by Steve Laug

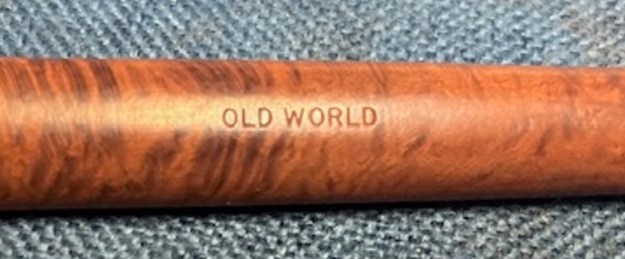

I am taking a break from the last two of the four pipes I am working on for Jack to clean up and match a stem with a nice freehand pipe that I have here in my box. It is another quick cleanup and restore and gives me a break from the heavier restoration work on Jack’s next pipe. This bowl has a mixed smooth and rusticated finish with a plateau rim top and shank end. The finish was a bit dull and lifeless. It showed promise under the grit and grime of the years. On the underside of the shank it was clearly stamped Soren [over] Hand-Carved [over] Made in Denmark. The bowl had a thin cake and some lava overflow on the smooth and plateau areas of the rim top. The bowl also had some dust and debris in rusticated patch on the right side of the bowl as well as in the crevices of the plateau on the shank end. I took some photos of the bowl before I started my work on it.

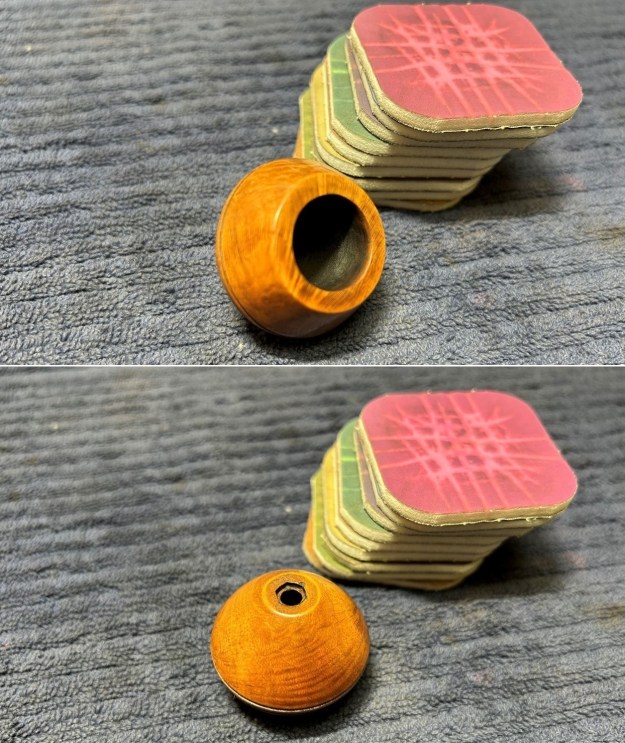

I took a close up photo of the bowl to give an idea of what I had to work with. The bowl was very dirty and had a moderately thick cake. The smooth portions of the rim top have a lava coat the plateau portions are also almost filled in with lava. I also took a photo of the plateau on the shank end to show its condition – dirty but in good shape.

I took a close up photo of the bowl to give an idea of what I had to work with. The bowl was very dirty and had a moderately thick cake. The smooth portions of the rim top have a lava coat the plateau portions are also almost filled in with lava. I also took a photo of the plateau on the shank end to show its condition – dirty but in good shape. I took a photo to try and capture the stamping on the underside of the shank. It is present and is readable in person far more than the photos show. It is stamped as noted above.

