Blog by Steve Laug

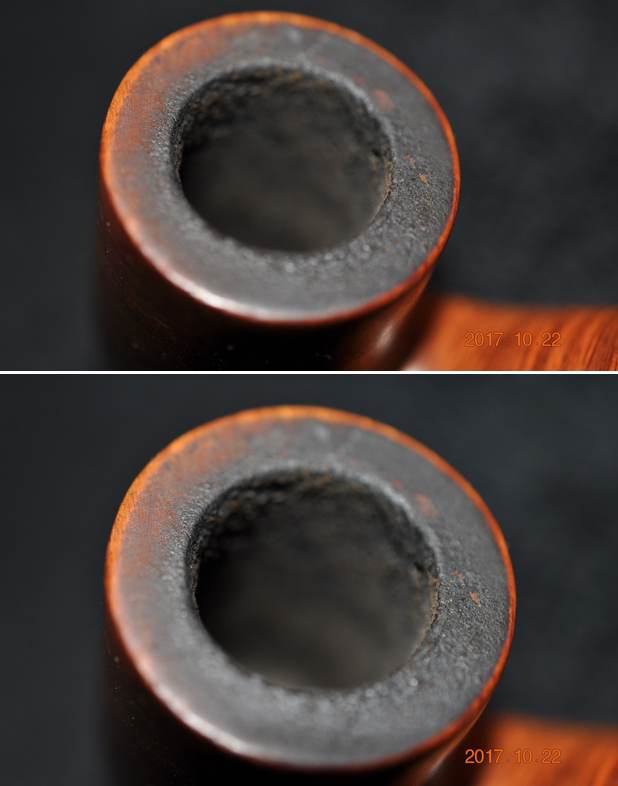

The next pipe on the table was purchased from an antique store on 10/20/2017 in Pocatello, Idaho, USA. It is stamped on the left side of the shank and reads Peterson’s [over] “Dunmore”. On the right side it is stamped Made in the Republic of Ireland followed by the shape number 79. It was someone’s favourite pipe as could be seen from the thick cake in the bowl and the lava build up on the rim top. The finish looked good underneath all of the grime that was ground into the bowl sides and heel. The beaded decoration on the shank end is in excellent condition. Like other Dunmore’s I have worked on it had a flattened shank and the pipe functioned as a sitter. The stem was in excellent condition with some very light tooth marks and chatter on both sides ahead of the p-lip. The “P” stamp on the left side of the stem was clear and just needed to be touched up otherwise it looked good. Jeff took photos of the pipe before he started his clean up work on it. It is a pretty pipe!

The next photos show the bowl and rim top as well as the stem condition. The bowl was clean and ready to fire up. The rim edge was out of round and showed some damage and darkening. The rim top also had some darkening. The stem looked very good with some light tooth chatter and scratches.

The next photos show the bowl and rim top as well as the stem condition. The bowl was clean and ready to fire up. The rim edge was out of round and showed some damage and darkening. The rim top also had some darkening. The stem looked very good with some light tooth chatter and scratches.

Jeff took a photo of the heel of the bowl and shank to show the swirling patterns of the grain in the briar. It is unique and quite beautiful. I can’t wait to see it once it is cleaned and polished.

Jeff took a photo of the heel of the bowl and shank to show the swirling patterns of the grain in the briar. It is unique and quite beautiful. I can’t wait to see it once it is cleaned and polished. The stamping on the shank sides was very readable and read as noted above. It had been buffed but was not overly damaged.

The stamping on the shank sides was very readable and read as noted above. It had been buffed but was not overly damaged.

I turned to a previous blog on the Dunmore I had worked on and reread it before starting my work (https://rebornpipes.com/2019/08/18/restoring-a-petersons-dunmore-70-bent-apple-sitter-from-bob-kerrs-estate/). I quote from the blog on the Dunmore line below.

I turned to a previous blog on the Dunmore I had worked on and reread it before starting my work (https://rebornpipes.com/2019/08/18/restoring-a-petersons-dunmore-70-bent-apple-sitter-from-bob-kerrs-estate/). I quote from the blog on the Dunmore line below.

