Blog by Steve Laug

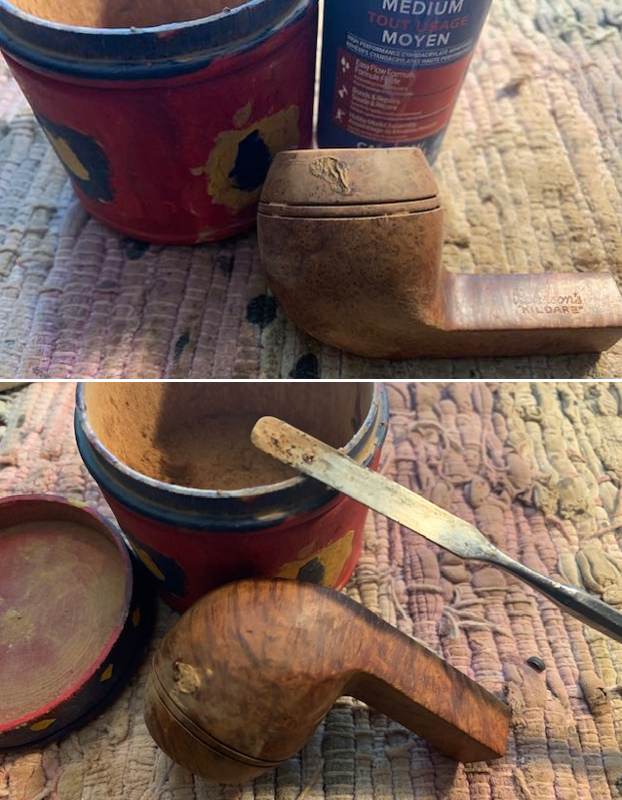

I received an email from a fellow in England who was looking for a bowl for a Peterson’s Beligique that he had. His small Beligique was cracked and irreparable and he was looking for a new bowl. Interestingly I had a bowl without a stem in my box of Peterson’s here. I was looking for a stem for it so this was one of those interesting connections. He sent me the bowl and stem of his damaged pipe to me to see if it would work with my bowl. His damaged pipe was severely cracked and was exactly what he had said it was. It was Peterson’s of Dublin Belgique military mount with a P-lip stem. It was stamped on the left side of the shank with the words Peterson’s [arched over] Of Dublin. On the right side of the shank it is stamped London Made [over] England. It has no shape number on them and a vulcanite shank extension bearing the Peterson’s “P”. The stem was in good condition with chatter and tooth marks on both sides ahead of the button. It also has some light oxidation.

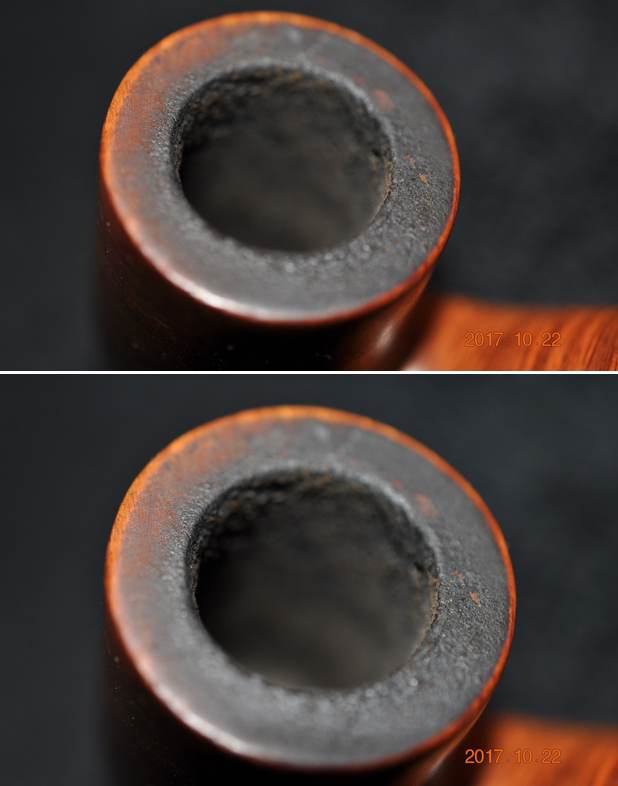

I took photos of the crack around the bowl – all the way across the back of the bowl and across the left side with a branched crack going down the side of the bowl almost to the heel. It was a nasty crack. There was a thick cake in the bowl that told the story of how the crack had happened.

