Blog by Paresh Deshpande

A very warm Namaste to all the followers of Reborn Pipes! It’s been a while since I posted any write up on rebornpipes.com and those that were posted have been projects which I had worked on prior to December 2020! The main reason being my relocation to a new place of work, numerous quarantine periods, waiting for allotment of house followed by shifting of family from Pune to my place of work, setting up the new house (only to up stake and move to a new place in 2 years!) and amidst these hectic activities, jostle with the kids and Abha, my wife, for a small corner where I could set up my work table. Thus, with everything well settled and having got back to our day to day routine, it was back to restoring pipes! Oh how I missed handling these pieces of art and history!

Through this time, I came to appreciate the reach of Reborn pipes and the yeoman service it provides in getting like minded pipers closer to each other. Now I am saying this because of the first hand experience I had when one fine day, I received a message from Steve that a gentleman piper from India wants to get in touch with me and that he had shared my email address. Soon enough, I received a mail from Karthik and since then our friendship has only been growing. Karthik was keen to start his own restoration work and was especially interested in a Peterson’s System pipe. Now, here in our part of the world, these are very difficult to come by and when they do, the cost is in INR five figures! When I told Karthik that the many Peterson’s System pipes that he read about on Reborn pipes were from my personal collection, I could sense his disappointment. Readers who have been following my write ups are well aware that one of my set goals has been to make available high quality restored pipes at reasonable price to fellow pipers from India and thus began my hunt for a Peterson’s System pipe in a reasonably good condition at an acceptable price point. A couple of months later, Chris from England (I have purchased a number of pipes from him earlier) had a Peterson’s System pipe that ticked all the right boxes and soon the pipe made its way to Pune and Abha, my wife, shared pictures of the received pipe. Karthik was mighty pleased with the way the pipe looked and so was I. Before I could get to work on this pipe, my move came about and the rest I have described above…

I had requested Karthik to introduce himself to all the readers of Reborn pipes and I am sanguine that we shall soon get to know and see his work. I received his mail and have reproduced it below (I have edited a very tiny portion of the mail though! Sorry Karthik, I too am still in the process of learning and hence the edit, hope you understand).

Hi Paresh sir,

Here’s my intro, hope it’s not too long:

Hello world! I’m Karthik, an engineer in India. I picked up pipe smoking last year as a way of staying off cigarettes, but have since fallen in love with the hobby itself. Living in India, I don’t have easy and immediate access to great pipes. So the idea of buying antiques and restoring them piqued my interest and I stumbled upon Reborn Pipes. As I read through post after post, I happened upon one of Paresh’s posts and both his name and his mention of Pune made me fall over myself in my rush to get in touch with him. I immediately emailed Steve, who graciously put me in touch with Paresh. Since then Paresh has been a great guide in my pipe smoking journey. Unfortunately I haven’t been able to start restoring any pipes myself, but I hope to get to that soon. In the meantime, Paresh generously showed me some of his collection and kept me in mind when he found something of interest. I hope to start down the path of restorations in the near future myself, with his guidance.

Regards,

Karthik

Definitely Karthik, together we shall learn and progress further.

And Now On To Restoring Karthik’s Pipe…

I have researched and worked on a few vintage as well as new Peterson’s and at first glance I knew this pipe to be a new era Peterson’s. The stummel has a spread of mixed grains all around and a nice feel in the hand thanks to its medium sized bowl. It is stamped vertically on the left side of the shank as “PETERSON’S” without a forked ‘P’ over “SYSTEM” over “STANDARD”. The right side of the shank close to the edge of the ferrule bears the COM stamp “MADE IN THE” over “REPUBLIC” over “OF IRELAND” while model/ shape code “# 314” is stamped below the COM stamp. The nickel ferrule bears the trademark Kapp & Peterson’s official logo of “K&P” followed by “PETERSON’S” over the three usual cartouche with first having Shamrock, the second a Prone Fox and lastly a Stone Tower. While dating a Peterson’s pipe, I always fall back to my under mentioned favorite site; http://thepetersonpipeproject.blogspot.com/2007/07/dating-petersons-pipes.html

While dating a Peterson’s pipe, I always fall back to my under mentioned favorite site; http://thepetersonpipeproject.blogspot.com/2007/07/dating-petersons-pipes.html

I quote from the above site:-

Stamping of Bowl:

During the years of Kapp and Peterson’s business operations, the country of Ireland has undergone several name changes and K&P’s stamping on their pipes reflects these changes. Knowing these changes, a Peterson pipe can be roughly dated and placed in “eras.”

- The Republic Era is from 1949 until the present. The Republic of Ireland was formed on 17 April 1949. From 1949 to present the stamp for this era is “Made in the Republic of Ireland” in a block format generally in three lines but two lines have been used with or without Republic being abbreviated.

With the provenance of the pipe thus established, I moved ahead with the initial visual inspection of the pipe.

