Blog by Steve Laug

The next pipe I chose to work on came is another one from the lot of 11 pipes I purchased from a lady in Regina, Saskatchewan. She had found them in a house she bought and wanted to know if I wanted them. We struck a deal, I paid for the pipes and shipping and the box arrived while I was traveling in Europe. In the box were 4 Stanwells, 1 Danmore Bowl, 1 Soren Freehand, 1 Calabash with a Briar Bowl, 1 Nording Freehand, 1 Italian Made Bertenetti, 1 Rhodesian with a banded cracked shank, and 1 Brigham. I have restored the Nording, the snapped Stanwell, the Brigham, the Gourd Calabash with the briar bowl, restemmed the Danmore bowl, cleaned the Lorenzetti, restored the Stanwell Made in Denmark 11 Pot, the Stanwell Antique 25 Scoop and the Danish Sovereign Stanwell Second 64 Dublin. There are blogs on each restoration available. I now am down to one remaining pipe.

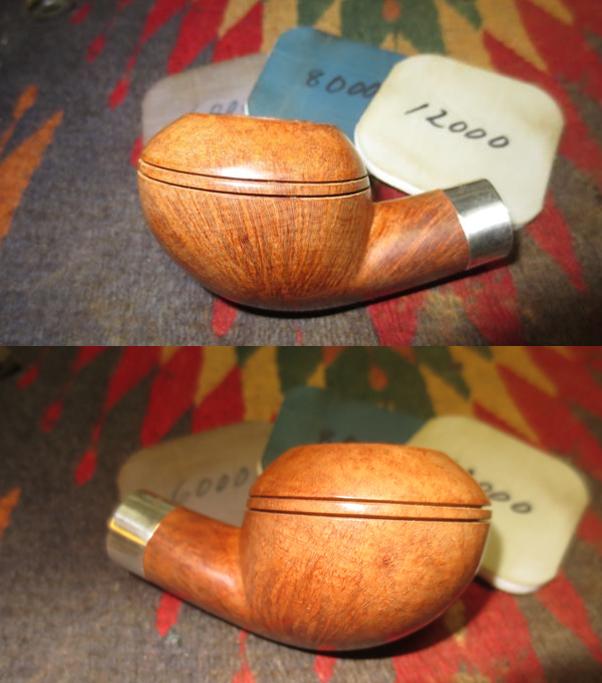

The next pipe on the table is the last of the dirty pipes in a box full of very dirty pipes. There appears to be some stamping on the shank sides but it is so worn that it is utterly unreadable. The pipe was obviously someone’s favourite. The Rhodesian is one of my favourite pipe shapes. This one had not only been smoked to a point of heavy damage on the rim top and inner edge but the band on the shank held together a repair of three branched cracks on the shank. The stem fit well but there was a lot of grit and grime built up in the shank. There was a thick cake in the bowl, debris in the bottom and on the bowl walls and some remnants of tobacco. The airway was plugged and there was no draught on the pipe. There was a heavy lava overflow on the rim top and down the sides of the bowl and shank. The inner edges of the bowl were heavily damage, particularly on the right front side. The outer edge actually looked quite good under the grime. The rim cap was worn at an angle with more briar at the back of the bowl and on the left side than on the front side and the right side. The finish was dirty and there was lava on the sides and heel of the bowl. The stem was in rough shape in appearance but underneath the calcification and oxidation the tooth marks and chatter looked minimal. I took photos of the pipe before I started my cleanup work on it.

The next pipe on the table is the last of the dirty pipes in a box full of very dirty pipes. There appears to be some stamping on the shank sides but it is so worn that it is utterly unreadable. The pipe was obviously someone’s favourite. The Rhodesian is one of my favourite pipe shapes. This one had not only been smoked to a point of heavy damage on the rim top and inner edge but the band on the shank held together a repair of three branched cracks on the shank. The stem fit well but there was a lot of grit and grime built up in the shank. There was a thick cake in the bowl, debris in the bottom and on the bowl walls and some remnants of tobacco. The airway was plugged and there was no draught on the pipe. There was a heavy lava overflow on the rim top and down the sides of the bowl and shank. The inner edges of the bowl were heavily damage, particularly on the right front side. The outer edge actually looked quite good under the grime. The rim cap was worn at an angle with more briar at the back of the bowl and on the left side than on the front side and the right side. The finish was dirty and there was lava on the sides and heel of the bowl. The stem was in rough shape in appearance but underneath the calcification and oxidation the tooth marks and chatter looked minimal. I took photos of the pipe before I started my cleanup work on it.