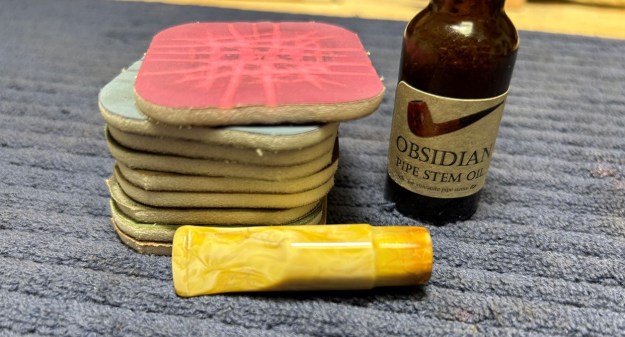

I took a photo to try and capture the stamping on the underside of the shank. It is present and is readable in person far more than the photos show. It is stamped as noted above. I went through my cans of stems here and found a nice vulcanite fancy saddle stem that would fit quite well ONCE I REPLACED THE SNAPPED TENON. It was dirty and needed a thorough cleaning but I think it will look good.

I went through my cans of stems here and found a nice vulcanite fancy saddle stem that would fit quite well ONCE I REPLACED THE SNAPPED TENON. It was dirty and needed a thorough cleaning but I think it will look good. I have worked on quite a few Soren pipes over the years and turned to one of the blogs that I wrote on another interesting Soren Freehand Sitter (https://rebornpipes.com/2020/02/26/this-interesting-soren-hand-carved-freehand-turned-out-to-be-more-work-than-expected/). I quote from that blog below.

I have worked on quite a few Soren pipes over the years and turned to one of the blogs that I wrote on another interesting Soren Freehand Sitter (https://rebornpipes.com/2020/02/26/this-interesting-soren-hand-carved-freehand-turned-out-to-be-more-work-than-expected/). I quote from that blog below.

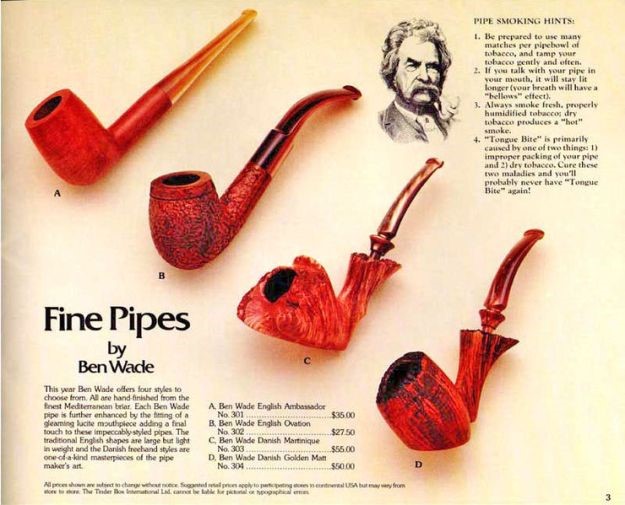

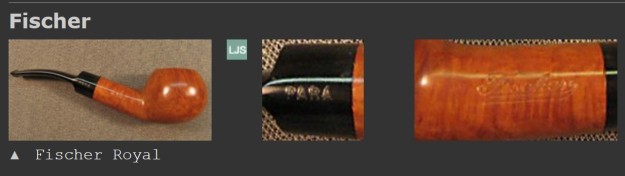

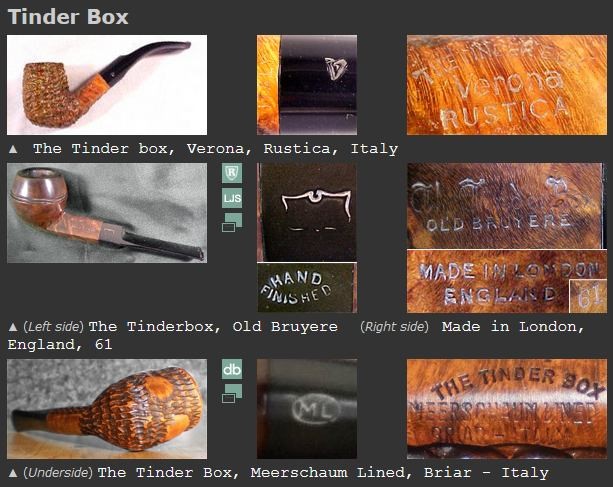

I looked up the brand on Pipephil (http://www.pipephil.eu/logos/en/logo-s10.html) and found that the brand was carved by Søren Refbjerg Rasmussen. Pipes that he made for the European market were mostly stamped “Refbjerg” while those made for the US market were stamped “Soren”. Thus, I knew that one I was working on was imported into the US market.