Initial Visual Inspection

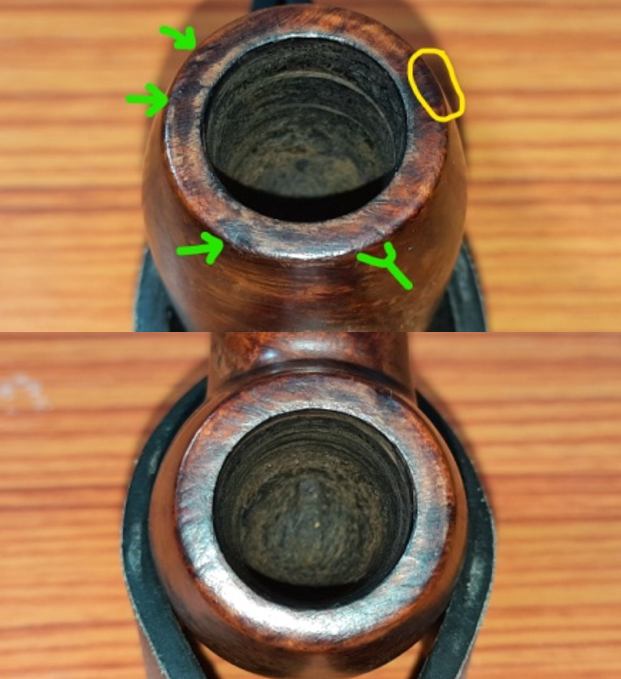

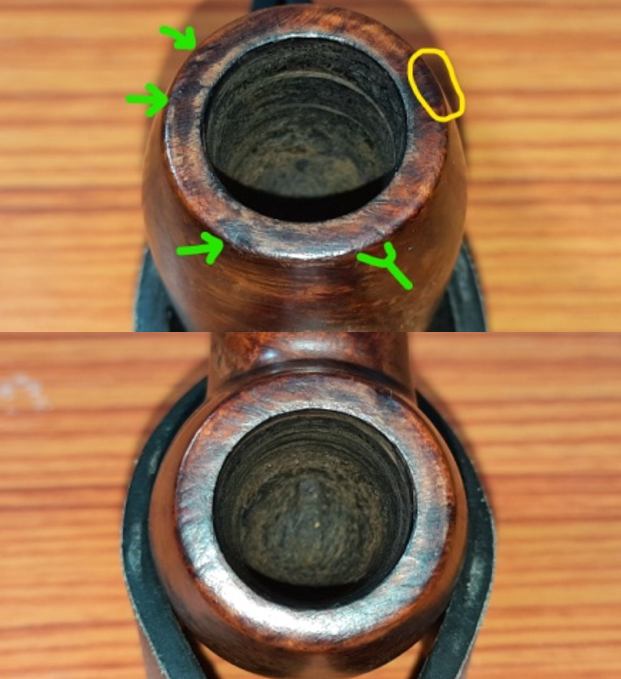

The chamber has a thin layer of cake signifying either limited usage or that it had been recently cleaned. The rim top surface has several scratch marks and darkening which would need to be addressed. The inner edge of the rim is charred in 3 o’clock direction (encircled in yellow). Nicks and dings are also seen along the outer rim edge (indicated with green arrows) and deep gouges on the right (encircled in yellow). Chamber has strong odors of sweet smelling tobaccos. The condition of the inner walls of the chamber appears solid and also going by the solid feel of the external surface, I do not foresee any serious issues/ surprises with the chamber walls.

The stummel surface is clean but appears dull and lackluster. A number of minor dents and scratches are seen over the stummel, notably towards the front, foot and the bottom of the shank. There is not a single fill over the entire stummel surface. The mortise and the sump shows traces of dried out oils and tars. The pipe smells are too strong.

The stummel surface is clean but appears dull and lackluster. A number of minor dents and scratches are seen over the stummel, notably towards the front, foot and the bottom of the shank. There is not a single fill over the entire stummel surface. The mortise and the sump shows traces of dried out oils and tars. The pipe smells are too strong.

The bent P-lip vulcanite stem is in a relatively good condition with light tooth chatter on either surfaces of the stem. The bite zone of the upper surface has deep tooth indentations with the button edge nearly obliterated and bite marks over the upper P- lip portion causing the slot edges to deform. These will need to be rebuilt and sharpened. The lower surface of the P-lip has distinct deep bite marks and the button edge is completely deformed. The stem is heavily oxidized with minor scratches towards the tenon end.

The bent P-lip vulcanite stem is in a relatively good condition with light tooth chatter on either surfaces of the stem. The bite zone of the upper surface has deep tooth indentations with the button edge nearly obliterated and bite marks over the upper P- lip portion causing the slot edges to deform. These will need to be rebuilt and sharpened. The lower surface of the P-lip has distinct deep bite marks and the button edge is completely deformed. The stem is heavily oxidized with minor scratches towards the tenon end.

