Blog by Kenneth Lieblich

Next on the chopping block is a charming bent Dublin churchwarden (ten inches long), commissioned for a priest friend of mine. He expressly asked for a churchwarden (of course, he did). Fortunately, I had one on hand and I did a nifty restoration job on it. This is just a quick-and-dirty report for two reasons. First, I lost most of the photos I took of the restoration. Grrr. Second, this pipe has literally no markings on it, so I have no information to provide on its origins. The pipe was in decent condition. It had been well-smoked, but the bowl and shank were fairly clean. The bowl had notable cake on the inside and some lava on the rim. I felt that some burning was possibly there too. On the bottom of the stummel, there was a strange, hard, brown substance – possibly wood glue or putty. Not sure what it was, but it wasn’t supposed to be there! Similarly, the stem was relatively clean – not much oxidation to speak of, and what I would describe as “typical” tooth marks on the bit. The stem was slightly bent out of shape (in the yaw and roll axes) and would need to be corrected.

The pipe was in decent condition. It had been well-smoked, but the bowl and shank were fairly clean. The bowl had notable cake on the inside and some lava on the rim. I felt that some burning was possibly there too. On the bottom of the stummel, there was a strange, hard, brown substance – possibly wood glue or putty. Not sure what it was, but it wasn’t supposed to be there! Similarly, the stem was relatively clean – not much oxidation to speak of, and what I would describe as “typical” tooth marks on the bit. The stem was slightly bent out of shape (in the yaw and roll axes) and would need to be corrected.

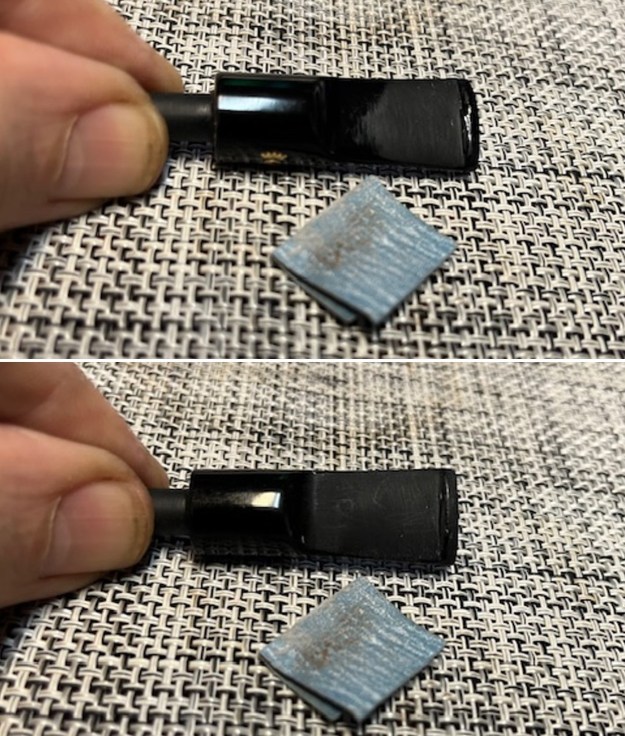

The stem was first on my list. I wiped the outside down with Murphy’s Oil Soap on some cotton pads. I cleaned out the insides with lemon-infused isopropyl alcohol and some churchwarden pipe cleaners.

The stem was first on my list. I wiped the outside down with Murphy’s Oil Soap on some cotton pads. I cleaned out the insides with lemon-infused isopropyl alcohol and some churchwarden pipe cleaners.

I then heated the stem with my heat gun and gently worked the twisted stem back into place. I have bent many stems before, but churchwardens always seem trickiest – perhaps because they’re so long. In the end, I got it looking just as it should.

I scrubbed the stem with SoftScrub on some cotton pads. I built up the remaining marks on the stem with black cyanoacrylate adhesive and then cured it with the aid of some CA glue accelerator. I then carefully sanded the adhesive down with 220- and 400-grit sandpapers to meld seamlessly into the stem. I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing (from 3,600 onward).

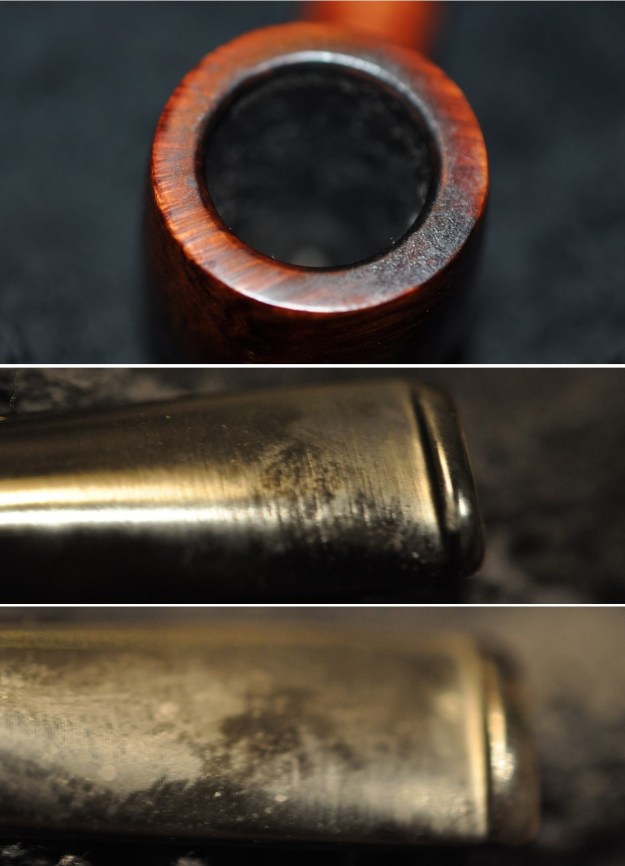

Now for the stummel. I reamed out the bowl to remove the built-up cake and followed that with 220-grit sandpaper taped to a dowel to eliminate as much as I could. I took the chamber down to bare briar, as I wanted to ensure there were no hidden flaws in the wall. Fortunately, there were none.

I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and lemon-infused isopropyl alcohol. There was quite a bit of filth inside this stummel and it took a fair amount of cotton to get it clean. I used cotton rounds and some Murphy’s Oil Soap to scrub the outside of the stummel. I followed that up by cleaning the insides of the stummel with some Castile soap and tube brushes.

Next, I decided to de-ghost the pipe in order to remove any lingering smells of the past. I thrust cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused any remaining oils, tars and smells to leach out into the cotton. The bowl was nice and clean after this.

In order to safely remove the damage on the rim, I “topped” the pipe – that is to say, I gently and evenly sanded down the rim on a piece of 220-grit sandpaper. This effectively removed the damage, without altering the look of the pipe. I used some 220-grit sandpaper to remove the brown stuff on the bottom. No harm done. Then I sanded the stummel down with all nine Micromesh pads (1,500 through 12,000 grit).

Finally, I applied some Before & After Restoration Balm and buffed it with a microfiber cloth. During the restoration, I noticed some previously repaired damage to the end of the shank. The repair was sound but ugly, so I decided to add a charming band to the shank. I think it suits the pipe quite well and brings a bit of “bling”.

I then took the pipe to my bench polisher and buffed it with White Diamond and a few coats of carnauba wax. Wow – the pipe really looks lovely.

This churchwarden will suit my priest friend very well and I know that he will enjoy smoking it for many years to come. I hope you enjoyed reading the story of this pipe as much I as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or email me directly at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.