Guest Blog by Robert M. Boughton

Member, International Society of Codgers

Member, North American Society of Pipe Collectors

http://www.naspc.org

http://www.roadrunnerpipesnm.biz

http://about.me/boughtonrobert

Photos © the Author

If it ain’t broke, don’t fix it.

― Thomas Bertram “Bert” Lance (1931-2013), U.S. bank teller to president and Director of the Office of Management and Budget under President Jimmy Carter, in the May 1977 issue of “Nation’s Business” magazine

INTRODUCTION

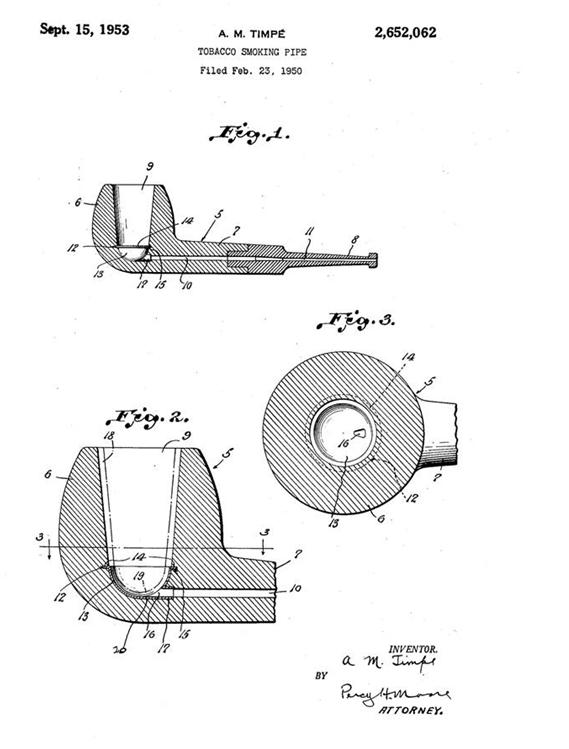

This is a sad tale for all involved: the eBay seller from whom I purchased the GBD straight apple sitter this blog concerns, for $39.99 in April of last year, which the good lady in England refunded five days later; me, as the buyer who requested the refund after receiving the pipe and finding that the photos posted by the seller did not reveal the hidden nomenclature from a previous silver banding to fix an apparent crack in the shank, and at last, in a very real way, the person or persons unknown responsible for the banding itself that, nine months later, I have only just discovered was unnecessary. At least the last of the concerned parties is/are blithely unaware.

That’s right, you read correctly. Although I was justified in asking for the refund, and intended to pay the high postage required to return it to the seller beforehand, she responded, to my gentle but detailed account of the reasoning, with a message that can only be described as hysterical from an obvious sense of unjustified guilt for having “falsely advertised” the GBD. I never used that phrase in my request.

As I recall – though I can’t locate the exchange of emails between the Englishwoman and me that followed my awaiting the arrival of the GBD, with great expectations that were dashed by its clear flaws upon receipt – she wrote back that I should not bother returning it at all, but instead that she would promptly refund my money and I should “keep it, sell it for whatever you can, or throw it away, I don’t care.”

At that point, I was filled with remorse over the anguish in the tone and content of her message that literally rang in my ears, even without an exclamation point. I nevertheless attempted, in a final, unanswered message, to express my intent merely to let her know, in order to sell this pipe or any other (they are not her specialty), that she only needed to add a brief note of the band work and its effect on the nomenclature, as these are important details to collectors and sellers, and perhaps lower her asking price.

After showing the pipe to Chuck Richards, my good friend and mentor, before the emails described above and allowing him to discover on his own the same flaws I detected, he concluded that if I paid more than $10 for it, I should immediately ask for a refund, as I had bought it for my own estate pipe business with the prospect of a quick clean-up for resale. When I told Chuck the actual amount I had shelled out, he was speechless for a moment before all but insisting I seek the refund.

