Blog by Steve Laug

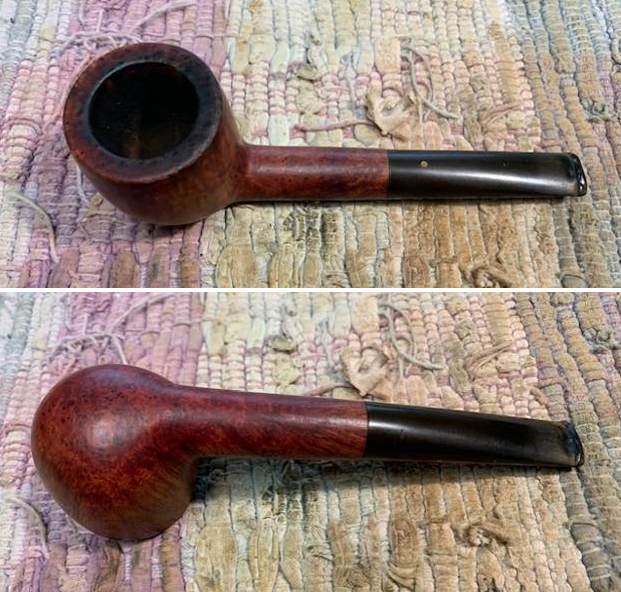

The next pipe on my work table literally called out to me from my box. The Straight Grain on the bowl just called me to pay attention. This one is stamped La Savinelli [over] Giubileo D’Oro on the left side of the shank. On the underside of the shank it is stamped Straight Grain [over] – Fiammata – [over] two stars. On the right side of the shank it is stamped with the Savinelli Shield S logo followed by the shape number 114KS [over] Italy. The saddle stem has three brass dots on the top. The briar has some nice straight and flame grain around the bowl with birdseye on the top of the bow, shank and the underside of both. This pipe was bought on December 12, 2019 from a fellow in Los Angeles, California, USA. The finish was dirty but the grain shone through well. The rim top was quite clean but there was some light lava on top and on the bevel. There is a thick cake in the bowl and some tobacco debris. The shank and stem airway was very dirty. The stem was oxidized, calcified and had light tooth chatter on both sides ahead of the button. Jeff took photos of the pipe before he started his clean up.

