Blog by Dal Stanton

This Bulldog is simply cool. It was one of those wonderful surprises one hopes for when you buy many pipes in one fell swoop on eBay. In many of my restoration blogs I’ve mentioned the Lot of 66 which I landed last year while back in the US. What can I say – God knew that I was restoring pipes to benefit the Daughters of Bulgaria and this Lot of 66 has been a gift that keeps on giving. It isn’t possible to see all the pipes in the landscape pictures provided and one hopes in the percentages – there has to be some good pipes in the Lot! Here is the Lot of 66 that I saw then and have pictured several times before. I’m not positive, but the GBD Rustified Rim Bulldog is on the extreme lower right below – only his bowl showing. Many of my restorations for the Daughters come from people seeing a pipe in my “For ‘Pipe Dreamers’ Only” section on The Pipe Steward blog. I came up with the idea of this ‘before restoration offerings’ when I found that when people visited us here in Bulgaria, they would know about our work with the Daughters of Bulgaria and that I restored pipes that benefited that cause. Almost always they wanted to see what pipes I had in the “Help Me! Basket” and they would choose one to be restored. The interesting thing I discovered was that people live in hope for what something can become. Estate pipes can be pretty nasty, but people know the amazing wonders of what the restorative processes can produce and so they see the potential and trust me to realize that hope as I bring a pipe to The Pipe Steward worktable on the 10th floor of a former Communist apartment block in Sofia, Bulgaria! What a story! I’m living the dream 😊.

Many of my restorations for the Daughters come from people seeing a pipe in my “For ‘Pipe Dreamers’ Only” section on The Pipe Steward blog. I came up with the idea of this ‘before restoration offerings’ when I found that when people visited us here in Bulgaria, they would know about our work with the Daughters of Bulgaria and that I restored pipes that benefited that cause. Almost always they wanted to see what pipes I had in the “Help Me! Basket” and they would choose one to be restored. The interesting thing I discovered was that people live in hope for what something can become. Estate pipes can be pretty nasty, but people know the amazing wonders of what the restorative processes can produce and so they see the potential and trust me to realize that hope as I bring a pipe to The Pipe Steward worktable on the 10th floor of a former Communist apartment block in Sofia, Bulgaria! What a story! I’m living the dream 😊.

Chris, a dedicated pipe man and regular contributor on the Facebook group, ‘The Gentlemen’s Pipe Smoking Society’ was ‘Pipe Dreaming’ while tooling around looking at the offerings and saw the GBD International Bulldog. What attracted him to the Bulldog was the unique rustified rim with hearty agreement from me. It adds a flair that you don’t often see on a London Made Bulldog. The bent stem is cool, too, adding a bit more flare. Here are some of the pictures Chris saw in the “For ‘Pipe Dreamers’ Only” page:

Chris commissioned the GBD Bulldog, which put it in the queue for restoration. After the restoration is completed and published, I then place a value on the pipe resulting from my research. The commissioner has the first opportunity to claim the pipe from The Pipe Steward Store. Chris will have first dibs on this Bulldog when completed.

Chris commissioned the GBD Bulldog, which put it in the queue for restoration. After the restoration is completed and published, I then place a value on the pipe resulting from my research. The commissioner has the first opportunity to claim the pipe from The Pipe Steward Store. Chris will have first dibs on this Bulldog when completed.

