Blog by Steve Laug

The next pipe on the table was purchased from an estate lot on 06/13/22 from Fort Myers, Florida, USA. It has that verve that I have come to associate with pipe made by Preben Holm and the fellow we purchase this lot from obviously love Preben Holm pipes because we acquired several from him in this lot from the IIS pipes to a Danish Pride still to come. They are unique and beautiful. The pipe is stamped on a smooth panel on the underside. It reads Monte Verde over Made in Denmark by Hand. Underneath that there is a script stamp that reads Twin Finish. I have refurbished several Monte Verde pipe so if you are interested in the brand here is a link to one I did back in 2019 that is very similar to this one (https://rebornpipes.com/2019/02/09/new-life-for-a-preben-holm-monte-verde-twin-finish-freehand/). It was quite dirty, like the rest of the pipes in this collection. There was a thick cake in the bowl and a heavy lava overflow on the rim top that filled in the rustication. The inner and outer edges of the bowl looked very good. The stem had some light tooth marks and chatter on both sides near the button but really was in quite remarkable condition. Jeff took photos of the pipe before he started his cleanup process.

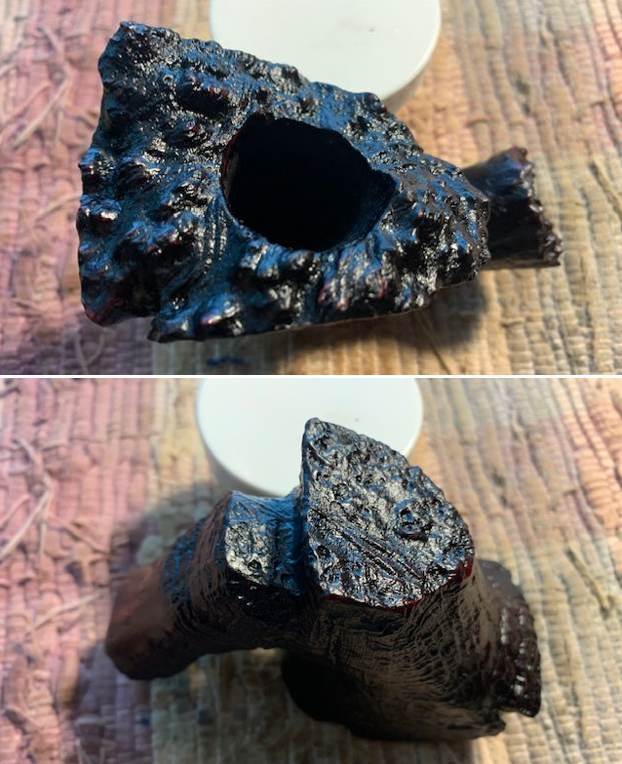

The next photos show a close up of the bowl and rim top as well as both sides of the stem. You can see the thick cake in the bowl and heavy overflow of lava on the rim top. The close up photos of the stem show the light tooth marks in the surface near the button on both sides.

The next photos show a close up of the bowl and rim top as well as both sides of the stem. You can see the thick cake in the bowl and heavy overflow of lava on the rim top. The close up photos of the stem show the light tooth marks in the surface near the button on both sides.