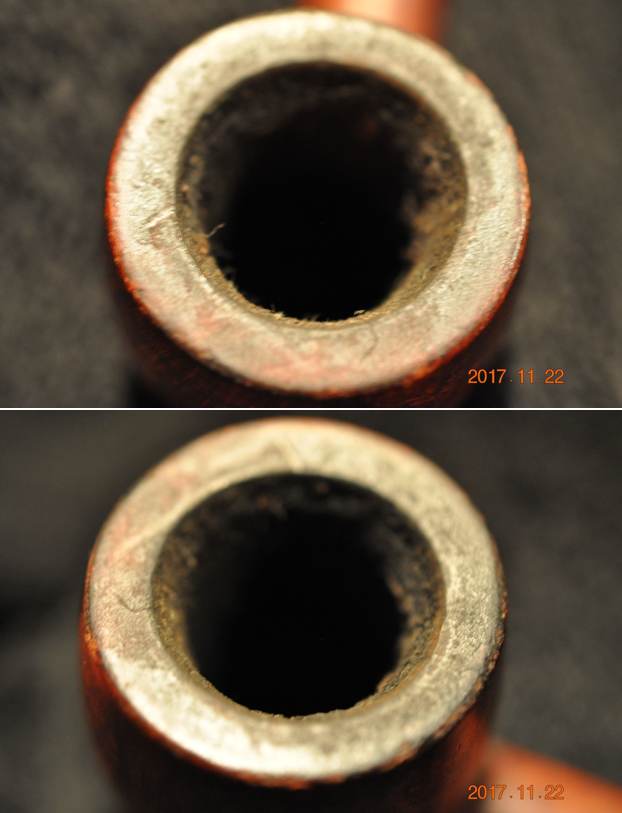

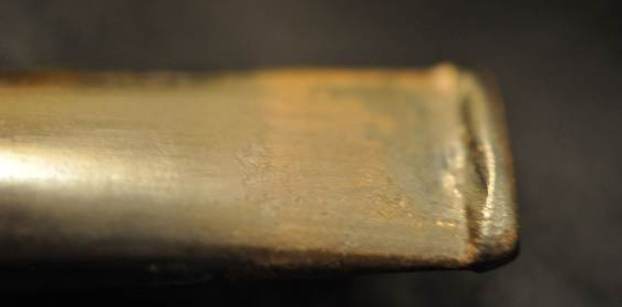

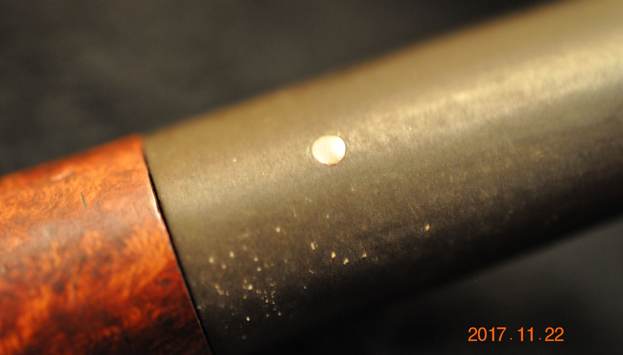

He took photos of the rim top and bowl to show the cake in the bowl, the lava on the bevel and rim top. The stem photos show the oxidation, calcification and tooth chatter very well.

He took photos of the rim top and bowl to show the cake in the bowl, the lava on the bevel and rim top. The stem photos show the oxidation, calcification and tooth chatter very well.

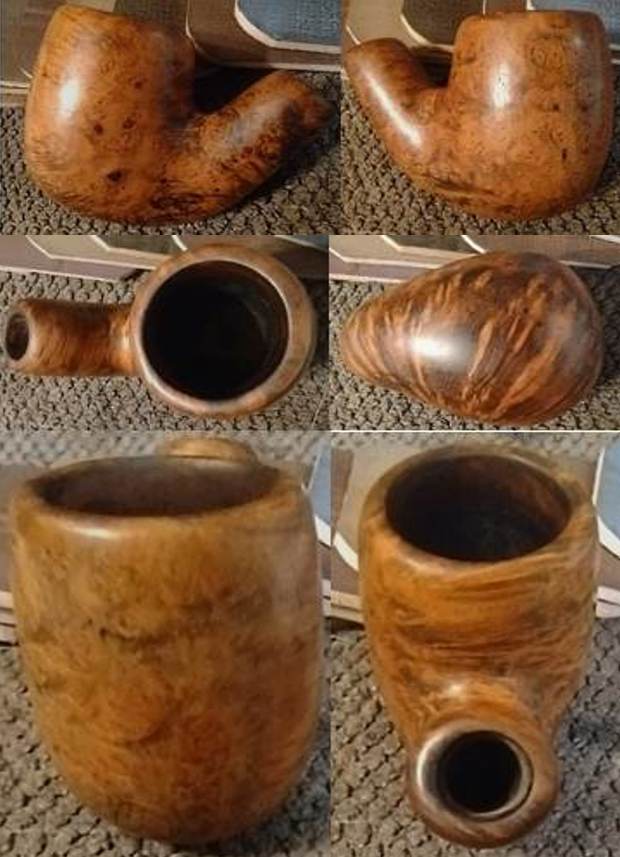

Jeff took photos of the sides of the bowl to highlight the amazing straight grain that explains the Straight Grain – Fiammata stamping on this pipe. It is quite stunning even though it is dirty.

Jeff took photos of the sides of the bowl to highlight the amazing straight grain that explains the Straight Grain – Fiammata stamping on this pipe. It is quite stunning even though it is dirty. He captured the stamping on the shank sides in the next photos. They are clean and readable as noted above.