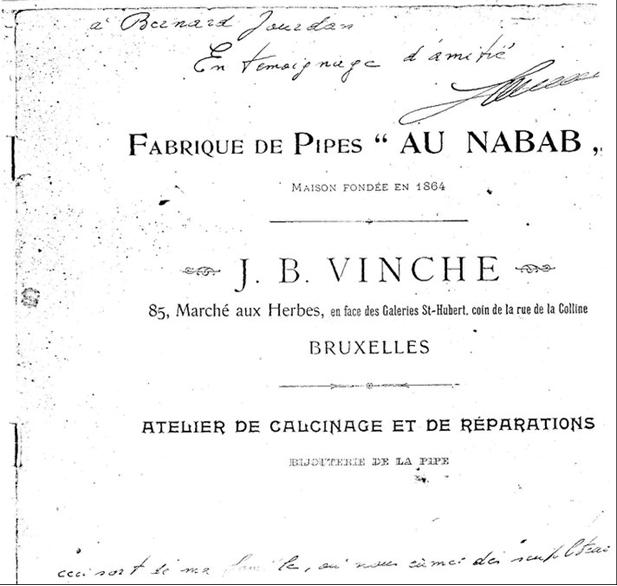

GBD (Pipedia’s article on GBD), was the handshake enterprise started by three French ‘Master Pipemakers’, Ganneval, Bondier and Donninger in Paris in 1850 to manufacture Meerschaum pipes, which was the primary material used in manufacturing pipes along with clay. This was true until the discovery of briar in Saint Claude, France, a discovery that changed the pipe manufacturing world. In 1902 Marechal and Ruchon sold GBD to A. Oppenheimer & Co. in London, which began the shift of GBD to being primarily a British enterprise, even though GBD pipes continued to be produced in Paris and Saint Claude, until 1981, with the closing of the French operation when the name, GBD, was merged with the Cadogan Group. I enjoy rehearsing the historical developments of pipe names and companies because they add to the enjoyment and appreciation of restoring pipes.

I take some additional pictures of the GBD International Bulldog on my worktable.

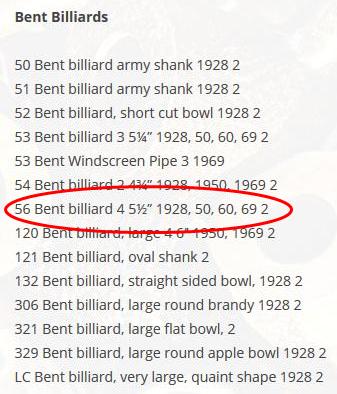

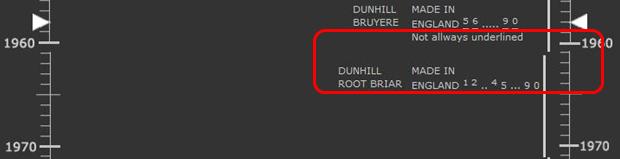

The nomenclature has on the left side of the shank, a GBD circled with an oval over INTERNATIONAL over LONDON MADE. The right side has LONDON ENGLAND over 546, the shape number. The shape number lines up as a Bulldog, ¼ bent, Diamond shank according to Jerry Hanna’s GBD shapes chart listings in Pipedia. The dating of the pipe is pre-1980s. The stem’s brass rondel along with the “London, England” stamp indicates a pre-Cadogan era GBD. The merger was 1981. This information is clear.

The nomenclature has on the left side of the shank, a GBD circled with an oval over INTERNATIONAL over LONDON MADE. The right side has LONDON ENGLAND over 546, the shape number. The shape number lines up as a Bulldog, ¼ bent, Diamond shank according to Jerry Hanna’s GBD shapes chart listings in Pipedia. The dating of the pipe is pre-1980s. The stem’s brass rondel along with the “London, England” stamp indicates a pre-Cadogan era GBD. The merger was 1981. This information is clear.

There’s some information that is proving to be a bit more difficult to mine in my research. I’ve contacted Al Jones (Upshallfan), a regular contributor to rebornpipes, on a few GBDs I’ve restored in the past. Al is a gold mine of information about GBDs and I appreciate his help. Previously, he had sent me a PDF he had gleaned from now defunct www.perardua.net/ entitled ‘GBD Model Information’. From that PDF I found this reference regarding the ‘International’ line of GBD. I clipped it: I was excited to get a lead on what appears to be a GBD pipe line of “carved top rims” that were stained black. The reference in the second line is to a 1976 catalog where I could hopefully find more about the International line. Hopeful of finding this catalog, I went to the internet. Unfortunately, I could find nothing. Also disheartening, the usual go to page for catalogs, Chris’ Pipe Pages, I discovered some time ago, now seems to be defunct. Sad. So, again I sent Al a note with some questions. His reply came very quickly with this picture of at least one ‘GBD International’ from the 1977 Tinderbox catalog. The writing is not easy to make out but the “M.” example of the International line is a nice looking oval shank Volcano shape which I can make out has a carved rim like the Bulldog. With this information, my thinking is that the GBD Bulldog I have is dated from 1976 but earlier than 1981. Again, much thanks to Al Jones!

I was excited to get a lead on what appears to be a GBD pipe line of “carved top rims” that were stained black. The reference in the second line is to a 1976 catalog where I could hopefully find more about the International line. Hopeful of finding this catalog, I went to the internet. Unfortunately, I could find nothing. Also disheartening, the usual go to page for catalogs, Chris’ Pipe Pages, I discovered some time ago, now seems to be defunct. Sad. So, again I sent Al a note with some questions. His reply came very quickly with this picture of at least one ‘GBD International’ from the 1977 Tinderbox catalog. The writing is not easy to make out but the “M.” example of the International line is a nice looking oval shank Volcano shape which I can make out has a carved rim like the Bulldog. With this information, my thinking is that the GBD Bulldog I have is dated from 1976 but earlier than 1981. Again, much thanks to Al Jones! Looking at the GBD International Bulldog itself, it is in decent condition. There is some cake build up in the chamber and the carved rim shows some expected grime but not too much. The twin dome grooves are full of debris and need to be cleaned. The bowl itself looks very good – it has some expected grime, but the briar looks exceptional underneath. It will look good when cleaned up. The stem has some deep oxidation and the bit shows some dents and tooth chatter that will need correcting.

