Blog by Dal Stanton

I would have never come up with this on my own. Seth already commissioned the restoration of a French GEFAPIP 500 Bent Bulldog which he found calling his name in the online collection of pipes I call, For “Pipe Dreamers” Only!. The Bulldog needed a lot of stem work which included deep oxidation, a button rebuild and re-seating the stem/shank fit. I was pleased with the results of that transformation pictured below. While I was working on the GEFAPIP Bulldog, Seth emailed me with a question – could he commission a Churchwarden project by repurposing another pipe’s bowl listed in For “Pipe Dreamers” Only!. A Sculpted Bull’s Head with a bent stem had gotten his attention and with a little ‘dreaming’ applied, Seth could envision the Bull’s Head mounted on a Warden stem. I found the Bull’s Head in the inventory and pulled it out to look at through Seth’s eyes… Yep! I could see it, too. What was missing in the mix were the Bull’s horns. I responded that we could do this and after working out the details, I added the Bull’s Head CW project to follow the Bulldog project! Here are pictures of the Sculpted Bull’s Head which got Seth’s attention:

While I was working on the GEFAPIP Bulldog, Seth emailed me with a question – could he commission a Churchwarden project by repurposing another pipe’s bowl listed in For “Pipe Dreamers” Only!. A Sculpted Bull’s Head with a bent stem had gotten his attention and with a little ‘dreaming’ applied, Seth could envision the Bull’s Head mounted on a Warden stem. I found the Bull’s Head in the inventory and pulled it out to look at through Seth’s eyes… Yep! I could see it, too. What was missing in the mix were the Bull’s horns. I responded that we could do this and after working out the details, I added the Bull’s Head CW project to follow the Bulldog project! Here are pictures of the Sculpted Bull’s Head which got Seth’s attention:

The Bull’s profile is detailed and a bit on the whimsical side, especially with his missing horns. He seems to be smiling in the picture above. There are no identifying marks on the pipe. When the Bull made it to the worktable, the question that came to my mind was how would I fashion the missing horns? I took this question to ‘Google search’ to find other sculpted bull heads to get some ideas. I clipped a screen shot of the search results and you can see that the horns are not uniform which is true of real bulls. I looked through the pictures to see if I could find a bull that resembled Seth’s Bull, but I could not. The interesting thing was that I found that many bull heads were from Italy. What I noticed as well, was the similarities and differences between the pipes. The eyes were made of differing materials and also the shaping of the ears situated behind the horns were distinctive and showed bulls sculpted by the same ‘school’ or carver.

The Bull’s profile is detailed and a bit on the whimsical side, especially with his missing horns. He seems to be smiling in the picture above. There are no identifying marks on the pipe. When the Bull made it to the worktable, the question that came to my mind was how would I fashion the missing horns? I took this question to ‘Google search’ to find other sculpted bull heads to get some ideas. I clipped a screen shot of the search results and you can see that the horns are not uniform which is true of real bulls. I looked through the pictures to see if I could find a bull that resembled Seth’s Bull, but I could not. The interesting thing was that I found that many bull heads were from Italy. What I noticed as well, was the similarities and differences between the pipes. The eyes were made of differing materials and also the shaping of the ears situated behind the horns were distinctive and showed bulls sculpted by the same ‘school’ or carver.  After concluding the online search, I decided that I would send a note to Seth asking him to do the same search and to let me know what horns looked best – with the understanding this Bull’s Head will be mounted at the front end of a Churchwarden stem. I’m thinking about the balancing and general look. After sending the email, I place the Bull’s Head stummel with a Warden stem to get an overall sense of proportion. I like it!

After concluding the online search, I decided that I would send a note to Seth asking him to do the same search and to let me know what horns looked best – with the understanding this Bull’s Head will be mounted at the front end of a Churchwarden stem. I’m thinking about the balancing and general look. After sending the email, I place the Bull’s Head stummel with a Warden stem to get an overall sense of proportion. I like it! I begin the Sculpted Bull’s Head Churchwarden project with the general cleaning of the stummel before fashioning the stem. I take a picture of the chamber showing very little cake buildup, but I do see vestiges of the former steward’s tobacco. I use the Savinelli Fitsall Tool to scrape the walls of the narrower than usual chamber. After wrapping 240 grade paper around a Sharpie Pen, sanding the chamber removes more carbon. I finish this phase by wiping the chamber with a cotton pad wetted with isopropyl 95%. After inspecting the chamber, I determine that all looks good.

I begin the Sculpted Bull’s Head Churchwarden project with the general cleaning of the stummel before fashioning the stem. I take a picture of the chamber showing very little cake buildup, but I do see vestiges of the former steward’s tobacco. I use the Savinelli Fitsall Tool to scrape the walls of the narrower than usual chamber. After wrapping 240 grade paper around a Sharpie Pen, sanding the chamber removes more carbon. I finish this phase by wiping the chamber with a cotton pad wetted with isopropyl 95%. After inspecting the chamber, I determine that all looks good.

Moving to the cleaning of the external surface, using undiluted Murphy’s Oil Soap and a bristled tooth brush I go to work scrubbing all the crevasses of the sculpting.

Moving to the cleaning of the external surface, using undiluted Murphy’s Oil Soap and a bristled tooth brush I go to work scrubbing all the crevasses of the sculpting. From the worktable, I transfer the Bull’s Head to the kitchen sink where I rinse the surface with warm water as well as clean the internals. Using anti-oil dish soap, long shank brushes scrub the internals. Afterwards, the stummel is rinsed thoroughly – inside and out.

From the worktable, I transfer the Bull’s Head to the kitchen sink where I rinse the surface with warm water as well as clean the internals. Using anti-oil dish soap, long shank brushes scrub the internals. Afterwards, the stummel is rinsed thoroughly – inside and out. The appearance of the Sculpting is realistic, especially the carving around the eyes.

The appearance of the Sculpting is realistic, especially the carving around the eyes.

I continue cleaning the internals using cotton buds and a pipe cleaner – all dipped in isopropyl 95%. The internals are good, and I move on.

I continue cleaning the internals using cotton buds and a pipe cleaner – all dipped in isopropyl 95%. The internals are good, and I move on. With the stummel clean, it’s time to begin fashioning the Warden stem. The first step is to take some measurements using my German made electronic caliper – one of the best additions to the toolbox I’ve made. I measure the internal diameter of the mortise to establish the target size of the tenon. The measurement is 6.80mm.

With the stummel clean, it’s time to begin fashioning the Warden stem. The first step is to take some measurements using my German made electronic caliper – one of the best additions to the toolbox I’ve made. I measure the internal diameter of the mortise to establish the target size of the tenon. The measurement is 6.80mm.  Next, after mounting the drill bit provided by the PIMO Tenon Turning Tool set, the airway is drilled out to receive the Guide Pin of the TTT.

