C. centered on the shank. The finish had a lot of grime ground into the smooth finish on the bowl and some darkening around the sides of the bowl. The bowl was moderately caked with an overflowing lava coat on the top of the rim, heavier toward the back of the bowl. The edges looked okay other than some potential damage on the back inner edge. The ruined replacement twin bore, or bite proof stem was calcified, oxidized, dirty and had tooth chatter and many bite throughs and chips on the top and underside near the button. The photos show the condition of the stem surface. It will need to be replaced. There were not markings or a logo on the taper stem. Like the rest of the Bertrams that Jack sent, this one had promise but it was very dirty. I took photos of the pipe before I started his cleanup work.

I took photos of the rim top and the stem to show the condition. You can see the thick cake in the bowl and overflow of lava on the rim top. The photos of the damaged (I would say ruined) stem show the thick calcification, tooth marks, bite throughs and heavy damage in the vulcanite on the top and underside of the stem and the button.

I took photos of the rim top and the stem to show the condition. You can see the thick cake in the bowl and overflow of lava on the rim top. The photos of the damaged (I would say ruined) stem show the thick calcification, tooth marks, bite throughs and heavy damage in the vulcanite on the top and underside of the stem and the button.  I took photos of the stamping on the left and underside of the shank to capture it. The Bertram stamp was clear and readable as noted above. The 30 stamp was more faint on the underside but is visible in person. I removed the stem and took a photo of the parts to give a sense of the look of the pipe. I took a photo of the bite proof stem end showing the twin bore airways in the button.

I took photos of the stamping on the left and underside of the shank to capture it. The Bertram stamp was clear and readable as noted above. The 30 stamp was more faint on the underside but is visible in person. I removed the stem and took a photo of the parts to give a sense of the look of the pipe. I took a photo of the bite proof stem end showing the twin bore airways in the button.

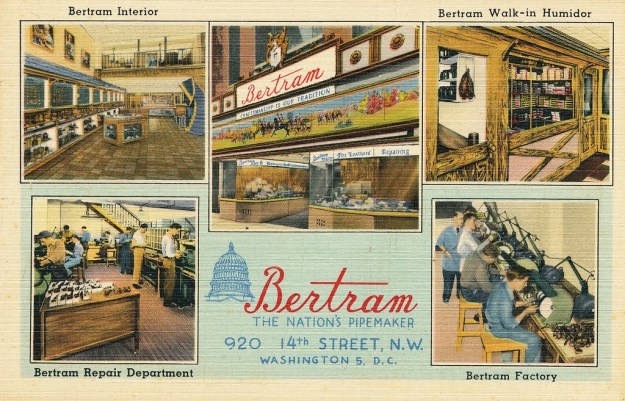

As I have worked on a lot Bertrams in the past, I have written on the brand and have included the following information. If you have read it in past blogs, you can skip over it. If you have not, I have included the link to Bertram history and information. I would recommend that if you don’t know much about them take some time to read the background. I include a link to the write up on Pipedia (http://pipedia.org/wiki/Bertram).

As I have worked on a lot Bertrams in the past, I have written on the brand and have included the following information. If you have read it in past blogs, you can skip over it. If you have not, I have included the link to Bertram history and information. I would recommend that if you don’t know much about them take some time to read the background. I include a link to the write up on Pipedia (http://pipedia.org/wiki/Bertram). Bertram pipes were based out of Washington DC. They were popular among famous politicians and celebrities of the time. They made many products for them from FDR’s cigarette holders to Joseph Stalin’s favorite pipe. They were considered some of the best America had to offer till they finally closed their doors in the 70s. Bertram graded their pipes by 10s and sometimes with a 5 added (15, 25, 55 etc.), the higher the grade the better. Above 60s are uncommon and 80-90s are quite rare. I have worked on one 120 Grade billiard. I have several blogs that I have written on rebornpipes that give some history and background to Bertram pipes. (https://rebornpipes.com/2015/06/16/an-easy-restoration-of-a-bertram-grade-60-217-poker/).

Bertram pipes were based out of Washington DC. They were popular among famous politicians and celebrities of the time. They made many products for them from FDR’s cigarette holders to Joseph Stalin’s favorite pipe. They were considered some of the best America had to offer till they finally closed their doors in the 70s. Bertram graded their pipes by 10s and sometimes with a 5 added (15, 25, 55 etc.), the higher the grade the better. Above 60s are uncommon and 80-90s are quite rare. I have worked on one 120 Grade billiard. I have several blogs that I have written on rebornpipes that give some history and background to Bertram pipes. (https://rebornpipes.com/2015/06/16/an-easy-restoration-of-a-bertram-grade-60-217-poker/).