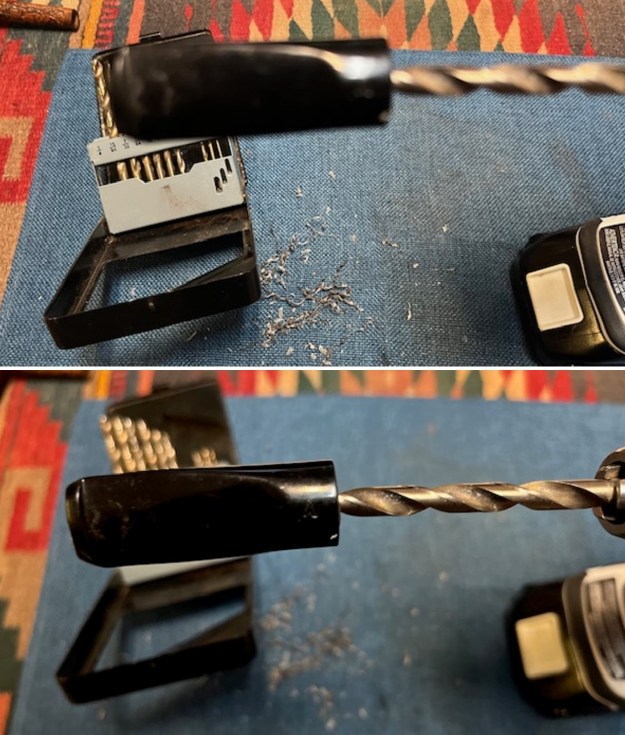

It was time to work on the pipe! I decided to start with refitting the new tenon to the stem I had chosen. Hmmm…I thought I was done with that for a while but this stem just worked with the bowl. I flattened the broken tenon remnants on the stem end with a Dremel and sanding drum and then further smoothed it out with a topping board and 220 grit sandpaper. I wanted a smooth surface for my drilling. I learned a helpful trick on the last batch of six tenon replacements. I use a small pen knife to give the airway in the stem end a slight chamfer to guide the drill bit into it and keep it straight. Once I did that I used a series of drill bits to open the airway to receive the threaded portion of the tenon. I choose to use threaded replacement tenons as they provide a rough serrated surface for the glue to bind to the drilled hole in the stem. It has worked well for me a for a long time.

I learned a helpful trick on the last batch of six tenon replacements. I use a small pen knife to give the airway in the stem end a slight chamfer to guide the drill bit into it and keep it straight. Once I did that I used a series of drill bits to open the airway to receive the threaded portion of the tenon. I choose to use threaded replacement tenons as they provide a rough serrated surface for the glue to bind to the drilled hole in the stem. It has worked well for me a for a long time. Once it fit well in the stem I needed to reduce the diameter of the portion that went in the shank mortise. I use a Dremel and sanding drum to work it until it fits well in the shank of the pipe. I took photos of the look of the tenon when it was finished and put it in the shank and put the stem on it and took photos. I think it will work very well!

Once it fit well in the stem I needed to reduce the diameter of the portion that went in the shank mortise. I use a Dremel and sanding drum to work it until it fits well in the shank of the pipe. I took photos of the look of the tenon when it was finished and put it in the shank and put the stem on it and took photos. I think it will work very well!

I checked the fit of the stem to the tenon, the tenon to the shank repeatedly and once it was proper I glued it in place with black CA glue.

I checked the fit of the stem to the tenon, the tenon to the shank repeatedly and once it was proper I glued it in place with black CA glue. I set the stem aside to allow the glue to cure. While it dried I took a photo of the stem and the bowl together to give a sense of the look of the pipe and stem. Proportions and look just work together in my opinion.