Next, after mounting the drill bit provided by the PIMO Tenon Turning Tool set, the airway is drilled out to receive the Guide Pin of the TTT.

After drilling the airway, the TTT is mounted. The first cut of the tenon is intentionally larger to act as a starting point for the measurement. In the picture below the guide pen is in the now enlarged airway. In the past, I’ve learned the hard way that it’s critically to cut the tenon of the precast Churchwarden stem all the way to and through the raw stem facing. I’ve put an arrow at the facing that is shouldered coming from the casting. If this shoulder is not removed, it simply migrates to the pipe which is not good.

After drilling the airway, the TTT is mounted. The first cut of the tenon is intentionally larger to act as a starting point for the measurement. In the picture below the guide pen is in the now enlarged airway. In the past, I’ve learned the hard way that it’s critically to cut the tenon of the precast Churchwarden stem all the way to and through the raw stem facing. I’ve put an arrow at the facing that is shouldered coming from the casting. If this shoulder is not removed, it simply migrates to the pipe which is not good. I do the initial cut of the tenon through the ‘shoulder’ so that a sharp 45-degree angle is left which will be able to seat more exactly with the shank facing.

I do the initial cut of the tenon through the ‘shoulder’ so that a sharp 45-degree angle is left which will be able to seat more exactly with the shank facing. Again, I measure and the tenon after the initial cut and it is 8.92mm. The difference between the starting cut and the target size of the tenon (6.80mm) is 2.12mm. In order to approach the target size conservatively through sanding, 40mm is added to the target size of the tenon to create a ‘fat’ target – to leave a bit of sanding to be able to customize the fit. Adding .40mm to 6.80mm gives a fat target of about 7.20mm. This is what I aim for with the PIMO Tenon Turning Tool before transitioning to sanding the raw tenon.

Again, I measure and the tenon after the initial cut and it is 8.92mm. The difference between the starting cut and the target size of the tenon (6.80mm) is 2.12mm. In order to approach the target size conservatively through sanding, 40mm is added to the target size of the tenon to create a ‘fat’ target – to leave a bit of sanding to be able to customize the fit. Adding .40mm to 6.80mm gives a fat target of about 7.20mm. This is what I aim for with the PIMO Tenon Turning Tool before transitioning to sanding the raw tenon. After a few cuts closing in on the ‘fat’ target, I settle for 7.31mm. I now transition to sanding.

After a few cuts closing in on the ‘fat’ target, I settle for 7.31mm. I now transition to sanding.

Using a coarse 120 grade, I pinch the paper around the tenon as evenly as possible and rotate the stem while holding the paper stationary. My goal is to size down the tenon evenly so that the whole tenon is maintaining contact snuggly on the mortise walls once seated. Progress is patient as I sand and test the fit.

Using a coarse 120 grade, I pinch the paper around the tenon as evenly as possible and rotate the stem while holding the paper stationary. My goal is to size down the tenon evenly so that the whole tenon is maintaining contact snuggly on the mortise walls once seated. Progress is patient as I sand and test the fit.

As the progression moves closer to completion, I transition to 240 grade paper to do the final sanding.

As the progression moves closer to completion, I transition to 240 grade paper to do the final sanding. The tenon is fitting well – snug but not too tight. The pictures below show the seated stem. The stem is almost perfectly flush with the upper shank, but the stem is fat on the lower quadrant.

The tenon is fitting well – snug but not too tight. The pictures below show the seated stem. The stem is almost perfectly flush with the upper shank, but the stem is fat on the lower quadrant. After taping the shank with a layer of masking tape to buffer the briar from the heavy sanding, I attack the fat lip of the lower stem using coarse 120 grade sanding paper. The goal is to sand the excess vulcanite to form a uniform shank/stem union.

After taping the shank with a layer of masking tape to buffer the briar from the heavy sanding, I attack the fat lip of the lower stem using coarse 120 grade sanding paper. The goal is to sand the excess vulcanite to form a uniform shank/stem union. After achieving a good union at the shank, I continue the sanding with the 120 paper over the entire precast Warden stem. The stem, even though it is new, has the casting seam down both sides that needs sanding and uneven rippling that needs smoothing. After the 120 grade paper, I follow by sanding the entire stem with 240.

After achieving a good union at the shank, I continue the sanding with the 120 paper over the entire precast Warden stem. The stem, even though it is new, has the casting seam down both sides that needs sanding and uneven rippling that needs smoothing. After the 120 grade paper, I follow by sanding the entire stem with 240. After the stem proper has been sanded, I switch the focus to the rough precast button. Pictures of the upper and lower raw button show the imperfections that are first filed using a flat needle file.

After the stem proper has been sanded, I switch the focus to the rough precast button. Pictures of the upper and lower raw button show the imperfections that are first filed using a flat needle file. After doing the major shaping with the file, I follow with 120 and 240 sanding papers to fine tune the button shaping.

After doing the major shaping with the file, I follow with 120 and 240 sanding papers to fine tune the button shaping. Without a doubt, the least pleasing aspect of fashioning Churchwardens is sanding the stems and dealing with all the rubber dust! I’m thankful to move to the fine sanding stage by wet sanding with 600 grade paper followed by applying 000 grade steel wool to the entire stem.

Without a doubt, the least pleasing aspect of fashioning Churchwardens is sanding the stems and dealing with all the rubber dust! I’m thankful to move to the fine sanding stage by wet sanding with 600 grade paper followed by applying 000 grade steel wool to the entire stem. Next, with the stummel and stem united, I remove the masking tape to begin sanding with micromesh pads. At this point, I focus the sanding on the stem/shank junction and the stummel. Sanding the shank with the stem engaged keeps the junction edges from shouldering. I also sand the stummel to clean it up. There’s no doubt that this Bull’s Head sculpting will remain ‘rough’ and rustic, but I want to sand the smooth briar points of the Bull’s head: shank, underside, muzzle and the high points of the sculpting ridges. Pictures of the landscape show the smooth briar patches that will be the focus of the micromesh pads.

Next, with the stummel and stem united, I remove the masking tape to begin sanding with micromesh pads. At this point, I focus the sanding on the stem/shank junction and the stummel. Sanding the shank with the stem engaged keeps the junction edges from shouldering. I also sand the stummel to clean it up. There’s no doubt that this Bull’s Head sculpting will remain ‘rough’ and rustic, but I want to sand the smooth briar points of the Bull’s head: shank, underside, muzzle and the high points of the sculpting ridges. Pictures of the landscape show the smooth briar patches that will be the focus of the micromesh pads.