Looking at the GBD International Bulldog itself, it is in decent condition. There is some cake build up in the chamber and the carved rim shows some expected grime but not too much. The twin dome grooves are full of debris and need to be cleaned. The bowl itself looks very good – it has some expected grime, but the briar looks exceptional underneath. It will look good when cleaned up. The stem has some deep oxidation and the bit shows some dents and tooth chatter that will need correcting.

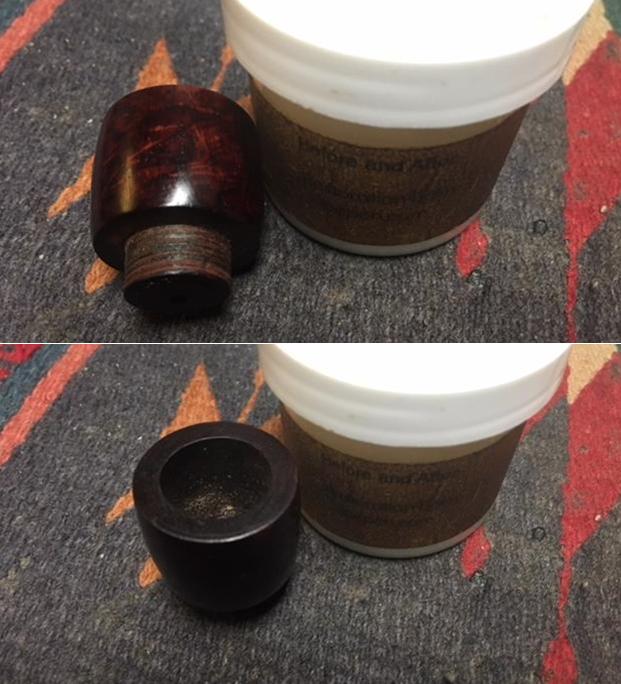

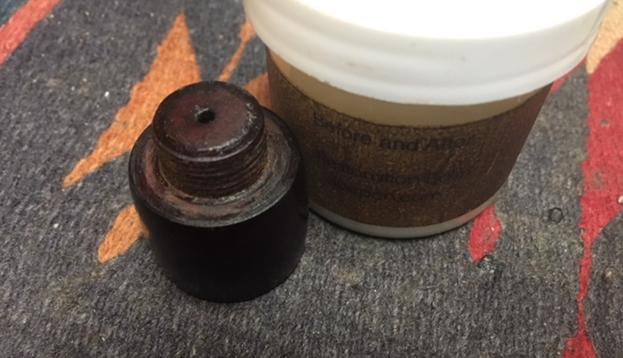

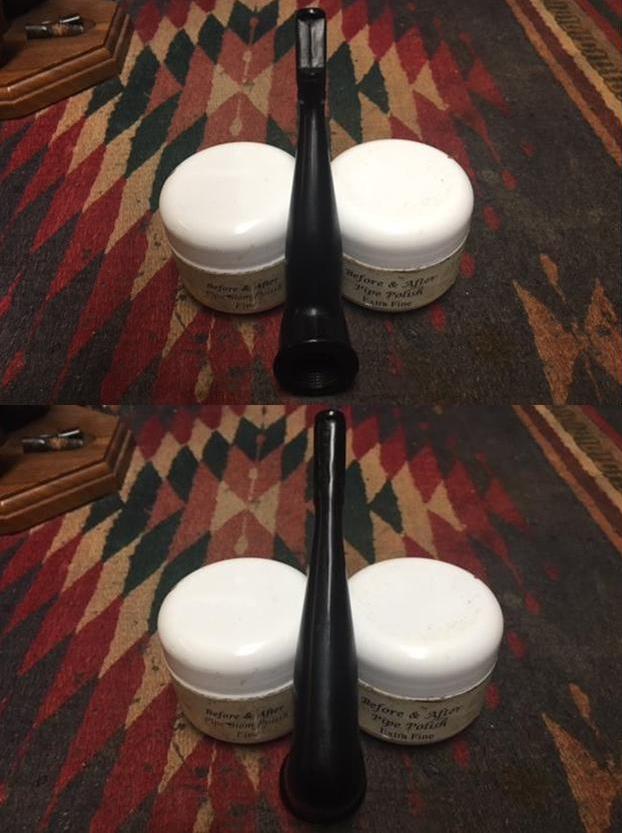

I begin the restoration of this GBD International Bulldog by adding the stem to a soak using Before & After Deoxidizer. After running pipe cleaners dipped in isopropyl 95% through the internals of the stem, it joins 5 other pipe stems in queue for restoration. I leave the stem in the soak for a few hours then fishing the GBD stem out, I wipe it off with a cotton pad wetted with light paraffin oil. I also put a pipe cleaner through the stem to push the fluid out and follow with a pipe cleaner dipped in isopropyl 95% to assure that the airway is clear.