The Process

The Process

I decided to work the stummel first as I was keen to see how the stummel shaped up and so was Karthik on appreciating the grains on this piece of briar. I carefully and gently scrapped out the thin layer of cake with a sharp knife followed by sanding the chamber walls with a folded piece of 220 grit sand paper. I checked the chamber walls closely and was happy to note that the walls were pristine and without any issues.

With the chamber now clean, I moved ahead with the internal cleaning of the shank and the sump. Using my sharp fabricated knife, I scraped out all the dried tars and gunk from the walls of the mortise. I used q-tips and pipe cleaners with alcohol to clean out the sump and the draught hole. I shall continue deep cleaning of the mortise and the sump when I will clean the internals using salt and alcohol treatment.

With the chamber now clean, I moved ahead with the internal cleaning of the shank and the sump. Using my sharp fabricated knife, I scraped out all the dried tars and gunk from the walls of the mortise. I used q-tips and pipe cleaners with alcohol to clean out the sump and the draught hole. I shall continue deep cleaning of the mortise and the sump when I will clean the internals using salt and alcohol treatment. Next I decided to address the issue of strong ghost smells in the chamber. To eliminate the ghost smells from the pipe, I decided to treat it with salt and alcohol. I packed the sump with cotton and drew out a wick from the cotton and along with a folded regular pipe cleaner, inserted it into the mortise and through the draught hole into the chamber. I tightly packed cotton balls in to the remaining portion of the mortise. Thereafter, I soaked the cotton balls with isopropyl alcohol up to the brim. About half an hour later, the level of alcohol had gone down, having being absorbed by the cotton. I topped it up once again and set it aside overnight. By next afternoon, the cotton and alcohol had drawn out all the remaining oils and tars from the chamber, sump and mortise. I removed the cotton balls and the dirt can be gauged by the appearance and coloration of the cotton balls and the pipe cleaner. With my fabricated knife and dental tools, I spent the next hour scrapping out the entire loosened gunk from the mortise and the sump. I ran pipe cleaners through the mortise and draught hole to clean out all the loosened tars and gunk that was lodged in the draught hole, sump and mortise. The chamber now smelled clean, fresh and looked it too. I set the stummel to dry out naturally.

Next I decided to address the issue of strong ghost smells in the chamber. To eliminate the ghost smells from the pipe, I decided to treat it with salt and alcohol. I packed the sump with cotton and drew out a wick from the cotton and along with a folded regular pipe cleaner, inserted it into the mortise and through the draught hole into the chamber. I tightly packed cotton balls in to the remaining portion of the mortise. Thereafter, I soaked the cotton balls with isopropyl alcohol up to the brim. About half an hour later, the level of alcohol had gone down, having being absorbed by the cotton. I topped it up once again and set it aside overnight. By next afternoon, the cotton and alcohol had drawn out all the remaining oils and tars from the chamber, sump and mortise. I removed the cotton balls and the dirt can be gauged by the appearance and coloration of the cotton balls and the pipe cleaner. With my fabricated knife and dental tools, I spent the next hour scrapping out the entire loosened gunk from the mortise and the sump. I ran pipe cleaners through the mortise and draught hole to clean out all the loosened tars and gunk that was lodged in the draught hole, sump and mortise. The chamber now smelled clean, fresh and looked it too. I set the stummel to dry out naturally.

To clean the exterior of the stummel surface, I applied “Briar Cleaner”, a product that has been developed by my friend Mark Hoover, to the external surface of the bowl. It works similar to Murphy’s oil soap and needs to be applied to the stummel surface and set aside for 5- 10 minutes. The product pulls out all the dirt and grime to the surface making further cleaning easy. I am quite happy with this product. I used a hard bristled tooth brush to scrub the stummel with the gel like product, wiped it clean with a moist cloth and dried it using paper towels and a soft cotton cloth. I deliberately cleaned the rim with a piece of Scotch Brite. I thoroughly cleaned the mortise and draught hole with a shank brush. I set the stummel aside to dry out naturally. The clean stummel had revealed a few more scratches which would need to be erased.

To clean the exterior of the stummel surface, I applied “Briar Cleaner”, a product that has been developed by my friend Mark Hoover, to the external surface of the bowl. It works similar to Murphy’s oil soap and needs to be applied to the stummel surface and set aside for 5- 10 minutes. The product pulls out all the dirt and grime to the surface making further cleaning easy. I am quite happy with this product. I used a hard bristled tooth brush to scrub the stummel with the gel like product, wiped it clean with a moist cloth and dried it using paper towels and a soft cotton cloth. I deliberately cleaned the rim with a piece of Scotch Brite. I thoroughly cleaned the mortise and draught hole with a shank brush. I set the stummel aside to dry out naturally. The clean stummel had revealed a few more scratches which would need to be erased.

Once the stummel had dried, aided by the extreme hot weather conditions prevalent here, I addressed the issues of numerous scratches and nicks by sanding the stummel smooth with a folded piece of 220 grit sandpaper. The sanding marks that are visible in the pictures below were obliterated once the stummel was subjected to the complete cycle of micromesh sanding and subsequent polishing and waxing.

