Blog by Steve Laug

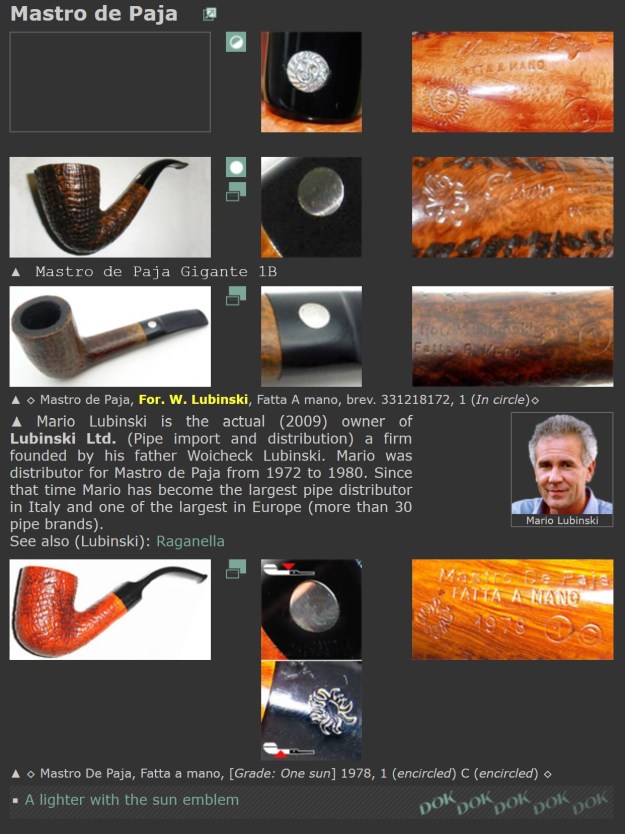

A few weeks ago I was contacted from a fellow in Montana who was selling his pipes as they had not been used for quite a few years. I asked him for a picture and he sent me the one to the left. It included the following brands (from the top to the bottom of the photo): Savinelli Autograph 5 Freehand, Mastro de Paja Ciocco 0C Bulldog, Mastro de Paja Media 1B Bent Billiard, Ser Jacopo Delecta Octagonal Bent Billiard, Caminetto Business KS 118 Canadian, Radici Rind Rhodesian, Dunhill Bruyere ODA 836 Panel Billiard, Barontini Straight Grain B3 Freehand and a Ben Wade Martinique Hand Made in Denmark Freehand.

A few weeks ago I was contacted from a fellow in Montana who was selling his pipes as they had not been used for quite a few years. I asked him for a picture and he sent me the one to the left. It included the following brands (from the top to the bottom of the photo): Savinelli Autograph 5 Freehand, Mastro de Paja Ciocco 0C Bulldog, Mastro de Paja Media 1B Bent Billiard, Ser Jacopo Delecta Octagonal Bent Billiard, Caminetto Business KS 118 Canadian, Radici Rind Rhodesian, Dunhill Bruyere ODA 836 Panel Billiard, Barontini Straight Grain B3 Freehand and a Ben Wade Martinique Hand Made in Denmark Freehand.

Almost all of them were higher end pipes and all were hand made pipes. They were a mix of finishes – smooth, sandblast and also rusticated. They were a mix of shapes as well and the majority of them were Italian Made other than the Dunhill and the Ben Wade Martinique. They were beautiful pipes and after exchanging quite a few photos of the pipes from various angles to get a sense of what was there we struck a deal. We sent him the payment and the pipes arrived in Idaho a few days after I left for Vancouver.

Jeff cleaned them all and this week I received them in Vancouver. I am impressed with the way they cleaned up and the beauty of the brands. They truly are some beautiful pipes. I just need to put the final touches on each of them and address minor issues on the bowl rims and the stems and they should be good to go. I am really looking forward to working on each of them in the days ahead.

