by Steve Laug

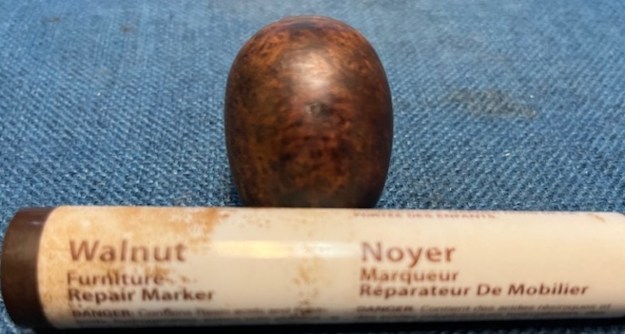

I have worked on this Radford Ravel Rhodesian for this pipe man quite often and I know that this is at least the second stem I have worked on for this pipe. That does not include the many rebuilds and refits that I have done on the first stem. The pipe is one of his favourites and one that he repeatedly is drawn to. I remember restoring the pipe originally in 2017 – repairing and banding the cracked shank (https://rebornpipes.com/2017/03/19/banding-and-restoring-a-radford-ravel-rhodesian/). I cleaned up the stem, reshaped, repaired and polished it. In 2023 he brought the pipe back as the stem was loose. I reworked the thin saddle stem to improve the fit and shape (https://rebornpipes.com/2023/04/28/restemming-a-radford-ravel-rhodesian/). Since then I have rebuilt the area ahead of the button and the button area where tooth marks both marked it and ended up becoming bite throughs. Yesterday he stopped by left the pipe with me to replace. The top of the stem had cracked and the repaired areas on the topside were gone. I took photos of the pipe before I started the restemming process. Have a look at what I saw.

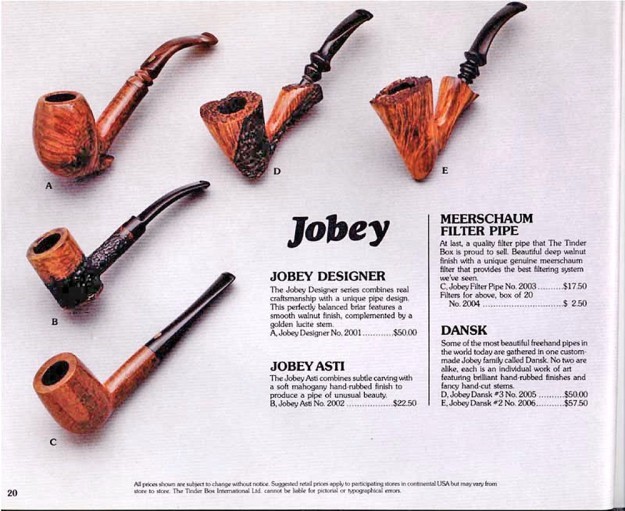

I went through my can of stems and could not find a saddle stem that would fit. I did find a new vulcanite taper stem that would work once I fit the tenon to the shank. It was a little larger than the shank in diameter and I would need to remove the excess material to get a fit.