I took photos of the crack around the bowl – all the way across the back of the bowl and across the left side with a branched crack going down the side of the bowl almost to the heel. It was a nasty crack. There was a thick cake in the bowl that told the story of how the crack had happened.

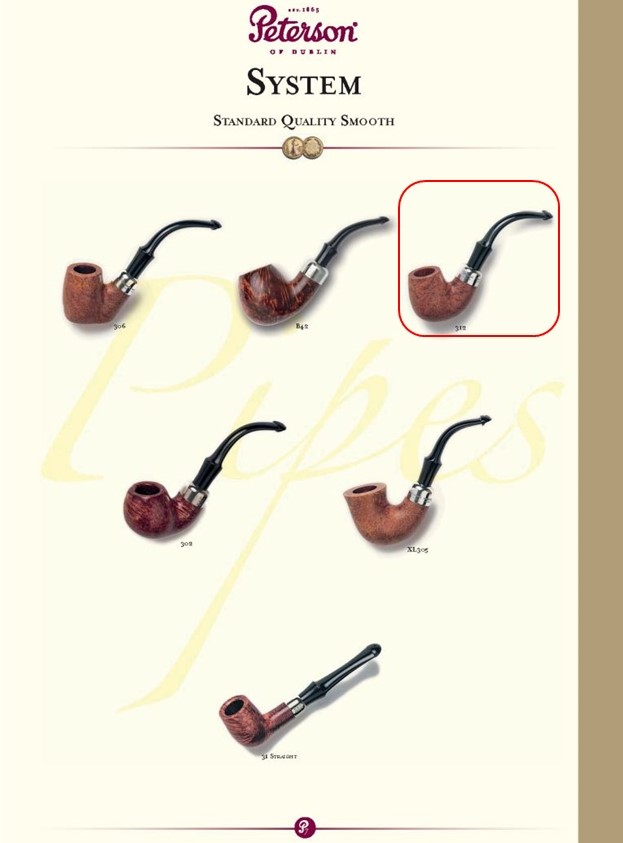

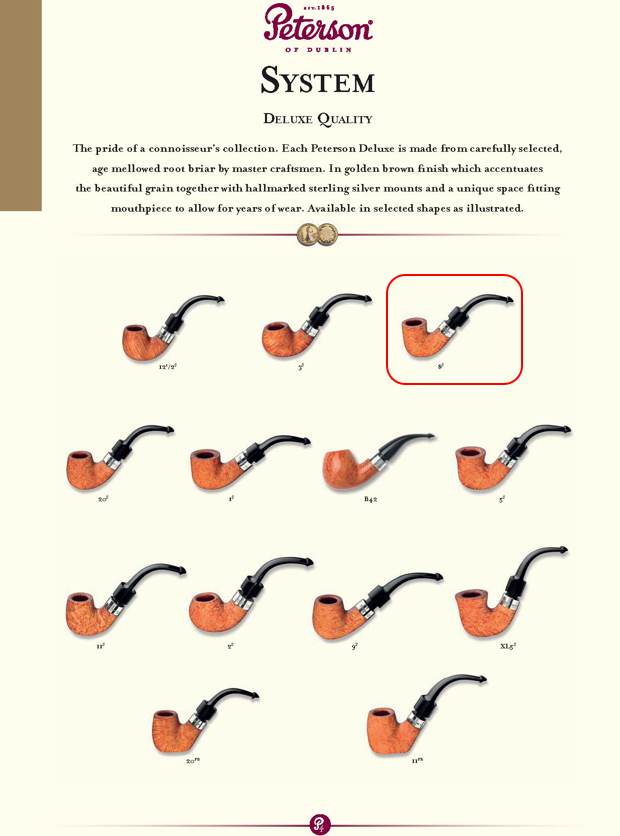

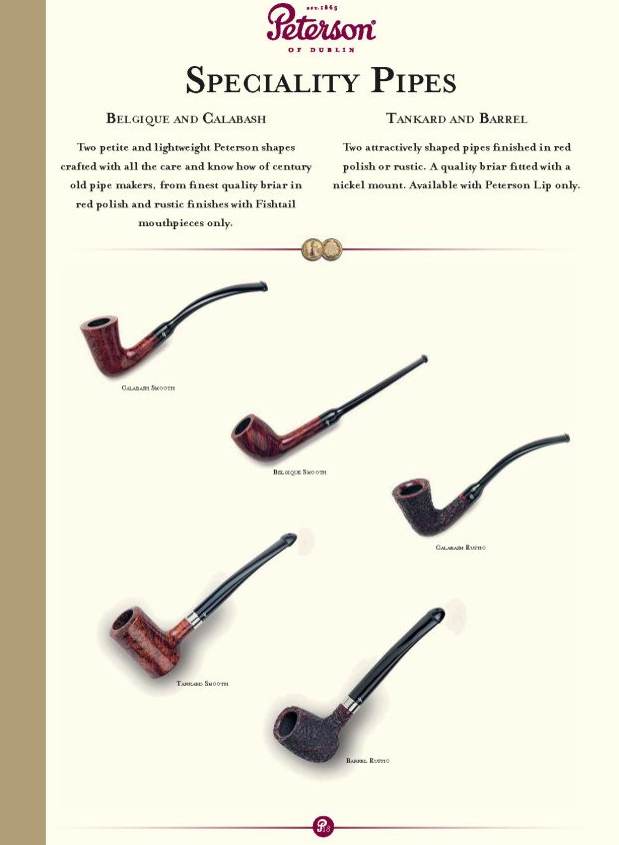

I have a 2010 Peterson Catalogue on rebornpipes that shows the various shapes that Peterson made. There is a page there on Specialty Pipes that shows the pipes that I am working on. The pipes pictured are different from the two that I am working on in that both of these are military mount stem. It states that the Belgique and Calabash are two petite and lightweight Peterson crafted with all the care and know how of century old pipe makers, from finest quality briar in red polish and rustic finishes with Fishtail mouthpieces only. However they are described in the catalogue the two shapes that are extremely lightweight. These two are not red polish but actually a rich matte brown finish. The fishtail mouthpieces are classic military mounts that can easily be removed to fit in the pocket. They represent the best micro-pocket pipe within the Peterson portfolio. I have included the noted page below (https://rebornpipes.com/2015/05/15/).

I have a 2010 Peterson Catalogue on rebornpipes that shows the various shapes that Peterson made. There is a page there on Specialty Pipes that shows the pipes that I am working on. The pipes pictured are different from the two that I am working on in that both of these are military mount