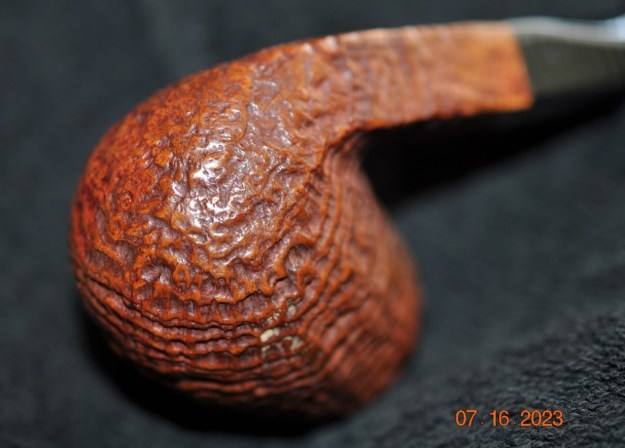

This afternoon after work I decided to continue working on the lot. I chose to work on the sandblast Savinelli Autograph Freehand. To me Savinelli Autographs have an easily recognizable look to them. This one had a great sandblast finish and a smooth rim top and bowl base so it functioned as a sitter. The pipe is stamped on heel of the bowl. It was clear and readable and says Savinelli [over] Autograph [over] 5. There is an autograph on the left side of the stem. The stamping is clear and readable. The medium brown stained finish was very dirty with grime ground into the valleys of the sandblast briar. The bowl had a thick cake and the rim top/inner edge had thick lava flowing up from the bowl. It was heavier on the back side of the bowl and rim than the rest. The inner edge of the bowl was covered enough with lava that it was hard to know its condition with certainty. The taper stem is black vulcanite and was dirty, oxidized and had tooth marks and chatter on both sides ahead of the button. Jeff took photos of the pipe before he started his clean up work on it.  Jeff took photos of the bowl and rim top to show what they looked like before the clean up. You can see the thick cake in the bowl overflowing as lava on the inner edge and rim top. He also took some photos of the stem to show the condition of both sides. You can see the tooth marks and chatter on the top and underside next to the button.

Jeff took photos of the bowl and rim top to show what they looked like before the clean up. You can see the thick cake in the bowl overflowing as lava on the inner edge and rim top. He also took some photos of the stem to show the condition of both sides. You can see the tooth marks and chatter on the top and underside next to the button.

The photos of the sides and heel of the bowl show the beautiful sandblast finish around the bowl and shank. The stain adds depth finish on the pipe. Even under the grime it is a real beauty.

The photos of the sides and heel of the bowl show the beautiful sandblast finish around the bowl and shank. The stain adds depth finish on the pipe. Even under the grime it is a real beauty.

The stamping on the heel of the bowl is shown in the photos below. It is clear and readable as noted above. The second photo shows the autograph on the side of the stem.

The stamping on the heel of the bowl is shown in the photos below. It is clear and readable as noted above. The second photo shows the autograph on the side of the stem.  I wanted to remind myself a bit about the Autograph line from Savinelli so I reread a blog I had written on a previous Autograph restoration (https://rebornpipes.com/2019/01/05/restoring-a-savinelli-autograph-3-rhodesian-dublin-long-shank/). I quote a portion of the blog now:

I wanted to remind myself a bit about the Autograph line from Savinelli so I reread a blog I had written on a previous Autograph restoration (https://rebornpipes.com/2019/01/05/restoring-a-savinelli-autograph-3-rhodesian-dublin-long-shank/). I quote a portion of the blog now:

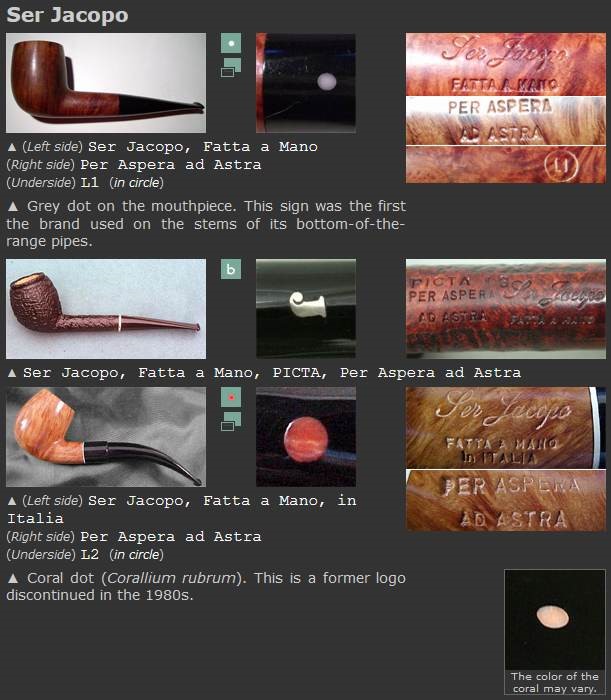

I turned first to the Pipephil website (http://www.pipephil.eu/logos/en/logo-savinelli1.html) to get a brief overview of the Autograph line. There I found out that the Autographs were hand made and unique. The Autograph Grading system is ascending: 3, 4, … 8, 0, 00, 000.

