by Kenneth Lieblich

Here’s a charming pipe! I’ve been restoring a good number of pipes for a local family and this is the latest of the bunch: a Butz-Choquin Vendôme Extra 1688. This is an apple shape (in French, the shape is called boule – meaning ball), with a round shank and a tapered stem. It’s an attractive pipe, but it has seen better days. Time to spiff it up for its new owner.

Let’s have a look at the markings on this pipe. As the photos show, the left side of the shank reads, Butz-Choquin [over] Vendôme [over] Extra. The right side of the stem reads, St Claude [over] France [over] 1688. Additionally, the stem shows the BC logo of Butz-Choquin in a clear, acrylic circle.

Let’s have a look at the markings on this pipe. As the photos show, the left side of the shank reads, Butz-Choquin [over] Vendôme [over] Extra. The right side of the stem reads, St Claude [over] France [over] 1688. Additionally, the stem shows the BC logo of Butz-Choquin in a clear, acrylic circle.

Both Pipedia and Pipephil have good write-ups on the history of Butz-Choquin and I encourage you to read both. Also, Steve has restored quite a few and it’s worth having a look at his writings too. For the moment, here is some information from Pipedia:

Both Pipedia and Pipephil have good write-ups on the history of Butz-Choquin and I encourage you to read both. Also, Steve has restored quite a few and it’s worth having a look at his writings too. For the moment, here is some information from Pipedia:

The pipe, from Metz to Saint-Claude.

Jean-Baptiste Choquin of Metz started out as a tobacconist. This enterprise was prosperous; he had several employees. Among those, there was a certain Gustave Butz who was its first workman and who became his son-in-law by marrying Choquin’s daughter Marie in 1858.

In 1858 Jean-Baptiste Choquin created, in collaboration with Gustave Butz, the Choquin pipe. This bent pipe with a flat-bottomed bowl was finished with an albatross-bone mouthpiece, fixed with silver rings.

In 1858, still in Metz, Gustave Butz built an establishment for the manufacture of the Choquin pipe which took the name of. In 1951, the Berrod-Regad company bought the trademark, continuing manufacture until 2002. Departing from Metz, the workshop was relocated to Saint-Claude, then also called “the world capital of the briar pipe”, under the Berrod-Regad group. The Berrod-Regad group would go on to completely rebuild the network of representatives until finally entering the export market in 1960 and has since won several prizes, as well as the Gold Cup of French good taste.

In a few years, the brand’s collection increased from ten to seventy series. 135 years after it was founded, the pipe is still well-known not only in France but throughout the world. In 2002, the Berrod family, wishing to preserve manufacture of pipes in Saint-Claude, handed over the company to Fabien Guichon, a native of the area, who will continue to develop the brand during the 21st century. Meanwhile, Pipephil says this:

Meanwhile, Pipephil says this:

The origin of the brand reaches back to 1858 when Jean-Baptiste Choquin in collaboration with his son-in-law Gustave Butz created their first pipe in Metz (France). Since 1951 Butz-Choquin Site officiel Butz Choquin, pipes de Saint-Claude jura. BC pipe de bruyere luxe is a brand of the Berrod-Regad group (Saint-Claude, France).

Jean Paul Berrod managed the company from 1969 to 2002 when he retired and sold the corporate to Mr Fabien Gichon. Denis Blanc, allready owner of EWA, took over the S.A. Berrod-Regad in 2006.

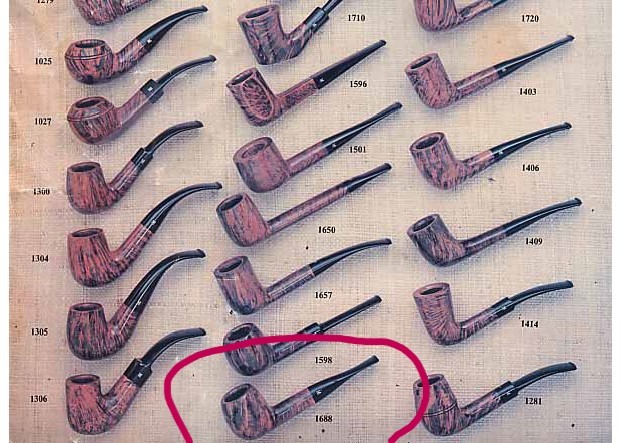

In an old Butz-Choquin catalogue, I found the pipe shape in question, listed with its requisite number: An inspection of the pipe showed a few flaws to be addressed. The bowl was dirty and stained. It also had some burn marks on the rim top. Furthermore, it had an unattractive lacquer-like finish to it. Meanwhile, the stem was dirty and scratched. There were minor bite marks and there was some oxidation.