I have been unable to get the shame-riddled emailed words of the kind seller, who as far as I’m concerned made an honest mistake and acted, throughout the transaction, in absolute good faith, out of my mind ever since. I have entertained various options concerning the ultimate disposition of the pipe’s rightful ownership. Of course, I could (A) keep the still beautiful pipe and restore it as best I could to put in my own collection or sell with appropriate disclaimers; (B) clean it up and return it, like a good gentleman, to the grief-stricken lady, with the emphatic suggestion that she give it to a friend who enjoys pipes and would likely treasure this one, if she still didn’t wish to sell it on eBay with a lower price and notices, or (C) complete the work that could be done to fix the damages wrought on the hapless GBD, keep it or sell it but under no circumstances toss it in the trash as the seller advocated, and write the blog now presented as a full and sincere apology to the lady, with the intent of depositing the refunded money back into her PayPal account and forwarding her the link to the blog.

With great effort, I at last located the transaction numbers and dates of the original purchase and refund, and with them was able to obtain the lady’s name and email address.

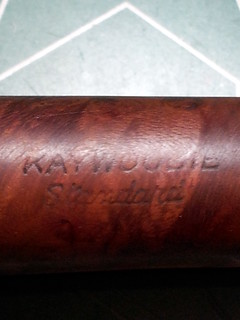

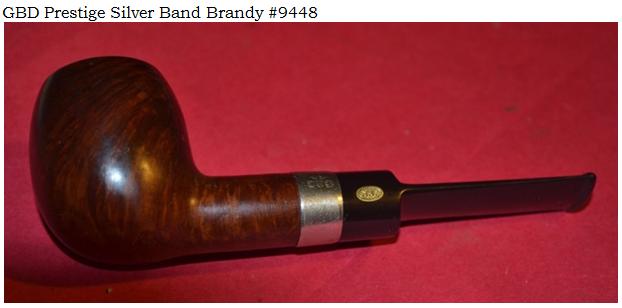

I will save my final decision for later in this account of the restoration of the GBD Prestige straight apple sitter, which research has disclosed was made prior to the acquisition of GBD (an abbreviation of the three founders of the brand in 1850 in Paris – Ganneval, Bondier and Donninger) by Cadogan of the Oppenheimer group in the 1970s. The imprint “London England” in a straight line on the right side of the shank, almost half of which was obliterated by the band, narrowed the pipe to the pre-Cadogan era and also signified that it might have been made in France despite the nomenclature. GBD was last taken over in 1981 by Comoy’s.

The other nomenclature on the Prestige was critically faint, before I started work on it, and included on the left shank the small letters GBD in an oval, barely visible beside the band, and the model name in cursive that took hours to decipher enough to make out the first uncovered letters, “Prest,” which led the excellent Englishwoman to suspect Presto, but I Googled and found the full correct name. On the right shank, equally as light as the left and below “on England,” were three numbers for the shape, 448, which I understood was 9448. Here is what another version of the pipe looked like. The apple of my eyes in this blog is remarkably similar, discounting the nomenclature.

The apple of my eyes in this blog is remarkably similar, discounting the nomenclature.

RESTORATION

[Note the unusual, perfect, pale half oval indentation in the top of the shank in the sixth photo above: I have.no rational explanation for the presence of this mark other than the appearance that it is neither a natural aspect of the wood nor any type of damage, such as a crack. I believe the previous restorer attempted to use a self-made metal band, with the idea of reinforcing the top of the shank without covering any of the nomenclature. If this admittedly crazy-sounding guess is correct, the restorer likely intended to do the same on the bottom of the shank but aborted the idea altogether after failing with the top piece. Call me nuts, but this mark is not an accident.]

[Note the unusual, perfect, pale half oval indentation in the top of the shank in the sixth photo above: I have.no rational explanation for the presence of this mark other than the appearance that it is neither a natural aspect of the wood nor any type of damage, such as a crack. I believe the previous restorer attempted to use a self-made metal band, with the idea of reinforcing the top of the shank without covering any of the nomenclature. If this admittedly crazy-sounding guess is correct, the restorer likely intended to do the same on the bottom of the shank but aborted the idea altogether after failing with the top piece. Call me nuts, but this mark is not an accident.]