I have included the following link to give a bit of historical information on the pipe company. It is a well written article that gives a glimpse of the heart of the company. http://www.streetsofwashington.com/2012/01/bertrams-pipe-shop-on-14th-street.html#

From this information I learned that all of these Bertrams were made before the closure of the shop in the 1970s. This Bertram Prince has stunning straight and flame grain around the bowl. This pipe has a 30 Grade stamp on it which I am sure explains the quality of the briar. But like many of these Bertrams the Grading system is a mystery to me.

I started my work on the pipe by reaming the bowl with a PipNet reamer. I used the first cutting head and took the cake back to bare briar. I cleaned up the reaming with a Savinelli Fitsall Pipe Knife and removed all the remnants of the cake. I scraped the rim top with the flat edge of the blade at the same time and removed most of the thick lava build up. I sanded the walls of the bowl with a piece of dowel wrapped in 220 grit sandpaper. The walls look very good at his point in the process.

The darkening on the rim top and inner edge of the bowl would need to be dealt with. I cleaned up the inner edge and the rim with a folded piece of 220 grit sandpaper and was able to remove the darkening.

The darkening on the rim top and inner edge of the bowl would need to be dealt with. I cleaned up the inner edge and the rim with a folded piece of 220 grit sandpaper and was able to remove the darkening. I scrubbed the exterior of the bowl and shank with a tooth brush and undiluted Murphy’s Oil Soap. I scrubbed the lava on the rim top and overflow on the outside of the bowl with the soap. I rinsed the briar with warm water to remove the grime and debris of the scrubbing. It looked significantly better after the scrubbing. The darkening on the rim top is very clear.

I scrubbed the exterior of the bowl and shank with a tooth brush and undiluted Murphy’s Oil Soap. I scrubbed the lava on the rim top and overflow on the outside of the bowl with the soap. I rinsed the briar with warm water to remove the grime and debris of the scrubbing. It looked significantly better after the scrubbing. The darkening on the rim top is very clear.

As I cleaned it up, I noticed that the fills on the right side and the front mid bowl were shrunken and damaged. I filled them in with clear CA glue and briar dust. Once the repair cured I sanded it with 220 grit sandpaper to flatten the repair and blend it into the surface of the briar.

As I cleaned it up, I noticed that the fills on the right side and the front mid bowl were shrunken and damaged. I filled them in with clear CA glue and briar dust. Once the repair cured I sanded it with 220 grit sandpaper to flatten the repair and blend it into the surface of the briar.

I sanded the bowl it with 320-3500 grit sanding pads to finish the rim top, the bowl and shank. The briar began to take on a rich shine and the darkening on the top was gone and the fill blended in better with work. The photos tell the story.

I sanded the bowl it with 320-3500 grit sanding pads to finish the rim top, the bowl and shank. The briar began to take on a rich shine and the darkening on the top was gone and the fill blended in better with work. The photos tell the story.

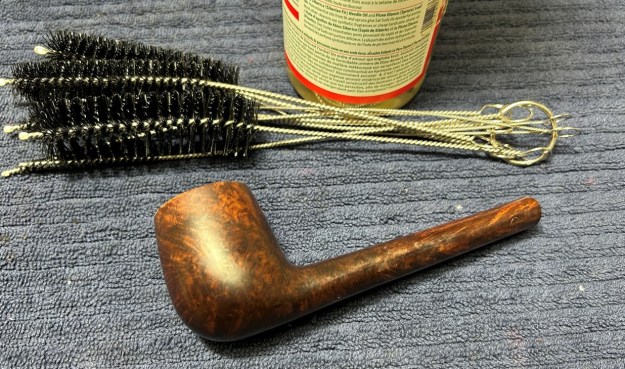

I remembered that I had forgotten to clean the pipe. I cleaned out the shank, the airway and the mortise with alcohol, cotton swabs, hard bristle and soft bristle pipe cleaners. It was a very dirty pipe which just meant that it had really been enjoyed by the previous pipe man. Since I was restemming the pipe I would do the clean out on the new stem when I got it.

I remembered that I had forgotten to clean the pipe. I cleaned out the shank, the airway and the mortise with alcohol, cotton swabs, hard bristle and soft bristle pipe cleaners. It was a very dirty pipe which just meant that it had really been enjoyed by the previous pipe man. Since I was restemming the pipe I would do the clean out on the new stem when I got it. I polished the bowl and rim top with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I wiped the bowl down with a damp cloth after each sanding pad. The grain started to rise to the surface as I polished it.

I polished the bowl and rim top with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I wiped the bowl down with a damp cloth after each sanding pad. The grain started to rise to the surface as I polished it.

I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the finish on the bowl and shank. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. It is a beautiful bowl.