An inspection of the pipe showed a few flaws to be addressed. The bowl was dirty and stained. It also had some burn marks on the rim top. Furthermore, it had an unattractive lacquer-like finish to it. Meanwhile, the stem was dirty and scratched. There were minor bite marks and there was some oxidation. To begin, I used oil soap on a few cotton rounds and wiped the stem down to provide an initial cleaning of filth before moving on. The primary cleaning comes next. I cleaned the inside of the stem with both pipe cleaners and cotton swabs dipped in 99% lemon-infused isopropyl alcohol. I scrubbed thoroughly to make sure the interior was clean.

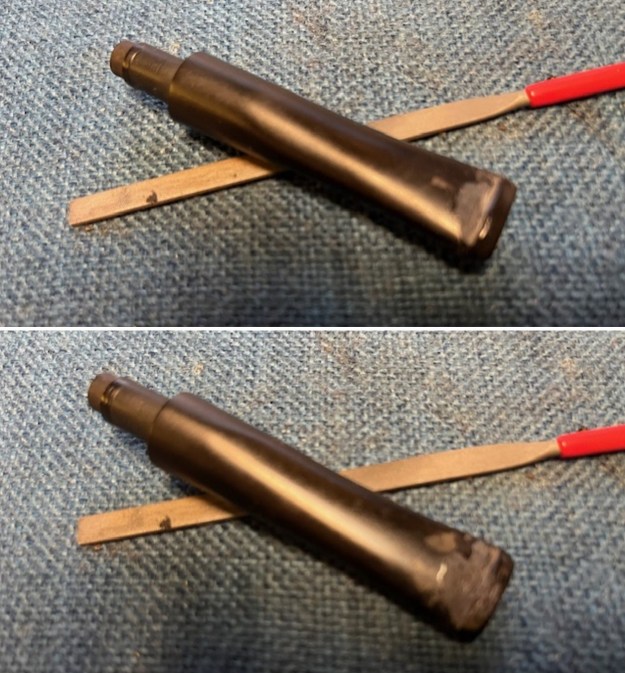

To begin, I used oil soap on a few cotton rounds and wiped the stem down to provide an initial cleaning of filth before moving on. The primary cleaning comes next. I cleaned the inside of the stem with both pipe cleaners and cotton swabs dipped in 99% lemon-infused isopropyl alcohol. I scrubbed thoroughly to make sure the interior was clean. The goal of the next step is the removal (or minimization) of oxidation. Going to my sink, I used cream cleanser, cotton rounds, and a toothbrush, and scoured the stem to remove as much surface oxidation as possible. As the photos show, the result is a hideous brownish mess – but better off the stem than on it.

The goal of the next step is the removal (or minimization) of oxidation. Going to my sink, I used cream cleanser, cotton rounds, and a toothbrush, and scoured the stem to remove as much surface oxidation as possible. As the photos show, the result is a hideous brownish mess – but better off the stem than on it. Once the stem was reasonably clean, I soaked it overnight in some de-oxidation fluid. This solution works to draw oxidation in the stem to the surface. This is a major aid and an important step in ensuring a clean stem. The following day, I drew the stem out from its bath and scrubbed the lingering fluid with a toothbrush.

Once the stem was reasonably clean, I soaked it overnight in some de-oxidation fluid. This solution works to draw oxidation in the stem to the surface. This is a major aid and an important step in ensuring a clean stem. The following day, I drew the stem out from its bath and scrubbed the lingering fluid with a toothbrush. Now that the stem is clean and dry, I set about fixing the marks and dents in the vulcanite. This is done by filling those divots with black cyanoacrylate adhesive, impregnated with carbon and rubber. I left this to cure and moved on.