Already considering re-banding the apple with a shorter sterling variety, I tugged at the one used in the first place, without much hope that it might be loose, and was surprised when it flew off of the shank and onto my lap. Now that was fortunate indeed, for, upon closer inspection, I was able to see that the tiny line in the shank’s opening, which ignited some daft restorer’s passion to fix something that wasn’t broken, was a mere blemish that led nowhere and, in fact, disappeared with a few seconds of sanding. I have to add an acknowledgement of my simultaneous relief that the shank was not cracked and disgust with the previous restorer who desecrated the otherwise weathered but fine pipe by ruining so much of the invaluable nomenclature. The only remaining imprints were the indentations left from the hallmarks and sterling silver designation on the once tight band. I scoffed out loud after my brain digested this enormous error in judgment that more or less ended any real value – and prestige, so to say – this GBD might have had.

Now that was fortunate indeed, for, upon closer inspection, I was able to see that the tiny line in the shank’s opening, which ignited some daft restorer’s passion to fix something that wasn’t broken, was a mere blemish that led nowhere and, in fact, disappeared with a few seconds of sanding. I have to add an acknowledgement of my simultaneous relief that the shank was not cracked and disgust with the previous restorer who desecrated the otherwise weathered but fine pipe by ruining so much of the invaluable nomenclature. The only remaining imprints were the indentations left from the hallmarks and sterling silver designation on the once tight band. I scoffed out loud after my brain digested this enormous error in judgment that more or less ended any real value – and prestige, so to say – this GBD might have had.

Not yet wanting to deal with the majority of the stummel’s outer area, I decided to start by removing the years of accumulated dirt and whatnot from the wood with small soft white pieces of cotton gun cleaner cloths and much of the rim char with wet micromesh pads and a light touch of superfine steel wool. I followed those tasks by clearing the small amount of excess carbon in the chamber with a 19mm reamer and 200- and 500-grit paper, swabbing with Everclear-soaked cotton cloth pieces, and a retort of the pipe.

The retort turned out to be the hardest part of these preliminary steps, as neither of the two rubber tubes that span the few inches from the boiling Everclear to the lip of the bit would fit the extra wide mouthpiece that was part of the GBD. And so, ad-libbing somewhat, I sought out another bit from my collection with a tenon that fit the GBD and a lip that matched the rubber tube. Of course, the last possible pipe I checked was a match – or closely enough. It was from a favorite Ropp. I had no trouble cleaning the metal inlaid GBD bit with a couple of alcohol-soaked bristly cleaners.

The photos above show the surprising cleanliness of the well-worn sitter, and by inference, the degree of care its fortunate owner once accorded the bijou. The later of two test tubes full of Everclear used in the retort was almost clear, with only a few small, solid pieces of flotsam at the bottom.

The photos above show the surprising cleanliness of the well-worn sitter, and by inference, the degree of care its fortunate owner once accorded the bijou. The later of two test tubes full of Everclear used in the retort was almost clear, with only a few small, solid pieces of flotsam at the bottom.

Here, alas, is where I erred, and will have to accept the consequences, until the day I die, for the heartbreaking lesson they provided. In hindsight, I suppose I might, at this critical stage, have sought the guidance of Chuck or Steve (my second if unofficial mentor in this ever-evolving process of learning). But, as Jesse Eisenberg’s character in “Zombieland,” Columbus (for the city in Ohio where he was born), repeated slowly as a sort of mantra: “Shoulda-coulda-woulda.” Much as Columbus had come up with rules for surviving a zombie apocalypse, so have I adopted a set of guidelines, from my own experiences and those of others, for pipe restoring.

Sometimes I ignore one of these, for the most part with success, and sometimes I have to learn the hard way, on my own. Still, as I type this, I find myself experiencing emotions I prefer to avoid. Recognizing my harshness with the previous restorer, and my own share of fault for the apple’s present condition, I nevertheless tell myself I did my best, alone, to return the splendid pipe to its potential glory. My mistake, although unintentionally made in the pursuit of correcting one more egregious that I believed necessitated my next step, is on me.

To the point, and in spite of a note in my previous blog that I try my best to avoid full stripping of a pipe’s original stain and waxes with an Everclear bath, that is what I did.

