by Steve Laug

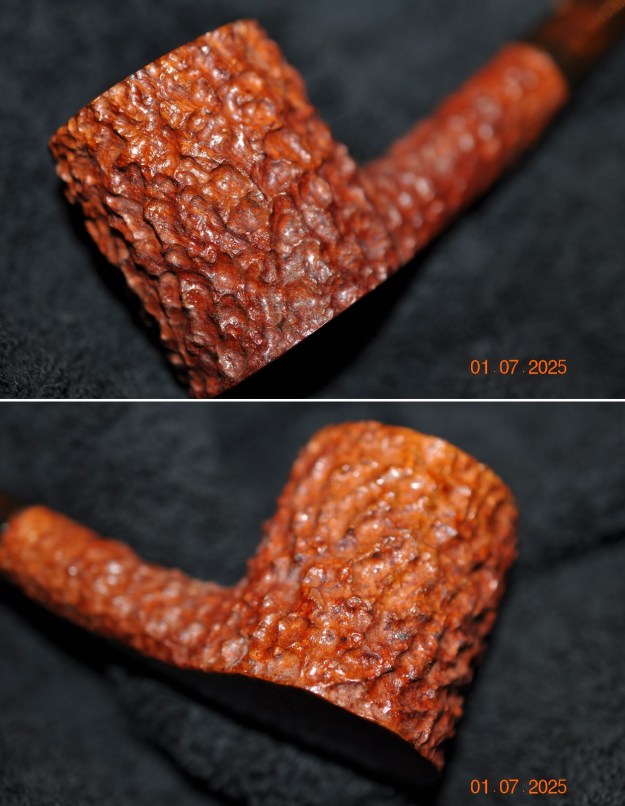

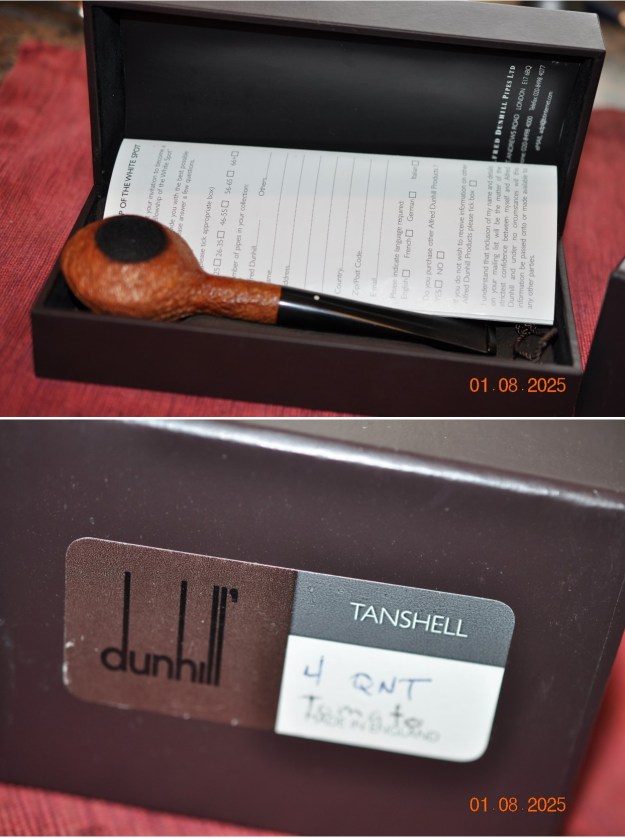

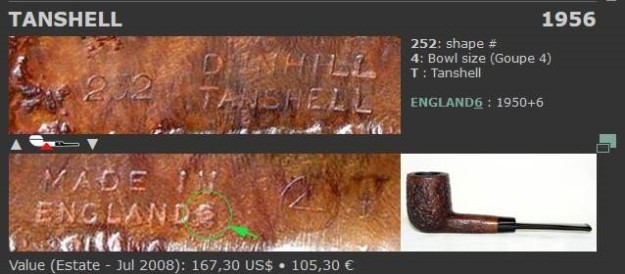

The next pipe on the table is one that came to us from the group of pipes that Jeff and I purchased from our connection in Copenhagen, Denmark on 10/17/2022. It is clearly a Danish Freehand style sandblast that is in good condition. It is stamped on a smooth panel on end of the shank and reads Handmade in Denmark stamped diagonally across the shank end. There is no other stamping on the pipe so it is unclear who made it. The rim top and shank end are plateau briar and quite rugged. Everything about the pipe suggests that it is a Preben Holm made pipe but of course I cannot prove that. The pipe has a mix of black and brown stains on a sandblast finish and some amazing grain that the shape follows well. The finish was dusty around the nooks and crannies of the sandblast but otherwise fairly clean. The rim top had a thick lava cake on the top in the plateau that was heavier on the left side. There was also lava on the inner edge flowing from thick cake in the bowl. The fancy saddle stem was oxidized, dirty and had light chatter ahead of the button. Jeff took photos of the pipe to show what it looked like before he started working on it.