stem. It states that the Belgique and Calabash are two petite and lightweight Peterson crafted with all the care and know how of century old pipe makers, from finest quality briar in red polish and rustic finishes with Fishtail mouthpieces only. However they are described in the catalogue the two shapes that are extremely lightweight. These two are not red polish but actually a rich matte brown finish. The fishtail mouthpieces are classic military mounts that can easily be removed to fit in the pocket. They represent the best micro-pocket pipe within the Peterson portfolio. I have included the noted page below (https://rebornpipes.com/2015/05/15/). On a previous restoration I did a bit more digging on the Peterson Pipe Notes blog. There I found that Mark had included a photo of the various Specialty pipes. Peterson’s first put these four small pipes on the market in 1945 – Tankard & Barrel, Calabash & Belgique seen in the photo below. Here is the link to Mark’s Blog (https://www.petersonpipenotes.org/tag/peterson-valentia-pipe/).

On a previous restoration I did a bit more digging on the Peterson Pipe Notes blog. There I found that Mark had included a photo of the various Specialty pipes. Peterson’s first put these four small pipes on the market in 1945 – Tankard & Barrel, Calabash & Belgique seen in the photo below. Here is the link to Mark’s Blog (https://www.petersonpipenotes.org/tag/peterson-valentia-pipe/). I did a bit more digging and found some descriptions of the two shapes that I am working on. The various descriptions of the Belgique come from a variety of sites and the final one is quoted on the Brothers of Briar site.