These photos show two things: the wonderful success in removing the remaining rim char and reducing the wood to its natural smoothness, and, as an unexpected result of the latter, also eliminating almost every vestige of the remaining nomenclature. Anyone who loves pipes with all of his heart, as I do, will comprehend the complete hollowness, in the pit of my stomach and consuming my mind, I experienced upon seeing with my own eyes the gaff I had committed. I sat there on my couch awhile, stunned, until I forced myself to snap out of the melancholy reverie and get on with it.

These photos show two things: the wonderful success in removing the remaining rim char and reducing the wood to its natural smoothness, and, as an unexpected result of the latter, also eliminating almost every vestige of the remaining nomenclature. Anyone who loves pipes with all of his heart, as I do, will comprehend the complete hollowness, in the pit of my stomach and consuming my mind, I experienced upon seeing with my own eyes the gaff I had committed. I sat there on my couch awhile, stunned, until I forced myself to snap out of the melancholy reverie and get on with it.

Flashing on memories of a few pipes restored by Chuck, and which I bought despite the blemishes I detected and wondered why he let them remain, I knew the full answer he omitted, in his enigmatic way, when I asked him. Some flaws, as battles, are better left unfought. Before I reached this conclusion – as my mind was still rampaging with thoughts of how I should have approached the same notion of stripping the original stain and waxes from just the bowl and chamber, or could have accomplished the goal better, or would have saved the fragile markings that could now be visible – I had to suffer the unavoidable fact of my misdeed. Shoulda-coulda-woulda.

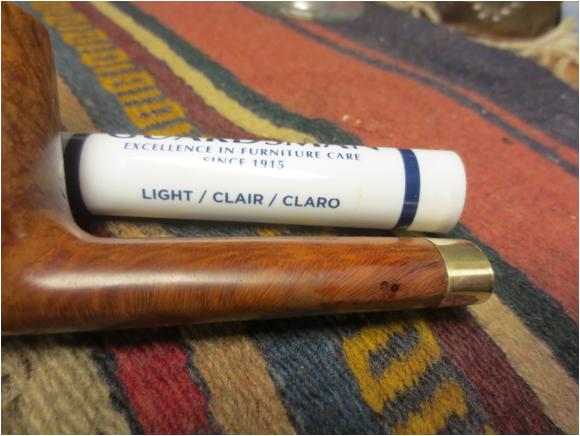

Thus I embarked on the only course of action I had left – to re-smooth and finish cleaning the chamber with 150-, 200- and 500-grit papers followed by small cotton cloths soaked with alcohol, and returning the sheen of the wood using superfine steel wool and then 3600-12000 micromesh pads. I then re-stained the briar, first trying Lincoln Medium Brown leather dye and flaming it before buffing with 6000 and 8000 micromesh.

I saw that the clear, pale half-oval shape, from the suspected attempt by the previous restorer to use an adornment band to fix the misperceived shank crack, remained stubbornly. And so, having nothing to lose, I sanded the open end of the shank with 150-, 200-, 320- and 500-grit papers before micro-meshing and staining again. I’ll tell you straight out, this was not the end of the struggle to fix the single blemish.

I saw that the clear, pale half-oval shape, from the suspected attempt by the previous restorer to use an adornment band to fix the misperceived shank crack, remained stubbornly. And so, having nothing to lose, I sanded the open end of the shank with 150-, 200-, 320- and 500-grit papers before micro-meshing and staining again. I’ll tell you straight out, this was not the end of the struggle to fix the single blemish. Of course, I buffed off the char from flaming the end of the shank with 6000 and 8000 micromesh, and reattached the bit to the shank with the band removed, to check the fit. The bit was still a match with the shank!