I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the finish on the bowl and shank. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. It is a beautiful bowl.

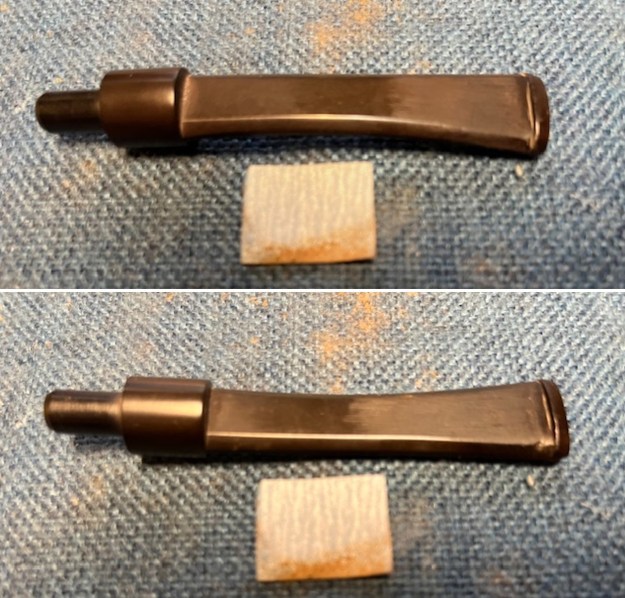

I laid the bowl aside and turned my attention to fitting a new stem. I went through my stems and found one that did not have a tenon but was very close to the diameter of the shank – slightly larger but very workable. I would pitch the chewed up twin bore stem in light of this fishtail one. I pushed a tenon in the stem for the photos below. I would need to secure once I started.

I laid the bowl aside and turned my attention to fitting a new stem. I went through my stems and found one that did not have a tenon but was very close to the diameter of the shank – slightly larger but very workable. I would pitch the chewed up twin bore stem in light of this fishtail one. I pushed a tenon in the stem for the photos below. I would need to secure once I started. I gave the threaded end of the tenon a coat of black CA rubberized glue and pressed it into the stem. I turned it until all was aligned and straight and then secured it until the glue hardened and the tenon was solid.

I gave the threaded end of the tenon a coat of black CA rubberized glue and pressed it into the stem. I turned it until all was aligned and straight and then secured it until the glue hardened and the tenon was solid. Since there was little to do on the stem other than cosmetic adjustments I decided to give it a slight bend to match the damaged stem and the flow of the bowl. I have found that if I “paint” the area where I want the bend with a lighter until the surface softens I can save getting my heat gun out. I do this while the stem is on the pipe. Once the surface was soft I press the top of the bowl and the stem down against my worktable to get the bend in place. I let it sit that way with pressure from my hand until the rubber of the stem cools. You can speed up the process by putting the stem under cold water but I did not do this on this pipe. Once cooled I took a photo of the look of the bent stem. Those paying attention to the photos of the bowl work will see that I bent the stem before I did any of the clean up on the bowl 😉

Since there was little to do on the stem other than cosmetic adjustments I decided to give it a slight bend to match the damaged stem and the flow of the bowl. I have found that if I “paint” the area where I want the bend with a lighter until the surface softens I can save getting my heat gun out. I do this while the stem is on the pipe. Once the surface was soft I press the top of the bowl and the stem down against my worktable to get the bend in place. I let it sit that way with pressure from my hand until the rubber of the stem cools. You can speed up the process by putting the stem under cold water but I did not do this on this pipe. Once cooled I took a photo of the look of the bent stem. Those paying attention to the photos of the bowl work will see that I bent the stem before I did any of the clean up on the bowl 😉 I worked on the diameter of the stem at the shank first with my Dremel and sanding drum to get it close to what I wanted. I followed that by sanding it with 220 grit sandpaper. I sanded the rest of the stem to clean up the casting marks on the sides and button end. I constantly checked the fit on the shank and once I had it ready I wiped the stem down with a bit of Obsidian Oil and took the photos below. It began to really look very good.