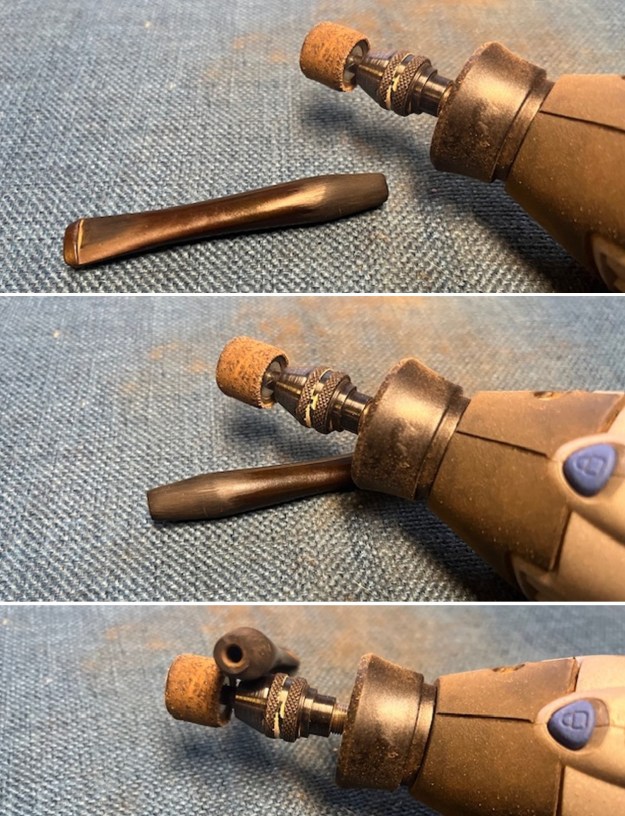

I went through my can of stems and could not find a saddle stem that would fit. I did find a new vulcanite taper stem that would work once I fit the tenon to the shank. It was a little larger than the shank in diameter and I would need to remove the excess material to get a fit. I used the Dremel and a sanding drum to knock off the marks on the tenon and smooth it out to fit the shank. I took photos of the newly fit stem to show the casting marks on the sides of the stem and on the button/slot end. You can also see that the stem is slightly larger in diameter than the shank and nickel band. It is going to look very good!

I used the Dremel and a sanding drum to knock off the marks on the tenon and smooth it out to fit the shank. I took photos of the newly fit stem to show the casting marks on the sides of the stem and on the button/slot end. You can also see that the stem is slightly larger in diameter than the shank and nickel band. It is going to look very good!

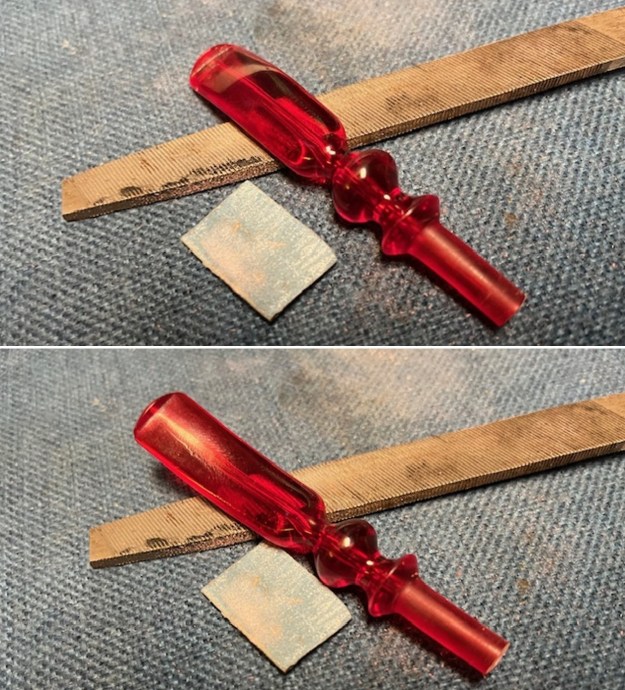

I used my Dremel and a sanding drum to knock off the casting debris on the stem sides and button end. I also began the process of reducing the diameter of the stem to match the shank. I took the majority of the excess of the vulcanite off the stem to start the fitting. I was working to get it down to where it would fit inside the band.

I used my Dremel and a sanding drum to knock off the casting debris on the stem sides and button end. I also began the process of reducing the diameter of the stem to match the shank. I took the majority of the excess of the vulcanite off the stem to start the fitting. I was working to get it down to where it would fit inside the band.

I worked on it some more with the Dremel and sanding drum to get close. I was getting there. I wiped it down with some Obsidian Oil and then heated the stem with a lighter. Once the vulcanite was flexible I bent it to the angle that matched the bends of the shank and bowl.