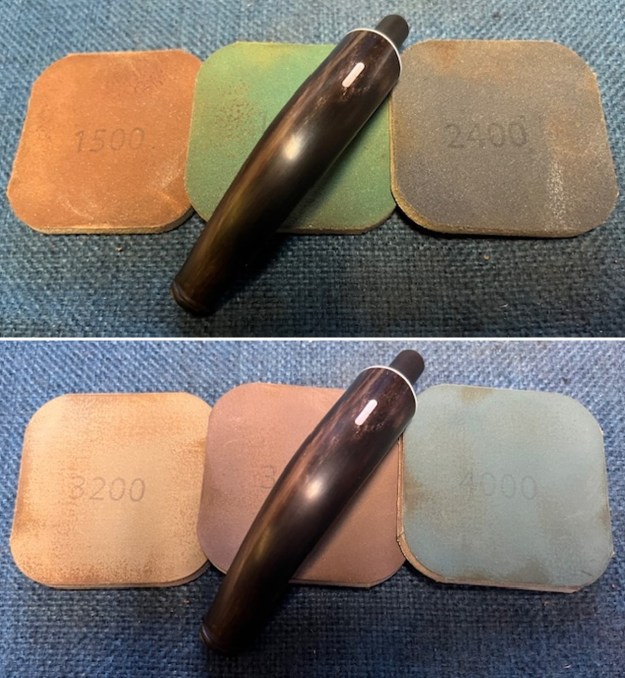

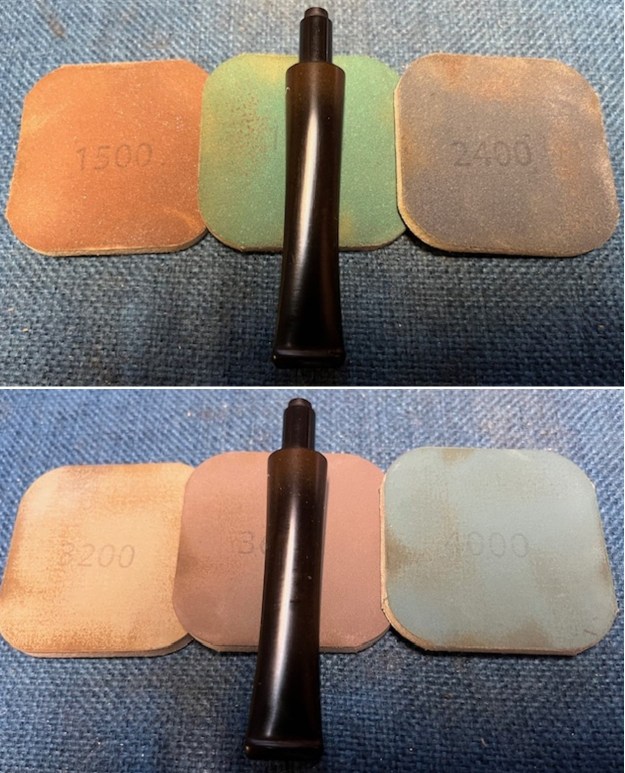

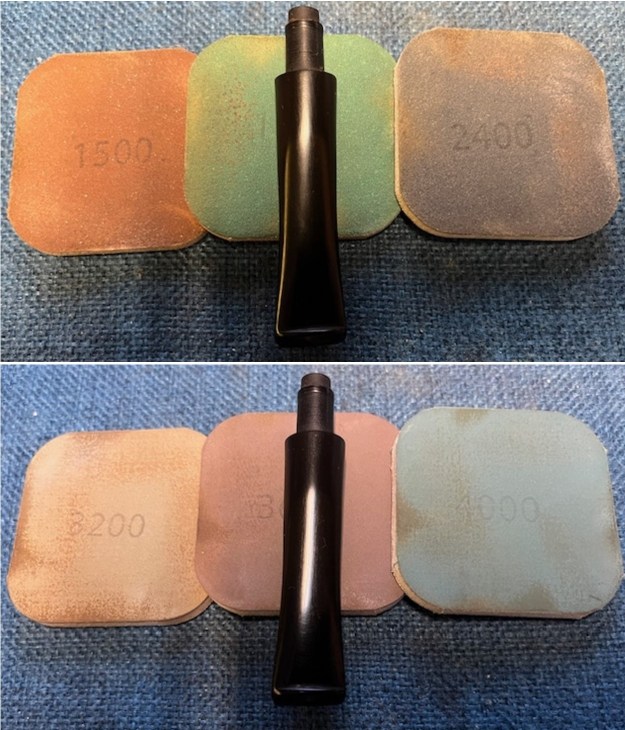

Now that the stem is clean and dry, I set about fixing the marks and dents in the vulcanite. This is done by filling those divots with black cyanoacrylate adhesive, impregnated with carbon and rubber. I left this to cure and moved on. The penultimate step for the stem is sanding. First, with my set of needle files, I reduce the bulk of the cyanoacrylate repairs. I want to remove the excess adhesive as near to the surface as possible, without cutting into the vulcanite. Following that, I use all nine of the micromesh sanding pads (1,500 through 12,000 grit) to sand out flaws, even out the vulcanite, and provide gentle polishing of the finished surface. I also apply pipe-stem oil while using the last five micromesh pads. There was a wonderful, deep black shine to the stem when I was done.

The penultimate step for the stem is sanding. First, with my set of needle files, I reduce the bulk of the cyanoacrylate repairs. I want to remove the excess adhesive as near to the surface as possible, without cutting into the vulcanite. Following that, I use all nine of the micromesh sanding pads (1,500 through 12,000 grit) to sand out flaws, even out the vulcanite, and provide gentle polishing of the finished surface. I also apply pipe-stem oil while using the last five micromesh pads. There was a wonderful, deep black shine to the stem when I was done. Now that the stem is (nearly) complete, I can move on to the stummel. The first step for me is to ream out the bowl – that is to say, remove all the cake inside the bowl. This accomplishes a couple of things. First (and most obviously), it cleans the bowl and provides a refurbished chamber for future smoking. Second, when the old cake is removed, I can inspect the interior walls of the bowl and determine if there is damage or not. I used a reamer, a pipe knife, and a piece of sandpaper taped to a wooden dowel. Collectively, these ensure that all the debris is removed. Plenty of cake in there…

Now that the stem is (nearly) complete, I can move on to the stummel. The first step for me is to ream out the bowl – that is to say, remove all the cake inside the bowl. This accomplishes a couple of things. First (and most obviously), it cleans the bowl and provides a refurbished chamber for future smoking. Second, when the old cake is removed, I can inspect the interior walls of the bowl and determine