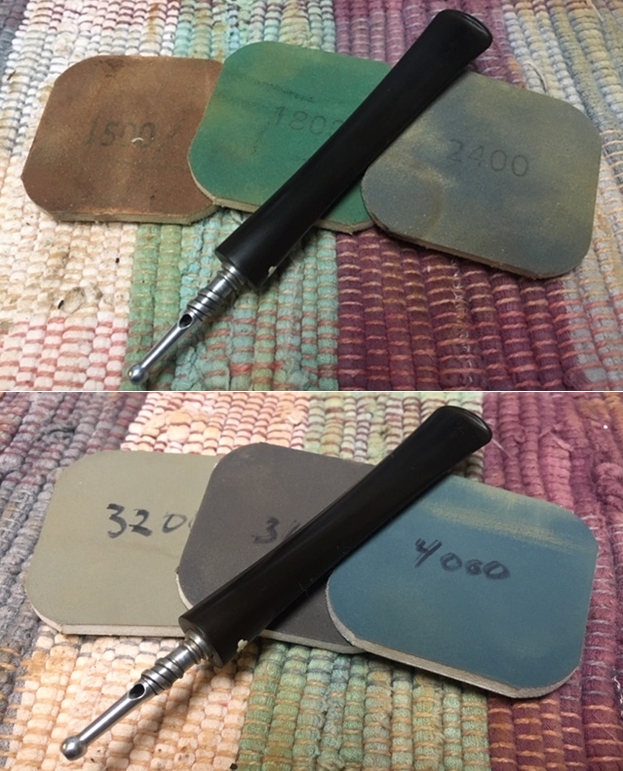

I begin by first wet sanding with pads 1500 to 2400, followed by 3200 to 4000 and 6000 to 12000.

I begin by first wet sanding with pads 1500 to 2400, followed by 3200 to 4000 and 6000 to 12000.

Next, I address the stummel’s hue. The original pictures of the Sculpted Bull’s Head indicate an original darker stummel. What I believe will look good is to darken the stummel again and then lightly sand the peaks of the sculpting to bring out highlights giving the overall appearance more depth and contrast. The crevasses of the sculpting will hold on to the darkened hue while the peaks will lighten. I’ll use Fiebing’s Dark Brown Leather Dye to do the job. After removing the stem, I clean the stummel using a cotton pad and isopropyl 95%. It takes a bit of time as I get into each crevasse of the sculpting.

Next, I address the stummel’s hue. The original pictures of the Sculpted Bull’s Head indicate an original darker stummel. What I believe will look good is to darken the stummel again and then lightly sand the peaks of the sculpting to bring out highlights giving the overall appearance more depth and contrast. The crevasses of the sculpting will hold on to the darkened hue while the peaks will lighten. I’ll use Fiebing’s Dark Brown Leather Dye to do the job. After removing the stem, I clean the stummel using a cotton pad and isopropyl 95%. It takes a bit of time as I get into each crevasse of the sculpting. I assemble the staining station and use the hot air gun to warm the stummel before applying the stain. This opens the briar to help its receptivity to the dye. Unlike my normal approach of flaming the aniline dye after painting it on the briar surface, with the rough texture I apply a simple dye wash and allow it to dry and set.

I assemble the staining station and use the hot air gun to warm the stummel before applying the stain. This opens the briar to help its receptivity to the dye. Unlike my normal approach of flaming the aniline dye after painting it on the briar surface, with the rough texture I apply a simple dye wash and allow it to dry and set.

I use the bent over pipe cleaner to apply dye in all the crevasses of the sculpted surface. After applying the leather dye, I let the stummel rest for several hours.

I use the bent over pipe cleaner to apply dye in all the crevasses of the sculpted surface. After applying the leather dye, I let the stummel rest for several hours. With the stummel resting now, I turn back to the stem. Before, with the stummel attached, I have already applied micromesh to the junction area. Now I continue with the rest of the stem starting with wet sanding with micromesh pads 1500 to 2400 then dry sanding with pads 3200 to 4000 and 6000 to 12000. Between each set of 3 pads, Obsidian Oil is applied to the stem. Steve did an informative blog on comparing Obsidian Oil with Briarville’s, No Oxy Pipe Stem Oil (See LINK). His conclusion was that both seemed to be equally good products. What I didn’t know before reading Steve’s blog was about the anti-oxidation properties of Obsidian Oil. It doesn’t remove oxidation if already present, but it hinders the growth of oxidation. As a result, I’ve started using Obsidian Oil for the maintenance of my own pipes in rotation.

With the stummel resting now, I turn back to the stem. Before, with the stummel attached, I have already applied micromesh to the junction area. Now I continue with the rest of the stem starting with wet sanding with micromesh pads 1500 to 2400 then dry sanding with pads 3200 to 4000 and 6000 to 12000. Between each set of 3 pads, Obsidian Oil is applied to the stem. Steve did an informative blog on comparing Obsidian Oil with Briarville’s, No Oxy Pipe Stem Oil (See LINK). His conclusion was that both seemed to be equally good products. What I didn’t know before reading Steve’s blog was about the anti-oxidation properties of Obsidian Oil. It doesn’t remove oxidation if already present, but it hinders the growth of oxidation. As a result, I’ve started using Obsidian Oil for the maintenance of my own pipes in rotation.

Putting the stem aside for the time, I take up the stummel which has been resting for several hours after applying the dye. I use a cotton pad wetted with alcohol to give the stummel a wipe to remove excess dye.

Putting the stem aside for the time, I take up the stummel which has been resting for several hours after applying the dye. I use a cotton pad wetted with alcohol to give the stummel a wipe to remove excess dye.

Next, I mount a cotton cloth buffing wheel to the Dremel with the speed set at about 40% full power. I apply a light application of Blue Diamond compound and I intentionally keep the compound light because I want to avoid caking in the crevasses. My focus is primarily buffing on the smooth briar and the peaks of the sculpting.

Next, I mount a cotton cloth buffing wheel to the Dremel with the speed set at about 40% full power. I apply a light application of Blue Diamond compound and I intentionally keep the compound light because I want to avoid caking in the crevasses. My focus is primarily buffing on the smooth briar and the peaks of the sculpting. After application of the compound, I use a felt cloth to give the stummel a rigorous buffing to remove the compound dust from the surface. I very much like the results. The effect I was shooting for with the contrast between the smooth briar peaks and the darker crevasses is evident. The rough, rustic texture is preserved but the smooth briar pops in comparison. I’m surprised also by the mahogany leaning hue resulting from the dark brown dye that I applied. The following pictures show what I see.

