by Steve Laug

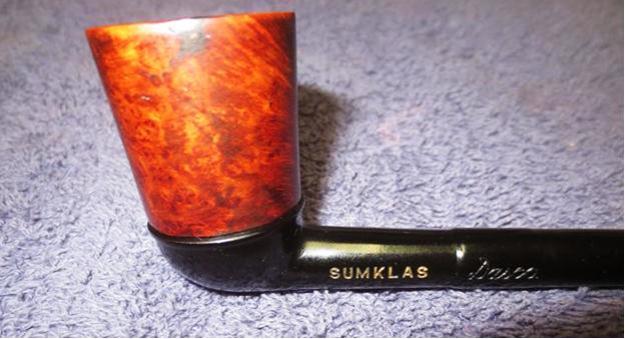

A while back I was asked by a customer and friend, Jack to take on some projects for him. I have worked on a few pipes for him over the years so we seem to have a standing agreement that I will clean up his pipes. This time he sent a batch containing 11 pipes – six Bertrams, an Arlington, a GBD, an old WDC Triangle Bakelite and one marked Texaco. All of them were in various conditions and would need different types of work. I took a photo of the pipes before I started working on them. I chose to work on the older Triangle WDC Bakelite Bent Bulldog first. This richly stained Bent Bulldog is a beautiful pipe. It is clearly stamped on the left side of the shank and reads Triangle [arched over] WDC in a triangle [over] BAKELITE. On the right side it is stamped at angle along the shank and reads Italian Briar. There is a diamond shaped silver coloured band on the shank end that is stamped and reads Oxford Plate [over] Made in U.S.A. It is oxidized but in good condition. The grain around the bowl is highlighted by the stain and really stands out. It has a rich darker, reddish brown finish that is on the bowl and shank. It was filthy with dust and debris ground into the sides of the bowl. The rim top has a heavy lava overflow on the top and edges coming from a thick cake in the bowl. The tapered Bakelite stem had a bone tenon that screwed into the shank. It had some deep tooth marks and chatter on both sides ahead of the button. I took photos of the pipe before I started working on it. It really is a beauty.

I chose to work on the older Triangle WDC Bakelite Bent Bulldog first. This richly stained Bent Bulldog is a beautiful pipe. It is clearly stamped on the left side of the shank and reads Triangle [arched over] WDC in a triangle [over] BAKELITE. On the right side it is stamped at angle along the shank and reads Italian Briar. There is a diamond shaped silver coloured band on the shank end that is stamped and reads Oxford Plate [over] Made in U.S.A. It is oxidized but in good condition. The grain around the bowl is highlighted by the stain and really stands out. It has a rich darker, reddish brown finish that is on the bowl and shank. It was filthy with dust and debris ground into the sides of the bowl. The rim top has a heavy lava overflow on the top and edges coming from a thick cake in the bowl. The tapered Bakelite stem had a bone tenon that screwed into the shank. It had some deep tooth marks and chatter on both sides ahead of the button. I took photos of the pipe before I started working on it. It really is a beauty.

I took photos of the rim top and the stem to show the condition. You can see the thick cake in the bowl and overflow of lava on the rim top. The photos of the stem show the tooth marks and damage in the Bakelite on the top and underside ahead of the button.

I took photos of the rim top and the stem to show the condition. You can see the thick cake in the bowl and overflow of lava on the rim top. The photos of the stem show the tooth marks and damage in the Bakelite on the top and underside ahead of the button. I took photos of the stamping on the sides of the diamond shank to capture it. It was clear and readable as noted above. I tried to capture some of the stamping on the oxidized band as well. It is a little blurry but it is clear and readable under the oxidation. I removed the stem from the shank and took a photo of the parts.

I took photos of the stamping on the sides of the diamond shank to capture it. It was clear and readable as noted above. I tried to capture some of the stamping on the oxidized band as well. It is a little blurry but it is clear and readable under the oxidation. I removed the stem from the shank and took a photo of the parts.

Before working on the pipe, I followed my usual procedure of looking for history on both the brand and the Triangle Bakelite line. I have included a quick history of the brand from Pipedia that is interesting and is helpful (https://pipedia.org/wiki/William_Demuth_Company).

Before working on the pipe, I followed my usual procedure of looking for history on both the brand and the Triangle Bakelite line. I have included a quick history of the brand from Pipedia that is interesting and is helpful (https://pipedia.org/wiki/William_Demuth_Company).