He captured the stamping on the shank sides in the next photos. They are clean and readable as noted above.

I have worked on at one previous La Savinelli Guibileo D’ Oro in the past that I remembered so I turned there on the blog to read the background on the brand and remind myself how to understand the stamping on the shank. Here is the link (https://rebornpipes.wordpress.com/wp-admin/post.php?post=74052&action=edit&classic-editor). I quote from the blog below rather than redo the research.

I have worked on at one previous La Savinelli Guibileo D’ Oro in the past that I remembered so I turned there on the blog to read the background on the brand and remind myself how to understand the stamping on the shank. Here is the link (https://rebornpipes.wordpress.com/wp-admin/post.php?post=74052&action=edit&classic-editor). I quote from the blog below rather than redo the research.

There were several things about the stamping that I was unfamiliar with so I did some searching online. I wanted to know when Savinelli stamped their pipe “La Savinelli”. I wanted to know about the “Giubileo D’ Oro” and where it fit in the hierarchy of pipes from the company. I also wanted to understand the three gold dots on the stem.

I turned first to Pipephil – http://www.pipephil.eu/logos/en/logo-savinelli2.html and there I found the first helpful information. Some of my questions were answered in the notes on the page.

- The “LA” article precedes the “SAVINELLI” stamping on all pipes from the Giubileo d’Oro line.

- 4 digit shape number means The pipe predates the 1970’s. This new one does not have the four digit number but a three digit 114KS stamp

- Additional 2 stars indicating the grade (from 1 to 3 stars)

I then turned to the Pipedia article to see if I could learn more about the pipe

( https://pipedia.org/wiki/Savinelli). I have included to pages from Brochures that give some interesting information about the brand. It seems that Golden Jubilee pipe is made from very rare briar burls from Sardinia. Due to the limited raw materials available the pipe can only be produced in small quantities. Each pipe originally came with a certificate of authenticity. Sadly this was missing with the pipe I am working on.

I also did a websearch of Savinelli’s 50th Anniversary and was immediately given a link to their site (https://www.savinelli.it/rw2_en/catalog/product/view/id/15909/s/giubileo-oro-prime-0005?__from_store=rw2_en). They describe the line as follows:

The significance of ‘Golden Jubilee’ is to commemorate the “50th anniversary”; it defines the rarity of these pipes. Only 0.1% of our total production has the quality to be worthy of this unique series. Nature gives us this rare jewel of a pipe as an unparalleled and exceptional combination of perfect raw material and outstanding grain. The selection process is passed on only by word of mouth and is determined by the experience and high quality standards of Savinelli, a guarantee of reliability and elegant style.

Putting all of that together I learned that the pipe was a 50th Anniversary Commemorative and part of a limited production “Golden Jubilee” series. That would make it a mid 70s pipe rather than what Pipephil noted above. It is selected for its special and unique grain and handpicked for a shape to highlight the grain. The entire line was stamped with the La Savinelli marking. It is a unique piece of history. Now to get to work on it!

Jeff cleaned up the pipes with his usual thoroughness – reaming the bowl with a PipNet pipe reamer and cleaning up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed the internals of the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior with Murphy’s Oil Soap to clean off the dust and grime on the finish. When he sent it the pipe was ready to restore. I could not believe how good the rim top looked in comparison to what it was when he started. I took photos of the pipe when I unpacked it. The briar was clean and the grain quite stunning. The finish looked dull and lifeless.

I took a close up photo of the bowl and rim top after Jeff had cleaned it up. The look of the rim top and edges is very good. He had been able to remove the cake and the lava very well. The bowl was spotless. The stem is also shown and was very clean but lightly oxidized. He had scrubbed it with Soft Scrub and then soaked it in Mark’s Before & After Deoxidizer. There was light tooth chatter still remaining.