After application of the compound, I use a felt cloth to give the stummel a rigorous buffing to remove the compound dust from the surface. I very much like the results. The effect I was shooting for with the contrast between the smooth briar peaks and the darker crevasses is evident. The rough, rustic texture is preserved but the smooth briar pops in comparison. I’m surprised also by the mahogany leaning hue resulting from the dark brown dye that I applied. The following pictures show what I see.

I decide to condition the dried Sculpted Bull’s Head stummel using Before & After Restoration Balm. I place some Balm on my fingers and work it well into the crevasses of the sculpting and over the smooth briar surfaces. During this process, I note that the dye applied to the stummel earlier is coloring the Balm somewhat as it’s worked into the briar. I also see some coloring on my fingers. After working the Balm in well, I place it aside to allow the Balm to do its thing and then I use a cotton cloth that I will discard to wipe the excess Balm which is also colored somewhat with the fresh brown dye that is lifting off the stummel.

I decide to condition the dried Sculpted Bull’s Head stummel using Before & After Restoration Balm. I place some Balm on my fingers and work it well into the crevasses of the sculpting and over the smooth briar surfaces. During this process, I note that the dye applied to the stummel earlier is coloring the Balm somewhat as it’s worked into the briar. I also see some coloring on my fingers. After working the Balm in well, I place it aside to allow the Balm to do its thing and then I use a cotton cloth that I will discard to wipe the excess Balm which is also colored somewhat with the fresh brown dye that is lifting off the stummel.  To address the leaching dye issue, which is normal for newly dyed woods – briar is no exception, is to heat the stummel with the hot air gun which helps the dye to fully leach. When the stummel is heated, I wipe it first with a cotton cloth and then with a paper towel. The hopeful result of this is after the pipe reaches his new steward, when the steward fires it up for the first few uses, dye will not leach on his hands from the heated stummel – or be minimized greatly!

To address the leaching dye issue, which is normal for newly dyed woods – briar is no exception, is to heat the stummel with the hot air gun which helps the dye to fully leach. When the stummel is heated, I wipe it first with a cotton cloth and then with a paper towel. The hopeful result of this is after the pipe reaches his new steward, when the steward fires it up for the first few uses, dye will not leach on his hands from the heated stummel – or be minimized greatly! Next: bending the Warden stem. After reuniting the stem and stummel I place the pipe on a piece of paper to sketch the angle of curve needed to help as a template. I first draw a horizontal line to serve as the plane of the plateau. I use the horizontal shelf behind the angled chamber stack to line up with the horizontal plane. After outlining the unbent angle, I sketch the bend to bring it into alignment with the horizontal to serve as my template.

Next: bending the Warden stem. After reuniting the stem and stummel I place the pipe on a piece of paper to sketch the angle of curve needed to help as a template. I first draw a horizontal line to serve as the plane of the plateau. I use the horizontal shelf behind the angled chamber stack to line up with the horizontal plane. After outlining the unbent angle, I sketch the bend to bring it into alignment with the horizontal to serve as my template. Even though the bend needed is not great, a pipe cleaner is inserted into the end of the stem to guard the airway integrity during the bend. Using the hot air gun, the middle of the stem is heated because this is where I want the bend to be so that the end of the stem resolves nicely along the horizontal plane. I remove the stummel so that I can place the stem flat on the template after it is heated so that the stem is not angled or twisted to the left or right during the vulcanite’s supple stage.

Even though the bend needed is not great, a pipe cleaner is inserted into the end of the stem to guard the airway integrity during the bend. Using the hot air gun, the middle of the stem is heated because this is where I want the bend to be so that the end of the stem resolves nicely along the horizontal plane. I remove the stummel so that I can place the stem flat on the template after it is heated so that the stem is not angled or twisted to the left or right during the vulcanite’s supple stage. As the stem heats, I’m careful to keep ‘up’ up, so that the fit of the stem in the mortise isn’t accidentally flipped! As the rubber heats, I gently apply pressure to the bend area. When the heating has sufficiently warmed the vulcanite, I bring the stem to the template and create the bend according to the template and hold it in place for a few minutes as the rubber cools and the bend is held in place. The first attempt renders perfect results! I move on.

As the stem heats, I’m careful to keep ‘up’ up, so that the fit of the stem in the mortise isn’t accidentally flipped! As the rubber heats, I gently apply pressure to the bend area. When the heating has sufficiently warmed the vulcanite, I bring the stem to the template and create the bend according to the template and hold it in place for a few minutes as the rubber cools and the bend is held in place. The first attempt renders perfect results! I move on. With the stem now bent, I catch it up with the stummel by applying Blue Diamond compound to the entire stem. After mounting a cotton cloth buffing wheel onto the Dremel and with the speed set at about 40% full power, I apply compound to the stem. After finishing the application, I wipe/buff the stem with a felt cloth to remove the leftover carbon dust.

With the stem now bent, I catch it up with the stummel by applying Blue Diamond compound to the entire stem. After mounting a cotton cloth buffing wheel onto the Dremel and with the speed set at about 40% full power, I apply compound to the stem. After finishing the application, I wipe/buff the stem with a felt cloth to remove the leftover carbon dust. I’m very pleased how things are shaping up. Before the final polishing, I have one project left which is a little daunting: the horns. I’ve been thinking throughout (and even before starting!) the restoration how I was going to address the fashioning of the horns. The sides of the Bull’s head have holes which provide the diameter of the horn mass. As I looked at many examples on the internet of sculpted Bull’s heads, I found that there are a several varieties of horn style which is true with real life bulls! To narrow in on a style, I described sending Seth an email asking him to do some online research.

I’m very pleased how things are shaping up. Before the final polishing, I have one project left which is a little daunting: the horns. I’ve been thinking throughout (and even before starting!) the restoration how I was going to address the fashioning of the horns. The sides of the Bull’s head have holes which provide the diameter of the horn mass. As I looked at many examples on the internet of sculpted Bull’s heads, I found that there are a several varieties of horn style which is true with real life bulls! To narrow in on a style, I described sending Seth an email asking him to do some online research. I received his reply stating that he liked the shorter, stockier horns that turn up slightly on the ends. He also sent a couple pictures to illustrate his desires which were very helpful. As I’ve thought about this part of the project, fashioning one horn is not the greatest challenge, but fashioning two is! The challenge is to match the two but in reverse orientation – left and right horns! The pictures Seth provided are helpful, but there is a contrasting complexity even between the two examples he sent. The picture on the left shows the horns set on a vertical platform shaped on the side of the bull’s head to allow the visible horn to have more mass with (I’m assuming) a smaller peg inserted into the holes. Whereas, the example on the right, more like what I have on my worktable, the horn diameter and mass are confined to the diameter of the hole. It seems to be that the general proportion of the examples Seth sent below and many of the online examples I’ve seen is that the visible horn is about half the width of the bull’s head.