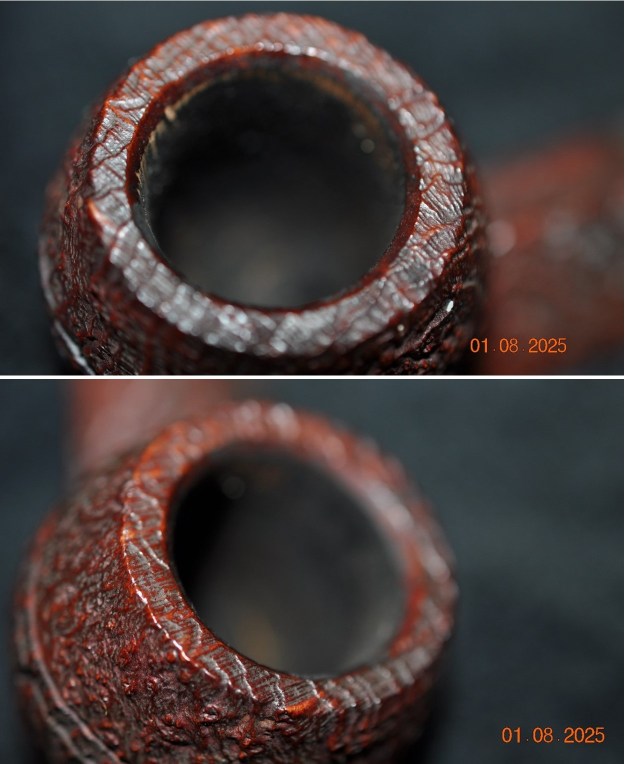

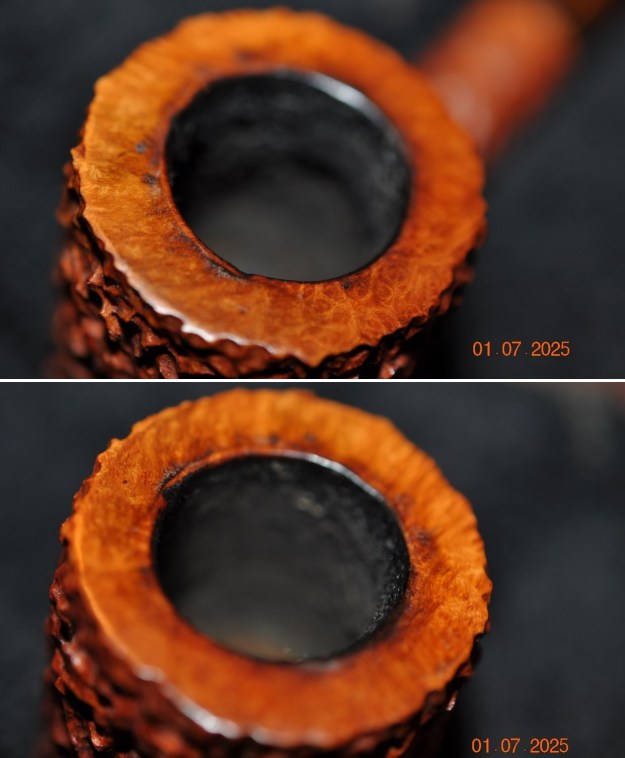

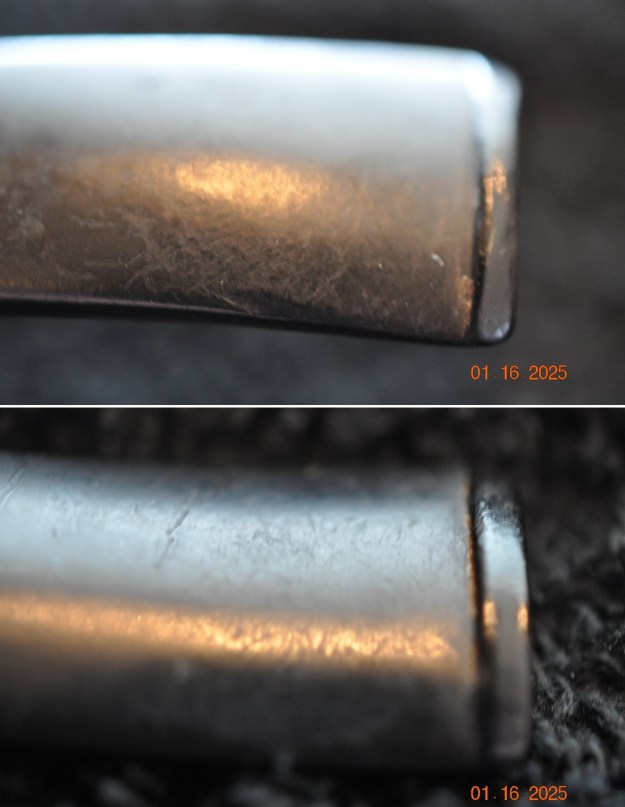

Jeff took photos of the bowl and rim top to show the condition. There is a thick cake in the bowl and a thick lava in the plateau on the rim. He captured the condition of the stem when it arrived. The stem has light chatter ahead of the button.

Jeff took photos of the bowl and rim top to show the condition. There is a thick cake in the bowl and a thick lava in the plateau on the rim. He captured the condition of the stem when it arrived. The stem has light chatter ahead of the button.

He took photos of the sides of the bowl and the heel to show the beautiful grain in the sandblast around the bowl. It really is a beautiful piece of briar that has a shape that follows the grain. The finish is nice but it also dirty with dust ground into the finish.

He took photos of the sides of the bowl and the heel to show the beautiful grain in the sandblast around the bowl. It really is a beautiful piece of briar that has a shape that follows the grain. The finish is nice but it also dirty with dust ground into the finish.