I worked on it some more with the Dremel and sanding drum to get close. I was getting there. I wiped it down with some Obsidian Oil and then heated the stem with a lighter. Once the vulcanite was flexible I bent it to the angle that matched the bends of the shank and bowl. I sat on the front porch and sanded the stem with 220 grit sandpaper to further shape and fit the stem to the shank. The bend and flow of the stem looked very good at this point in the process.

I sat on the front porch and sanded the stem with 220 grit sandpaper to further shape and fit the stem to the shank. The bend and flow of the stem looked very good at this point in the process. I sanded the tenon to smooth out the marks and striations still remaining as well as fine tuning the shape and fit of the stem in the band.

I sanded the tenon to smooth out the marks and striations still remaining as well as fine tuning the shape and fit of the stem in the band.

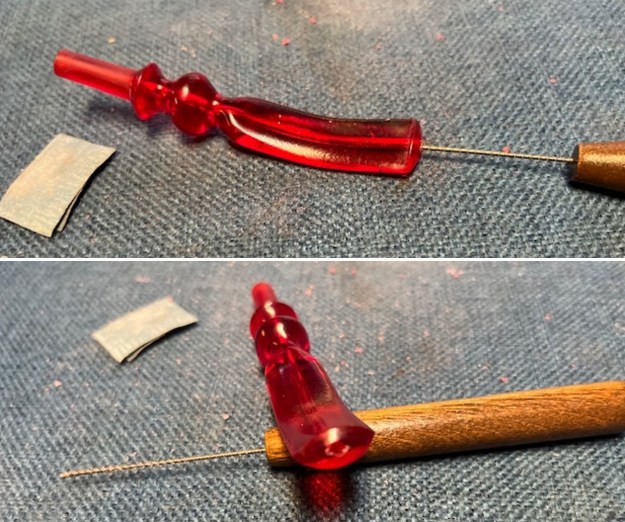

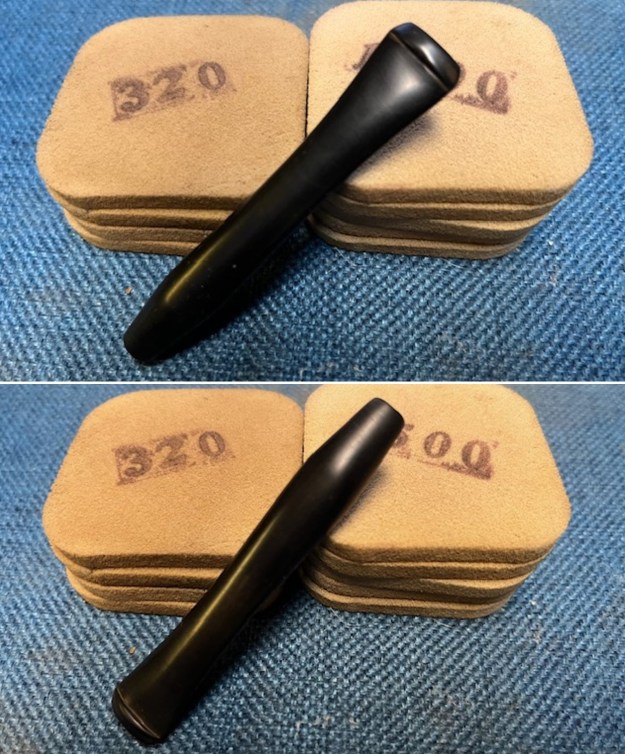

I continued sanding the stem surface with 2×2 inch sanding pads – grits 320-3500. By the end all of the sanding marks were removed and the stem began to take on a shine as did the tenon. It was looking very good.