I did a bit more digging and found some descriptions of the two shapes that I am working on. The various descriptions of the Belgique come from a variety of sites and the final one is quoted on the Brothers of Briar site.

…The Belgique is yet another extremely lightweight, petite pipe. It can be described as a tulip shape, and is fitted… and fishtail mouthpiece. A rich brown hue adorns the briar and makes for an attractive finish to this pocket companion.

…The Peterson Belgique Pipe is a straight cutty, which is a traditional shape derived from the old clay pipes. It is a small un-filtered pipe made from the finest Briar that Peterson have become renowned for. It has a smooth polished finish with a rich Brown stain to show of the natural grain pattern of the Briar.

…I have a pre rep Belgique love it. As you know the bowl is pretty large for the small pipe measuring 5/8″ ID and 1 1/4″ deep. My pipe is just shy of 6″ long and only weighs 11.7 grams. the bowl is not tapered which makes the capacity rather nice. Depending on what tobacco you load you will get a 30- 45 min smoke. The Belgique has thin walls so you have to sip very slowly and tamp more than usuall. The newer models have a fishtail stem which i believe makes the newer pipes not as delicate as my military p lip. If you decide to get the Belgique I am sure you will not be disappointed. (http://www.brothersofbriar.com/t16010-anybody-familiar-with-peterson-s-belgique-model).

…The Belgique is one of our favorite shapes in the Peterson line up. Interestingly, while it was a serious mainstay of the brand in decades past, it sort of faded into obscurity for a few years there, before being seriously revived in the past decade. A particularly small shape, and sort of an oddity in Peterson’s shaping lexicon (a bit like Native American loan words in English), it nonetheless fits the timeless, elegant style for which Peterson is known and loved.

I took the bowl I had without a stem out and took photos of it. You can that is the same shape and over all size as the cracked bowl. It is stamped on the left side and reads Peterson’s [arched over] Dublin. The right side is stamped Made in the Republic of Ireland (three lines). It is all clear and readable. The bowl had been cleaned and reamed. The rim top was damaged, slightly out of round and had some darkening on the top and edges.

I put the two bowls side by side and took photos of them. They are quite similar. The top one in the photo was the cracked original bowl and the bottom one is the new bowl. There is some variation but that is quite normal. The new bowl is a bit thicker and the shank is a bit shorter. But they look similar enough.

I put the two bowls side by side and took photos of them. They are quite similar. The top one in the photo was the cracked original bowl and the bottom one is the new bowl. There is some variation but that is quite normal. The new bowl is a bit thicker and the shank is a bit shorter. But they look similar enough.

I took photos of the stamping on the sides of the shank. It was clear and readable on both sides. The ”P” logo stamp was clear on the left side of the vulcanite ferrule. It will need to be touched up but it is clear.

I took photos of the stamping on the sides of the shank. It was clear and readable on both sides. The ”P” logo stamp was clear on the left side of the vulcanite ferrule. It will need to be touched up but it is clear.  I decided to turn my attention to cleaning up the rim top and the inner edge of the bowl. I wanted to remove the burn and darkening damage from both. I used a folded piece of 220 grit sandpaper to work over the edge and the rim top. I also worked on the darkening on the outside edge of the bowl. It looked much better.

I decided to turn my attention to cleaning up the rim top and the inner edge of the bowl. I wanted to remove the burn and darkening damage from both. I used a folded piece of 220 grit sandpaper to work over the edge and the rim top. I also worked on the darkening on the outside edge of the bowl. It looked much better. I used a piece of 220 grit sandpaper to reduce the diameter of the tenon end of the stem to better fit the shank extension. I used a rolled piece of sandpaper and several round and flat files to open the diameter of the shank extension. I worked on it until it matched the diameter of the opening in the shank extension of the cracked bowl.