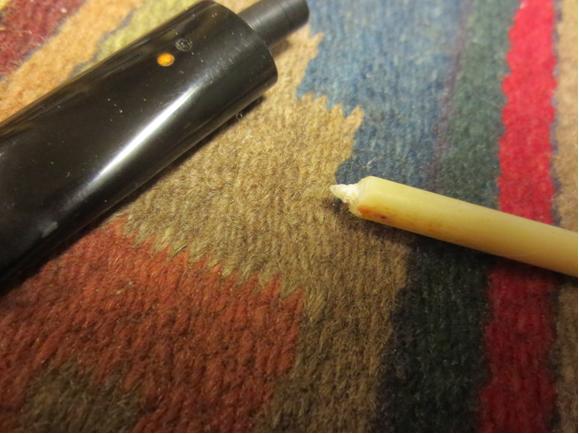

Of course, I buffed off the char from flaming the end of the shank with 6000 and 8000 micromesh, and reattached the bit to the shank with the band removed, to check the fit. The bit was still a match with the shank! Grateful to have something go right, I turned in that direction and went after the bit. The photos below show before, as it arrived in the mail, and after I worked on it with the tools displayed.

Grateful to have something go right, I turned in that direction and went after the bit. The photos below show before, as it arrived in the mail, and after I worked on it with the tools displayed.

This blog is nothing if not a cautionary tale about the horrors of reversing someone else’s mistakes – of which mine, unfortunately, cannot be undone. I return to the battle of the pernicious, aborted oval pipe band, at the very moment I concluded that maybe a darker staining, adding Lincoln’s version of burgundy red to the medium brown I applied earlier, would help me be out, out with the foul spot. I was wrong, but here’s what it looked like after flaming the alcohol out of the stain.

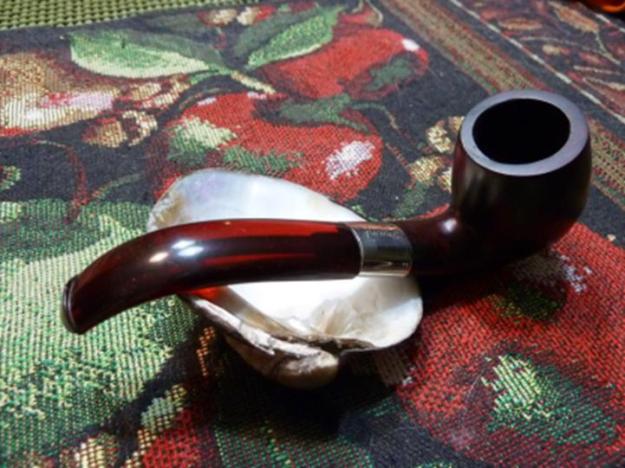

This blog is nothing if not a cautionary tale about the horrors of reversing someone else’s mistakes – of which mine, unfortunately, cannot be undone. I return to the battle of the pernicious, aborted oval pipe band, at the very moment I concluded that maybe a darker staining, adding Lincoln’s version of burgundy red to the medium brown I applied earlier, would help me be out, out with the foul spot. I was wrong, but here’s what it looked like after flaming the alcohol out of the stain. However, this was, at least, a step in the right direction. I concluded that, despite my deepest desire not to be forced to re-shackle the apple sitter with the excellent but unnecessary sterling band that caused this ruckus in the first place, I had no choice. I Super Glued the band firmly back onto the shank, with the hallmarks on the left side, and it did serve to obscure most of the oval shape. Before I snapped the next photos, I added another spot stain using more of the medium brown, flamed it and buffed with 8000 micromesh. That was pretty much the end of the oval spot!

However, this was, at least, a step in the right direction. I concluded that, despite my deepest desire not to be forced to re-shackle the apple sitter with the excellent but unnecessary sterling band that caused this ruckus in the first place, I had no choice. I Super Glued the band firmly back onto the shank, with the hallmarks on the left side, and it did serve to obscure most of the oval shape. Before I snapped the next photos, I added another spot stain using more of the medium brown, flamed it and buffed with 8000 micromesh. That was pretty much the end of the oval spot!

At long last, I was ready for the final buffing on my electric wheels, which as always involved the clean buffer after each of the waxes. For the bit, I used the regular red and white Tripoli and White Diamond. Having let every other convention fly in the wind, the thought occurred to me to wax the stummel with the red Tripoli as well as white, followed by White Diamond and a slow double-coat of carnauba.