I set the stem aside to allow the glue to cure. While it dried I took a photo of the stem and the bowl together to give a sense of the look of the pipe and stem. Proportions and look just work together in my opinion.  While the glue cured I turned my attention to the bowl. I reamed it with a PipNet Pipe Reamer using the 2nd and 3rd cutting heads to remove the cake. I cleaned up the remnants with a Savinelli Fitsall Pipe Knife. I finished the bowl by sanding the walls with a piece of 220 grit sandpaper wrapped around a piece of dowel. The bowl walls looked very good.

While the glue cured I turned my attention to the bowl. I reamed it with a PipNet Pipe Reamer using the 2nd and 3rd cutting heads to remove the cake. I cleaned up the remnants with a Savinelli Fitsall Pipe Knife. I finished the bowl by sanding the walls with a piece of 220 grit sandpaper wrapped around a piece of dowel. The bowl walls looked very good.

I scrubbed out the internals with pipe cleaners (normal & bristle), cotton swabs and alcohol to remove the tars and oils in the shank between the mortise and the entrance of the airway into the bowl. It was quite dirty.

I scrubbed out the internals with pipe cleaners (normal & bristle), cotton swabs and alcohol to remove the tars and oils in the shank between the mortise and the entrance of the airway into the bowl. It was quite dirty. I cleaned up the plateau areas on the rim top and shank end with a brass bristle wire brush. I worked on it until the groves were clean. I wiped it down with a damp cloth to remove all the debris. I sanded the smooth portions on the rim top with a folded piece of 200 grit sandpaper. It was looking better each step!

I cleaned up the plateau areas on the rim top and shank end with a brass bristle wire brush. I worked on it until the groves were clean. I wiped it down with a damp cloth to remove all the debris. I sanded the smooth portions on the rim top with a folded piece of 200 grit sandpaper. It was looking better each step! I scrubbed the exterior of the bowl and shank with a tooth brush and undiluted Murphy’s Oil Soap. I worked it into the grain on the sides, the plateau on the rim top and shank end and the rusticated patch on the right side of the bowl with the tooth brush. I rinsed the soap and grime off with warm water and dried it off with a soft towel. I looked much better at this point. The grain really stands out.

I scrubbed the exterior of the bowl and shank with a tooth brush and undiluted Murphy’s Oil Soap. I worked it into the grain on the sides, the plateau on the rim top and shank end and the rusticated patch on the right side of the bowl with the tooth brush. I rinsed the soap and grime off with warm water and dried it off with a soft towel. I looked much better at this point. The grain really stands out.

I sanded the smooth part of the bowl with 320-3500 grit sanding pads to start the polishing process. I wiped down the bowl with a damp cloth after each sanding pad.

I sanded the smooth part of the bowl with 320-3500 grit sanding pads to start the polishing process. I wiped down the bowl with a damp cloth after each sanding pad.

I followed that by polishing the smooth portions of the bowl sides with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each pad.

I followed that by polishing the smooth portions of the bowl sides with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each pad.

With the briar polished I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips and into the plateau rim top, shank end and rustication with a horsehair shoe brush. The product works to clean, enliven and protect the briar. I let the Balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. While the Balm did its work, I worked on the “new stem”.

With the briar polished I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips and into the plateau rim top, shank end and rustication with a horsehair shoe brush. The product works to clean, enliven and protect the briar. I let the Balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. While the Balm did its work, I worked on the “new stem”.

