Blog by Steve Laug

I have finished restoring quite a few of the pipes in this collection that we purchased from the older gentleman. He sent me the photos and I was amazed at what I saw. You have seen many of the pipes that he had. These included Dunhill, BBB, Orlik, Barclay Rex, a cased Ben Wade, an H. Simmons all briar, Hardcastles and some Meerschaums. There were also some assorted others that I will get to in the days ahead. It was a great collection.

I have finished restoring quite a few of the pipes in this collection that we purchased from the older gentleman. He sent me the photos and I was amazed at what I saw. You have seen many of the pipes that he had. These included Dunhill, BBB, Orlik, Barclay Rex, a cased Ben Wade, an H. Simmons all briar, Hardcastles and some Meerschaums. There were also some assorted others that I will get to in the days ahead. It was a great collection.

The next pipe I have chosen is a tired and worn looking older style Bulldog with a Bakelite stem with a bone tenon. I don’t know what it is about this pipe that caught my eye but something did. It certainly was not the condition of pipe. The bowl was in very rough shape. There was a thick cake in the bowl and the rim top and edges were told buried under a thick coat of lava. The pipe was really a stranger to pipe cleaners. It was filthy both inside and out. The shape probably caught my eye because it is quite lovely even under the grime and wear. The stem is Bakelite and it was a complete mess. It had the end gnawed off leaving behind a chipped and chewed end that was not eve square. I am not sure how much longer it was when it was made but it must have been longer than what we saw when we got. This was one well loved pipe that had been “ridden hard and put away wet”! It would be a challenge to see what I could do with it! In the end that is probably what drew me to the pipe!

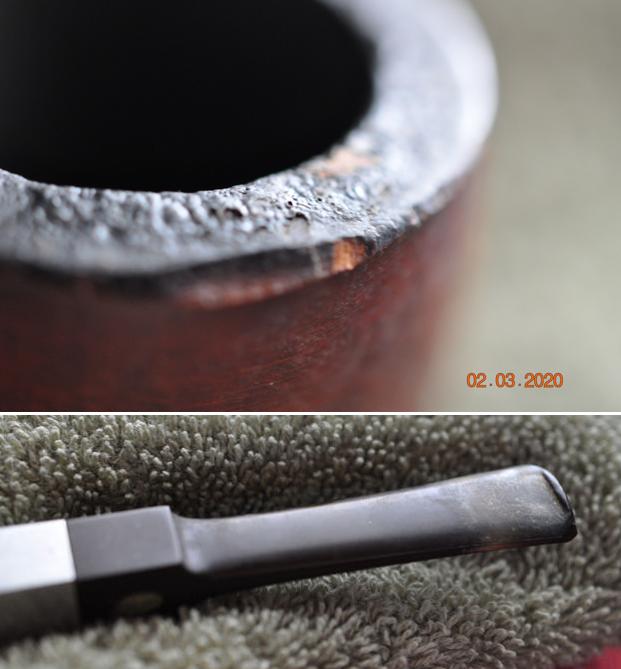

Jeff took some photos of the Bakelite Stemmed Bulldog before he worked his magic in cleaning up the pipe. It is a an interesting pipe with a lot of potential and what appears to be some great grain under the grime and debris of the years. Jeff took photos of the bowl, rim top to show the thickness of the cake in the bowl and the thick lava on the rim top. The rim top and both inner and outer edges are so thickly covered that it is hard to know their condition. It appears that there were nicks and chips on the outer edge at the back of the bowl that will require a bit of attention. All of the issues will become clearer after the clean up. He took photos of the top and underside of the Bakelite stem showing the gnawed end of the stem and the broken and missing chunks from the stem end. It appears that there were button remnants on both sides.

Jeff took photos of the bowl, rim top to show the thickness of the cake in the bowl and the thick lava on the rim top. The rim top and both inner and outer edges are so thickly covered that it is hard to know their condition. It appears that there were nicks and chips on the outer edge at the back of the bowl that will require a bit of attention. All of the issues will become clearer after the clean up. He took photos of the top and underside of the Bakelite stem showing the gnawed end of the stem and the broken and missing chunks from the stem end. It appears that there were button remnants on both sides.

Jeff also took some photos of the bone tenon and the shank end to show the appearance and condition of both.

Jeff also took some photos of the bone tenon and the shank end to show the appearance and condition of both. Jeff took photos of the sides and heel of the bowl to show the condition of the briar. You can see the beautiful shape of the bowl and some interesting grain even through the dirt and debris of many years.

Jeff took photos of the sides and heel of the bowl to show the condition of the briar. You can see the beautiful shape of the bowl and some interesting grain even through the dirt and debris of many years.