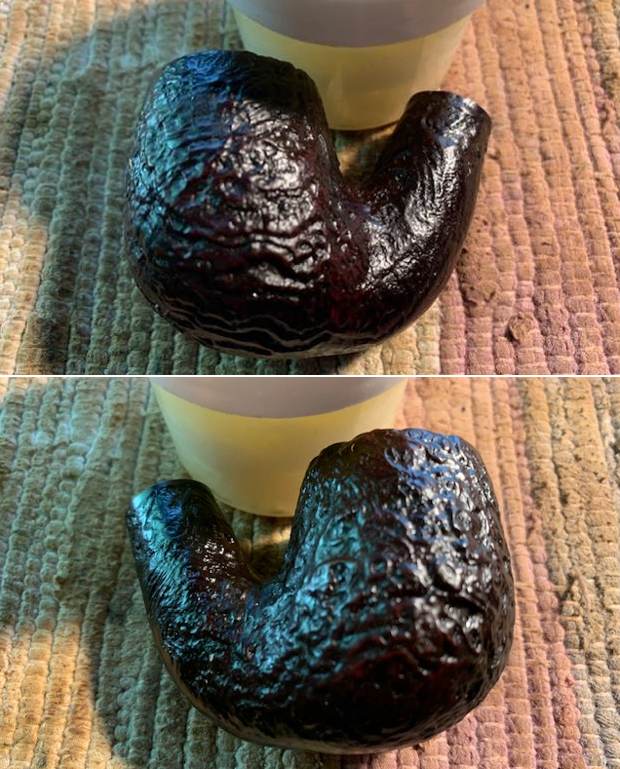

He took photos of the sides and heel of the bowl to show the look the double rustication on the sides and heel of the bowl. The curved shape of the pipe makes it a tall Dublinesque Stack but the rustication gives it a tactile look that can only mean an added dimension to the pipe when it is smoked.

He took photos of the sides and heel of the bowl to show the look the double rustication on the sides and heel of the bowl. The curved shape of the pipe makes it a tall Dublinesque Stack but the rustication gives it a tactile look that can only mean an added dimension to the pipe when it is smoked.  The next photos show the stamping on the underside of the shank and the top of the saddle stem. It is quite clear and legible. The top of the stylized saddle stem has a Crown MV stamped into the surface. It appears to have originally been gold.

The next photos show the stamping on the underside of the shank and the top of the saddle stem. It is quite clear and legible. The top of the stylized saddle stem has a Crown MV stamped into the surface. It appears to have originally been gold.  I turned to Pipephil’s site to get a read on the brand (http://pipephil.eu/logos/en/logo-m6.html). It confirms that the Monte Verdi line was made by Preben Holm. The pipe in the photo had a very similar rustication to the Monte Verdi I was working on. I did a screen capture of the section on Pipephil. I have included it below.

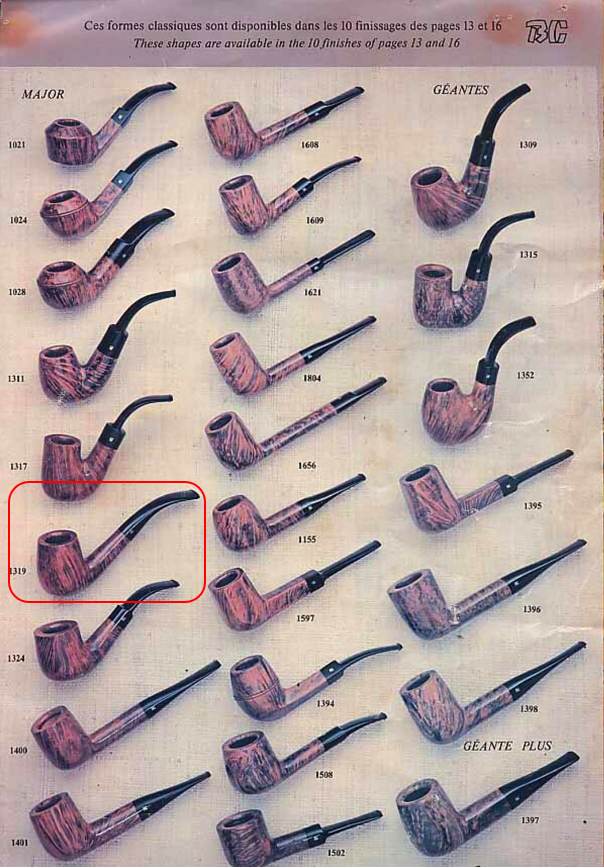

I turned to Pipephil’s site to get a read on the brand (http://pipephil.eu/logos/en/logo-m6.html). It confirms that the Monte Verdi line was made by Preben Holm. The pipe in the photo had a very similar rustication to the Monte Verdi I was working on. I did a screen capture of the section on Pipephil. I have included it below.  There were also photos that were included on Pipephil of what this particular pipe looked like when it left Denmark. The rustication around the bowl and shank is very similar. The pipe I have does not have a shank extension but otherwise the finish is much the same. The pipe in the photo had a fancy turned vulcanite stem. The stem on the one I have in front of me is the original stem on the pipe and it is a fancy double saddle pearlized acrylic or Lucite stem.