Once the stummel had dried, aided by the extreme hot weather conditions prevalent here, I addressed the issues of numerous scratches and nicks by sanding the stummel smooth with a folded piece of 220 grit sandpaper. The sanding marks that are visible in the pictures below were obliterated once the stummel was subjected to the complete cycle of micromesh sanding and subsequent polishing and waxing.

Having addressed the issues of scratches and nicks over the stummel surface, I moved on to address the numerous dents and dings and charred edges over the rim top surface. I topped the rim over a piece of 220 grit sand paper by slowly rotating the rim over the sand paper. I hate to lose briar any more than absolutely necessary and so frequently checked the progress I was making. I was quite pleased with the appearance of the stummel at this stage in restoration.

Having addressed the issues of scratches and nicks over the stummel surface, I moved on to address the numerous dents and dings and charred edges over the rim top surface. I topped the rim over a piece of 220 grit sand paper by slowly rotating the rim over the sand paper. I hate to lose briar any more than absolutely necessary and so frequently checked the progress I was making. I was quite pleased with the appearance of the stummel at this stage in restoration. The time I was working on the stummel, my wife Abha was busy cleaning the stem. She cleaned the stem internals with q-tips, pipe cleaners and isopropyl alcohol. She further cleaned the stem airway with shank brush and dish washing soap. It feels really nice to have her around to help with the project. Once the stem internals were cleaned up to her exacting standards, she handed me the stem to address the issue of tooth indentations and chatter over the stem surface.

The time I was working on the stummel, my wife Abha was busy cleaning the stem. She cleaned the stem internals with q-tips, pipe cleaners and isopropyl alcohol. She further cleaned the stem airway with shank brush and dish washing soap. It feels really nice to have her around to help with the project. Once the stem internals were cleaned up to her exacting standards, she handed me the stem to address the issue of tooth indentations and chatter over the stem surface. The next stem issue to be addressed was that of the damage over the P-lip end of the stem. I heated both the surfaces with the flame of a lighter to raise the tooth chatter and bite marks to the surface and sanded the entire stem surface with a folded piece of 220 grit sandpaper to even out the surface as well as loosen the oxidation and handed over the stem to Abha for further process.

The next stem issue to be addressed was that of the damage over the P-lip end of the stem. I heated both the surfaces with the flame of a lighter to raise the tooth chatter and bite marks to the surface and sanded the entire stem surface with a folded piece of 220 grit sandpaper to even out the surface as well as loosen the oxidation and handed over the stem to Abha for further process.

She dropped the stem in to “Before and After Deoxidizer” solution developed by Mark Hoover. The solution helps to draw out heavy oxidation to the surface, making its further removal a breeze, while the minor oxidation is eliminated to a very great extent. The initial sanding helps to draw out the complete oxidation as the sanding opens up the stem surface that has been initially covered with oxidation. By next afternoon, the deoxidizer solution had worked its magic. Abha fished the stem out and cleaned it under warm while scrubbing the stem surface with a Scotch-Brite pad. She ran a couple of pipe cleaners through the stem’s airway to completely remove any remnants of the solution.

She dropped the stem in to “Before and After Deoxidizer” solution developed by Mark Hoover. The solution helps to draw out heavy oxidation to the surface, making its further removal a breeze, while the minor oxidation is eliminated to a very great extent. The initial sanding helps to draw out the complete oxidation as the sanding opens up the stem surface that has been initially covered with oxidation. By next afternoon, the deoxidizer solution had worked its magic. Abha fished the stem out and cleaned it under warm while scrubbing the stem surface with a Scotch-Brite pad. She ran a couple of pipe cleaners through the stem’s airway to completely remove any remnants of the solution. I mixed clear superglue and activated charcoal and applied it over the both button edges, upper P-lip surface and lower surface of the P-lip. I set the stem aside for the fills to cure.

I mixed clear superglue and activated charcoal and applied it over the both button edges, upper P-lip surface and lower surface of the P-lip. I set the stem aside for the fills to cure. Next afternoon, I worked the stem fills which had hardened considerably. With a flat head needle file, I sanded these fills to achieve a rough match. I further fine tuned the match by sanding the filled area with a folded piece of 220 grit sand paper pinched between my thumb and forefinger. I followed it up by sanding the entire stem surface using 320, 400, 600 and finally with a piece of 800 grit sand paper. This serves to remove the deep seated oxidation and also reduces the sanding marks of the more abrasive sand papers. I also sharpened the button edges while sanding. I wiped the stem with a cotton swab and alcohol to remove all the oxidation and sanding dust from the surface. I applied a little Extra Virgin Olive oil over the stem and set it aside to be absorbed by the vulcanite.