if there is damage or not. I used a reamer, a pipe knife, and a piece of sandpaper taped to a wooden dowel. Collectively, these ensure that all the debris is removed. Plenty of cake in there… The inside of the stummel needs to be cleaned thoroughly. Similar to the stem, I then cleaned it with both pipe cleaners and cotton swabs dipped in 99% lemon-infused isopropyl alcohol. With a pipe this dirty, it took quite a while and much cotton to get clean (as the photos will attest).

The inside of the stummel needs to be cleaned thoroughly. Similar to the stem, I then cleaned it with both pipe cleaners and cotton swabs dipped in 99% lemon-infused isopropyl alcohol. With a pipe this dirty, it took quite a while and much cotton to get clean (as the photos will attest). I then decided to ‘de-ghost’ the pipe – that is to say, exorcize the remaining filth from the briar. I filled the bowl and the shank with cotton balls, then saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused any remaining oils, tars and smells to leach out into the cotton.

I then decided to ‘de-ghost’ the pipe – that is to say, exorcize the remaining filth from the briar. I filled the bowl and the shank with cotton balls, then saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused any remaining oils, tars and smells to leach out into the cotton. To tidy up the briar, I also wiped down the outside with some oil soap on cotton rounds (and a toothbrush). This does a good job of cleaning any latent dirt on the surface of the briar. The last step of the cleaning process is to scour the inside of the stummel with some soap and tube brushes. This is normally the culmination of a lot of hard work in getting the pipe clean.

To tidy up the briar, I also wiped down the outside with some oil soap on cotton rounds (and a toothbrush). This does a good job of cleaning any latent dirt on the surface of the briar. The last step of the cleaning process is to scour the inside of the stummel with some soap and tube brushes. This is normally the culmination of a lot of hard work in getting the pipe clean. However, I noticed that the lacquer was flaking and looking terrible. As a result, I chose to remove it all with acetone on some cotton rounds. Of course, acetone is a volatile chemical, and I only use it rarely and judiciously in my pipe work. In this case, it acted perfectly to remove what I needed and left beautiful wood underneath. In fact, it looked so much better after having wiped it down.