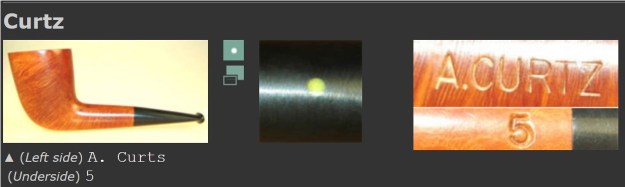

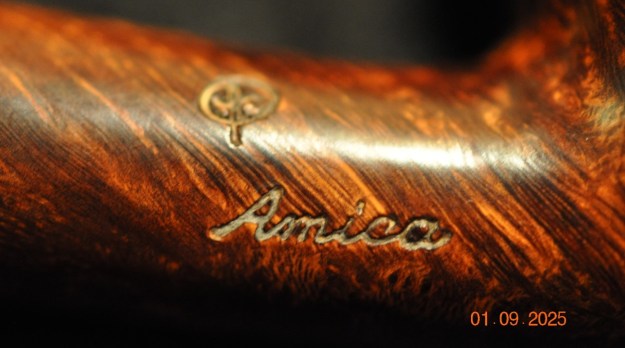

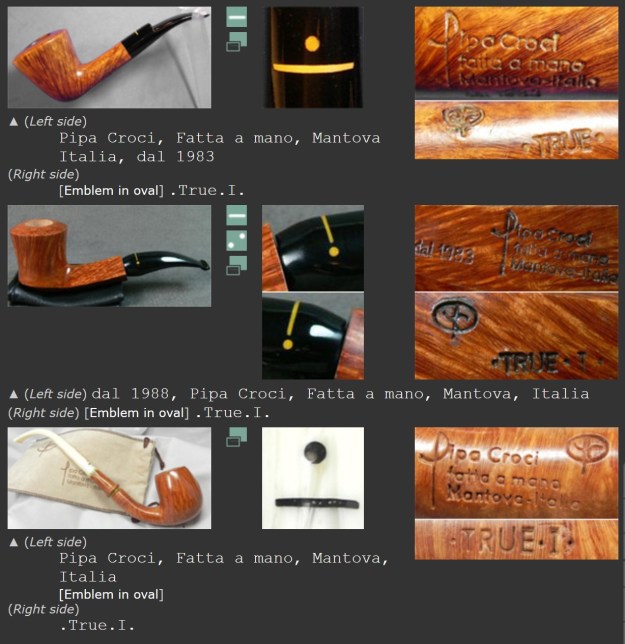

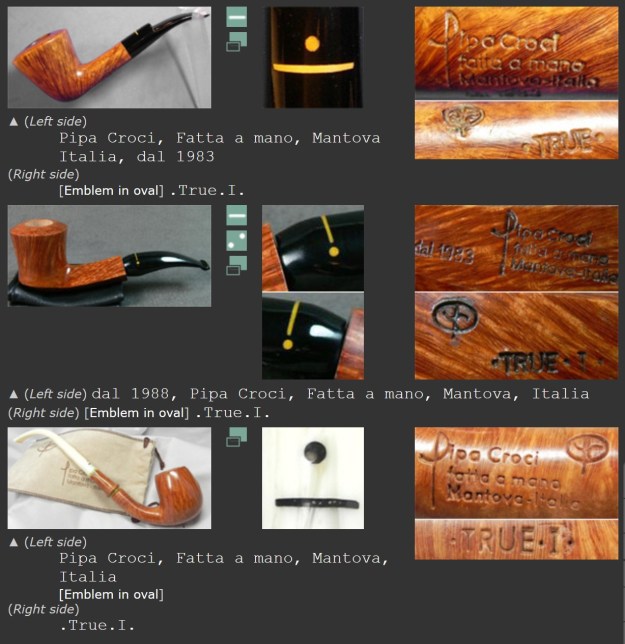

Jeff took photos of the stamping on the underside of the shank. It is clear and readable and reads as noted above.

Jeff took photos of the stamping on the underside of the shank. It is clear and readable and reads as noted above. Once again it is on pipes like this that I really appreciate Jeff’s thorough cleaning process. It gives me real freedom in dealing with pipes when they arrive here. He reamed it with a PipNet pipe reamer and got rid of the cake. He cleaned up the reaming with a Savinelli Fitsall Pipe Knife so that we could see the walls of the bowl and assess for damage. He cleaned the internals of the shank and stem with alcohol, pipe cleaners and alcohol. He scrubbed the exterior of the bowl with undiluted Murphy’s Oil Soap and a tooth brush. He rinsed it under warm water. He dried it off with a cloth and then let it air dry. He soaked the vulcanite stem in Briarville’s Pipe Stem Deoxidizer and once finished rinsed off the remaining product when he removed it from the mixture. I took pictures of the pipe to show how it looked when I unpacked it. Look at the amazing sandblast grain on this beauty.