Next afternoon, I worked the stem fills which had hardened considerably. With a flat head needle file, I sanded these fills to achieve a rough match. I further fine tuned the match by sanding the filled area with a folded piece of 220 grit sand paper pinched between my thumb and forefinger. I followed it up by sanding the entire stem surface using 320, 400, 600 and finally with a piece of 800 grit sand paper. This serves to remove the deep seated oxidation and also reduces the sanding marks of the more abrasive sand papers. I also sharpened the button edges while sanding. I wiped the stem with a cotton swab and alcohol to remove all the oxidation and sanding dust from the surface. I applied a little Extra Virgin Olive oil over the stem and set it aside to be absorbed by the vulcanite. Next, I wet sand the stem with 1500 to 12000 girt micromesh pads to bring a deep black shine to the vulcanite. I rub a small quantity of extra fine stem polish that I had got from Mark and set it aside to let the balm work its magic. After about 10 minutes, I hand buffed the stem with a microfiber cloth to a nice shine. I rubbed a small quantity of olive oil into the stem surface to hydrate it and set it aside.

Next, I wet sand the stem with 1500 to 12000 girt micromesh pads to bring a deep black shine to the vulcanite. I rub a small quantity of extra fine stem polish that I had got from Mark and set it aside to let the balm work its magic. After about 10 minutes, I hand buffed the stem with a microfiber cloth to a nice shine. I rubbed a small quantity of olive oil into the stem surface to hydrate it and set it aside. While I worked the stem, Abha polished the stummel with micromesh pads, wet sanding with 1500 to 12000 pads. She polished the freshly topped rim surface to a nice luster, wiping the surface with a soft cloth at the end of the micromesh cycle. The stummel looks amazing with a deep shine and beautiful grains popping over the stummel surface. I am surprised that the rim top surface has the same deep brown coloration as the rest of the stummel surface and that the use of a stain pen was not required.

While I worked the stem, Abha polished the stummel with micromesh pads, wet sanding with 1500 to 12000 pads. She polished the freshly topped rim surface to a nice luster, wiping the surface with a soft cloth at the end of the micromesh cycle. The stummel looks amazing with a deep shine and beautiful grains popping over the stummel surface. I am surprised that the rim top surface has the same deep brown coloration as the rest of the stummel surface and that the use of a stain pen was not required.

She massaged a small quantity of “Before and After Restoration Balm” with her fingers into the briar. The immediate and incredible transformation that takes place is a worthy reward for all the efforts!! She let the balm sit on the surface to be absorbed in to the briar for about 20 minutes. The bowl now looks fresh and attractive with the grains popping out any which way you look at the briar. She polished off the balm with a soft cloth to a lovely shine.

She massaged a small quantity of “Before and After Restoration Balm” with her fingers into the briar. The immediate and incredible transformation that takes place is a worthy reward for all the efforts!! She let the balm sit on the surface to be absorbed in to the briar for about 20 minutes. The bowl now looks fresh and attractive with the grains popping out any which way you look at the briar. She polished off the balm with a soft cloth to a lovely shine.

Now on to the polishing cycle…I mounted a cotton cloth buffing wheel on to my hand held rotary tool and applied a coat of Blue Diamond to the stummel and the stem to polish out the minor scratches.

Now on to the polishing cycle…I mounted a cotton cloth buffing wheel on to my hand held rotary tool and applied a coat of Blue Diamond to the stummel and the stem to polish out the minor scratches. With a cotton buffing wheel that I use for carnauba wax, I applied a coat of carnauba wax and continued to work on it till the complete coat of wax had been polished out. I mounted a clean cotton cloth buffing wheel and gave the pipe a once over buff. I finished the restoration by giving the entire pipe a rigorous hand buff using a microfiber cloth to raise the shine further. The finished pipe looks beautiful and will soon be on its way for Karthik to enjoy his dream pipe!!

With a cotton buffing wheel that I use for carnauba wax, I applied a coat of carnauba wax and continued to work on it till the complete coat of wax had been polished out. I mounted a clean cotton cloth buffing wheel and gave the pipe a once over buff. I finished the restoration by giving the entire pipe a rigorous hand buff using a microfiber cloth to raise the shine further. The finished pipe looks beautiful and will soon be on its way for Karthik to enjoy his dream pipe!!

Sincere gratitude to all the readers who have shared this part of my journey in to the world of pipe restoration……Cheers!!!

Sincere gratitude to all the readers who have shared this part of my journey in to the world of pipe restoration……Cheers!!!