At long last, I was ready for the final buffing on my electric wheels, which as always involved the clean buffer after each of the waxes. For the bit, I used the regular red and white Tripoli and White Diamond. Having let every other convention fly in the wind, the thought occurred to me to wax the stummel with the red Tripoli as well as white, followed by White Diamond and a slow double-coat of carnauba.

CONCLUSION

The foul spot still remains enough for a good eye to catch, if not the camera for once. I’m going to sum this up with the note that I sincerely hope I succeeded in creating a final result that, despite its one glaring disaster, reveals a more beautiful grain than the original darker version. And one more thing: I have decided to return the money the Englishwoman who gave me this fine GBD refunded to me last April, and then forward the link to this explanation. At this point in the whole experience with the cursed and enchanted apple sitter, I am happy to take a loss for once, and will try to sell the pipe for $25. I have no doubt the lady in England is lovely. How could she not be, given her obvious love of pipes that equals mine?

SOURCES

http://www.pipephil.eu/logos/en/logo-gbd.html

http://yeoldebriars.com/gbd013.html

https://www.youtube.com/watch?v=LPIuIfAywvY Zombieland Rules (AC, AL, GL, V)

UPCOMING RESTORES

Wondering what else would go wrong with this restoration I proceeded carefully with one eye looking over my shoulder. It seems these comedies of error come in sets. Who knows what would come next in the folly of this clean up. I poured out my can of stems and went through them until I found a stem that was close to the diameter of the shank. I drilled the airway in the tenon end to accommodate the centre pin on the PIMO tenon turning tool and then pushed the stem onto it. I slowly and by stages turned the tenon to fit the shank. My normal practice is to turn it as close as possible with the tool and then fine tune it by hand with sandpaper. I saw no need to invite trouble so I followed that process to the letter.

Wondering what else would go wrong with this restoration I proceeded carefully with one eye looking over my shoulder. It seems these comedies of error come in sets. Who knows what would come next in the folly of this clean up. I poured out my can of stems and went through them until I found a stem that was close to the diameter of the shank. I drilled the airway in the tenon end to accommodate the centre pin on the PIMO tenon turning tool and then pushed the stem onto it. I slowly and by stages turned the tenon to fit the shank. My normal practice is to turn it as close as possible with the tool and then fine tune it by hand with sandpaper. I saw no need to invite trouble so I followed that process to the letter. I used a Dremel and sanding drum to cut back the excess vulcanite of the stem. This is handwork and takes a steady hand so as not to nick the shank of the pipe. Whew! I made it without damaging the briar and making more work for myself. I used a rasp to remove more of the excess diameter on the stem at the shank.

I used a Dremel and sanding drum to cut back the excess vulcanite of the stem. This is handwork and takes a steady hand so as not to nick the shank of the pipe. Whew! I made it without damaging the briar and making more work for myself. I used a rasp to remove more of the excess diameter on the stem at the shank. I worked on it with the rasp until I had the fit close, then I put a plastic washer between the shank and the stem and sanded it with 220 grit sandpaper. I wanted to smooth out the surface and remove the marks left by the Dremel and the rasp at the transition point.

I worked on it with the rasp until I had the fit close, then I put a plastic washer between the shank and the stem and sanded it with 220 grit sandpaper. I wanted to smooth out the surface and remove the marks left by the Dremel and the rasp at the transition point. I don’t know about you but after all of the detailed Dremel, filing and sanding work my hands need a break. I laid aside the stem and did some simple work. I cleaned out the inside of the bowl and shank with pipe cleaners, cotton swabs and alcohol.

I don’t know about you but after all of the detailed Dremel, filing and sanding work my hands need a break. I laid aside the stem and did some simple work. I cleaned out the inside of the bowl and shank with pipe cleaners, cotton swabs and alcohol. After that my hands were quite rested and it was time to get back to the stem. The fine tuning of the shape of the stem is tedious when it is done by hand. I don’t have a belt sander or power tools to make this go more quickly, so it is just ongoing hand work. I continued to use 220 grit sandpaper to shape and clean up the fit of the stem at the shank.