There were also photos that were included on Pipephil of what this particular pipe looked like when it left Denmark. The rustication around the bowl and shank is very similar. The pipe I have does not have a shank extension but otherwise the finish is much the same. The pipe in the photo had a fancy turned vulcanite stem. The stem on the one I have in front of me is the original stem on the pipe and it is a fancy double saddle pearlized acrylic or Lucite stem. I also Googled the brand and found a thread on Pipes Magazine about the brand that gave me some more information (http://pipesmagazine.com/forums/topic/monte-verde-pipes). I include that below.

I also Googled the brand and found a thread on Pipes Magazine about the brand that gave me some more information (http://pipesmagazine.com/forums/topic/monte-verde-pipes). I include that below.

The Monte Verdi line was indeed a pipe style offered by Holm. It usually features heavily blasted and rusticated briar and smaller group sizes than some of his other lines. Some refer to this line as a “second”, but it provided an outlet for briar that had flaws and therefore unsuitable his other lines. Holm marketed many different lines featuring a variety of finishes in both stains and carvings and this is merely one of those. The ones I own are good pipes and smoke well. The blast finish is very interesting to look at and the tactile sensations make it fun to hold.

Jeff reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl. He rinsed it under running water. He dried it off with a soft cloth. He was able to remove most of the lava build up on the rim top and you could see a little remaining in the depths of the rustication. He cleaned out the inside of the stem with pipe cleaners, cotton swabs and alcohol. He scrubbed the surface o the stem with Soft Scrub Cleanser. The stem looked very good. I took photos of the pipe to show its condition before I started my work on it.

I took close up photos of the bowl and rim top as well as the stem. You can see the condition of the rim top and bowl in the first photo. Jeff was able to remove almost all of the tar and oils but there was some deep lava in the rustication at the back of the rim. The Lucite stem had light tooth chatter and tooth marks on the top and underside of the stem near and on the button surface. The swirled browns, tans, blacks and greys of the Lucite looked good with the variegated browns of the briar.

I took close up photos of the bowl and rim top as well as the stem. You can see the condition of the rim top and bowl in the first photo. Jeff was able to remove almost all of the tar and oils but there was some deep lava in the rustication at the back of the rim. The Lucite stem had light tooth chatter and tooth marks on the top and underside of the stem near and on the button surface. The swirled browns, tans, blacks and greys of the Lucite looked good with the variegated browns of the briar.  I also took a photo of the stamping on the underside of the shank. The stamping is very clear and readable. You can also see the scratches in the smooth finish of the area in the photo below.

I also took a photo of the stamping on the underside of the shank. The stamping is very clear and readable. You can also see the scratches in the smooth finish of the area in the photo below. I removed the stem from the shank and took a photo of the parts. It is a nice looking pipe with the flumed top, the rugged double rustication and the double saddle smoky acrylic stem.

I removed the stem from the shank and took a photo of the parts. It is a nice looking pipe with the flumed top, the rugged double rustication and the double saddle smoky acrylic stem. I started by working on the rim top. I used a brass bristle wire brush to clean off the remaining lava debris on the rim top. I was able to remove all of the remaining debris and the rim top looked really good. The deep rustication and the second wire rustication gave the pipe a very unique look.

I started by working on the rim top. I used a brass bristle wire brush to clean off the remaining lava debris on the rim top. I was able to remove all of the remaining debris and the rim top looked really good. The deep rustication and the second wire rustication gave the pipe a very unique look. With the rim top cleaned I worked some Before & After Restoration Balm into the rusticated surface of the briar with my fingertips to clean, enliven and protect it. It took some time to really get it into the grooves and valleys of the rustication but I was able to work it in. I used a shoe brush to make sure it was deep in the grooves. I let the balm sit for 10 minutes and then buffed it with a cotton cloth to raise the shine. The following photos show the bowl at this point in the restoration process. The bowl and the rim top look really good and the darkening and lava are gone. I am very happy with the results.