I then turned to the book I should have consulted first, The Peterson Pipe, by Mark Irwin and Gary Malmberg. On page 298 there is an entry for Dunmore pipes. It reads as follows:

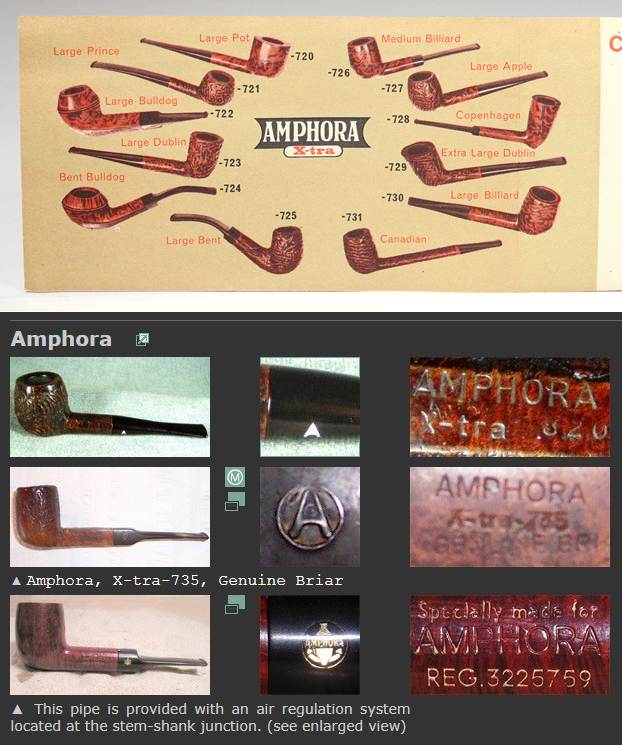

Dunmore (1971-c.1984 2006-10). Appeared first as Iwan Ries & Co. exclusive line “Dunmoor,” a Premier-grade in light-brown smooth or rustic red in all System shapes, with beading at the shank. Documented in the Associated Imports Catalog from 1973. Classic Range Dunmore shapes from ’78. A third Dunmore line (’06-10) featured standard and some B shapes, with beading around bowl instead of at shank-face, produced for European market.

On page 165 there were also photos of pages from a catalogue with the description: The unmounted Dunmore Premier debuted in both System and Classic Range shapes circa 1973 with a final appearance in the 1981 catalogue.

The information blurb on each page read: “Dunmore Briars.” Beautifully grained best quality briar in light-brown, matt or rustic finish. Often described as “Petersons Unmounted System” has all the advantages of the system range. Ten models each fitted with the Peterson Lip mouthpiece.

With that information in hand I knew what I was dealing with in terms of the stamping on the pipe. It is a Late Republic era pipe. It showed up in Peterson Catalogue in 1973. Now it was time to work on the pipe.