After cleaning the stem of the Deoxidizer, I can still detect oxidation in the vulcanite. I take another picture of the stem with the aperture open more to show what I’m seeing.

After cleaning the stem of the Deoxidizer, I can still detect oxidation in the vulcanite. I take another picture of the stem with the aperture open more to show what I’m seeing. I decide to give the stem another soak in an OxiClean solution. After covering the rondel with petroleum jelly, I put it in the soak. I’m not sure if the brass rondel will react or not to the OxiClean, but I take no chances.

I decide to give the stem another soak in an OxiClean solution. After covering the rondel with petroleum jelly, I put it in the soak. I’m not sure if the brass rondel will react or not to the OxiClean, but I take no chances. While the stem is in the OxiClean cooker, I turn to the stummel. First, I use the Pipnet Reaming Kit to remove the carbon cake from the Bulldog’s chamber. It takes 2 of the 4 blade heads available in the kit. I follow this using the Savinelli Fitsall Tool to fine tune more by scraping the chamber walls removing more carbon. To get down to fresh briar, I then wrap a 240 grit piece of sanding paper around a Sharpie Pen and sand the chamber. To clean up, I wipe out the carbon dust with a cotton pad wetted with isopropyl 95%. The pictures show the progress.

While the stem is in the OxiClean cooker, I turn to the stummel. First, I use the Pipnet Reaming Kit to remove the carbon cake from the Bulldog’s chamber. It takes 2 of the 4 blade heads available in the kit. I follow this using the Savinelli Fitsall Tool to fine tune more by scraping the chamber walls removing more carbon. To get down to fresh briar, I then wrap a 240 grit piece of sanding paper around a Sharpie Pen and sand the chamber. To clean up, I wipe out the carbon dust with a cotton pad wetted with isopropyl 95%. The pictures show the progress.

Moving along with the stummel, I use undiluted Murphy’s Oil Soap with a cotton pad to scrub the surface of the briar. To clean the rim, I use a bristled tooth brush with Murphy’s to clean the carved angles and valleys. I then rinse the bowl with cool tap water. The last thing I do is take a sharp dental probe and run it through the twin dome grooves to remove the small debris that had lodged in the grooves. With my wife’s help, I record a picture of this surgery.

Moving along with the stummel, I use undiluted Murphy’s Oil Soap with a cotton pad to scrub the surface of the briar. To clean the rim, I use a bristled tooth brush with Murphy’s to clean the carved angles and valleys. I then rinse the bowl with cool tap water. The last thing I do is take a sharp dental probe and run it through the twin dome grooves to remove the small debris that had lodged in the grooves. With my wife’s help, I record a picture of this surgery. Since I like working on clean pipes and I know new stewards like smoking with clean pipes, I turn to the internals of the stummel. Using cotton buds and pipe cleaners with isopropyl 95%, I go to work. I’m thankful to discover that there is little resistance. Later, at the end of the day, I’ll clean the internals further by using a kosher salt and alcohol soak.