I turned then to Pipedia to get a more background on the Autograph line. I had the outline I needed from pipephil for the pipe but wanted more (https://pipedia.org/wiki/Savinelli). I quote in part from the article on that site.

While Savinelli’s serially produced pipes account for around 98% of annual production, the marque also creates a number of artisanal, handmade pieces as well. The Autographs, the Creativity line, and the Mr. A. line are all the result of Savinelli’s unique handmade process, with the Autographs reflecting the larger Freehand aesthetic, the Creativity line delving into more complex hand carving, and the Mr. A. line sidestepping the standard shape chart for remarkable and unusual pipes.

All of the briar for Savinelli’s Autographs and other freehand pipes is sourced specifically for those pieces. While the majority of the marque’s serial production is made from extra grade ebauchon blocks, Savinelli keeps a separate supply of Extra Extra plateau blocks for Freehands. This variety of briar is much larger, and of a higher quality, which explains why so many Autographs and Savinelli handmades are naturally larger designs.

All of the briar for Savinelli’s Autographs and other freehand pipes is sourced specifically for those pieces. While the majority of the marque’s serial production is made from extra grade ebauchon blocks, Savinelli keeps a separate supply of Extra Extra plateau blocks for Freehands. This variety of briar is much larger, and of a higher quality, which explains why so many Autographs and Savinelli handmades are naturally larger designs.

These handmade pieces are shaped much like traditional Danish Freehands: they are shaped first and drilled second. Using this method, Savinelli’s team of artisans is able to showcase their own creativity, as it maximizes flexibility and facilitates a more grain-centric approach to shaping. The resulting Freehand designs are at once both a departure from the marque’s classical standard shapes, yet very much still “Savinelli” in their nature—i.e. proportioned so that the bowl is the visual focus when viewed from the profile, juxtaposed by the comparatively trim lines of the shank and stem. To provide a little more insight into the differences between Savinelli’s standard production and freehand lines, Luisa Bozzetti comments:

“When we choose to make Freehand pipes we must stop production on the standard shapes. The process for Freehands is much more involved and takes much more time. Finding the best people from the production line and pulling them to make Freehands is challenging since it’s not an assembly line, but rather a one or two man operation.

After the rough shaping of the stummel, we must get together and brainstorm which style of stem will be paired before the pipe can be finished since we do not use pre-shaped stems. All accents and stems for the Freehands are cut from rod here in the factory. A lot of care goes into the few pieces lucky enough to make the cut; to end up with a certain number of Autographs, for instance, means that many, many more will be made, and only the few will be selected.”

The quality control process for Savinelli handmades is even more rigorous than that employed in the standard lineup. Many blocks are started and later discarded because of pits or defects. While Savinelli’s briar sourcing is a constant process, working with some of Italy’s top cutters to ensure only the finest and most suitable blocks make their way to the factory, it’s impossible to source plateau briar that’s completely free from flaws. That’s just nature. Savinelli creates the standard for quality by working through the rough (a very high-quality rough, mind you) to find that shining diamond with the potential to become a Savinelli handmade.

It looks like the Autograph 5 I am working is pretty high in the hierarchy of the line. Like other autographs I have worked on in the past this one has a signature on the left side of the vulcanite stem. Jeff once again did an amazing job cleaning the pipe. He reamed it with a PipNet pipe reamer and cleaned up the bowl walls with a Savinelli Fitsall Pipe Knife. He got rid of the cake so that we could see the walls of the bowl and assess for damage. He cleaned the internals of the shank and stem with alcohol, pipe cleaners and alcohol. He scrubbed the exterior with undiluted Murphy’s Oil Soap and a tooth brush to get into the grooves and valleys of the rustication. He rinsed the pipe under warm water. He dried it off with a cloth and then let it air dry. The stem was scrubbed with Soft Scrub and then soaked in Briarville’s Pipe Stem Deoxidizer. It came out looking pretty good with a light coat of oxidation still present. The finish on the bowl and the rim top cleaned up pretty good. I took pictures of the pipe to show how it looked when I unpacked it.