I received his reply stating that he liked the shorter, stockier horns that turn up slightly on the ends. He also sent a couple pictures to illustrate his desires which were very helpful. As I’ve thought about this part of the project, fashioning one horn is not the greatest challenge, but fashioning two is! The challenge is to match the two but in reverse orientation – left and right horns! The pictures Seth provided are helpful, but there is a contrasting complexity even between the two examples he sent. The picture on the left shows the horns set on a vertical platform shaped on the side of the bull’s head to allow the visible horn to have more mass with (I’m assuming) a smaller peg inserted into the holes. Whereas, the example on the right, more like what I have on my worktable, the horn diameter and mass are confined to the diameter of the hole. It seems to be that the general proportion of the examples Seth sent below and many of the online examples I’ve seen is that the visible horn is about half the width of the bull’s head.  Unfortunately, in my 10th floor flat in the formerly Communist period apartment block, I do not possess much in the way of precision wood working equipment, like a lathe! Shaping the horns will be by hand using a Dremel, files and sanding paper. I plan to use cherrywood as the material for the horns. Cherry trees grow almost everywhere in Bulgaria and there are several in the green area in front of our block. A couple years ago I harvested a couple very straight branches from a cherrywood tree in the front green area to dry out and to use with a project of restoring a French made cherrywood Ropp stummel and stem. I trimmed them down and they’ve been in my bucket waiting for some time – now, very much dried and ready. The Ropp project will continue to wait!

Unfortunately, in my 10th floor flat in the formerly Communist period apartment block, I do not possess much in the way of precision wood working equipment, like a lathe! Shaping the horns will be by hand using a Dremel, files and sanding paper. I plan to use cherrywood as the material for the horns. Cherry trees grow almost everywhere in Bulgaria and there are several in the green area in front of our block. A couple years ago I harvested a couple very straight branches from a cherrywood tree in the front green area to dry out and to use with a project of restoring a French made cherrywood Ropp stummel and stem. I trimmed them down and they’ve been in my bucket waiting for some time – now, very much dried and ready. The Ropp project will continue to wait!

I begin with horn number one. First, I cut a length of the cherrywood stem the width of the bull’s head. I know that roughly half of this will be the horn. The other half will be what is eventually inserted in the hole which is the ‘peg’ side.

I begin with horn number one. First, I cut a length of the cherrywood stem the width of the bull’s head. I know that roughly half of this will be the horn. The other half will be what is eventually inserted in the hole which is the ‘peg’ side. In order to give a center orientation for the peg, I use a small sanding drum to trace a guide circle.

In order to give a center orientation for the peg, I use a small sanding drum to trace a guide circle. After drawing a line around the piece of wood to mark the extent of peg shaping, I use a sanding drum in a circular motion around the end and gradually shape out the peg.

After drawing a line around the piece of wood to mark the extent of peg shaping, I use a sanding drum in a circular motion around the end and gradually shape out the peg.

As I was progressing on shaping the horn peg, I notice the line of a grain crack – ugh. I decide to see if it might work after some sanding and filing, but the crack will be a problem. I’m hoping that this is not characteristic of this wood! I move on and start over.

As I was progressing on shaping the horn peg, I notice the line of a grain crack – ugh. I decide to see if it might work after some sanding and filing, but the crack will be a problem. I’m hoping that this is not characteristic of this wood! I move on and start over. With the second start, I decide not to cut the short piece of cherrywood but to shape the horn peg first. I do this so that I can save wood if I must cut it off again and restart. Again, I mark the center horn peg template and use the sanding drum mounted on the Dremel to shape the peg.

With the second start, I decide not to cut the short piece of cherrywood but to shape the horn peg first. I do this so that I can save wood if I must cut it off again and restart. Again, I mark the center horn peg template and use the sanding drum mounted on the Dremel to shape the peg. I sanded and tested the fit a few times until the horn peg finally found home in the side of the bull’s head! Next, I cut off the smaller piece measuring to leave a little more than half the width of the Bull’s head. I leave extra length to enable me to sand down to a good fit.

I sanded and tested the fit a few times until the horn peg finally found home in the side of the bull’s head! Next, I cut off the smaller piece measuring to leave a little more than half the width of the Bull’s head. I leave extra length to enable me to sand down to a good fit. Next, with the picture that Seth sent to me showing the horn style he likes, I draw a horn template on the cherrywood inserted into the hole. The most critical thing at this point is to have a guide to help me stay within close parameters of proportion as I shape the horn step by step.

Next, with the picture that Seth sent to me showing the horn style he likes, I draw a horn template on the cherrywood inserted into the hole. The most critical thing at this point is to have a guide to help me stay within close parameters of proportion as I shape the horn step by step. Remembering that the first horn is easier than the second, I use the rounded angle of the sanding drum to create a consistent angle for the upswing of the horn tip. I’ll do the same for the second horn to minimize differences. With the Dremel set to slow, I press the drum into the wood to create the horn tip upswing angle.

Remembering that the first horn is easier than the second, I use the rounded angle of the sanding drum to create a consistent angle for the upswing of the horn tip. I’ll do the same for the second horn to minimize differences. With the Dremel set to slow, I press the drum into the wood to create the horn tip upswing angle.

I then remove the remaining excess wood on the upper side of the horn bringing the top parallel with the upper side of the peg.

I then remove the remaining excess wood on the upper side of the horn bringing the top parallel with the upper side of the peg.

Next, I turn the horn shaping over, with the horn tip facing down, to now work on the bottom of the horn. The hand saw cuts the excess off the cherrywood piece so that the cut is very close to the end of the horn. This saves on sanding.

Next, I turn the horn shaping over, with the horn tip facing down, to now work on the bottom of the horn. The hand saw cuts the excess off the cherrywood piece so that the cut is very close to the end of the horn. This saves on sanding.

Again, using the sanding drum mounted on the Dremel, I begin to take wood off the lower side of the horn piece. I start by sanding a horizontal base-line which identifies the horn’s lower side.

Again, using the sanding drum mounted on the Dremel, I begin to take wood off the lower side of the horn piece. I start by sanding a horizontal base-line which identifies the horn’s lower side. As the sanding moves toward the end of the cherrywood – toward the horn tip that is facing downwardly, I curve the sanding so that the angled underside of the horn is shaped toward the inverted horn tip.

