Guest Blog by Robert M. Boughton

Member, North American Society of Pipe Collectors

http://www.naspc.org

http://www.roadrunnerpipes.com

http://about.me/boughtonrobert

Photos © the Author

“There is nothing more stimulating than a case where everything goes against you.”

― Sir Arthur Ignatius Conan Doyle (1859-1930), Scottish author, in “The Hound of the Baskervilles,” 1902

INTRODUCTION

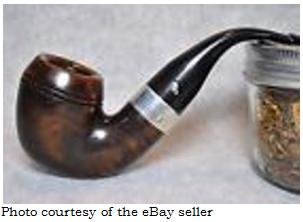

The first time I had occasion to suspect some force was working against me on the subject of this essay, restoring a Peterson’s Sherlock Holmes Baskerville smooth, was my belief that the pipe offered for sale was, in fact, not authentic. The discovery that my fear was misplaced was, of course, a happy relief and led me to purchase the distinctive Hungarian shaped model from an eBay seller. The desired confirmation was the result of an email I sent to Peterson’s of Dublin doubting the legitimacy of the pipe shown due to the absence of the Baskerville name on the nomenclature. In every other respect – its overall appearance, apparent beauty and shape – the pipe seemed right, but these days any online buyer cannot be too careful. I included in my query a link to the eBay listing and soon received the following reply from a gentleman named Glen:

“I can tell you this is a genuine item. It has discoloured due to smoking over the years and there are variations on stampings throughout the years of the lines.”

This brings me to my conclusion that the pipe I bought is from the original Sherlock Holmes Collection in 1987. Later issues tend to include the more common stamping of Peterson’s of Dublin/Sherlock Holmes/Baskerville, while mine is abbreviated to Peterson’s/Sherlock Holmes. The newer designs also have the inset sterling band, while the shape of my older Baskerville is smooth and uniform up the shank leading to the bit.

The other problems I faced with the restoration will be discussed in the order of their occurrences.

The other problems I faced with the restoration will be discussed in the order of their occurrences.

The Baskerville makes the second pipe from the several Peterson’s Sherlock Holmes series I have so far acquired. I expect someday to own the entire collection, in all of the other finishes that include the same number of rustics/sandblasts and eight ebony versions, not to mention one variety that really revs my engine. But that can wait. Here is my other SH pipe. A great fan of the riveting published adventures of the brilliant if fictional mystery sleuth, I never tire of re-reading them or watching the various movie and TV adaptations, in particular the BBCs recent modern-day “Sherlock” with Benedict Cumberbatch in the title role. And as I noted in a previous blog, Holmes, despite the myth born of generations of portrayals by many talented if misled actors, did not smoke a gourd calabash or churchwarden. The most common type or shape of pipe mentioned by his loyal chronicler, in fact, is cherry wood (with six references). See https://www.gutenberg.org/files/1661/1661-h/1661-h.htm – or better yet, re-visit the stories themselves – for details.

A great fan of the riveting published adventures of the brilliant if fictional mystery sleuth, I never tire of re-reading them or watching the various movie and TV adaptations, in particular the BBCs recent modern-day “Sherlock” with Benedict Cumberbatch in the title role. And as I noted in a previous blog, Holmes, despite the myth born of generations of portrayals by many talented if misled actors, did not smoke a gourd calabash or churchwarden. The most common type or shape of pipe mentioned by his loyal chronicler, in fact, is cherry wood (with six references). See https://www.gutenberg.org/files/1661/1661-h/1661-h.htm – or better yet, re-visit the stories themselves – for details.

I came across some curious similarities in the life of the celebrated creator of Mr. Sherlock Holmes of 221B Baker Street in London and the crime solver himself. Despite early stabs at writing, one of which was published, Doyle surprised his family by deciding to pursue a degree in medicine, which he received from the University of Edinburgh in 1881. [http://www.biography.com/people/arthur-conan-doyle-9278600#synopsis]

At least two real persons, both medical doctors contributed to Doyle’s ultimate creation of Sherlock Holmes: one of his professors and mentor, Dr. Joseph Bell, a renowned forensic scientist, had keen powers of observation, and Dr. Henry Littlejohn, a surgeon of police who for almost half a century consulted with Edinburgh police on medical issues related to crimes, both later contributed to Doyle’s unique detective character. [http://www.todayifoundout.com/index.php/2014/04/real-life-sherlock-holmes/]

After Doyle completed his third year of medical school, he signed on a ship’s surgeon for a vessel bound for the arctic circle. This experience gave him a zest for adventure.