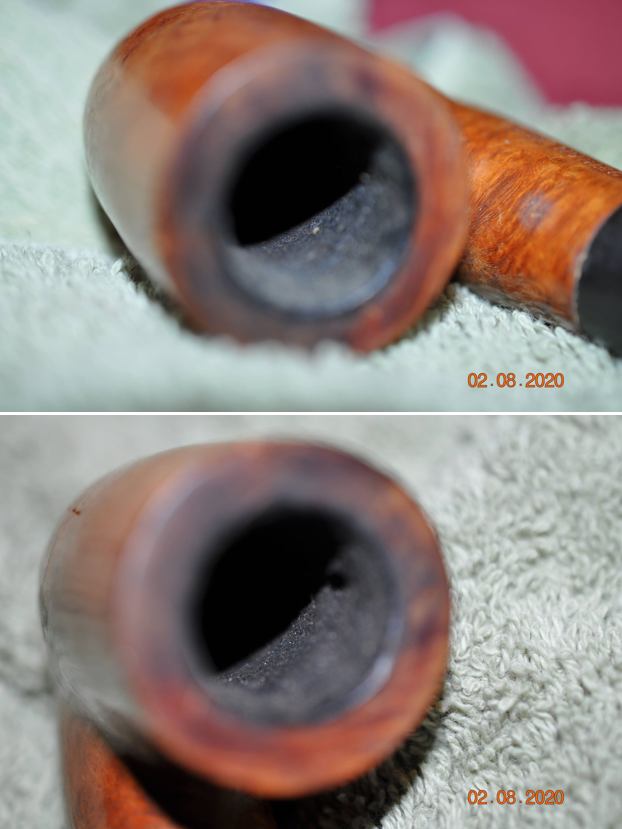

He took photos of the rim top and bowl to give a clear picture of the thickness of the cake and well as the lava and darkening on the front side of the rim top and inner edge. He also took photos of the top and underside of the stem to show the light oxidation and the chatter and tooth marks.

He took photos of the rim top and bowl to give a clear picture of the thickness of the cake and well as the lava and darkening on the front side of the rim top and inner edge. He also took photos of the top and underside of the stem to show the light oxidation and the chatter and tooth marks.

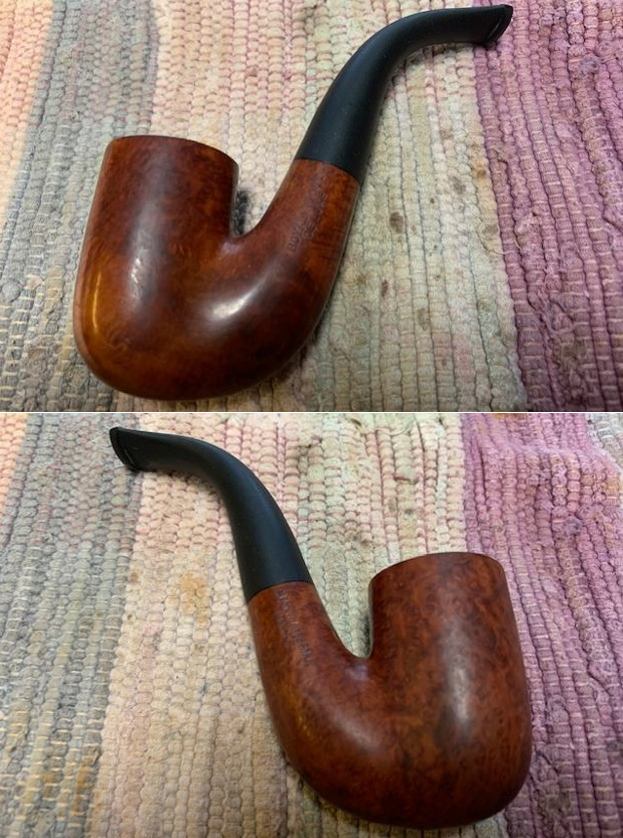

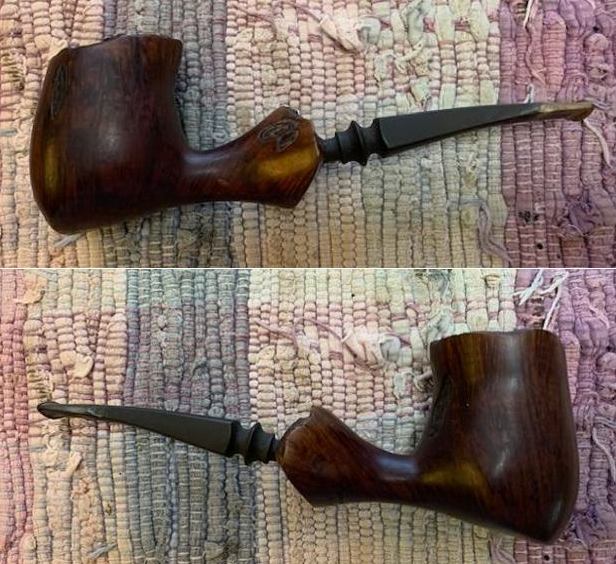

Jeff took a photo the sides and heel of the bowl to give a picture of the beautiful grain around the bowl and shank.

Jeff took a photo the sides and heel of the bowl to give a picture of the beautiful grain around the bowl and shank.

The stamping on the sides of the shank are clear and readable and read as noted above.

