Blog by Steve Laug

When I saw this pipe on Ebay I immediately threw in a low bid. The seller included two photos the clear side view of the pipe shown below and the second photo below – an out of focus picture of the stem end. It was obvious there was damage to the stem and that it would take some work but it was still interesting to me. I was the only bidder so the pipe became mine.

When I saw this pipe on Ebay I immediately threw in a low bid. The seller included two photos the clear side view of the pipe shown below and the second photo below – an out of focus picture of the stem end. It was obvious there was damage to the stem and that it would take some work but it was still interesting to me. I was the only bidder so the pipe became mine.

It was stamped Shamrock on the left side of the shank in capital letters (once it arrived I saw that on the right side of the shank it bore the stamping “A Peterson Product” over Made in the Republic of Ireland with 999 stamped next to that). While the seller never revealed the data stamped on the right side of the shank or the shape number it was clearly a Peterson 999 – one of my favourite shapes. I am particularly fond of the thick shanked older versions of the shape but this one looked workable. While I waited for it I did some research on the brand. I have several Shamrock pipes and fortunately all of them are very nicely grained briar.

It was stamped Shamrock on the left side of the shank in capital letters (once it arrived I saw that on the right side of the shank it bore the stamping “A Peterson Product” over Made in the Republic of Ireland with 999 stamped next to that). While the seller never revealed the data stamped on the right side of the shank or the shape number it was clearly a Peterson 999 – one of my favourite shapes. I am particularly fond of the thick shanked older versions of the shape but this one looked workable. While I waited for it I did some research on the brand. I have several Shamrock pipes and fortunately all of them are very nicely grained briar.

I wrote to a favourite source of all things Peterson, Mark Irwin, to inquire about the mark. He responded with the following helpful information. “There were two Shamrock lines—the Rogers Import U.S.-only line with the nickel band, and the Peterson unmounted line with a white “S” stamped on the mouthpiece. This line—which is what your pipe is from—debuted in the 1945 catalog in the 30 classic shapes then being offered, in both smooth and sandblast, always with a fishtail mouthpiece, and continued with the same finish and “S” stamp until the 1975 catalog. It was a “Product” line, so look carefully for fills, as Peterson always strives to get the most mileage out of their briar. If it does indeed lack fills, someone messed up in the workshop, as it would normally have been released in a much higher line. The name was subsequently used on newer “Shamrock” lines with various finishes and stains until very recently, but always as an entry-grade line.”

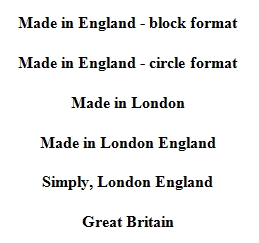

I also was a bit more information on the stamping on the other side of the shank so I read more on dating Peterson Pipes in an article here on the blog by Mike Leverette. In it I found that pipes that bore the Republic of Ireland stamping came from the Republic Era which extended from 1949 until the present. “The Republic of Ireland was formed on 17 April 1949. From 1949 to present the stamp for this era is “Made in the Republic of Ireland” in a block format generally in three lines but two lines have been used with or without Republic being abbreviated.”

Mike also addressed a further question on the stamping “A Peterson Product”. He wrote: “Also, we must address the stamp “A Peterson Product.” During the last few years of the Pre-Republic era and throughout the Republic era, Peterson began stamping their other lines, such as Shamrocks and Killarneys, with “A Peterson Product” over the COM stamp. So a pipe stamped thusly will have been made say from 1948 to the present with the COM stamp identifying it as a pre-Republic or a Republic pipe.”

That was helpful information. With Mark’s and Mike’s information I had learned a lot about my pipe even before it arrived. It came from the earlier Shamrock line which debuted in 1945 and continued until 1975. It certainly fit in the description of a classic shape and an unmounted line with a white S on the stem. It was a Republic Era pipe which put it after 1949 and bore the Peterson Product stamp which put it in the same time frame. That is as specific as I can get in dating this pipe.