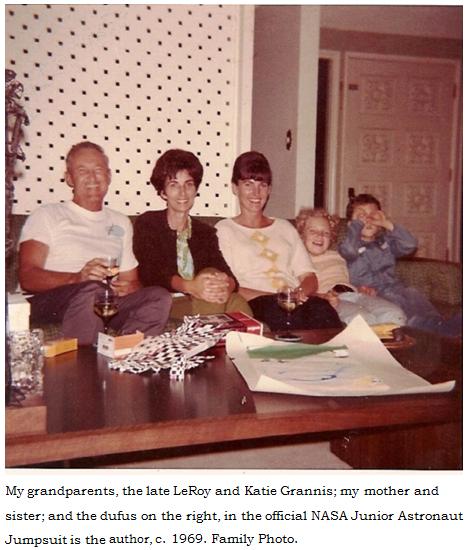

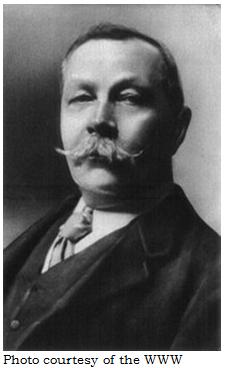

And then there is the Watson connection. Not only was Watson a physician, but take a look at this photo of the author himself and compare the likeness. RESTORATION

RESTORATION

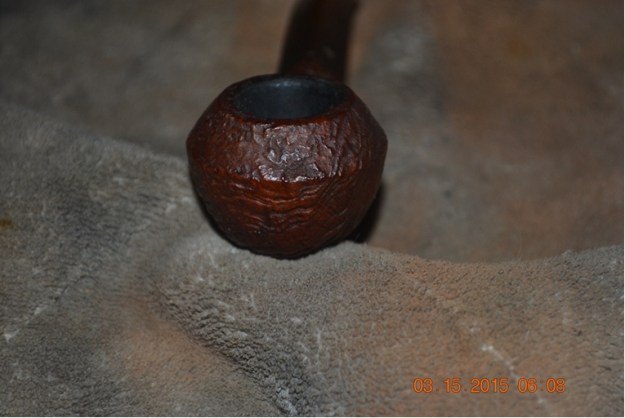

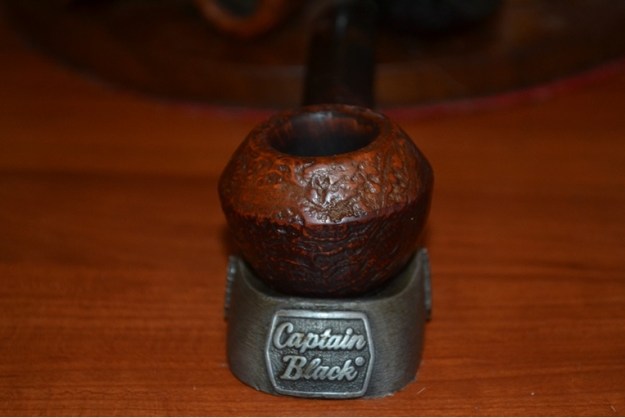

These photos of the Baskerville as I received it show how the picture in the eBay listing was a bit forgiving of the effects of age and smoking on the pipe, as noted by Glen from Peterson’s.

Here, in brief, is where everything truly began to go against me, although I might state the process that unfolded with greater accuracy and brevity as being my own fault, pure and simple. I actually reached the end of a full “restoration” and took what I thought would be the photos of the finished pipe when, upon closer scrutiny, I noted with a sick feeling in my heart and gut that the Baskerville was not up to my standards, even though I knew I was not about to offer this potential beauty for sale. One-dimensional pictures tend to reveal the flaws with unforgiving accuracy. Check out these two angles alone, which are representative of the whole as it was.

Here, in brief, is where everything truly began to go against me, although I might state the process that unfolded with greater accuracy and brevity as being my own fault, pure and simple. I actually reached the end of a full “restoration” and took what I thought would be the photos of the finished pipe when, upon closer scrutiny, I noted with a sick feeling in my heart and gut that the Baskerville was not up to my standards, even though I knew I was not about to offer this potential beauty for sale. One-dimensional pictures tend to reveal the flaws with unforgiving accuracy. Check out these two angles alone, which are representative of the whole as it was.

For the most part, I’ll leave the criticism to the readers, but I will point out the most noticeable flaws, including unfixed scratches and other blemishes, not to mention the awful look of the chamber in the first photo above. Most disturbing to me was my failure to remove certain black areas caused, as noted before, by age and use, as well as the general lack of discernible graining I had intended to enhance.

For the most part, I’ll leave the criticism to the readers, but I will point out the most noticeable flaws, including unfixed scratches and other blemishes, not to mention the awful look of the chamber in the first photo above. Most disturbing to me was my failure to remove certain black areas caused, as noted before, by age and use, as well as the general lack of discernible graining I had intended to enhance.

And so, as the traditional children’s song goes, “Finnegan, begin again.”

Removing the newly-applied waxes and stain, this time with 500-grit paper for a slow, gentle approach, proved much easier and faster than the far more laborious work I did the first time around. I only had to focus on the unresolved scratches and black areas. The paper alone was perfect for the small but pervasive scratches and a good deal of the blackened briar.

The dark patches were the most difficult to remove, and when I reached the point where the sandpaper wasn’t up to the task, I finished with the finest grade steel wool. This part required considerable effort around the bottom, front and back of the bowl as well as the shank, but it worked. At last, the wood was the right shade and with no more serious dark spots.