Once again it is on pipes like this that I really appreciate Jeff’s thorough cleaning process. It gives me real freedom in dealing with pipes when they arrive here. He reamed it with a PipNet pipe reamer and got rid of the cake. He cleaned up the reaming with a Savinelli Fitsall Pipe Knife so that we could see the walls of the bowl and assess for damage. He cleaned the internals of the shank and stem with alcohol, pipe cleaners and alcohol. He scrubbed the exterior of the bowl with undiluted Murphy’s Oil Soap and a tooth brush. He rinsed it under warm water. He dried it off with a cloth and then let it air dry. He soaked the vulcanite stem in Briarville’s Pipe Stem Deoxidizer and once finished rinsed off the remaining product when he removed it from the mixture. I took pictures of the pipe to show how it looked when I unpacked it. Look at the amazing sandblast grain on this beauty.

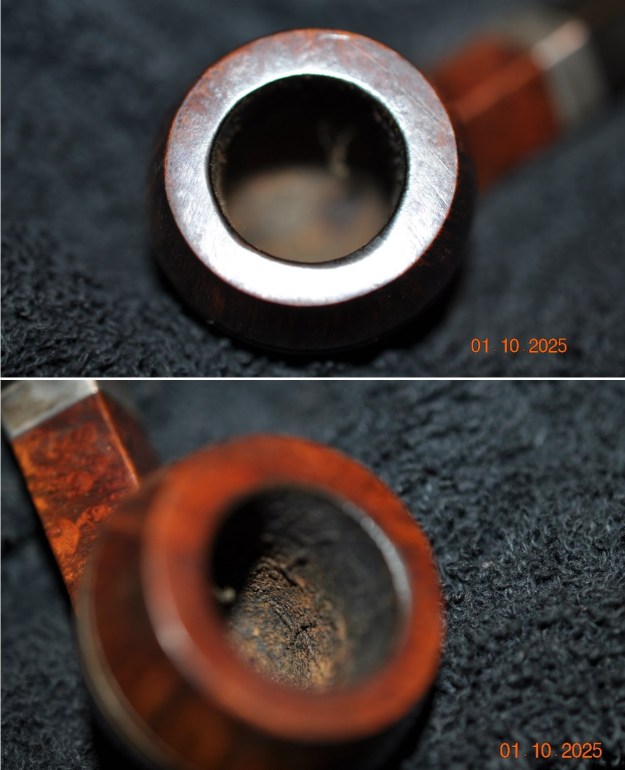

I took photos of the bowl and rim top from a closer angle to show how good it looked. The darks stain on the rim stop is slightly washed out and will need to be restained. The stem photos show how good the stem looks and even the tooth chatter is gone. I took a photo of the pipe with the stem removed to show the look of the parts of the pipe to give a sense of size and perspective.

I took photos of the bowl and rim top from a closer angle to show how good it looked. The darks stain on the rim stop is slightly washed out and will need to be restained. The stem photos show how good the stem looks and even the tooth chatter is gone. I took a photo of the pipe with the stem removed to show the look of the parts of the pipe to give a sense of size and perspective.

I tried to capture the diagonal stamp on the underside of the shank. It is clear but I did not capture it well. It reads as noted above.

I tried to capture the diagonal stamp on the underside of the shank. It is clear but I did not capture it well. It reads as noted above. I touched up the stain on the plateau on the rim top and shank end with a black stain pen. It looked much better after staining. I went over it with a brass bristle brush to knock off an loose pieces in the plateau.

I touched up the stain on the plateau on the rim top and shank end with a black stain pen. It looked much better after staining. I went over it with a brass bristle brush to knock off an loose pieces in the plateau. I worked some Before & After Restoration Balm into the surface of the briar with my finger tips and a shoe brush to get it into the nooks and crannies of the plateau and blast. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the wood while giving it a deep glow. It is a product I use on every pipe I restore.

I worked some Before & After Restoration Balm into the surface of the briar with my finger tips and a shoe brush to get it into the nooks and crannies of the plateau and blast. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the wood while giving it a deep glow. It is a product I use on every pipe I restore.