When the pipe arrived I opened the box and took it out of the bubble wrap. The stem was frozen in the shank and did not fit against the shank. The grain was beautiful and the natural finish was dirty. The bowl had a thick cake and still had a half bowl of unsmoked tobacco. The rim had a build up of tar on it that was thick. The inner and outer edge of the rim was undamaged and the bowl was still round. The stem was oxidized and the button end had significant damage as can be seen in the third photo below.

I put the pipe in the freezer and left it overnight so that the temperature change would do its magic and loosen the stem in the shank. In the morning I took it out and was able to remove the stem with no problems. The photo below shows the damage to the button very clearly. There is also a sand pit visible in the side of the bowl. It is unfilled and from what I could see of the rest of the bowl there were not any fills.

I put the pipe in the freezer and left it overnight so that the temperature change would do its magic and loosen the stem in the shank. In the morning I took it out and was able to remove the stem with no problems. The photo below shows the damage to the button very clearly. There is also a sand pit visible in the side of the bowl. It is unfilled and from what I could see of the rest of the bowl there were not any fills. I left the tobacco in the bowl while I worked on the rim. I scrubbed it with saliva and cotton pads until I was able to remove all of the tarry build up. I also scrubbed down the rest of the exterior of the bowl and shank.

I left the tobacco in the bowl while I worked on the rim. I scrubbed it with saliva and cotton pads until I was able to remove all of the tarry build up. I also scrubbed down the rest of the exterior of the bowl and shank. I removed the tobacco with a dental pick and then reamed the pipe with a PipNet reamer and took the cake back to bare wood.

I removed the tobacco with a dental pick and then reamed the pipe with a PipNet reamer and took the cake back to bare wood. I used the dental pick to also clean out the twin rings around the bowl. These were packed with dust and wax from previous buffing.

I used the dental pick to also clean out the twin rings around the bowl. These were packed with dust and wax from previous buffing. I set up my retort and put the tube on the broken stem. I loosely stuff a cotton ball in the bowl and heated the alcohol over a tea light candle. I ran the alcohol through until it came out a rich brown. I emptied the test tube and refilled it with alcohol and repeated the process. The second time the alcohol came out clean. I removed the retort and cleaned out the shank and bowl with cotton swabs and pipe cleaners.

I set up my retort and put the tube on the broken stem. I loosely stuff a cotton ball in the bowl and heated the alcohol over a tea light candle. I ran the alcohol through until it came out a rich brown. I emptied the test tube and refilled it with alcohol and repeated the process. The second time the alcohol came out clean. I removed the retort and cleaned out the shank and bowl with cotton swabs and pipe cleaners.

I debated for a long time what to do with the damaged stem. I could try a stem splice or replace the stem. I could also cut off the stem and reshape the button. In looking over the stem I decided there was enough length and material to allow me to cut if off and reshape it. I used a Dremel with a sanding drum to remove the broken part of the stem. I squared it off on the topping board and I was ready to recut the button.

I debated for a long time what to do with the damaged stem. I could try a stem splice or replace the stem. I could also cut off the stem and reshape the button. In looking over the stem I decided there was enough length and material to allow me to cut if off and reshape it. I used a Dremel with a sanding drum to remove the broken part of the stem. I squared it off on the topping board and I was ready to recut the button.

I use needle files to cut the lines of the new button. They give me a good square edge and let me cut the basic shape of the button.

I use needle files to cut the lines of the new button. They give me a good square edge and let me cut the basic shape of the button.

Once the line is cut I use a variety of tools to trim back the taper from the line back toward the shank. I used an emery board to work on the shape of the stem. Often this is all I need but in this case it was not enough.

Once the line is cut I use a variety of tools to trim back the taper from the line back toward the shank. I used an emery board to work on the shape of the stem. Often this is all I need but in this case it was not enough.

I used a knife blade shaped needle file to shave the stem back to the button. With this blade I removed a lot of the excess material and the button began to take shape. I also used the file to begin to shape the oval of the button and to open up the slot in the end of the button. I continued to work on the taper of the stem and smoothed out the flow o the stem to the button using 220 grit sandpaper.