I used a piece of 220 grit sandpaper to reduce the diameter of the tenon end of the stem to better fit the shank extension. I used a rolled piece of sandpaper and several round and flat files to open the diameter of the shank extension. I worked on it until it matched the diameter of the opening in the shank extension of the cracked bowl.

I polished the bowl with 1500-12000 grit micromesh sanding pads to raise a shine on the briar. Each successive pad raised more of a shine on the bowl. Once finished, It looked very good.

I polished the bowl with 1500-12000 grit micromesh sanding pads to raise a shine on the briar. Each successive pad raised more of a shine on the bowl. Once finished, It looked very good.

I touched up the “P” stamp on the shank extension with white acrylic fingernail polish. I filled in the stamping with the white acrylic and worked it into the stamp. Once it dried I used a worn micromesh 1500 grit pad to clean off the excess. It looked very good.

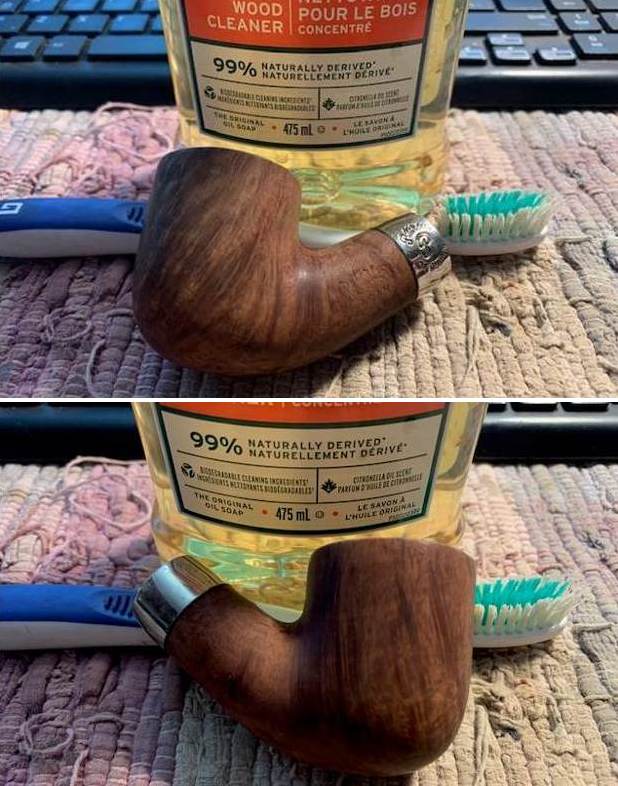

I touched up the “P” stamp on the shank extension with white acrylic fingernail polish. I filled in the stamping with the white acrylic and worked it into the stamp. Once it dried I used a worn micromesh 1500 grit pad to clean off the excess. It looked very good. I rubbed down the bowl with Before& After Restoration Balm. It works to clean, protect and preserve the briar. I worked it into the surface with my finger tips. I let it sit for 15 minutes then buffed it off with a soft cloth. The bowl looked good and the grain stood out clearly.

I rubbed down the bowl with Before& After Restoration Balm. It works to clean, protect and preserve the briar. I worked it into the surface with my finger tips. I let it sit for 15 minutes then buffed it off with a soft cloth. The bowl looked good and the grain stood out clearly.