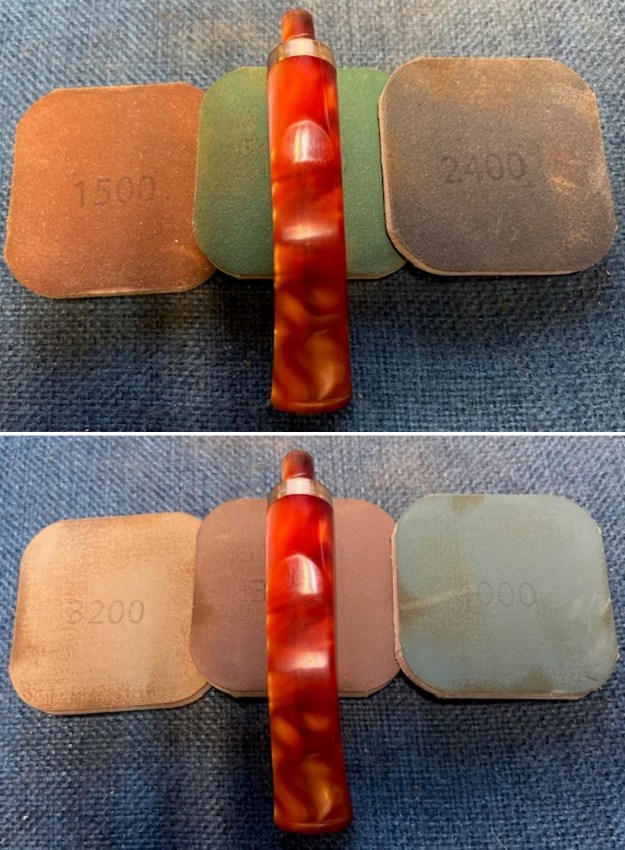

I continued sanding the stem surface with 2×2 inch sanding pads – grits 320-3500. By the end all of the sanding marks were removed and the stem began to take on a shine as did the tenon. It was looking very good. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth.

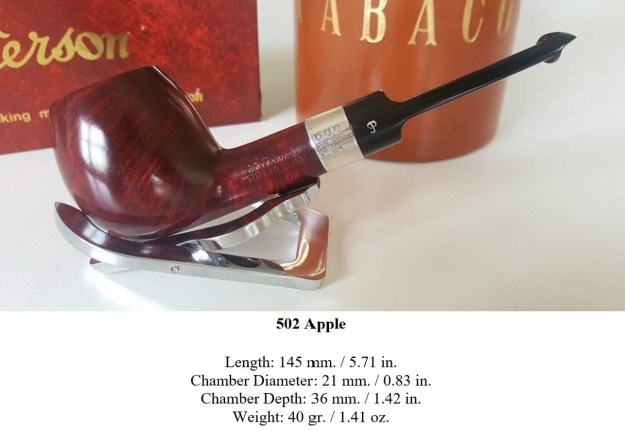

I finished the restem by buffing the bowl and stem with the Blue Diamond and moved on to buffing with carnauba wax. Once I have a good shine in the briar and vulcanite I always give the bowl and the stem multiple coats of carnauba wax. I have found that I can get a deeper shine if I following up the wax buff with a clean buffing pad. It works to raise the shine and then I follow that up with a hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished vulcanite stem. It really is a beautiful pipe. The smooth finish around the cap and shank show the grain shining through the rich brown stains of this Radford Ravel Rhodesian. The finished pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 2.05 ounces/57 grams. It is a beautiful pipe and now that I have finished restemming it, he will get to enjoy it once more.

I finished the restem by buffing the bowl and stem with the Blue Diamond and moved on to buffing with carnauba wax. Once I have a good shine in the briar and vulcanite I always give the bowl and the stem multiple coats of carnauba wax. I have found that I can get a deeper shine if I following up the wax buff with a clean buffing pad. It works to raise the shine and then I follow that up with a hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished vulcanite stem. It really is a beautiful pipe. The smooth finish around the cap and shank show the grain shining through the rich brown stains of this Radford Ravel Rhodesian. The finished pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 2.05 ounces/57 grams. It is a beautiful pipe and now that I have finished restemming it, he will get to enjoy it once more.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of those who follow us.