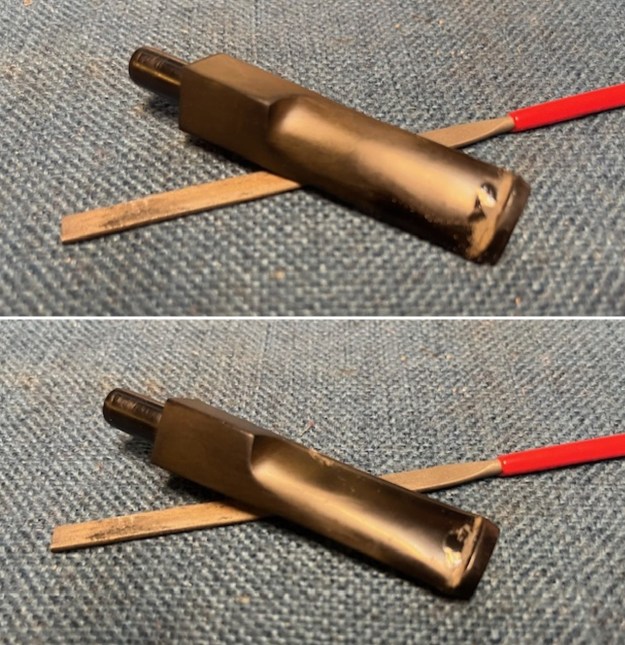

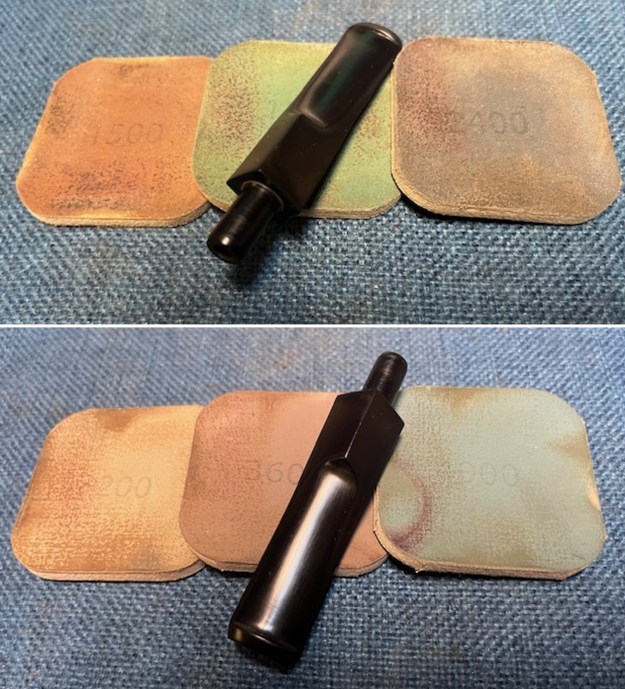

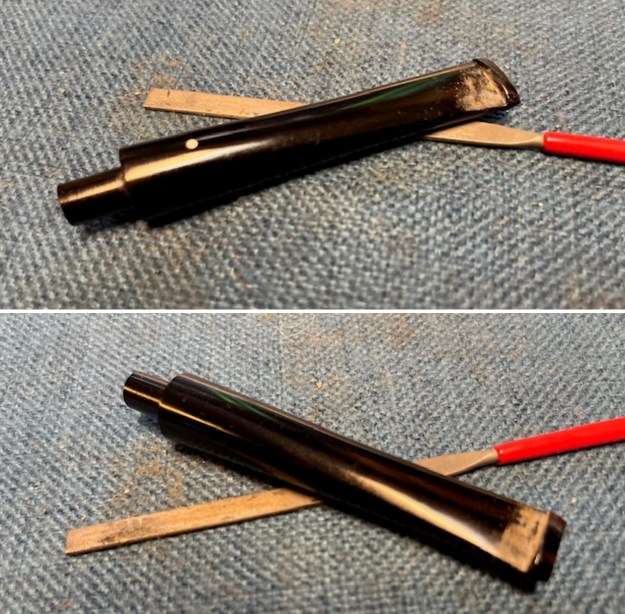

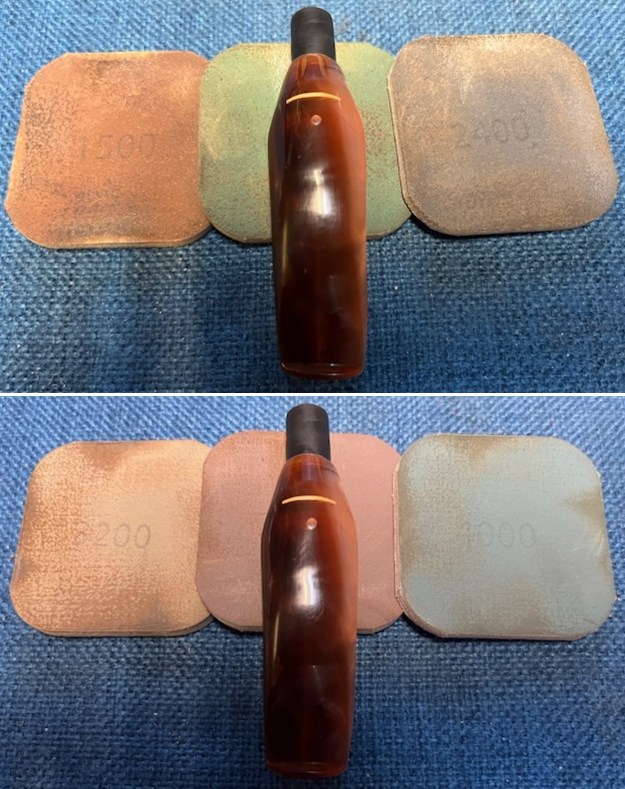

I set the bowl aside and turned to the vulcanite stem. I sanded the stem with 320-3500 grit sanding pads to remove the remnants of oxidation on the and finish blending in the chatter. It looked very good once finished.

I set the bowl aside and turned to the vulcanite stem. I sanded the stem with 320-3500 grit sanding pads to remove the remnants of oxidation on the and finish blending in the chatter. It looked very good once finished. I polished it with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I buffed the stem with a soft cloth to raise the shine. I gave it a final wipe down with Obsidian Oil to protect it.

I polished it with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I buffed the stem with a soft cloth to raise the shine. I gave it a final wipe down with Obsidian Oil to protect it.

I don’t know what it is about finishing a restoration but I have to tell you that it is my favourite part of the process. It is the moment when everything that I have worked on comes together. I can compare it to where I started and there is always satisfaction that it looks better than when we picked it up. As always, I put this Handmade in Denmark Freehand back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad and hand buffed it to raise the shine. It is fun to see what the polished bowl looks like along with the polished fancy vulcanite saddle stem. This Handmade in Denmark Freehand is a great looking pipe and I am sure that it will be comfortable in hand when smoking as it is light and well balanced for a pipe of this size. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 2 ½ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 2.26 ounces/65 grams. It is another beautiful pipe and one that will be on the rebornpipes store soon. You can find it in the section of Pipes by Danish Pipe Makers. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

I don’t know what it is about finishing a restoration but I have to tell you that it is my favourite part of the process. It is the moment when everything that I have worked on comes together. I can compare it to where I started and there is always satisfaction that it looks better than when we picked it up. As always, I put this Handmade in Denmark Freehand back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad and hand buffed it to raise the shine. It is fun to see what the polished bowl looks like along with the polished fancy vulcanite saddle stem. This Handmade in Denmark Freehand is a great looking pipe and I am sure that it will be comfortable in hand when smoking as it is light and well balanced for a pipe of this size. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 2 ½ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 2.26 ounces/65 grams. It is another beautiful pipe and one that will be on the rebornpipes store soon. You can find it in the section of Pipes by Danish Pipe Makers. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.