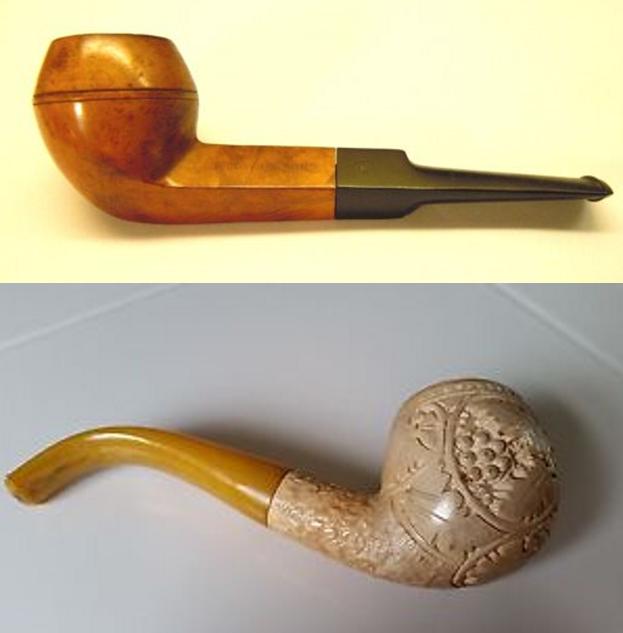

William Demuth. (Wilhelm C. Demuth, 1835-1911), a native of Germany, entered the United States at the age of 16 as a penniless immigrant. After a series of odd jobs, he found work as a clerk in the import business of a tobacco tradesman in New York City. In 1862 William established his own company. The William Demuth Company specialized in pipes, smoker’s requisites, cigar-store figures, canes and other carved objects.

The Demuth Company is probably well known for the famous trademark, WDC in an inverted equilateral triangle. William commissioned the figurative meerschaum Presidential series, 29 precision-carved likenesses of John Adams, the second president of the United States (1797-1801) to Herbert Hoover, the 30th president (1929-1933), and “Columbus Landing in America,” a 32-inch-long centennial meerschaum masterpiece that took two years to complete and was exhibited at the World’s Columbian Exposition in Chicago in 1893…

…In 1897 Ferdinand Feuerbach joined the Demuth company and by 1903 had become the production manager. Feuerbach is credited with developing Demuth’s popular Royal Demuth and Hesson Guard Milano pipelines. He left in 1919, when Sam Frank Sr. needed an experienced pipe man to run his pipe factory, located at 168 Southern Blvd., in the Bronx. Feuerbach and Frank had been close friends since Frank started his own business in 1900 and was closely associated with the sales staff of WDC, selling their line of pipes…

In early 1937, the City of New York notified S.M. Frank & Co. of their intent to take by eminent domain, part of the land on which the companies pipe factory was located. This was being done to widen two of the adjacent streets. As a result of this, Frank entered into negotiations to purchase the Wm. Demuth Co.’s pipe factory in the Richmond Hill section of Queens. It was agreed upon that Demuth would become a subsidiary of S.M. Frank and all pipe production of the two companies would be moved to DeMuth factory. New Corporate offices were located at 133 Fifth Avenue, NYC.

Demuth pipes continued to be made at the Richmond Hill plant till December 31. 1972. Then the Wm. Demuth Company met its official end as a subsidiary company by liquidation. Demuth’s mainstay pipe, the Wellington continued to be offered in the S.M. Frank catalog until 1976. In the mid-80’s, the Wellington even made a brief return as a direct to the consumer offer.

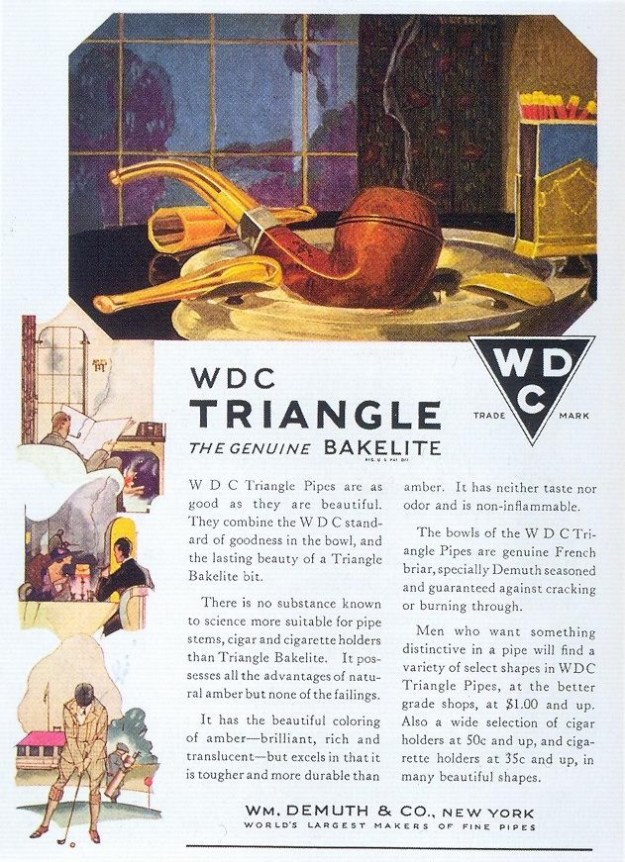

There was nothing specific on the Triangle Bakelite Line in the above article. I did a further Google search and found a link to an advertisement on the WDC Triangle Bakelite pipe that is quite interesting (https://farm1.static.flickr.com/198/460550444_b0cd63fa8f_o.jpg). I have included a copy of the file below. The above advertisement reads as follows:

The above advertisement reads as follows:

WDC Triangle Pipes are as good as they are beautiful. They combine the WDC standard of goodness in the bowl, and the lasting beauty of a Triangle Bakelite bit.

There is no substance known to science more suitable for pipe stems, cigar and cigarette holders than Triangle Bakelite. It possesses all the advantages of natural amber but none of the failings.

It has the beautiful coloring of amber – brilliant, rich and translucent – but excels in that it is tougher and more durable than amber. It has neither taste nor odor and is non-flammable.

The bowls of the WDC Triangle Pipes are genuine French briar, specially Demuth seasoned and guaranteed against cracking or burning through.

Me who want something distinctive in a pipe will find a wide variety of select shapes of WDC Triangle Pipe, at the better grade shops, at $1.00 and up. Also a wide selection of cigar holders at 50c and up, and cigarette holders at 35c and up, in many beautiful shapes.

That tells a lot about the manufacture and marketing of WDC pipes. They were viewed as spectacular and unique. They were chosen by discriminating smokers and enjoyed with durability and flavor. Now it was time to work on this pipe.

I started my work on the pipe by reaming the bowl with a PipNet reamer. I used the first cutting head and took the cake back to bare briar. I cleaned up the reaming with a Savinelli Fitsall Pipe Knife and removed all the remnants of the cake. I scraped the rim top with the flat edge of the blade at the same time and removed most of the thick lava build up. I sanded the walls of the bowl with a piece of dowel wrapped in 220 grit sandpaper. The walls look very good at his point in the process.

I cleaned out the shank, the airway and the mortise with alcohol, cotton swabs, hard bristle and soft bristle pipe cleaners. It was a very dirty pipe which just meant that it had really been enjoyed by the previous pipe man. I cleaned the bone tenon and the inside of the airway in the stem with alcohol, cotton swabs and pipe cleaners in the same way as I did the shank. It also was very dirty.

I cleaned out the shank, the airway and the mortise with alcohol, cotton swabs, hard bristle and soft bristle pipe cleaners. It was a very dirty pipe which just meant that it had really been enjoyed by the previous pipe man. I cleaned the bone tenon and the inside of the airway in the stem with alcohol, cotton swabs and pipe cleaners in the same way as I did the shank. It also was very dirty. I scrubbed the exterior of the bowl and shank with a tooth brush and undiluted Murphy’s Oil Soap. I scrubbed the lava on the rim top and overflow on the outside of the bowl with the soap. I rinsed the briar with warm water to remove the grime and debris of the scrubbing. It looked significantly better after the scrubbing. The damage on the bowl front and rim top is very clear.

I scrubbed the exterior of the bowl and shank with a tooth brush and undiluted Murphy’s Oil Soap. I scrubbed the lava on the rim top and overflow on the outside of the bowl with the soap. I rinsed the briar with warm water to remove the grime and debris of the scrubbing. It looked significantly better after the scrubbing. The damage on the bowl front and rim top is very clear.

The darkening on the rim top and the outside of the bull cap would need to be dealt with. I cleaned up the inner edge with a piece of sandpaper. I sanded the top of the rim and the sides of the cap with the piece of 220 grit sandpaper and was able to remove much of the darkening.

The darkening on the rim top and the outside of the bull cap would need to be dealt with. I cleaned up the inner edge with a piece of sandpaper. I sanded the top of the rim and the sides of the cap with the piece of 220 grit sandpaper and was able to remove much of the darkening. I finished that and moved on to it with 320-3500 grit sanding pads to finish minimizing the burn damage and reshape the rim top and the top half of the bowl. The briar began to take on a rich shine and the burn damage was by and large gone. The photos tell the story.

I finished that and moved on to it with 320-3500 grit sanding pads to finish minimizing the burn damage and reshape the rim top and the top half of the bowl. The briar began to take on a rich shine and the burn damage was by and large gone. The photos tell the story.

I polished the smooth rim top with micromesh sanding pads – dry sanding it with 1200-15000 grit pads. I wiped the bowl down with a damp cloth after each sanding pad. The grain started to rise to the surface as I polished it. The rusticated portions looked very good as well.