As the sanding moves toward the end of the cherrywood – toward the horn tip that is facing downwardly, I curve the sanding so that the angled underside of the horn is shaped toward the inverted horn tip. The roughing out of the upper and lower horn is looking good and it resembles a paddle at this stage. The next 3 pictures show the horn from the different angles and the excess wood on the end identified by the template is still needing to be sanded to better define the horn tip.

The roughing out of the upper and lower horn is looking good and it resembles a paddle at this stage. The next 3 pictures show the horn from the different angles and the excess wood on the end identified by the template is still needing to be sanded to better define the horn tip.

I insert the rough horn into the bull head to make sure I’m tracking in a good direction. I’m looking for good proportions. So far, very nice – but again, the first horn is easier!

I insert the rough horn into the bull head to make sure I’m tracking in a good direction. I’m looking for good proportions. So far, very nice – but again, the first horn is easier! I transition to a smaller sanding drum to begin the removal of the excess wood on the front and back portions of the rough horn. The horn starts to emerge very nicely during this part of the sanding which is patient – I am very careful sculpting with the sanding drum. I can’t replace wood!

I transition to a smaller sanding drum to begin the removal of the excess wood on the front and back portions of the rough horn. The horn starts to emerge very nicely during this part of the sanding which is patient – I am very careful sculpting with the sanding drum. I can’t replace wood! After patient shaping, I test the emerging horn and it looks great! The proportions are good on both the horizontal and vertical axis.

After patient shaping, I test the emerging horn and it looks great! The proportions are good on both the horizontal and vertical axis. With the challenge of now replicating the roughed-out horn, but in reverse, I try to emulate the same process and patiently move step by step. I draw the peg template and again use the drum to shape out the peg.

With the challenge of now replicating the roughed-out horn, but in reverse, I try to emulate the same process and patiently move step by step. I draw the peg template and again use the drum to shape out the peg. When the peg arrives in time with a good fit, I use the finished horn to draw a template on the second horn piece.

When the peg arrives in time with a good fit, I use the finished horn to draw a template on the second horn piece. Again, using the sanding drum, the angle is notched out creating the pitch toward the horn tip.

Again, using the sanding drum, the angle is notched out creating the pitch toward the horn tip. As before, I then remove the excess on the top bringing it roughly parallel to the upper side of the peg. With this done, I cut the cherrywood for a more manageable piece.

As before, I then remove the excess on the top bringing it roughly parallel to the upper side of the peg. With this done, I cut the cherrywood for a more manageable piece. To shorten this part of the write-up, after much careful sanding, shaping and test fittings, I arrive at two roughed-out horns.

To shorten this part of the write-up, after much careful sanding, shaping and test fittings, I arrive at two roughed-out horns. They aren’t identical but close enough to pass for the real deal!

They aren’t identical but close enough to pass for the real deal! To leave the horns in semi-rough condition with some texture, I sand both with 240 and 600 grade papers. This smooths the cherrywood but keeps the horns more rustic.

To leave the horns in semi-rough condition with some texture, I sand both with 240 and 600 grade papers. This smooths the cherrywood but keeps the horns more rustic. I’m not sure what it will do with the raw cherrywood, but I apply Before & After Restoration Balm to see what happens. After applying the Balm with my fingers, I let the Balm do its thing for about 20 minutes. The light cherrywood didn’t change much, but there is a more of a ivory-like hue to it now. Not bad.

I’m not sure what it will do with the raw cherrywood, but I apply Before & After Restoration Balm to see what happens. After applying the Balm with my fingers, I let the Balm do its thing for about 20 minutes. The light cherrywood didn’t change much, but there is a more of a ivory-like hue to it now. Not bad. Almost in the home stretch. Using BSI Maxi-Cure Extra Thick CA glue, I glue the horns in place. After placing a drop in each hole, with a toothpick, I spread the glue around the circumference of the hole. I then insert each horn and pitch it up as Seth requested.

Almost in the home stretch. Using BSI Maxi-Cure Extra Thick CA glue, I glue the horns in place. After placing a drop in each hole, with a toothpick, I spread the glue around the circumference of the hole. I then insert each horn and pitch it up as Seth requested. Now the home stretch. All that is lacking is applying carnauba wax to the pipe. After reuniting stem and stummel, I mount a cotton cloth buffing wheel to the Dremel and set the speed to about 40% full power. I apply carnauba wax to the stem and Sculpted Bull’s Head stummel and horns. I’m careful to go light on the wax in the sculpting staying primarily on the smooth briar and peaks. After application of the wax, I give the Churchwarden a rigorous hand buffing with a microfiber cloth to raise the shine.

Now the home stretch. All that is lacking is applying carnauba wax to the pipe. After reuniting stem and stummel, I mount a cotton cloth buffing wheel to the Dremel and set the speed to about 40% full power. I apply carnauba wax to the stem and Sculpted Bull’s Head stummel and horns. I’m careful to go light on the wax in the sculpting staying primarily on the smooth briar and peaks. After application of the wax, I give the Churchwarden a rigorous hand buffing with a microfiber cloth to raise the shine. Oh my! I love it, and I trust that Seth will as well. His idea of turning this Sculpted Bull’s Head into a Churchwarden is a winner hands down. The sculpting cleaned up nicely and the dark brown dye with the contrast highlighting with smooth briar is attractive, but the rustic air of the pipe is preserved. I’ve never fashioned horns in a restoration before this project, but I believe the Bulgarian cherrywood looks good and does a good job emulating the horns. Fashioning the horns wasn’t easy, but I’m pleased with the outcome. As the commissioner of this project, Seth will have the first opportunity to acquire this Sculpted Bull’s Head Churchwarden from The Pipe Steward Store. This pipe benefits the Daughters of Bulgaria, women and girls who have been trafficked and sexually exploited. Thanks for joining me!

Oh my! I love it, and I trust that Seth will as well. His idea of turning this Sculpted Bull’s Head into a Churchwarden is a winner hands down. The sculpting cleaned up nicely and the dark brown dye with the contrast highlighting with smooth briar is attractive, but the rustic air of the pipe is preserved. I’ve never fashioned horns in a restoration before this project, but I believe the Bulgarian cherrywood looks good and does a good job emulating the horns. Fashioning the horns wasn’t easy, but I’m pleased with the outcome. As the commissioner of this project, Seth will have the first opportunity to acquire this Sculpted Bull’s Head Churchwarden from The Pipe Steward Store. This pipe benefits the Daughters of Bulgaria, women and girls who have been trafficked and sexually exploited. Thanks for joining me!