I used a knife blade shaped needle file to shave the stem back to the button. With this blade I removed a lot of the excess material and the button began to take shape. I also used the file to begin to shape the oval of the button and to open up the slot in the end of the button. I continued to work on the taper of the stem and smoothed out the flow o the stem to the button using 220 grit sandpaper.

Once I had the shape and the taper of the stem correct I put a washer on the tenon and inserted it in the shank so that I could work on the stem. I sanded the stem with 220 grit sandpaper to remove the oxidation and then sanded it with a medium and a fine grit sanding sponge. I carefully avoided damaging the logo stamp on the stem. I also rubbed the bowl down with a little olive oil on a cotton pad. It really enlivened the grain on the pipe. I buffed it lightly with White Diamond and then gave it several coats of carnauba wax.

Once I had the shape and the taper of the stem correct I put a washer on the tenon and inserted it in the shank so that I could work on the stem. I sanded the stem with 220 grit sandpaper to remove the oxidation and then sanded it with a medium and a fine grit sanding sponge. I carefully avoided damaging the logo stamp on the stem. I also rubbed the bowl down with a little olive oil on a cotton pad. It really enlivened the grain on the pipe. I buffed it lightly with White Diamond and then gave it several coats of carnauba wax.

Once the oxidation was taken care of I used some liquid paper to re-whiten the S on the stem. The photos below show the shape of the button and the stem at this point in the process. The new button works well and the shortening of the stem did not too seriously damage the appearance of the pipe.

Once the oxidation was taken care of I used some liquid paper to re-whiten the S on the stem. The photos below show the shape of the button and the stem at this point in the process. The new button works well and the shortening of the stem did not too seriously damage the appearance of the pipe.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads and dry sanded it with 3200-12,000 grit pads. I rubbed the stem down with Obsidian Oil between each set of three grits of micromesh sanding pads.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads and dry sanded it with 3200-12,000 grit pads. I rubbed the stem down with Obsidian Oil between each set of three grits of micromesh sanding pads.

I rubbed it down with a final coat of Obsidian Oil and once it had been absorbed into the vulcanite I hand buffed it with a soft cloth and took the next two photos to show the finished look of the stem.

I rubbed it down with a final coat of Obsidian Oil and once it had been absorbed into the vulcanite I hand buffed it with a soft cloth and took the next two photos to show the finished look of the stem.

The finished pipe is shown below. The two profile photos show the look of the new button and the revised taper of the stem. It feels great in the hand and in the mouth. The bend matches my other 999 pipes and the overall length actually is the same as the chunkier stemmed early 999s that I have in my collection. I buffed the pipe and stem with White Diamond and gave it several coats of carnauba wax. I buffed it with a soft flannel buff to raise the shine on the pipe. It looks and smells fresh and clean. It is ready to load with a bowl of Virginia and give an inaugural smoke. In closing look at the grain on this old Shamrock – for the life of me I can find no fills in the briar. It is clean – two or three smalls sandpits but they in no way effect the overall look of the pipe. Amazing, I think that it did indeed slip through during production. No problem for me, I will enjoy it.

The finished pipe is shown below. The two profile photos show the look of the new button and the revised taper of the stem. It feels great in the hand and in the mouth. The bend matches my other 999 pipes and the overall length actually is the same as the chunkier stemmed early 999s that I have in my collection. I buffed the pipe and stem with White Diamond and gave it several coats of carnauba wax. I buffed it with a soft flannel buff to raise the shine on the pipe. It looks and smells fresh and clean. It is ready to load with a bowl of Virginia and give an inaugural smoke. In closing look at the grain on this old Shamrock – for the life of me I can find no fills in the briar. It is clean – two or three smalls sandpits but they in no way effect the overall look of the pipe. Amazing, I think that it did indeed slip through during production. No problem for me, I will enjoy it.