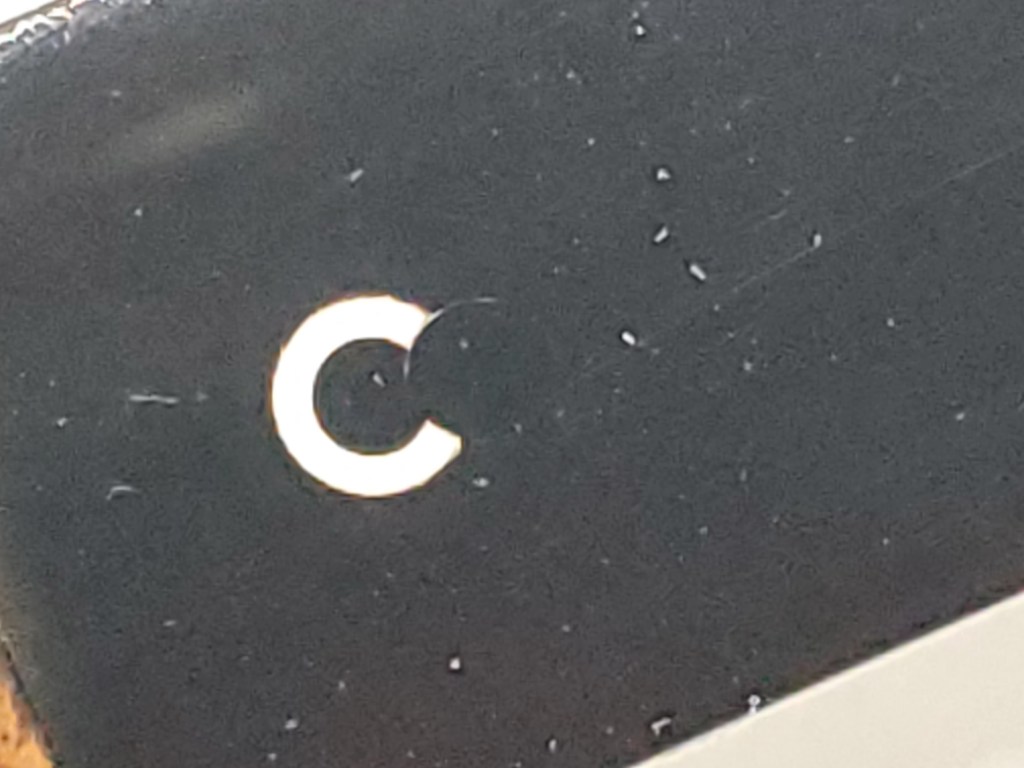

I took a close up photo of the bowl and rim top after Jeff had cleaned it up. The look of the rim top and edges is very good. He had been able to remove the cake and the lava very well. The bowl was spotless. The stem is also shown and was very clean but lightly oxidized. He had scrubbed it with Soft Scrub and then soaked it in Mark’s Before & After Deoxidizer. There was light tooth chatter still remaining. I took some photos of the stamping on the shank sides. The first photo shows the La Savinelli [over] Giubileo D’ Oro stamp on the left side. The second shows the shape number 114KS and the Savinelli Logo and the Italy stamp on the right side. The third shows the Straight Grain [over] –Fiammata- [over] two stars stamping on the underside of the shank. The final photo shows the three brass dots on the top of the saddle stem.

I took some photos of the stamping on the shank sides. The first photo shows the La Savinelli [over] Giubileo D’ Oro stamp on the left side. The second shows the shape number 114KS and the Savinelli Logo and the Italy stamp on the right side. The third shows the Straight Grain [over] –Fiammata- [over] two stars stamping on the underside of the shank. The final photo shows the three brass dots on the top of the saddle stem.  I removed the stem from the shank and took a photo to show the beauty of this pipe. The grain really is stunning.

I removed the stem from the shank and took a photo to show the beauty of this pipe. The grain really is stunning. I polished the briar with micromesh sanding pads – dry sanding (carefully avoiding the stamping on the shank sides) with 1500-12000 grit pads. I wiped the bowl down with a damp cloth between each pad. The grain to take on a shine.