The dark patches were the most difficult to remove, and when I reached the point where the sandpaper wasn’t up to the task, I finished with the finest grade steel wool. This part required considerable effort around the bottom, front and back of the bowl as well as the shank, but it worked. At last, the wood was the right shade and with no more serious dark spots.

Having enjoyed a few bowls of tobacco in the Baskerville (well, more than a few), I sanded out the small amount of carbon with 320 paper and retorted the pipe once more. Then I stained the outer wood with Fiebing’s Brown and flamed it. I took off the char with 4000 micromesh and buffed from 1500-4000.

I took off the char with 4000 micromesh and buffed from 1500-4000.

The stem, almost perfect, only wanted gentle micro-meshing in a few spots, with 3200 and 4000. I buffed it with red Tripoli and then again on the clean wheel. I buffed the bowl and shank with white Tripoli, White Diamond and carnauba.

The stem, almost perfect, only wanted gentle micro-meshing in a few spots, with 3200 and 4000. I buffed it with red Tripoli and then again on the clean wheel. I buffed the bowl and shank with white Tripoli, White Diamond and carnauba.

But remember how I was describing how everything turned against me, only it was really my own fault? Well, then, that brings me to the final error: one I have learned to avoid so often in the past but this time spaced until it was a single stroke too late. In my enthusiastic sanding with the 500-grit paper, I took off a little of the Peterson’s/Sherlock Holmes stamps – not all, but part.

But remember how I was describing how everything turned against me, only it was really my own fault? Well, then, that brings me to the final error: one I have learned to avoid so often in the past but this time spaced until it was a single stroke too late. In my enthusiastic sanding with the 500-grit paper, I took off a little of the Peterson’s/Sherlock Holmes stamps – not all, but part.

CONCLUSION

CONCLUSION

For this blog, I attempted considerable research into the various Peterson’s Sherlock Holmes pipe series. I use the word various because of the three main groups that are commonly known to connoisseurs of the great Irish pipe company established in Dublin in 1865: the Sherlock Holmes Original Collection (with the word Original added only after the decision to add another and then a so-called final series was made), the Return of Sherlock Holmes Collection and the Adventures of Sherlock Holmes Collection. My goal was not only to identify the differences in the several lines’ designs and names but to determine the date(s) of manufacture. Despite my previous knowledge of the incredible difficulty of dating pipes in general and Peterson’s in particular, I thought these tasks would be easier than usual. I have almost never been more mistaken.

Starting at the source, so to speak – in this case, http://www.peterson.ie/CatalogueCOMP.pdf – I found, on pages 10-13 of the catalogue, listings for the first two collections, but nothing concerning the Adventures pipes. And although this catalogue did give the date of the SH Original Collection as “First produced in 1987 to honour the most famous character in fiction, Sherlock Holmes,” the term “first produced in” was vague. Well, for this small amount of help I was grateful, although almost every other website on the subject repeated the same general year. Also, I am sure that no matter how popular Sir Arthur’s brilliant mystery sleuth may be, the notion that Mr. Holmes deserves the high place in all of literature that Peterson’s bestows upon him would be readily accepted by Holmes himself were he real and alive but hotly debated in scholarly circles.

Furthermore, the official Peterson’s catalogue showed only the smooth versions of that series with a note that the series was of seven pipes, one for each day of the wee, with shapes “most favoured by Holmes.” [Again, see my proof of the erroneous nature of this claim above.] Almost as an afterthought, the catalogue reveals that all of the smooth designs shown are also available in rustic, sandblast and ebony versions, and a gold band can be substituted for the sterling silver.

As for the Return of Sherlock Holmes Collection, no date(s) of manufacture is given, and Peterson’s again shows only the smooth versions and notes the availability of gold bands but makes no reference to the same alternative rustic, sandblast and ebony versions. But it does mention and show these a couple of pages down.

The greatest surprises are the absence of the Adventures of Sherlock Holmes Collection altogether but the inclusion of beautiful pure white, sterling banded Sherlock Holmes Meerschaums in the same designs as the Original Collection, but again undated.

Therefore, searching far and wide for a list of the Adventures of SH Collection, I came across another Peterson’s of Dublin site showing the seven newest designs, mixed among smooth, rustic and sandblast. [http://www.peterson.ie/c/164/adventures-of-sherlock-holmes] Again, no date(s).

Finally, as a last measure before finishing this blog, I thought of the obvious and Googled “dating peterson sherlock holmes pipes.” I was rewarded with a site [http://thepetersoncollector.blogspot.com/2010/07/welcome-to-my-new-blog.html] providing almost all of the hard-sought data:

Sherlock Holmes Original Collection 1987-c. 1989

Return of Sherlock Holmes Collection c. 1991

Sherlock Holmes Meerschaums 2006

And so, would anyone out there who knows when the Adventures of Sherlock Holmes Collection came to be please reply to this blog with the coveted information…and if possible, a URL to verify it?

Sure as there be five-leaf clovers, I will sleep better having read the end of the mystery.