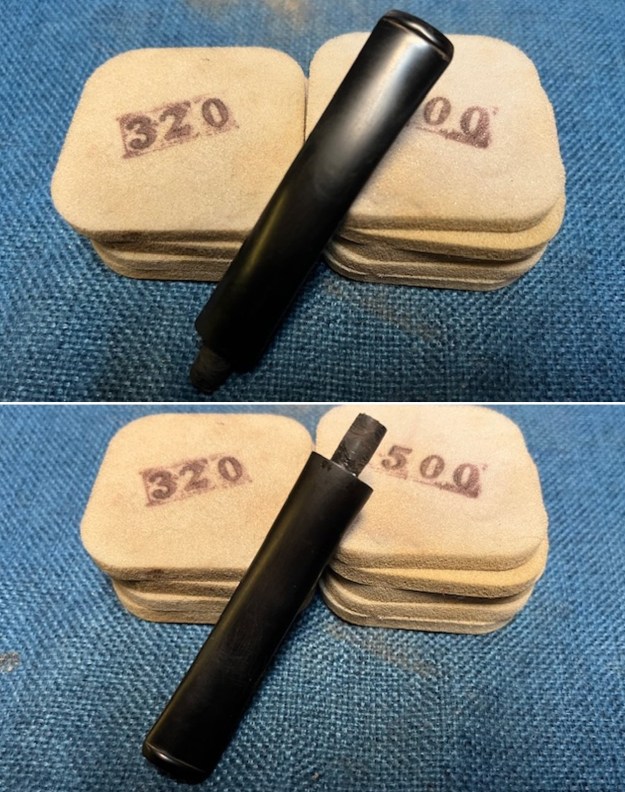

I sanded the tooth chatter and marks on the stem surface with a folded piece of 220 grit sandpaper. It was starting to look better.

I sanded the tooth chatter and marks on the stem surface with a folded piece of 220 grit sandpaper. It was starting to look better. I sanded the stem surface with 320-3500 grit sanding pads to further polish the stem. I wiped it down between sanding pads with a damp cloth.

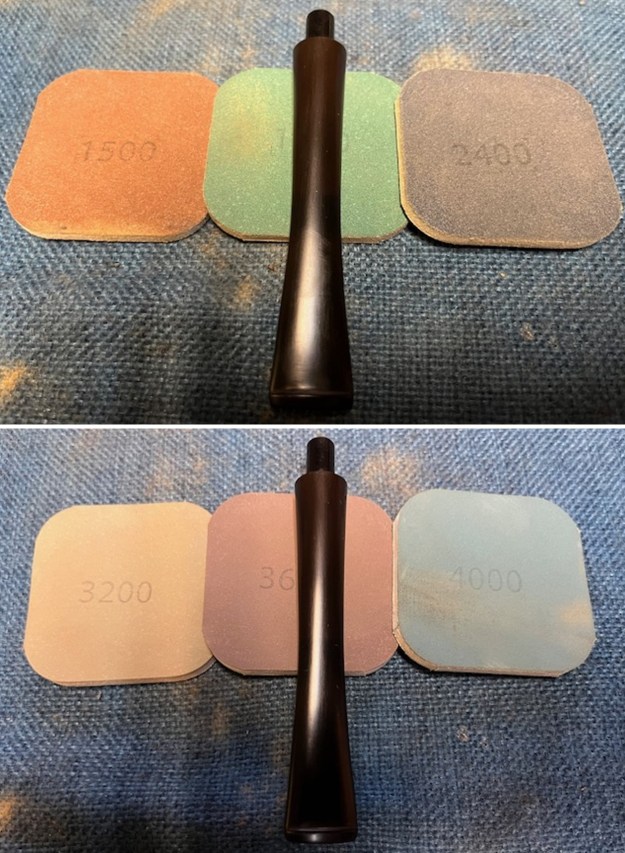

I sanded the stem surface with 320-3500 grit sanding pads to further polish the stem. I wiped it down between sanding pads with a damp cloth.  I polished the acrylic stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the acrylic stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This beautiful Soren Hand Carved Made In Denmark Freehand with a fancy, turned vulcanite saddle replacement stem is a great looking pipe now that it has been restored. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Soren Hand Carved Freehand fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ x 1 ¾ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 58 grams/2.12 ounces. If you are interested in adding this pipe to your collection send me a message or an email to slaug@uniserve.com. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will be putting it on the rebornpipes store in the Danish Pipe Makers Section shortly if you would like to add it to your collection. Thanks for your time.

This beautiful Soren Hand Carved Made In Denmark Freehand with a fancy, turned vulcanite saddle replacement stem is a great looking pipe now that it has been restored. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Soren Hand Carved Freehand fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ x 1 ¾ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 58 grams/2.12 ounces. If you are interested in adding this pipe to your collection send me a message or an email to slaug@uniserve.com. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will be putting it on the rebornpipes store in the Danish Pipe Makers Section shortly if you would like to add it to your collection. Thanks for your time.