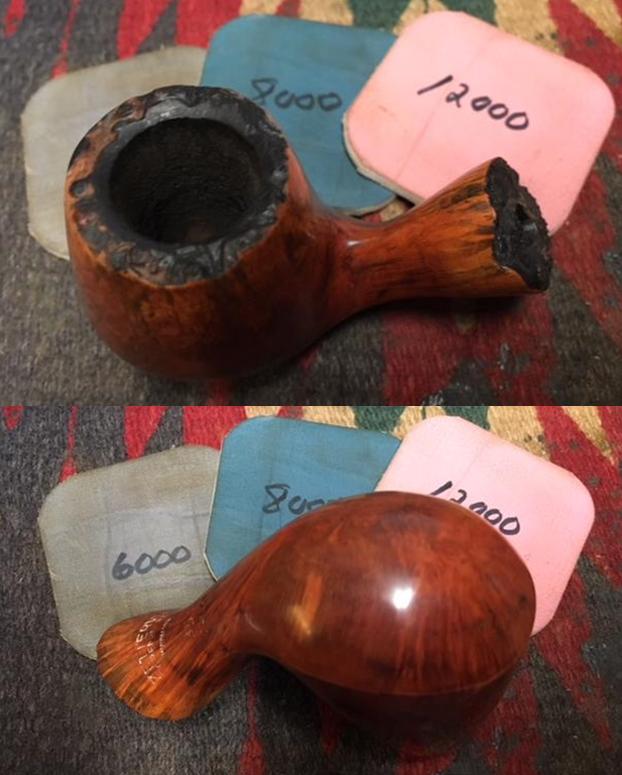

Since I like working on clean pipes and I know new stewards like smoking with clean pipes, I turn to the internals of the stummel. Using cotton buds and pipe cleaners with isopropyl 95%, I go to work. I’m thankful to discover that there is little resistance. Later, at the end of the day, I’ll clean the internals further by using a kosher salt and alcohol soak. With the internals clean, I turn again to the briar surface. To enliven the tired finish and to remove the small nicks and cuts that come from wear, I wet sand with micromesh pads 1500 to 2400, then dry sand with pads 3200 to 4000 and 6000 to 12000. With each cycle, I enjoyed watching the grain emerge. This GBD International Bulldog has nice grain – nice vertical flames rising to the carved plateau. I’m liking this.

With the internals clean, I turn again to the briar surface. To enliven the tired finish and to remove the small nicks and cuts that come from wear, I wet sand with micromesh pads 1500 to 2400, then dry sand with pads 3200 to 4000 and 6000 to 12000. With each cycle, I enjoyed watching the grain emerge. This GBD International Bulldog has nice grain – nice vertical flames rising to the carved plateau. I’m liking this.

I also want to freshen the carved black plateau – rim. I use a black furniture dye stick to apply to the rim. Later, when I apply compound, I’ll blend the black more, so it has more textured matte depth.

I also want to freshen the carved black plateau – rim. I use a black furniture dye stick to apply to the rim. Later, when I apply compound, I’ll blend the black more, so it has more textured matte depth.  Now, back to the stem. The GBD stem has been soaking in OxiClean as a second salvo against the oxidation in the vulcanite. After taking it out of the OxiClean bath, I use 600 grade paper and I wet sand the stem. I work on the areas that show the deeper oxidation. I then use 0000 steel wool and work over the entire stem, paying close attention to the area around the rondel. I’m not 100% satisfied, but I may do more after I work on the bit.

Now, back to the stem. The GBD stem has been soaking in OxiClean as a second salvo against the oxidation in the vulcanite. After taking it out of the OxiClean bath, I use 600 grade paper and I wet sand the stem. I work on the areas that show the deeper oxidation. I then use 0000 steel wool and work over the entire stem, paying close attention to the area around the rondel. I’m not 100% satisfied, but I may do more after I work on the bit.  I take a picture of the upper bit and the lower bit to show the tooth dents. The upper is not bad but the lower has two significant clinch bites and some damage to the button lip.

I take a picture of the upper bit and the lower bit to show the tooth dents. The upper is not bad but the lower has two significant clinch bites and some damage to the button lip. To lessen the severity of the dents I heat the vulcanite using a Bic lighter by painting the dented areas with a flame. As the vulcanite heats, it naturally expands and retakes some of the original ‘foot print’ of the dent. I heat both upper and lower. The upper will easily sand out but the lower still has work to do.

To lessen the severity of the dents I heat the vulcanite using a Bic lighter by painting the dented areas with a flame. As the vulcanite heats, it naturally expands and retakes some of the original ‘foot print’ of the dent. I heat both upper and lower. The upper will easily sand out but the lower still has work to do. To fill the dents and rebuild a little of the button, I use Starbond Black Medium CA glue. I spot drop the black CA glue on the dents and then I use an accelerator to quicken the curing time.

To fill the dents and rebuild a little of the button, I use Starbond Black Medium CA glue. I spot drop the black CA glue on the dents and then I use an accelerator to quicken the curing time. I then use a flat needle file and 240 grade sanding paper to sand down the patches. I use the file to freshen the button – to reestablish crisp button edges.

I then use a flat needle file and 240 grade sanding paper to sand down the patches. I use the file to freshen the button – to reestablish crisp button edges. The following two pictures show the lower bit/button work – first in progress then completed with filing and 240 paper.

The following two pictures show the lower bit/button work – first in progress then completed with filing and 240 paper. I continue the smoothing and erasing of the 240 scratches by using 600 grade paper and then finishing with 0000 grade steel wool. The patches look good, oxidation seems to be abated and the button shaping will be greatly appreciated by a new steward!