However, I noticed that the lacquer was flaking and looking terrible. As a result, I chose to remove it all with acetone on some cotton rounds. Of course, acetone is a volatile chemical, and I only use it rarely and judiciously in my pipe work. In this case, it acted perfectly to remove what I needed and left beautiful wood underneath. In fact, it looked so much better after having wiped it down.

The damage to the rim is not terrible, but it is notable. In order to lessen the burns on the rim, I ‘topped’ the pipe – that is to say, I gently and evenly sanded the rim on a piece of 220-grit sandpaper. This effectively minimizes the damage, without altering the look of the pipe. A little of the burn remains, but that is part of this pipe’s life story.

The damage to the rim is not terrible, but it is notable. In order to lessen the burns on the rim, I ‘topped’ the pipe – that is to say, I gently and evenly sanded the rim on a piece of 220-grit sandpaper. This effectively minimizes the damage, without altering the look of the pipe. A little of the burn remains, but that is part of this pipe’s life story. I used all nine micromesh pads (1,500 through 12,000 grit) on the outside of the stummel to finish it off. This sanding minimizes flaws in the briar and provides a beautiful smoothness to the wood.

I used all nine micromesh pads (1,500 through 12,000 grit) on the outside of the stummel to finish it off. This sanding minimizes flaws in the briar and provides a beautiful smoothness to the wood. The removal of the lacquer was a positive, necessary step, but it made the stummel a bit pale. I decided to stain the wood with an alcohol-based, aniline dye. I use this type of dye because it is easy to work with, uniform in colour, quite penetrating, and is easily thinned with isopropyl alcohol. For this pipe, I chose a light brown colour, as it most closely resembled what the pipe would have looked like when new. I spread the dye all over the outside of the stummel with a small dauber and then applied a gentle flame to it. This flame assists in setting the stain by quickly evaporating the isopropyl alcohol. If necessary, the stain can be lightened by wiping the briar with pure alcohol – and, in this case, that’s precisely what I did.

The removal of the lacquer was a positive, necessary step, but it made the stummel a bit pale. I decided to stain the wood with an alcohol-based, aniline dye. I use this type of dye because it is easy to work with, uniform in colour, quite penetrating, and is easily thinned with isopropyl alcohol. For this pipe, I chose a light brown colour, as it most closely resembled what the pipe would have looked like when new. I spread the dye all over the outside of the stummel with a small dauber and then applied a gentle flame to it. This flame assists in setting the stain by quickly evaporating the isopropyl alcohol. If necessary, the stain can be lightened by wiping the briar with pure alcohol – and, in this case, that’s precisely what I did.  I rubbed some Before & After Restoration Balm into the briar and let it sit for 20 minutes or so. The balm moisturizes the wood and gives a beautiful depth to the briar. I then buffed it with a microfibre cloth.

I rubbed some Before & After Restoration Balm into the briar and let it sit for 20 minutes or so. The balm moisturizes the wood and gives a beautiful depth to the briar. I then buffed it with a microfibre cloth.

For the final step, I took the pipe to my bench buffer and carefully polished it – first with a white diamond compound, then with three coats of carnauba wax. This procedure makes the pipe look its best – the stummel sings and the stem glows.

For the final step, I took the pipe to my bench buffer and carefully polished it – first with a white diamond compound, then with three coats of carnauba wax. This procedure makes the pipe look its best – the stummel sings and the stem glows. This Butz-Choquin Vendôme Extra 1688 apple is a very handsome pipe and will provide many years of smoking pleasure for its new owner. The approximate dimensions of the pipe are as follows: length 5¼ in. (134 mm); height 1⅝ in. (40 mm); bowl diameter 1⅓ in. (34 mm); chamber diameter ¾ in. (19 mm). The weight of the pipe is 1⅛ oz. (34 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or email me directly at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.

This Butz-Choquin Vendôme Extra 1688 apple is a very handsome pipe and will provide many years of smoking pleasure for its new owner. The approximate dimensions of the pipe are as follows: length 5¼ in. (134 mm); height 1⅝ in. (40 mm); bowl diameter 1⅓ in. (34 mm); chamber diameter ¾ in. (19 mm). The weight of the pipe is 1⅛ oz. (34 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or email me directly at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.