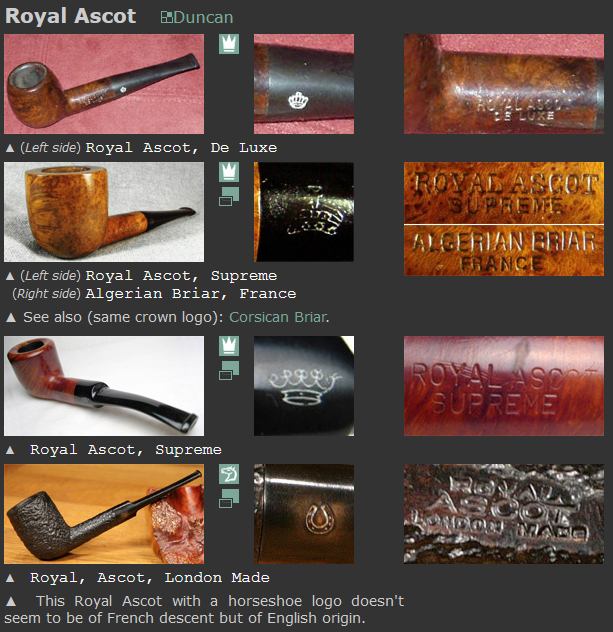

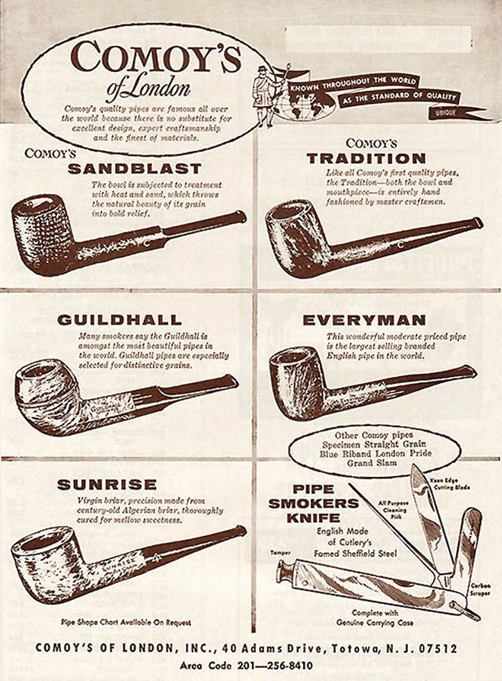

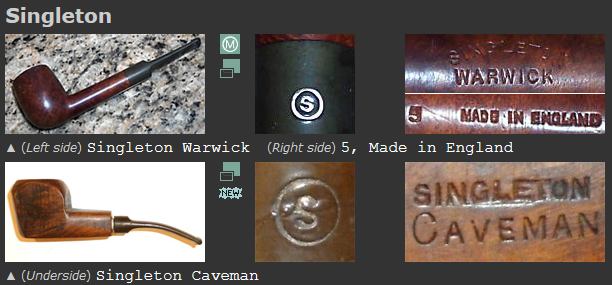

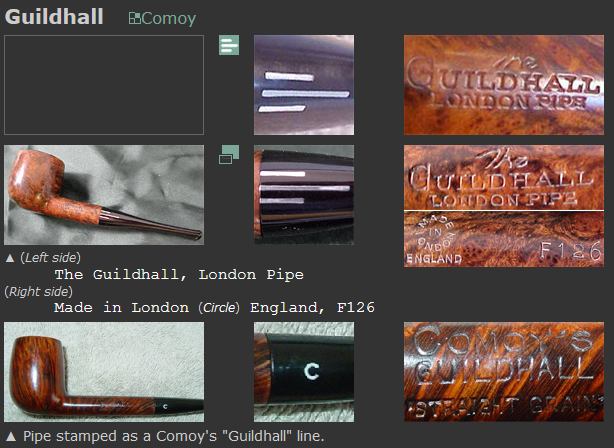

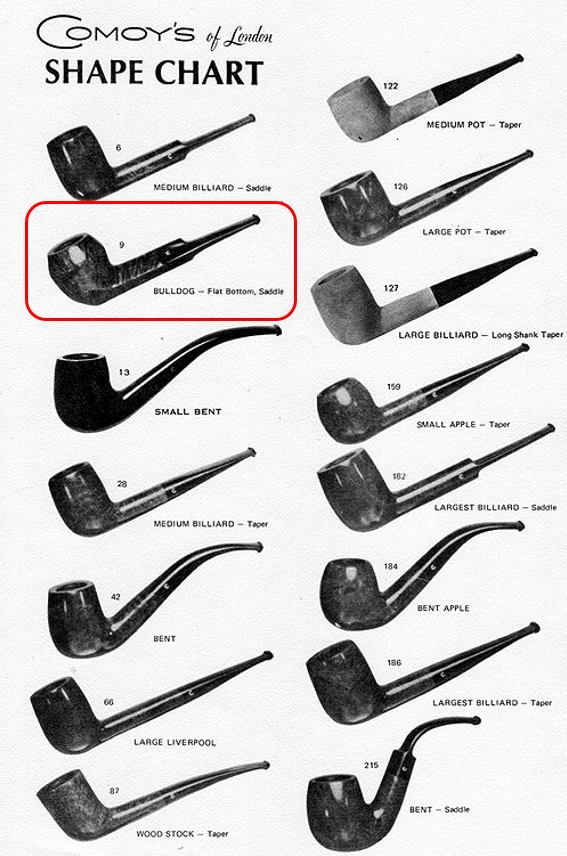

The stamping on the sides of the shank are clear and readable and read as noted above.  The Sunrise pipe was a Comoy’s made pipe and the France stamp on the shank pointed me to the connection between London and St. Claude (England/France). I turned to Pipephil’s site (http://www.pipephil.eu/logos/en/logo-s13.html) to get some background information on this beauty. I have included a screen capture of the pertinent section. The first pipe listed bears the same stamping as the one I am working on.