I took close up photos of both the rim top and the stem. Jeff had been able to get the grime and lava off of the rim top and it looked very clean. The stem looked very clean. The tooth marks and chatter were predominantly near the button.

I took close up photos of both the rim top and the stem. Jeff had been able to get the grime and lava off of the rim top and it looked very clean. The stem looked very clean. The tooth marks and chatter were predominantly near the button.  The stamping on the sides of the shank was readable as noted above. I took photos of the stamping on the heel of the bowl to show the condition and readability. I also took a photo of the autograph on the left side of the stem. I took a photo of the pipe with the stem removed to give an idea of the perspective and design of the pipe.

The stamping on the sides of the shank was readable as noted above. I took photos of the stamping on the heel of the bowl to show the condition and readability. I also took a photo of the autograph on the left side of the stem. I took a photo of the pipe with the stem removed to give an idea of the perspective and design of the pipe.

I polished the smooth heel of the bowl and rim top with micromesh sanding pads using 1500-12000 grit sanding pads and wiping it down after each sanding pad with a damp cloth to remove the sanding dust and debris.

I polished the smooth heel of the bowl and rim top with micromesh sanding pads using 1500-12000 grit sanding pads and wiping it down after each sanding pad with a damp cloth to remove the sanding dust and debris.

I worked some Before & After Restoration Balm into the finish of the bowl and shank with my fingers and a horsehair shoe brush. I want the product to go deep into the finish because it works to clean, enliven and protect the briar. Once I was confident that it was deeply worked into the finish I wiped it off and buffed it with a soft cloth to polish it. The pipe really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. The grain really stands out on the pipe in the photos below.

I worked some Before & After Restoration Balm into the finish of the bowl and shank with my fingers and a horsehair shoe brush. I want the product to go deep into the finish because it works to clean, enliven and protect the briar. Once I was confident that it was deeply worked into the finish I wiped it off and buffed it with a soft cloth to polish it. The pipe really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. The grain really stands out on the pipe in the photos below.

I set the bowl aside and turned to work on the stem. I painted the surface of the vulcanite with the flame of a lighter to lift the bite marks. I was able to lift them significantly. What remained I filled in with black CA glue. Once the repairs cured I flattened the repairs with a small file. I sanded the surface of the stem with 220 grit sandpaper and started the polishing with a folded piece of 600 grit wet dry sandpaper.

I set the bowl aside and turned to work on the stem. I painted the surface of the vulcanite with the flame of a lighter to lift the bite marks. I was able to lift them significantly. What remained I filled in with black CA glue. Once the repairs cured I flattened the repairs with a small file. I sanded the surface of the stem with 220 grit sandpaper and started the polishing with a folded piece of 600 grit wet dry sandpaper.

I touched up the autograph stamp on the left side of the stem with white acrylic fingernail polish. I worked it into the stamp with a tooth pick and cleaned off the excess with a worn 1500 micromesh sanding pad.