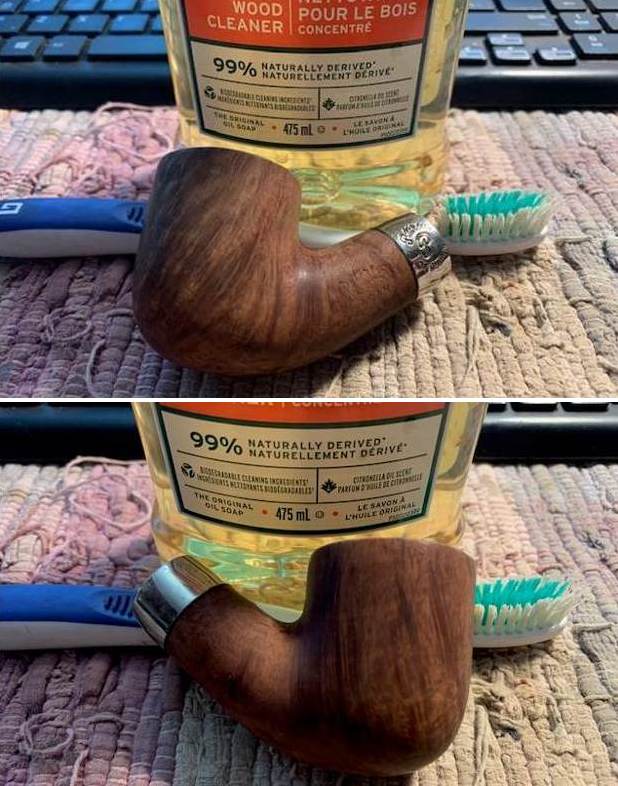

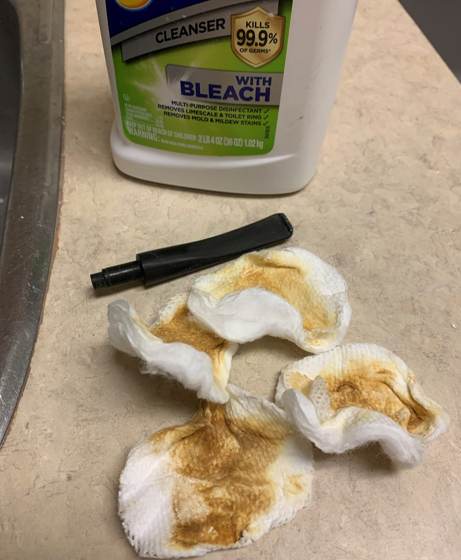

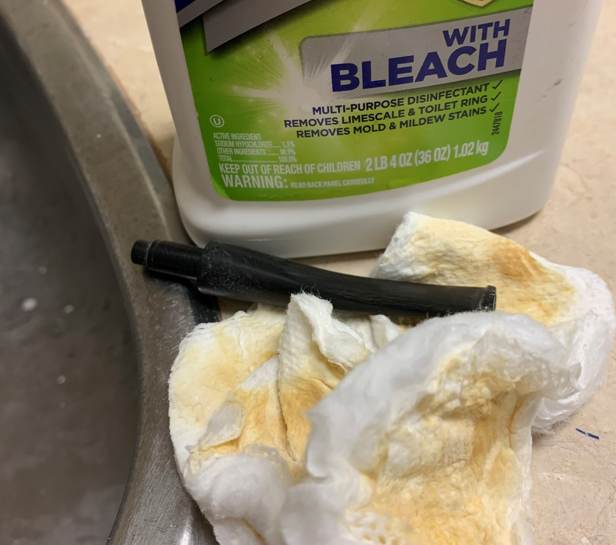

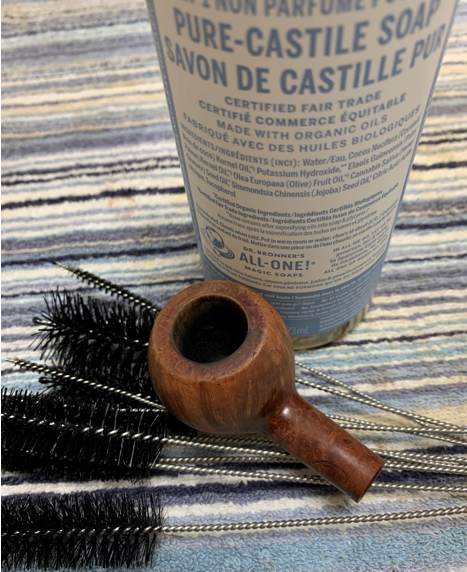

With that information at hand I turned to work on the pipe itself. Jeff had thoroughly cleaned up the pipe. He reamed the pipe with a PipNet Pipe Reamer and cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the stem with Soft Scrub to remove as much of the oxidation and calcification as possible. He soaked the stem in Before & After Deoxidizer and rinsed it off with warm water. I took photos of the pipe once I started to work on it.

I took close up photos of the bowl and the stem. You can see the reamed bowl and the darkening and damage on the rim top and the edges. The stem surface was clean but there are light tooth marks and chatter on both sides on and ahead of the button.

I took close up photos of the bowl and the stem. You can see the reamed bowl and the darkening and damage on the rim top and the edges. The stem surface was clean but there are light tooth marks and chatter on both sides on and ahead of the button.  I took a photo of the stamping on the sides of the shank. It is clear and readable as noted above. There is also a “P” stamp on the right side of the stem.

I took a photo of the stamping on the sides of the shank. It is clear and readable as noted above. There is also a “P” stamp on the right side of the stem. I removed the stem from the shank and took a photo to give a sense of the proportions of the pipe. It is really quite nice looking.

I removed the stem from the shank and took a photo to give a sense of the proportions of the pipe. It is really quite nice looking.  I decided to start my work on this one by reworking the inner edge of the rim with a folded piece of 220 grit sandpaper. I wanted to try and bring it back into round and smooth out the jagged condition.