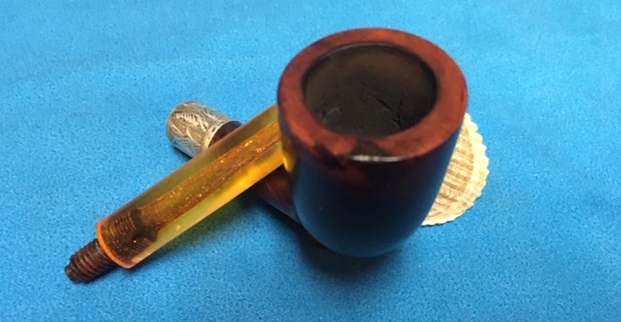

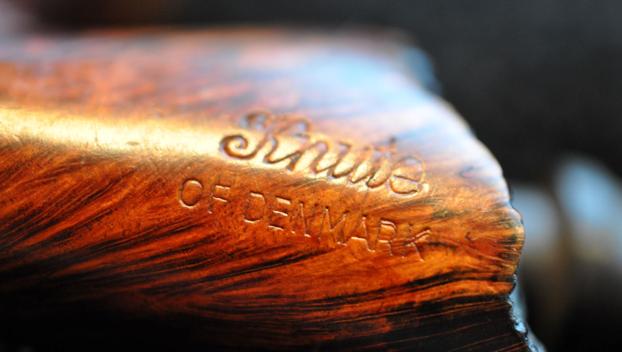

When I unwrapped it the pipe it was a tall Stack. It was stamped on the smooth underside of the shank. The stamping is faint but part of it was readable. There is no shape number to identify the pipe. Where it would have been it is followed by the Brigham Script over Can. Pat. 372982. It had a rusticated bowl and shank with a smooth rim top. The rim top had a lava overflow from the medium cake in the bowl. The bowl was in decent condition, slightly out of round on the inner edge. There was some darkening around the top and inner edges of the bowl. It was a dirty pipe but the finish appeared to be in okay condition under the grime. The 3 Dot tapered stem was oxidized and had tooth marks and chatter near the button on both sides. There was also some calcification for about an inch up the stem.

When I unwrapped it the pipe it was a tall Stack. It was stamped on the smooth underside of the shank. The stamping is faint but part of it was readable. There is no shape number to identify the pipe. Where it would have been it is followed by the Brigham Script over Can. Pat. 372982. It had a rusticated bowl and shank with a smooth rim top. The rim top had a lava overflow from the medium cake in the bowl. The bowl was in decent condition, slightly out of round on the inner edge. There was some darkening around the top and inner edges of the bowl. It was a dirty pipe but the finish appeared to be in okay condition under the grime. The 3 Dot tapered stem was oxidized and had tooth marks and chatter near the button on both sides. There was also some calcification for about an inch up the stem.

I took close up photos of the bowl and rim top to show the condition of the bowl and damage to the rim edge as well as the cake and lava overflowing onto the rim top. I also took close up photos of the stem to show its condition as mentioned above.

I took close up photos of the bowl and rim top to show the condition of the bowl and damage to the rim edge as well as the cake and lava overflowing onto the rim top. I also took close up photos of the stem to show its condition as mentioned above.  I took a photo of the faint stamping on the underside of the shank to show what I was speaking about above. It is very clear and readable. It reads Brigham in script over Can Pat. 372982.

I took a photo of the faint stamping on the underside of the shank to show what I was speaking about above. It is very clear and readable. It reads Brigham in script over Can Pat. 372982. I removed the stem from the shank to reveal the aluminum tube/tenon that held the Rock Maple Distillator. The distillator was missing and the tube was very dirty. It will need to be replaced.

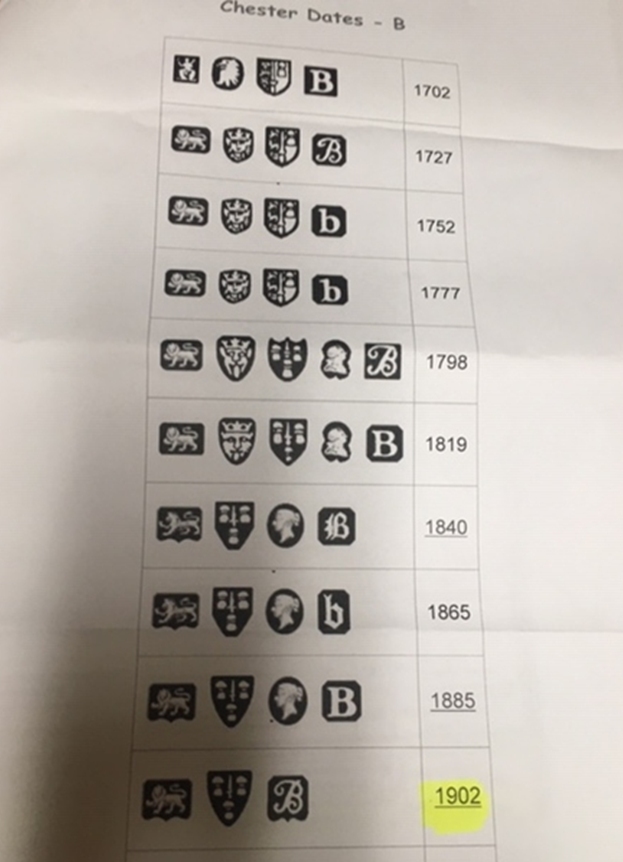

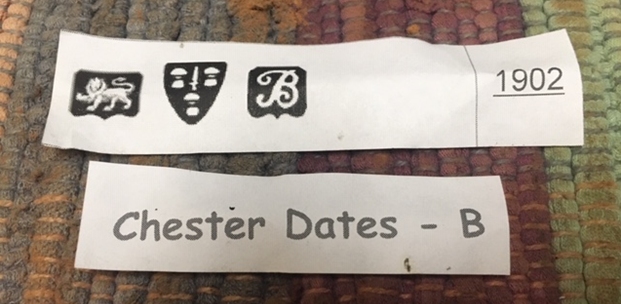

I removed the stem from the shank to reveal the aluminum tube/tenon that held the Rock Maple Distillator. The distillator was missing and the tube was very dirty. It will need to be replaced.  Before starting my clean up work on the pipe I turned to a chart that Charles Lemon of Dad’s Pipes sent to me on the patent era Brighams. There were made from 1938-1980. As the pipe I am working on is a Patent pipe, it’s more accurate to refer to its grade by name (the post 1980 grading scheme refers to Dots). Here is the chart that Charles sent me. The pipe I am working on is thus a Brigham Exclusive with the 3 brass pins arranged in a triangle.