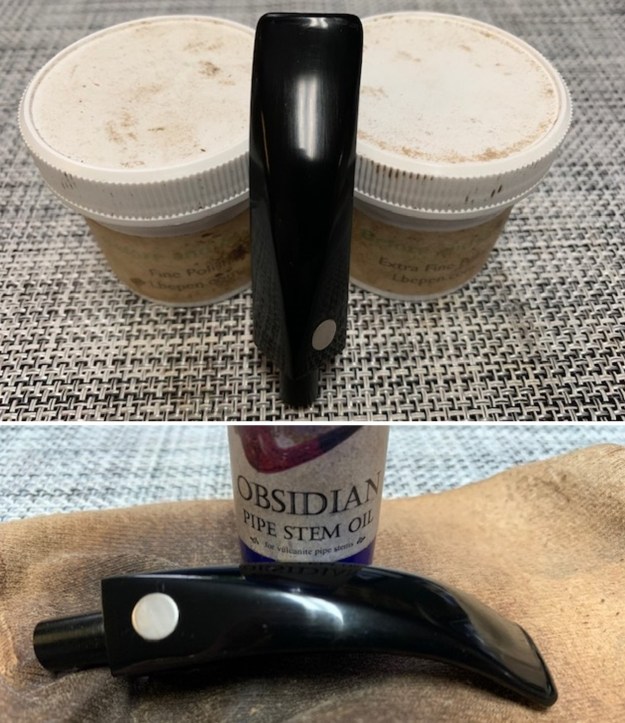

I touched up the autograph stamp on the left side of the stem with white acrylic fingernail polish. I worked it into the stamp with a tooth pick and cleaned off the excess with a worn 1500 micromesh sanding pad. I polished the vulcanite stem with micromesh sanding pads – wet sanding it with 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad.

I polished the vulcanite stem with micromesh sanding pads – wet sanding it with 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad.

I polished it with Before & After Pipe Polish – both the Fine and Extra Fine polishes. I gave it a final coat of oil and set it aside to dry.

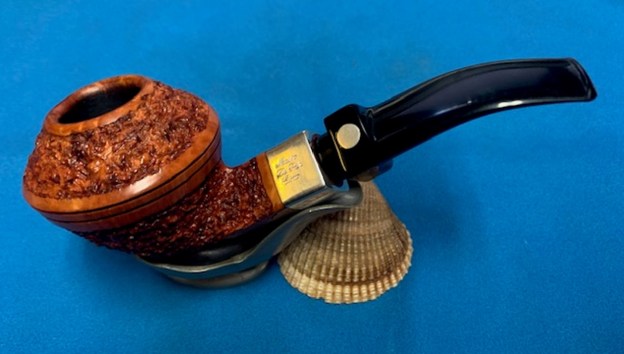

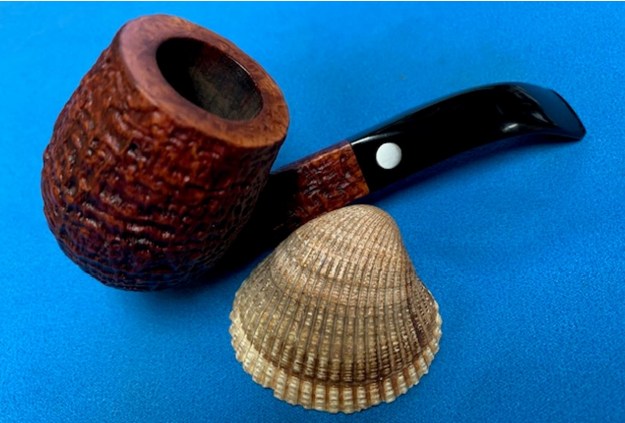

I polished it with Before & After Pipe Polish – both the Fine and Extra Fine polishes. I gave it a final coat of oil and set it aside to dry. I put the Savinelli Autograph 5 bowl and stem back together. I polished the smooth part of the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the sandblasted bowl and shank several coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The medium brown stains and the smooth and sandblast finish worked amazingly well with the polished black vulcanite stem. The sandblast was deep and craggy on the bowl and shank and looks quite remarkable. This is truly a beautiful Freehand pipe. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 ½ inches, Outside diameter of the bowl: 1 ¾ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 2.89 ounces/82 grams. I have restored quite a few Autographs over the years and this estate is another rare beauty. I will be putting it on the rebornpipes store shortly in the Italian Pipemakers Section. Thanks for walking through the restoration with me. Cheers.

I put the Savinelli Autograph 5 bowl and stem back together. I polished the smooth part of the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the sandblasted bowl and shank several coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The medium brown stains and the smooth and sandblast finish worked amazingly well with the polished black vulcanite stem. The sandblast was deep and craggy on the bowl and shank and looks quite remarkable. This is truly a beautiful Freehand pipe. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 ½ inches, Outside diameter of the bowl: 1 ¾ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 2.89 ounces/82 grams. I have restored quite a few Autographs over the years and this estate is another rare beauty. I will be putting it on the rebornpipes store shortly in the Italian Pipemakers Section. Thanks for walking through the restoration with me. Cheers.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.