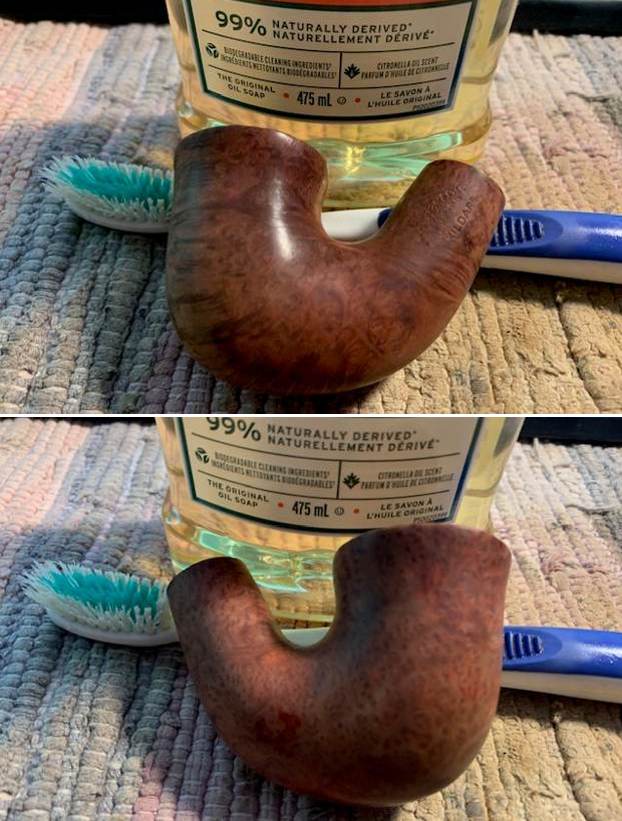

I decided to start my work on this one by reworking the inner edge of the rim with a folded piece of 220 grit sandpaper. I wanted to try and bring it back into round and smooth out the jagged condition. I polished the briar and the rim top with micromesh sanding pads – 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth. You can see a few of the flaws in the sides of the bowl and shank in the photos below. The bowl looks great though.

I polished the briar and the rim top with micromesh sanding pads – 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth. You can see a few of the flaws in the sides of the bowl and shank in the photos below. The bowl looks great though.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

I touched up the “P” stamp on the left side of the flared saddle stem with white acrylic fingernail polish. I applied it and worked it into the stamp with a tooth pick. Once it cured I scraped off the excess. It is definitely better though the stamp is faint in some spots.

I touched up the “P” stamp on the left side of the flared saddle stem with white acrylic fingernail polish. I applied it and worked it into the stamp with a tooth pick. Once it cured I scraped off the excess. It is definitely better though the stamp is faint in some spots.  I “painted” the tooth marks on the stem with the flame of a Bic lighter to lift them. I was able to lift them a lot. I filled in what remained with clear CA glue. Once the repairs cured I used a small file to flatten them and sanded them smooth with 220 grit sandpaper. I started polishing the stem with 400 grit wet dry sandpaper.

I “painted” the tooth marks on the stem with the flame of a Bic lighter to lift them. I was able to lift them a lot. I filled in what remained with clear CA glue. Once the repairs cured I used a small file to flatten them and sanded them smooth with 220 grit sandpaper. I started polishing the stem with 400 grit wet dry sandpaper.

I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

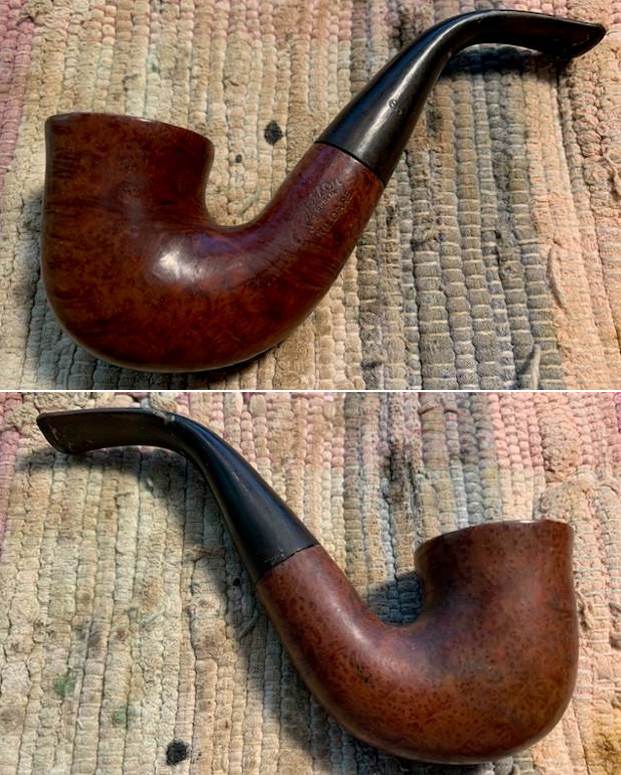

This nice looking Peterson’s Dunmore 79 Bent Billiard and a classic Peterson’s P-lip vulcanite stem looks much better now that it has been restored. The rim top and edges cleaned up very well. The rich brown stains on the bowl came alive with the polishing and waxing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Peterson’s Dunmore is a beauty and fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 59 grams/2.08 ounces. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This nice looking Peterson’s Dunmore 79 Bent Billiard and a classic Peterson’s P-lip vulcanite stem looks much better now that it has been restored. The rim top and edges cleaned up very well. The rich brown stains on the bowl came alive with the polishing and waxing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Peterson’s Dunmore is a beauty and fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 59 grams/2.08 ounces. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!