I continue the smoothing and erasing of the 240 scratches by using 600 grade paper and then finishing with 0000 grade steel wool. The patches look good, oxidation seems to be abated and the button shaping will be greatly appreciated by a new steward! I now turn to micromesh pads by first wet sanding with pads 1500 to 2400, then dry sanding with pads 3200 to 4000 then 6000 to 12000. After each set of three I apply Obsidian Oil to revitalize the vulcanite. The stem looks good.

I now turn to micromesh pads by first wet sanding with pads 1500 to 2400, then dry sanding with pads 3200 to 4000 then 6000 to 12000. After each set of three I apply Obsidian Oil to revitalize the vulcanite. The stem looks good.

Turning now to the stummel, to enrich the briar grain I apply Before & After Restoration Balm. I put a little on my finger and work it into the briar surface. As I work it in, the liquid thickens into a wax-like substance. After some minutes, I wipe off the Balm using a clean cloth. As the Balm comes off, the surface buffs up nicely.

Turning now to the stummel, to enrich the briar grain I apply Before & After Restoration Balm. I put a little on my finger and work it into the briar surface. As I work it in, the liquid thickens into a wax-like substance. After some minutes, I wipe off the Balm using a clean cloth. As the Balm comes off, the surface buffs up nicely. With my day ending, I continue cleaning the internals of the stummel. I use a kosher salt and alcohol soak. I fashion a wick by stretching and twisting a cotton ball. I insert the ‘wick’ down the mortise into the airway. I then fill the chamber with Kosher salt which, unlike iodized salt, leaves no aftertaste. I then situate the stummel in an egg crate giving it stability and then add isopropyl 95% with a large eye dropper until it surfaces over the salt. After a few minutes I top the alcohol once again and then turn out the lights.

With my day ending, I continue cleaning the internals of the stummel. I use a kosher salt and alcohol soak. I fashion a wick by stretching and twisting a cotton ball. I insert the ‘wick’ down the mortise into the airway. I then fill the chamber with Kosher salt which, unlike iodized salt, leaves no aftertaste. I then situate the stummel in an egg crate giving it stability and then add isopropyl 95% with a large eye dropper until it surfaces over the salt. After a few minutes I top the alcohol once again and then turn out the lights. The next morning the soak had produced results with soiled salt and the wick absorbed more oils and tars. I remove the expended salt to the waste and wipe the chamber with paper towel. I also blow through the mortise to remove any remaining salt particles. I then expend a few more pipe cleaners and cotton buds to clean up left overs from the soak. The internals are as fresh as I can make them.

The next morning the soak had produced results with soiled salt and the wick absorbed more oils and tars. I remove the expended salt to the waste and wipe the chamber with paper towel. I also blow through the mortise to remove any remaining salt particles. I then expend a few more pipe cleaners and cotton buds to clean up left overs from the soak. The internals are as fresh as I can make them. I reunite stem and stummel and mount a cotton cloth buffing wheel to the Dremel, setting the speed at the slowest. I then apply Blue Diamond compound to the entire pipe. I also work on blending the black matte plateaued rim. What I discover regarding the rim is that when I simply buff it with the Blue Diamond compound, is shines it up! The exact opposite than dulling it down to a matte, charcoal look. Then I came up with the idea of simply wetting a cotton pad with alcohol and dabbing it over the rim to dull the finish. It worked like I was hoping. I take a picture of before and after. It’s difficult to see different shades of black in a photo! But it does look good – the effect is striking.

I reunite stem and stummel and mount a cotton cloth buffing wheel to the Dremel, setting the speed at the slowest. I then apply Blue Diamond compound to the entire pipe. I also work on blending the black matte plateaued rim. What I discover regarding the rim is that when I simply buff it with the Blue Diamond compound, is shines it up! The exact opposite than dulling it down to a matte, charcoal look. Then I came up with the idea of simply wetting a cotton pad with alcohol and dabbing it over the rim to dull the finish. It worked like I was hoping. I take a picture of before and after. It’s difficult to see different shades of black in a photo! But it does look good – the effect is striking.  After completing the compound application and blending the rim, I wipe the pipe with a felt cloth to remove residue compound dust in preparation for the wax. I then switch to another cotton cloth wheel on the Dremel, increase the speed to about 40% full power and apply a few coats of carnauba wax to both stummel and stem. After application of the carnauba, I give the pipe a rigorous hand buffing to raise the shine.