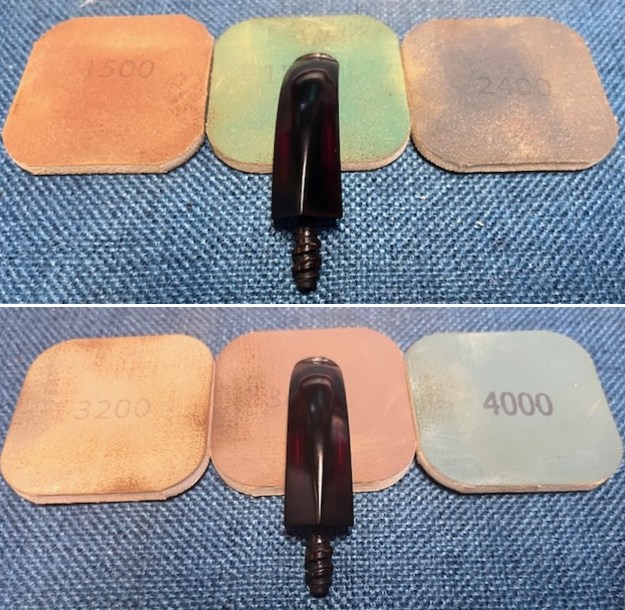

I worked on the diameter of the stem at the shank first with my Dremel and sanding drum to get it close to what I wanted. I followed that by sanding it with 220 grit sandpaper. I sanded the rest of the stem to clean up the casting marks on the sides and button end. I constantly checked the fit on the shank and once I had it ready I wiped the stem down with a bit of Obsidian Oil and took the photos below. It began to really look very good. I sanded the surface of the vulcanite with the 2 x 2-inch sanding pads – 320-3500 grit pads to clean up the sanding marks and remaining casting marks on the stem surface. By the final 3500 grit pad the stem started to really shine.

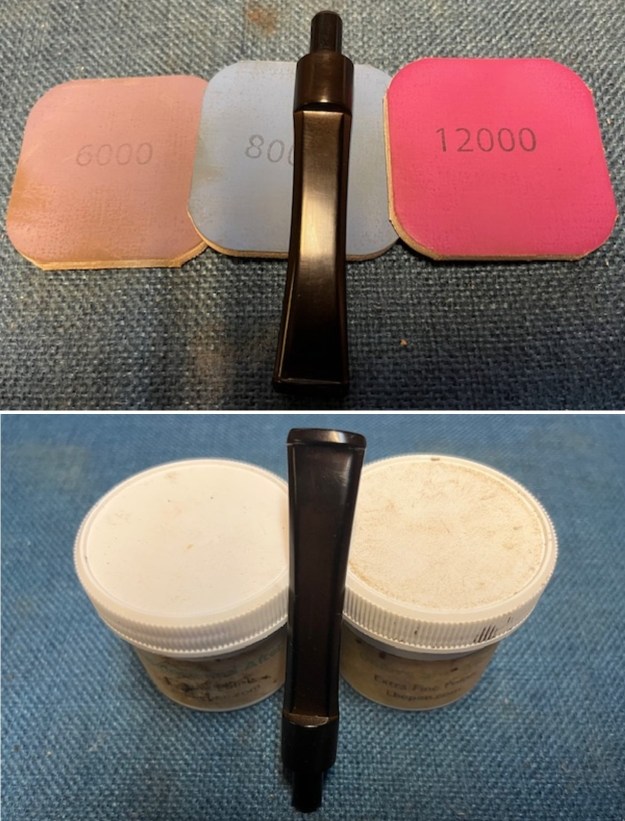

I sanded the surface of the vulcanite with the 2 x 2-inch sanding pads – 320-3500 grit pads to clean up the sanding marks and remaining casting marks on the stem surface. By the final 3500 grit pad the stem started to really shine. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished the stem with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a coat of Obsidian Pipe Stem Oil. It works to protect the stem from oxidizing. I set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished the stem with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a coat of Obsidian Pipe Stem Oil. It works to protect the stem from oxidizing. I set it aside to dry.

I cleaned out the drilling and sanding debris from the airway in the stem with pipe cleaners and isopropyl alcohol. It was clean other than the dust.

I cleaned out the drilling and sanding debris from the airway in the stem with pipe cleaners and isopropyl alcohol. It was clean other than the dust. I am excited to finish this Bertram Washington DC 30 Bent Billiard with a newly fit taper stem. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine and then by hand with a microfibre cloth to deepen it. It is fun to see what the polished bowl looks like with beautiful grain on the smooth portions and the rustication depths all around it. The polished grain on the pipe looks great with the black vulcanite stem. This Bertram Bent Billiard is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 3/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 49 grams/1.73 ounces. It is another beautiful pipe that I will send to Jack after I finish working on the other 4 pipes. I look forward to hear what he thinks of this next beauty. It should be a great smoking pipe.

I am excited to finish this Bertram Washington DC 30 Bent Billiard with a newly fit taper stem. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine and then by hand with a microfibre cloth to deepen it. It is fun to see what the polished bowl looks like with beautiful grain on the smooth portions and the rustication depths all around it. The polished grain on the pipe looks great with the black vulcanite stem. This Bertram Bent Billiard is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 3/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 49 grams/1.73 ounces. It is another beautiful pipe that I will send to Jack after I finish working on the other 4 pipes. I look forward to hear what he thinks of this next beauty. It should be a great smoking pipe.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.