Jeff took photos of the stamping on the sides of the shank to show the lack of a stamping. It appears that both sides had some sort of stamp on them but it was worn away.

Jeff took photos of the stamping on the sides of the shank to show the lack of a stamping. It appears that both sides had some sort of stamp on them but it was worn away. This unstamped Bulldog is an interesting looking pipe. Because the old gentleman that we bought the pipes from intimated that he purchased his pipes at the Manhattan Barclay-Rex store I would imagine that he may have purchased this one from them as well. I was unable to pin down any information regarding the date this pipe was made but the fact that it is among the old timers I have been working on and the older Bakelite stem make me think it is older as well.

This unstamped Bulldog is an interesting looking pipe. Because the old gentleman that we bought the pipes from intimated that he purchased his pipes at the Manhattan Barclay-Rex store I would imagine that he may have purchased this one from them as well. I was unable to pin down any information regarding the date this pipe was made but the fact that it is among the old timers I have been working on and the older Bakelite stem make me think it is older as well.

Jeff carefully cleaned the pipe. He reamed it with a PipNet pipe reamer and then cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed out the internals of the shank, stem and shank extension with alcohol, pipe cleaners and cotton swabs until the pipe was clean. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and grit on the briar and lava on the rim top. The finish looks much better and has a deep richness in the colour that highlights the dimensions of the grain. The edges looked good otherwise. He scrubbed the Bakelite stem with Soft Scrub to remove the grime and oils on the stem and chewed stem end. When the pipe arrived here in Vancouver I was amazed that it looked so good. Here are some photos of what I saw.

I took some close up photos of the rim top and the stem surface. The top and inner and outer edge of the rim showed damage. There was serious damage back outer edge of the bowl. The stem was gnawed and that damage is very visible in the photos.

I took some close up photos of the rim top and the stem surface. The top and inner and outer edge of the rim showed damage. There was serious damage back outer edge of the bowl. The stem was gnawed and that damage is very visible in the photos.  I took photos of the shank sides to show that the stamping was worn away.

I took photos of the shank sides to show that the stamping was worn away. I removed the stem from the shank and took a photo of the parts of the pipe.

I removed the stem from the shank and took a photo of the parts of the pipe.  I started my work on the pipe by dealing with the chewed end of the stem. I used a file/rasp that I have here to flatten the chewed off end. I squared it off to have a fresh surface to work on a new button. I propped the stem up on the shank to take a picture of the squared end of the stem.

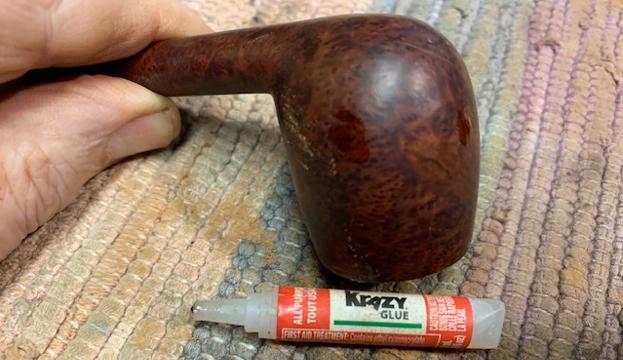

I started my work on the pipe by dealing with the chewed end of the stem. I used a file/rasp that I have here to flatten the chewed off end. I squared it off to have a fresh surface to work on a new button. I propped the stem up on the shank to take a picture of the squared end of the stem. I used a triangular file to recut the sharp edge of a button on the newly shaped stem end. I used 220 grit sandpaper to shape the top of the stem and shape the angles.

I used a triangular file to recut the sharp edge of a button on the newly shaped stem end. I used 220 grit sandpaper to shape the top of the stem and shape the angles. I spread a coat of clear CA glue on top of the button to seal the new edge and top of the button and set it aside to cure. I followed up on that by layering glue on the top of the button to build it up and give it some shape.

I spread a coat of clear CA glue on top of the button to seal the new edge and top of the button and set it aside to cure. I followed up on that by layering glue on the top of the button to build it up and give it some shape.

Once the button repair cured I used the triangle file and 180 grit sandpaper to shape the button surface.

Once the button repair cured I used the triangle file and 180 grit sandpaper to shape the button surface. There was still more shaping to do but the stem was taking form. I took profile pictures of it to give a sense of the shape. There is much more sanding to do but it was coming along.