Before starting my clean up work on the pipe I turned to a chart that Charles Lemon of Dad’s Pipes sent to me on the patent era Brighams. There were made from 1938-1980. As the pipe I am working on is a Patent pipe, it’s more accurate to refer to its grade by name (the post 1980 grading scheme refers to Dots). Here is the chart that Charles sent me. The pipe I am working on is thus a Brigham Exclusive with the 3 brass pins arranged in a triangle.  With this pipe I am returning to work on another Can Pat Brigham pipe from the nineteen pipe installment. I went to work on it immediately. I reamed the bowl with a PipNet pipe reamer using the second and second cutting head to take the cake back to bare briar so I could inspect the walls. I cleaned up the remnants with a Savinelli Fitsall Pipe Knife. I sanded the bowl walls with 220 grit sandpaper on a piece of dowel to smooth them out and further examine them. I was happy that the walls looked very good.

With this pipe I am returning to work on another Can Pat Brigham pipe from the nineteen pipe installment. I went to work on it immediately. I reamed the bowl with a PipNet pipe reamer using the second and second cutting head to take the cake back to bare briar so I could inspect the walls. I cleaned up the remnants with a Savinelli Fitsall Pipe Knife. I sanded the bowl walls with 220 grit sandpaper on a piece of dowel to smooth them out and further examine them. I was happy that the walls looked very good.

I worked on the darkening on the rim top and the rough inner edge of the bowl by first scraping it with the edge of the Fitsall reamer and the sanding it with a folded piece of 220 grit sandpaper. I was able to remove the darkening and smooth out the inner edge of the bowl.

I worked on the darkening on the rim top and the rough inner edge of the bowl by first scraping it with the edge of the Fitsall reamer and the sanding it with a folded piece of 220 grit sandpaper. I was able to remove the darkening and smooth out the inner edge of the bowl.

I cleaned out the mortise area and airway to the bowl and the interior of the metal tube and airway in the stem with pipe cleaners, cotton swabs and alcohol. The aluminum tube was dirty because it was missing the distillator and had been smoked sans filter.

I cleaned out the mortise area and airway to the bowl and the interior of the metal tube and airway in the stem with pipe cleaners, cotton swabs and alcohol. The aluminum tube was dirty because it was missing the distillator and had been smoked sans filter.  I scrubbed the surface of the bowl with undiluted Murphy’s Oil Soap and a tooth brush to remove the grime and grit as well as the remnants of the shiny finish on the smooth portions of the bowl.

I scrubbed the surface of the bowl with undiluted Murphy’s Oil Soap and a tooth brush to remove the grime and grit as well as the remnants of the shiny finish on the smooth portions of the bowl.

With the rim top cleaned off and the inner edge restored and the darkening gone the rim was lighter than the smooth underside of the shank. I stained it with a Maple Stain pen. I don’t worry too much about the evenness of the coverage at this point as I plan on polishing it with micromesh sanding pads.

With the rim top cleaned off and the inner edge restored and the darkening gone the rim was lighter than the smooth underside of the shank. I stained it with a Maple Stain pen. I don’t worry too much about the evenness of the coverage at this point as I plan on polishing it with micromesh sanding pads. I wet sanded the rim top and edges of the bowl with micromesh sanding pads – 1500-12000 grit sanding pads. I wiped the bowl surface down with a damp cloth after each sanding pad to remove the sanding dust. Once I finished the bowl looked good.

I wet sanded the rim top and edges of the bowl with micromesh sanding pads – 1500-12000 grit sanding pads. I wiped the bowl surface down with a damp cloth after each sanding pad to remove the sanding dust. Once I finished the bowl looked good.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on. It really makes the grain stand out on this pipe.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on. It really makes the grain stand out on this pipe.

I set the bowl aside and turned my attention to the stem. I rubbed the stem down with Soft Scrub on with a cotton pad and it removed the oxidation and the calcification build up. It looked a lot better.

I set the bowl aside and turned my attention to the stem. I rubbed the stem down with Soft Scrub on with a cotton pad and it removed the oxidation and the calcification build up. It looked a lot better.  I sanded out the tooth marks, chatter and oxidation with 220 grit sandpaper and started the polishing with 400 grit wet dry sandpaper.

I sanded out the tooth marks, chatter and oxidation with 220 grit sandpaper and started the polishing with 400 grit wet dry sandpaper.  I rubbed down the stem with Denicare Mouthpiece Polish and a cotton pad to remove the remnants of oxidation and to blend in the sanding. The polish is a red gritty paste that works wonders on removing stubborn remnants of oxidation in the crease. The stem is starting to show promise at this point in the process.

I rubbed down the stem with Denicare Mouthpiece Polish and a cotton pad to remove the remnants of oxidation and to blend in the sanding. The polish is a red gritty paste that works wonders on removing stubborn remnants of oxidation in the crease. The stem is starting to show promise at this point in the process.  Before I finished the polishing stem I decided to fit it with a new Rock Maple Distillator.

Before I finished the polishing stem I decided to fit it with a new Rock Maple Distillator.  I polished the stem with micromesh sanding pads – wet sanding it with 1500-12000 grit pads. I wiped the stem down after each sanding pad with a cotton pad to remove the sanding debris. I finished polishing the stem with Before & After Pipe Stem Polish – both fine and extra fine. I finished by wiping it down with Briarville’s No Oxy Oil and buffing it to a shine.

I polished the stem with micromesh sanding pads – wet sanding it with 1500-12000 grit pads. I wiped the stem down after each sanding pad with a cotton pad to remove the sanding debris. I finished polishing the stem with Before & After Pipe Stem Polish – both fine and extra fine. I finished by wiping it down with Briarville’s No Oxy Oil and buffing it to a shine.

I am excited to finish another of the lot as it moves me one pipe closer to being finished. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with the grain popping through on the rim top and the rustication coming to life. Added to that the polished black vulcanite stem with the shining brass pins was beautiful. This mixed smooth and rusticated finish Brigham Exclusive Stack is nice looking and feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. This is the 15th of the 19 pipes sent to me from Eastern Canada for restoration. Once again I am looking forward to what the pipeman who sent it thinks of this restoration. Lots more to do in this lot! Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next pipeman or woman.

I am excited to finish another of the lot as it moves me one pipe closer to being finished. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with the grain popping through on the rim top and the rustication coming to life. Added to that the polished black vulcanite stem with the shining brass pins was beautiful. This mixed smooth and rusticated finish Brigham Exclusive Stack is nice looking and feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. This is the 15th of the 19 pipes sent to me from Eastern Canada for restoration. Once again I am looking forward to what the pipeman who sent it thinks of this restoration. Lots more to do in this lot! Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next pipeman or woman.