With the rim top cleaned I worked some Before & After Restoration Balm into the rusticated surface of the briar with my fingertips to clean, enliven and protect it. It took some time to really get it into the grooves and valleys of the rustication but I was able to work it in. I used a shoe brush to make sure it was deep in the grooves. I let the balm sit for 10 minutes and then buffed it with a cotton cloth to raise the shine. The following photos show the bowl at this point in the restoration process. The bowl and the rim top look really good and the darkening and lava are gone. I am very happy with the results.

I set aside the bowl at this point and turned my attention to the stem. I repaired the tooth marks with clear super glue. Once the glue cured I sanded the repairs with 220 grit sandpaper to blend them into the rest of the stem surface. I polished the sanding marks with 400 grit wet dry sandpaper. The photos tell the story.

I set aside the bowl at this point and turned my attention to the stem. I repaired the tooth marks with clear super glue. Once the glue cured I sanded the repairs with 220 grit sandpaper to blend them into the rest of the stem surface. I polished the sanding marks with 400 grit wet dry sandpaper. The photos tell the story.

I touched up the stamping on the saddle portion of the stem with some Rub’n Buff Antique Gold. I let it dry in the stamping for a bit then buffed it off with a cotton pad. It looked much better. The MV was legible and the crown looked good. The side of the M was a little faint as the stamping was worn.

I touched up the stamping on the saddle portion of the stem with some Rub’n Buff Antique Gold. I let it dry in the stamping for a bit then buffed it off with a cotton pad. It looked much better. The MV was legible and the crown looked good. The side of the M was a little faint as the stamping was worn.  I polished the Lucite stem with micromesh sanding pads – wet sanding with 1500-2400 grit sanding pads and dry sanding it with 3200-12000 grit sanding pads. I wiped it down after each sanding pad with a damp cloth. I polished it with Before & After Pipe Stem Polish and wiped it down a last time with the damp cloth.

I polished the Lucite stem with micromesh sanding pads – wet sanding with 1500-2400 grit sanding pads and dry sanding it with 3200-12000 grit sanding pads. I wiped it down after each sanding pad with a damp cloth. I polished it with Before & After Pipe Stem Polish and wiped it down a last time with the damp cloth.

This beautiful, double rusticated Preben Holm carved Monte Verde Twin Finish Large Freehand is a special looking pipe and it feels amazing in the hand. I polished stem with Blue Diamond polish on the buffing wheel. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The multi-coloured grain shining through the rustication came alive with the buffing. The rich contrasting brown colour works well with the polished swirling brown, tan, black and white Lucite stem. The finished pipe is a beauty and feels great in the hand. Have a look at it with the photos below. The dimensions are Length: 6 ½ inches, Height: 3 inches, Outside diameter of the bowl: 2 inches, Chamber diameter: 1 inch. The weight of the pipe is 2.75 ounces/ 78 grams. I will be putting this Monte Verde by Preben Holm on the Danish Pipe Making Section on the rebornpipes online store soon. It is such an interesting tactile pipe and if you have been looking for a freehand then this might be the one for you. Thanks for walking through the restoration with me on this interestingly shaped Preben Holm Hand made pipe.

This beautiful, double rusticated Preben Holm carved Monte Verde Twin Finish Large Freehand is a special looking pipe and it feels amazing in the hand. I polished stem with Blue Diamond polish on the buffing wheel. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The multi-coloured grain shining through the rustication came alive with the buffing. The rich contrasting brown colour works well with the polished swirling brown, tan, black and white Lucite stem. The finished pipe is a beauty and feels great in the hand. Have a look at it with the photos below. The dimensions are Length: 6 ½ inches, Height: 3 inches, Outside diameter of the bowl: 2 inches, Chamber diameter: 1 inch. The weight of the pipe is 2.75 ounces/ 78 grams. I will be putting this Monte Verde by Preben Holm on the Danish Pipe Making Section on the rebornpipes online store soon. It is such an interesting tactile pipe and if you have been looking for a freehand then this might be the one for you. Thanks for walking through the restoration with me on this interestingly shaped Preben Holm Hand made pipe.