After completing the compound application and blending the rim, I wipe the pipe with a felt cloth to remove residue compound dust in preparation for the wax. I then switch to another cotton cloth wheel on the Dremel, increase the speed to about 40% full power and apply a few coats of carnauba wax to both stummel and stem. After application of the carnauba, I give the pipe a rigorous hand buffing to raise the shine.

Oh my. The grain on this GBD International London Made shouts for attention! I’m pleased with the results. The flame grain emerges from the heel of the bowl – out of densely populated bird’s eye and swirls to reach toward the dome of the stummel, culminating in the craggy plateau of the rim. There’s a lot going on with this bent Bulldog. It is headed to The Pipe Steward Store and since Chris saw the potential of this GBD International, he will have first dibs on bringing the Bulldog home. The sale of this pipe benefits the Daughters of Bulgaria – helping women and girls (and their children) who have been trafficked and sexually exploited. Thank you for joining me! I can’t resist starting off with a before and after picture lest we forget!

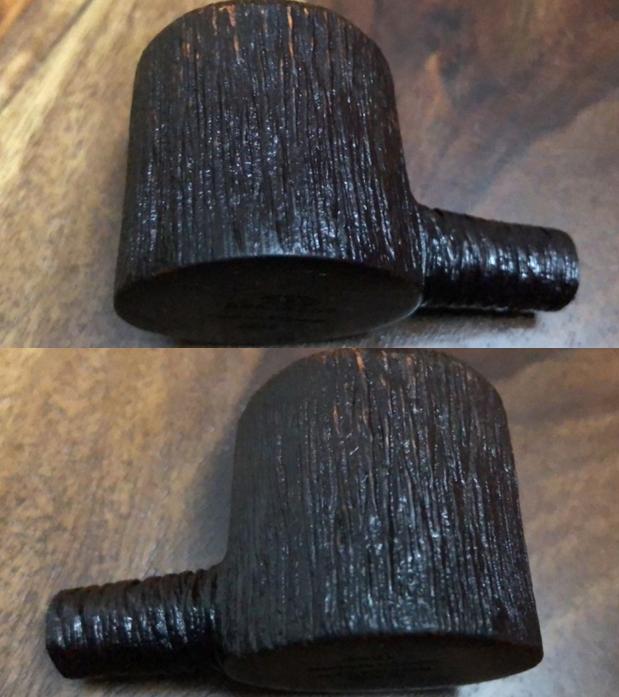

I took close up photos of the rim top and the shank end. I believe that the plateau “style” top of the rim was carved rather than natural. The shank end has a combination of carved finish and genuine plateau. The inside of the bowl has a thick cake around the bowl and some tar and oil on the top of the rim filling in the finish. Some of the original black finish was also worn off.

I took close up photos of the rim top and the shank end. I believe that the plateau “style” top of the rim was carved rather than natural. The shank end has a combination of carved finish and genuine plateau. The inside of the bowl has a thick cake around the bowl and some tar and oil on the top of the rim filling in the finish. Some of the original black finish was also worn off. I took photos of the pipe with the stem it had on the bowl when it had been found. It is a saddle stem made to fit flush against a rounded shank. It was not made for plateau style freehand shank ends.

I took photos of the pipe with the stem it had on the bowl when it had been found. It is a saddle stem made to fit flush against a rounded shank. It was not made for plateau style freehand shank ends.

I took a photo of the stamping on the underside of the shank. It is very clear and readable. The stamping is clearer than the photo shows.

I took a photo of the stamping on the underside of the shank. It is very clear and readable. The stamping is clearer than the photo shows. I decided that I would look up some information on the Zettervig brand before I started the clean up on the pipe. I looked up information on two of my favourite sites. The first was Pipedia. Here is the link: https://pipedia.org/wiki/Zettervig. I quote in full:

I decided that I would look up some information on the Zettervig brand before I started the clean up on the pipe. I looked up information on two of my favourite sites. The first was Pipedia. Here is the link: https://pipedia.org/wiki/Zettervig. I quote in full: I started my clean up on the bowl with reaming and then cleaning out the airway to the bowl and the inside of the mortise. I reamed the bowl with a Savinelli Fitsall Pipe Knife to remove the cake on the walls. I used a dowel wrapped with sandpaper to sand down the walls on the bowl. I cleaned out the airway with alcohol (99% isopropyl), pipe cleaners and cotton swabs until they were clean on the inside.

I started my clean up on the bowl with reaming and then cleaning out the airway to the bowl and the inside of the mortise. I reamed the bowl with a Savinelli Fitsall Pipe Knife to remove the cake on the walls. I used a dowel wrapped with sandpaper to sand down the walls on the bowl. I cleaned out the airway with alcohol (99% isopropyl), pipe cleaners and cotton swabs until they were clean on the inside.