I polished the briar with micromesh sanding pads – dry sanding (carefully avoiding the stamping on the shank sides) with 1500-12000 grit pads. I wiped the bowl down with a damp cloth between each pad. The grain to take on a shine.

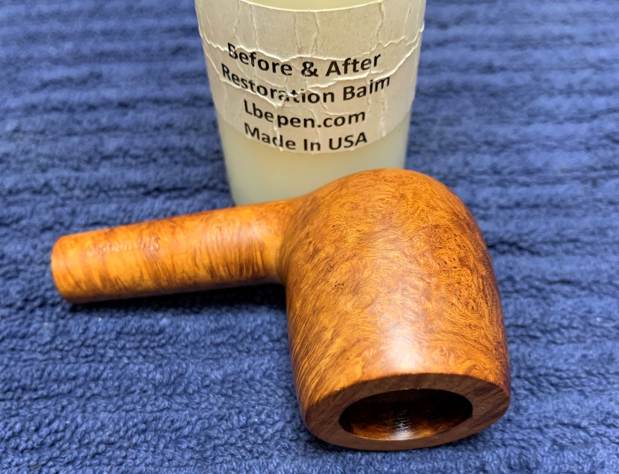

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips and let it do its magic. The product cleans, enlivens and preserves the briar. I let it sit for 10 minutes and then buffed it off with a cotton cloth. The bowl really is looking good at this point.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips and let it do its magic. The product cleans, enlivens and preserves the briar. I let it sit for 10 minutes and then buffed it off with a cotton cloth. The bowl really is looking good at this point.

I set the bowl aside and turned my attention to the stem. I scrubbed it with Soft Scrub cleanser to remove the residual oxidation that remained on the surface of both sides. I find that when I let the pipe sit a long time before getting to it this light oxidation almost always happens.

I set the bowl aside and turned my attention to the stem. I scrubbed it with Soft Scrub cleanser to remove the residual oxidation that remained on the surface of both sides. I find that when I let the pipe sit a long time before getting to it this light oxidation almost always happens. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with a cloth impregnated with Obsidian Oil. I polished it with Before & After Stem Polish – both Fine and Extra Fine then gave it a final coat of Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with a cloth impregnated with Obsidian Oil. I polished it with Before & After Stem Polish – both Fine and Extra Fine then gave it a final coat of Obsidian Oil and set it aside to dry.

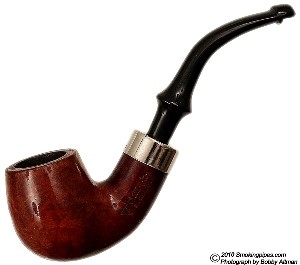

This incredibly beautiful La Savinelli Giubileo D’ Oro Straight Grain –Fiammata- 2 Stars Billiard (114) is an amazing looking pipe. It is a 50th Anniversary Commemorative and part of a limited production “Golden Jubilee” series. That would make it a mid 70s made of briar that was specially selected because of the spectacular grain. I put the stem on the shank and buffed the pipe with Blue Diamond on the wheel (being careful of the stamping so as not to damage that). I gave the bowl and stem multiple coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The dimensions of this pipe are – Length: 5 ¾ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.55 ounces/44 grams. It is really a gorgeous pipe and one that will reside in my own collection for now while I figure out if I want to hang on to it. I look forward to enjoying it soon.

This incredibly beautiful La Savinelli Giubileo D’ Oro Straight Grain –Fiammata- 2 Stars Billiard (114) is an amazing looking pipe. It is a 50th Anniversary Commemorative and part of a limited production “Golden Jubilee” series. That would make it a mid 70s made of briar that was specially selected because of the spectacular grain. I put the stem on the shank and buffed the pipe with Blue Diamond on the wheel (being careful of the stamping so as not to damage that). I gave the bowl and stem multiple coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The dimensions of this pipe are – Length: 5 ¾ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.55 ounces/44 grams. It is really a gorgeous pipe and one that will reside in my own collection for now while I figure out if I want to hang on to it. I look forward to enjoying it soon.