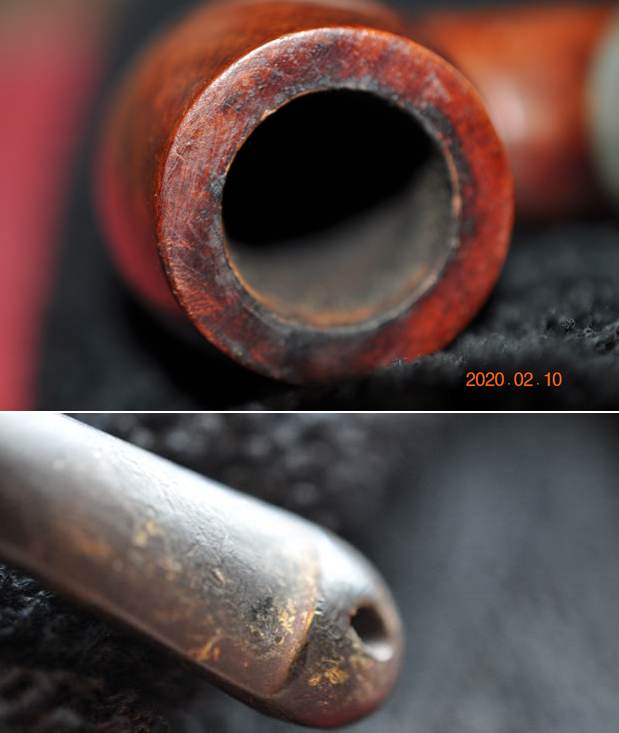

I set the bowl aside and worked on the stem. I took photos of the stem that came with the damaged bowl. The vulcanite ferrule was the same on both pipes but the opening on the new bowl was slightly smaller than the old one. I would need to open it up for a good fit in the shank. I would also need to reshape the tenon end of the stem for a proper look. There were also tooth marks and chatter on both sides as well as some light oxidation.

I set the bowl aside and worked on the stem. I took photos of the stem that came with the damaged bowl. The vulcanite ferrule was the same on both pipes but the opening on the new bowl was slightly smaller than the old one. I would need to open it up for a good fit in the shank. I would also need to reshape the tenon end of the stem for a proper look. There were also tooth marks and chatter on both sides as well as some light oxidation. I “painted” the tooth marks with the flame of a lighter. I filled in the remaining tooth marks with a clear CA glue. Once it cured, sanded the repairs smooth with 220 grit sandpaper. I also worked on the diameter of the tenon end of the stem at the same time. I started to polish it with 400 grit wet dry sandpaper.

I “painted” the tooth marks with the flame of a lighter. I filled in the remaining tooth marks with a clear CA glue. Once it cured, sanded the repairs smooth with 220 grit sandpaper. I also worked on the diameter of the tenon end of the stem at the same time. I started to polish it with 400 grit wet dry sandpaper.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a final coat of Obsidian Oil.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a final coat of Obsidian Oil.

This Peterson’s Speciality Pipe is a great addition. The Belgique shape is classic in every way. It is petite, lightweight and comfortable in the hand. It will be a short smoke. The briar is beautifully grained and the black vulcanite military/stick P-lip stem go well with the briar and the vulcanite shank extension. I polished stem and the bowl with Blue Diamond polish on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The rich stained briar on both bowls took on life with the buffing. The rich brown colour of the briar bowl works well with the polished vulcanite stem. The finished pipe has a rich look that is quite catching. Have a look at it with the photos below. The shape, finish and flow of the pipe and stem are very well done. The dimensions of the Belgique are Length: 5 inches, Height: 1 ½ inches, Outside diameter of the bowl: 7/8 of an inch, Chamber diameter: 5/8 of an inch. The weight of the pipe is .53 ounces/14 grams. I am pleased with how the pipe turned out. It looks very good and shows some signs of age. I will be sending it back to the fellow in England soon. Thanks for reading the blog.

This Peterson’s Speciality Pipe is a great addition. The Belgique shape is classic in every way. It is petite, lightweight and comfortable in the hand. It will be a short smoke. The briar is beautifully grained and the black vulcanite military/stick P-lip stem go well with the briar and the vulcanite shank extension. I polished stem and the bowl with Blue Diamond polish on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The rich stained briar on both bowls took on life with the buffing. The rich brown colour of the briar bowl works well with the polished vulcanite stem. The finished pipe has a rich look that is quite catching. Have a look at it with the photos below. The shape, finish and flow of the pipe and stem are very well done. The dimensions of the Belgique are Length: 5 inches, Height: 1 ½ inches, Outside diameter of the bowl: 7/8 of an inch, Chamber diameter: 5/8 of an inch. The weight of the pipe is .53 ounces/14 grams. I am pleased with how the pipe turned out. It looks very good and shows some signs of age. I will be sending it back to the fellow in England soon. Thanks for reading the blog.