I polished the smooth rim top with micromesh sanding pads – dry sanding it with 1200-15000 grit pads. I wiped the bowl down with a damp cloth after each sanding pad. The grain started to rise to the surface as I polished it. The rusticated portions looked very good as well.

I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the finish on the bowl and shank. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I used a horsehair shoe brush to work it into the twin lines around the bull cap. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. It is a beautiful bowl.

I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the finish on the bowl and shank. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I used a horsehair shoe brush to work it into the twin lines around the bull cap. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. It is a beautiful bowl.

I polished the plated band with a jeweller’s cloth to protect the band from oxidizing and discolouring.

I polished the plated band with a jeweller’s cloth to protect the band from oxidizing and discolouring.

I turned my attention to the stem. I filled in the deep tooth marks in the Bakelite with clear CA glue. After it cured I flattened the repairs with a small flat file. I sanded the repairs further to flatten out the tooth chatter with a folded piece of 220 grit sandpaper. Progress was happening!

I turned my attention to the stem. I filled in the deep tooth marks in the Bakelite with clear CA glue. After it cured I flattened the repairs with a small flat file. I sanded the repairs further to flatten out the tooth chatter with a folded piece of 220 grit sandpaper. Progress was happening!

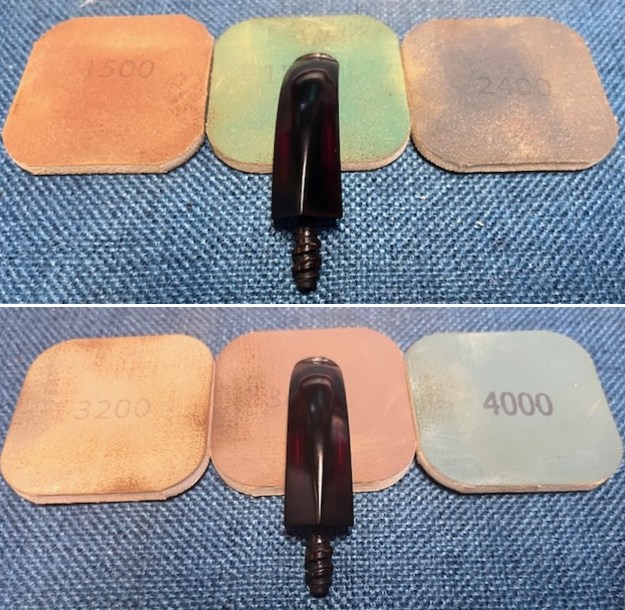

I sanded the surface of the vulcanite with the 2 inch sanding pads – 320-3500 grit pads to remove the remaining oxidation. I dry sanded the surface until I have removed all of the oxidation and the stem started to really shine.

I sanded the surface of the vulcanite with the 2 inch sanding pads – 320-3500 grit pads to remove the remaining oxidation. I dry sanded the surface until I have removed all of the oxidation and the stem started to really shine. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished the stem with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a coat of Obsidian Pipe Stem Oil. It works to protect the stem from oxidizing. I set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished the stem with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a coat of Obsidian Pipe Stem Oil. It works to protect the stem from oxidizing. I set it aside to dry.

The final steps in my process involves using the buffer. I buffed the bowl and stem with Blue Diamond to polish out the light scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I have found that I can get a deeper shine if I follow up the wax buff with a buff with a clean buffing pad. It works to raise the shine and then I hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished stem. It really is a nice pipe. The smooth, nicely grained bowl sides and the rusticated blaze on the left bowl side looks great with the vulcanite stem. The Triangle WDC Bakelite taper stem Bent Bulldog feels great in my hand. It is a well-balanced pipe. Have a look at it with the photos below. The dimensions are Length: 4 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.16 ounces/32 grams. It is a beautiful pipe that I will send to Jack after I finish working on the other 10 pipes. I look forward to hear what he thinks of this old beauty. It should be a great smoking pipe.

The final steps in my process involves using the buffer. I buffed the bowl and stem with Blue Diamond to polish out the light scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I have found that I can get a deeper shine if I follow up the wax buff with a buff with a clean buffing pad. It works to raise the shine and then I hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished stem. It really is a nice pipe. The smooth, nicely grained bowl sides and the rusticated blaze on the left bowl side looks great with the vulcanite stem. The Triangle WDC Bakelite taper stem Bent Bulldog feels great in my hand. It is a well-balanced pipe. Have a look at it with the photos below. The dimensions are Length: 4 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.16 ounces/32 grams. It is a beautiful pipe that I will send to Jack after I finish working on the other 10 pipes. I look forward to hear what he thinks of this old beauty. It should be a great smoking pipe.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.