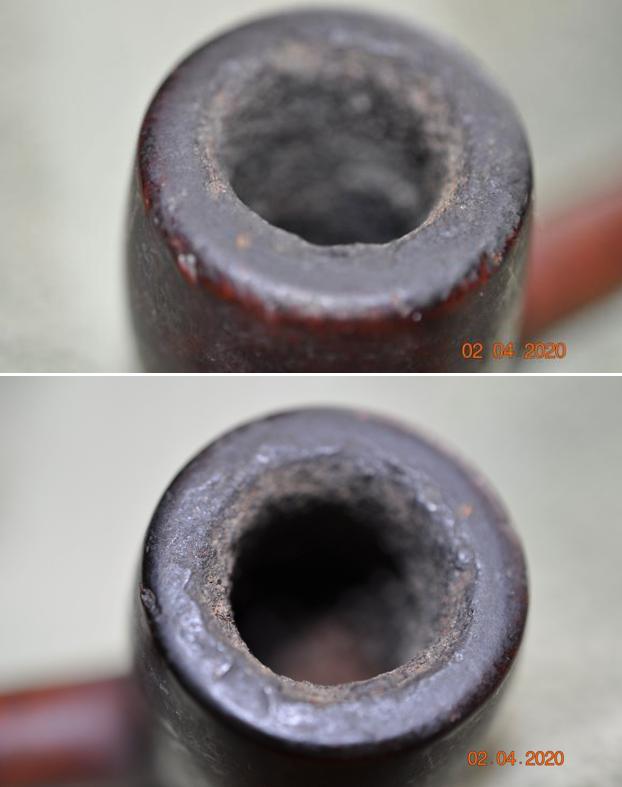

There was still more shaping to do but the stem was taking form. I took profile pictures of it to give a sense of the shape. There is much more sanding to do but it was coming along. I set the stem aside and turned my attention to the bowl. I used a folded piece of 180 grit sandpaper to bring the inner edges of the bowl back into round. I topped the bowl with 220 grit sandpaper to minimize the damage on the rim top and particularly the back of the bowl. I took a photo of the rim top after the topping.

I set the stem aside and turned my attention to the bowl. I used a folded piece of 180 grit sandpaper to bring the inner edges of the bowl back into round. I topped the bowl with 220 grit sandpaper to minimize the damage on the rim top and particularly the back of the bowl. I took a photo of the rim top after the topping.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down after each pad with a damp cloth to remove the sanding debris.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down after each pad with a damp cloth to remove the sanding debris.

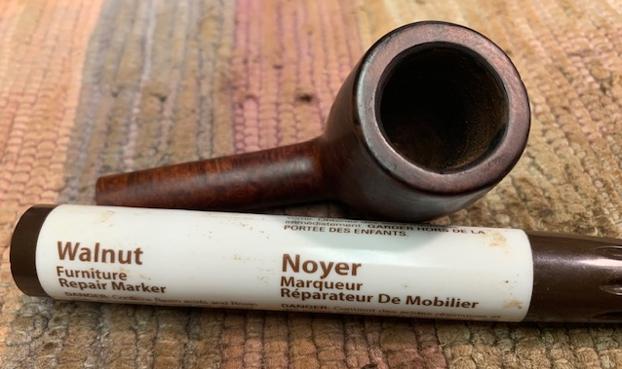

I stained the rim top with an Oak stain pen to match the surrounding briar. Once it is buffed the match should be perfect.

I stained the rim top with an Oak stain pen to match the surrounding briar. Once it is buffed the match should be perfect. I worked some Before & After Restoration Balm into the surface of the bowl and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the bowl and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

With stem reshaped and built earlier in the process all that remained was to polish it. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil.

With stem reshaped and built earlier in the process all that remained was to polish it. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil.

With the bowl and the stem finished I put the beautiful No Name Bulldog back together and buffed it on the wheel using Blue Diamond to give it a shine. I gave the bowl and the stem multiple coats of carnauba wax on the wheel. I buffed it with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The grain on this pipe really is a great looking. The dimensions of the pipe are – Length: 4 ¾ inches, Height: 1 ¾ inch, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of this large pipe is 1.16 ounces /33 grams. This Old Bakelite Stemmed Bulldog is another great find from this collection. It is much more beautiful in person than these photos can capture. This is another pipe that has the possibility of transporting the pipe man or woman back to a slower paced time in history where you can enjoy a respite. Thanks for walking through the restoration with me.

With the bowl and the stem finished I put the beautiful No Name Bulldog back together and buffed it on the wheel using Blue Diamond to give it a shine. I gave the bowl and the stem multiple coats of carnauba wax on the wheel. I buffed it with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The grain on this pipe really is a great looking. The dimensions of the pipe are – Length: 4 ¾ inches, Height: 1 ¾ inch, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of this large pipe is 1.16 ounces /33 grams. This Old Bakelite Stemmed Bulldog is another great find from this collection. It is much more beautiful in person than these photos can capture. This is another pipe that has the possibility of transporting the pipe man or woman back to a slower paced time in history where you can enjoy a respite. Thanks for walking through the restoration with me.