After that my hands were quite rested and it was time to get back to the stem. The fine tuning of the shape of the stem is tedious when it is done by hand. I don’t have a belt sander or power tools to make this go more quickly, so it is just ongoing hand work. I continued to use 220 grit sandpaper to shape and clean up the fit of the stem at the shank.

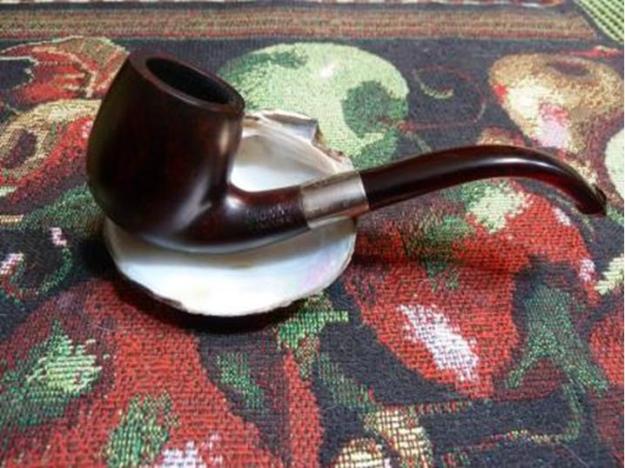

With the fit finished and being acceptable I breathed a sigh of relief. There were no more gaffes that happened up to this point. The stem looked acceptable and the pipe was taking shape. Not too much work left to do before I was finished and the drama was over. I sanded the stem with medium and fine grit sanding sponges to remove the scratches and rubbed the stem down with Obsidian Oil. I took photos of the pipe at this point to make up for the lack of photos due to operator error in the earlier part of the process.

With the fit finished and being acceptable I breathed a sigh of relief. There were no more gaffes that happened up to this point. The stem looked acceptable and the pipe was taking shape. Not too much work left to do before I was finished and the drama was over. I sanded the stem with medium and fine grit sanding sponges to remove the scratches and rubbed the stem down with Obsidian Oil. I took photos of the pipe at this point to make up for the lack of photos due to operator error in the earlier part of the process.

So far no bigger crises than forgetting photos. A few more steps left before I am in the clear on this one. I was moving to the buffer and if something could happen at this point it would be at the buffer. Nothing like getting this far and having the buffer snatch the pipe out of your hand and send it across the room snapping the tenon or cracking the shank. So with fear and trepidation I buffed the bowl and stem with White Diamond before continuing the process of polishing the stem. It worked well and I headed back to the work table. I wet sanded the stem with 1500-2400 micromesh sanding pads and then gave it a coat of Obsidian Oil. I dry sanded with 3200-12000 grit pads and then gave it a final rub down of the oil. I let the oil dry.

So far no bigger crises than forgetting photos. A few more steps left before I am in the clear on this one. I was moving to the buffer and if something could happen at this point it would be at the buffer. Nothing like getting this far and having the buffer snatch the pipe out of your hand and send it across the room snapping the tenon or cracking the shank. So with fear and trepidation I buffed the bowl and stem with White Diamond before continuing the process of polishing the stem. It worked well and I headed back to the work table. I wet sanded the stem with 1500-2400 micromesh sanding pads and then gave it a coat of Obsidian Oil. I dry sanded with 3200-12000 grit pads and then gave it a final rub down of the oil. I let the oil dry.

One more dangerous trip to the buffer to go and I was home free. I buffed the pipe with Blue Diamond on the wheel and then gave the bowl and stem multiple coats of carnauba wax. I buffed it with a clean buff with no drama so I was finished with that part of the work. I gave it final hand buff with a microfibre cloth. The finished pipe is shown below. Not too bad – only problem in the process was the photos. Whew! Now one question remains should I give the stem a slight bend or not. What do you think?

One more dangerous trip to the buffer to go and I was home free. I buffed the pipe with Blue Diamond on the wheel and then gave the bowl and stem multiple coats of carnauba wax. I buffed it with a clean buff with no drama so I was finished with that part of the work. I gave it final hand buff with a microfibre cloth. The finished pipe is shown below. Not too bad – only problem in the process was the photos. Whew! Now one question remains should I give the stem a slight bend or not. What do you think?