The Sunrise pipe was a Comoy’s made pipe and the France stamp on the shank pointed me to the connection between London and St. Claude (England/France). I turned to Pipephil’s site (http://www.pipephil.eu/logos/en/logo-s13.html) to get some background information on this beauty. I have included a screen capture of the pertinent section. The first pipe listed bears the same stamping as the one I am working on. The side bar includes this interesting piece of information. I quote:

The side bar includes this interesting piece of information. I quote:

The rim top cleaned up really well. The rim top and outer edge of the bowl appear to be in good condition other than some slight darkening on the front. The stem surface looked very good and the chatter on the stem on both sides near the button could easily be sanded out. The tooth marks on the button surface would need to be addressed.

The rim top cleaned up really well. The rim top and outer edge of the bowl appear to be in good condition other than some slight darkening on the front. The stem surface looked very good and the chatter on the stem on both sides near the button could easily be sanded out. The tooth marks on the button surface would need to be addressed.  The stamping on the top and underside of the shank is readable and reads as noted above.

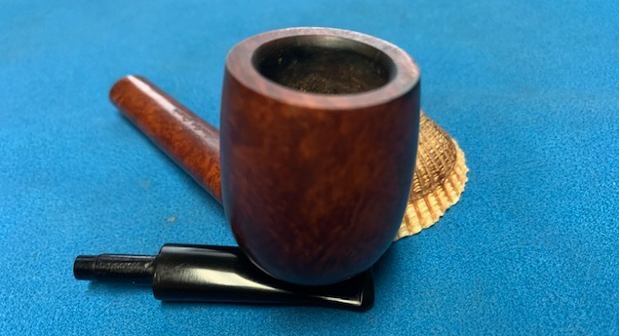

The stamping on the top and underside of the shank is readable and reads as noted above.  I removed the stem and took a photo of the pipe to give a sense of the whole. The bowl looked very good and once I cleaned up the stem the pipe would look very good.

I removed the stem and took a photo of the pipe to give a sense of the whole. The bowl looked very good and once I cleaned up the stem the pipe would look very good. Now it was time to do my work on the pipe. I topped the bowl lightly and sanded the beveled inner edge and top of the rim with 200 grit sandpaper to lighten the darkening that was there. There was also a spot on the front outer edge of the bowl that I needed to sand. I stained it with a Maple stain pen to match the colour of the bowl. The finished product looked better.

Now it was time to do my work on the pipe. I topped the bowl lightly and sanded the beveled inner edge and top of the rim with 200 grit sandpaper to lighten the darkening that was there. There was also a spot on the front outer edge of the bowl that I needed to sand. I stained it with a Maple stain pen to match the colour of the bowl. The finished product looked better.

I polished the briar with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad.

I polished the briar with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad.

The bowl was in such good condition that I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for ten minutes then buffed the bowl with a cotton cloth to raise the shine.

The bowl was in such good condition that I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for ten minutes then buffed the bowl with a cotton cloth to raise the shine.

I filled in the deep tooth marks on the button surface and the deeper ones on the stem itself with clear super glue. I let it cure and once it had hardened I reshaped the button and sanded the repairs smooth with 220 grit sandpaper. I started polishing the stem with 400 grit wet dry sandpaper.

I filled in the deep tooth marks on the button surface and the deeper ones on the stem itself with clear super glue. I let it cure and once it had hardened I reshaped the button and sanded the repairs smooth with 220 grit sandpaper. I started polishing the stem with 400 grit wet dry sandpaper.

I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This Comoy’s Made Sunrise Amber Grain Vintage Briar 299 Canadian is a great looking pipe now that it has been restored. The brown stained finish around the bowl is quite beautiful and highlights grain very well. The finish works well with the polished vulcanite oval taper stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Sunrise Amber Grain Vintage Briar Canadian sits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¾ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: ¾ inch. The weight of the pipe is 31 grams/1.09 ounces. I will be putting it on the rebornpipes store shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This Comoy’s Made Sunrise Amber Grain Vintage Briar 299 Canadian is a great looking pipe now that it has been restored. The brown stained finish around the bowl is quite beautiful and highlights grain very well. The finish works well with the polished vulcanite oval taper stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Sunrise Amber Grain Vintage Briar Canadian sits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¾ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: ¾ inch. The weight of the pipe is 31 grams/1.09 ounces. I will be putting it on the rebornpipes store shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!