I tried to wipe down the bowl with acetone to remove the shiny coat. It did not even begin to permeate the surface. I scrubbed the surface hard to try to break through the finish. It did not work. I sanded the finish with micromesh sanding pads to break the topcoat on the finish down. I wet sanded with 1500-2400 grit micromesh pads. I dry sanded it with 3200-12000 grit pads. I wiped it down after each pad with a cotton pad and acetone. That combination of sanding pads and acetone worked to break down the finish.

I tried to wipe down the bowl with acetone to remove the shiny coat. It did not even begin to permeate the surface. I scrubbed the surface hard to try to break through the finish. It did not work. I sanded the finish with micromesh sanding pads to break the topcoat on the finish down. I wet sanded with 1500-2400 grit micromesh pads. I dry sanded it with 3200-12000 grit pads. I wiped it down after each pad with a cotton pad and acetone. That combination of sanding pads and acetone worked to break down the finish.

I used a black Sharpie Pen to restain the rim top and the shank end. It was originally black and I have found over the years that the black pen matches the colour of the original stain.

I used a black Sharpie Pen to restain the rim top and the shank end. It was originally black and I have found over the years that the black pen matches the colour of the original stain. I rubbed down the briar with Before & After Restoration Balm. I worked it into the finish and the plateau style rim and shank end with my fingertips and finished working it in with a shoe brush. The balm worked to clean, preserve and enliven the surface of the finish on the small bowl. The briar was coming alive so I took some photos of the pipe at this point.

I rubbed down the briar with Before & After Restoration Balm. I worked it into the finish and the plateau style rim and shank end with my fingertips and finished working it in with a shoe brush. The balm worked to clean, preserve and enliven the surface of the finish on the small bowl. The briar was coming alive so I took some photos of the pipe at this point.

I buffed the plateau style rim top and shank end with a horsehair shoe brush to give it a shine.

I buffed the plateau style rim top and shank end with a horsehair shoe brush to give it a shine.  I went through my can of stems and found one that would work well on the freehand style Zettervig bowl. I had one was from a freehand pipe. I turned the end of the tenon down with the PIMO tenon turning tool. I did not need to remove too much material from the tenon so it did not take too long. Once I had turned it I sanded it smooth with a piece of sandpaper then tried it in the pipe for the fit and the look. It looked good but needed to be bent a little to follow the low of the bowl. I heated it with a Bic lighter until the vulcanite softened then bent it slightly to match the flow of the bowl.

I went through my can of stems and found one that would work well on the freehand style Zettervig bowl. I had one was from a freehand pipe. I turned the end of the tenon down with the PIMO tenon turning tool. I did not need to remove too much material from the tenon so it did not take too long. Once I had turned it I sanded it smooth with a piece of sandpaper then tried it in the pipe for the fit and the look. It looked good but needed to be bent a little to follow the low of the bowl. I heated it with a Bic lighter until the vulcanite softened then bent it slightly to match the flow of the bowl. The stem had two dents in the top surface. There was also some heavy oxidation in the vulcanite. I cleaned the areas around the button and filled in the dents with clear super glue. When the repair cured I sanded the repairs and the oxidation with 220 grit sandpaper. I folded the paper and worked in the grooves turned areas of the stem.

The stem had two dents in the top surface. There was also some heavy oxidation in the vulcanite. I cleaned the areas around the button and filled in the dents with clear super glue. When the repair cured I sanded the repairs and the oxidation with 220 grit sandpaper. I folded the paper and worked in the grooves turned areas of the stem. I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the stem down with Obsidian Oil between each sanding pad.

I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the stem down with Obsidian Oil between each sanding pad.

I put the stem back on the bowl and buffed the pipe with Blue Diamond polish on the buffing wheel. I lightly buffed the bowl so as not to fill in the sandblast finish. I also carefully avoided the stamping on the underside of the shank. I gave both the bowl and the stem multiple coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The finished pipe is shown in the photos below. I have two more pipes to finish for him – both of them that are finds he made while pipe hunting. This is a fun bunch of pipes to work on. I look forward to moving through the rest of them. Thanks for looking.

I put the stem back on the bowl and buffed the pipe with Blue Diamond polish on the buffing wheel. I lightly buffed the bowl so as not to fill in the sandblast finish. I also carefully avoided the stamping on the underside of the shank. I gave both the bowl and the stem multiple coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The finished pipe is shown in the photos below. I have two more pipes to finish for him – both of them that are finds he made while pipe hunting. This is a fun bunch of pipes to work on. I look forward to moving through the rest of them. Thanks for looking.