I took a close-up photo of the bowl and rim top to show the thick cake in the bowl. The rim top shows the thick lava on it and the edges. The inner edge of the bowl is so thickly coated lava that it is hard to know the condition. The outer edges of the bowl were very worn. You can also see how poorly the stem seats against the end of the mortise. There is a gap between the shank end and the saddle stem. I took photos of the top and underside of the stem surface and button to show its general condition. It looked very good under the calcification and oxidation.

I took a close-up photo of the bowl and rim top to show the thick cake in the bowl. The rim top shows the thick lava on it and the edges. The inner edge of the bowl is so thickly coated lava that it is hard to know the condition. The outer edges of the bowl were very worn. You can also see how poorly the stem seats against the end of the mortise. There is a gap between the shank end and the saddle stem. I took photos of the top and underside of the stem surface and button to show its general condition. It looked very good under the calcification and oxidation. I took a photo of the underside of the shank to show the cracks in the shank. There is one long crack with two branches off of it. It had been repaired and banded. I also took a photo of the shank end to show the crack and the gummy tars in the shank. It was a mess. I took the stem off the pipe and took a photo to give a sense of the proportion of the pipe.

I took a photo of the underside of the shank to show the cracks in the shank. There is one long crack with two branches off of it. It had been repaired and banded. I also took a photo of the shank end to show the crack and the gummy tars in the shank. It was a mess. I took the stem off the pipe and took a photo to give a sense of the proportion of the pipe.

Now it was time to work on the pipe. I removed the stem and turned my attention to the bowl clean up. I reamed the bowl with a PipNet pipe reamer using the fourth (and largest) cutting head to take the cake back to bare briar. I cleaned up the reaming with a Savinelli Fitsall Pipe Knife. I sanded the walls with a piece of 180 grit sandpaper wrapped around a dowel to smooth them out.

Now it was time to work on the pipe. I removed the stem and turned my attention to the bowl clean up. I reamed the bowl with a PipNet pipe reamer using the fourth (and largest) cutting head to take the cake back to bare briar. I cleaned up the reaming with a Savinelli Fitsall Pipe Knife. I sanded the walls with a piece of 180 grit sandpaper wrapped around a dowel to smooth them out.

I scrubbed the exterior of the briar with a tooth brush and undiluted Murphy’s Oil Soap. I rinsed it off with warm water to remove the grime and soap. It looked much better and the dust and debris was gone. I dried it with a cotton towel.

I scrubbed the exterior of the briar with a tooth brush and undiluted Murphy’s Oil Soap. I rinsed it off with warm water to remove the grime and soap. It looked much better and the dust and debris was gone. I dried it with a cotton towel.

I scrubbed out the internals of the shank, mortise and the airway in the stem with 99% isopropyl alcohol, pipe cleaners and cotton swabs. There was a lot of tar and oil in the shank and airway. It was a mess.

I scrubbed out the internals of the shank, mortise and the airway in the stem with 99% isopropyl alcohol, pipe cleaners and cotton swabs. There was a lot of tar and oil in the shank and airway. It was a mess. Once I had cleaned the shank with alcohol, pipe cleaners and cotton swabs I topped the bowl on a topping board with 220 grit sandpaper. You can see the repaired cracks in the shank under the band. Once the rim was topped the right side or the rim top and inner edge were very thin and work. The bowl was out of round and a real mess. What was I going to do with the mess? Leave it be or fuss with it? I chose to fuss and rebuilt the inner edge with clear CA glue and briar dust until the bowl was back in round.

Once I had cleaned the shank with alcohol, pipe cleaners and cotton swabs I topped the bowl on a topping board with 220 grit sandpaper. You can see the repaired cracks in the shank under the band. Once the rim was topped the right side or the rim top and inner edge were very thin and work. The bowl was out of round and a real mess. What was I going to do with the mess? Leave it be or fuss with it? I chose to fuss and rebuilt the inner edge with clear CA glue and briar dust until the bowl was back in round.

I cleaned up the inner edge of the rebuilt portion of the rim top with a folded piece of 220 grit sandpaper and my Dremel and sanding drum. I was actually pretty happy with the finish… it seems I made a good choice.

I cleaned up the inner edge of the rebuilt portion of the rim top with a folded piece of 220 grit sandpaper and my Dremel and sanding drum. I was actually pretty happy with the finish… it seems I made a good choice. I filled in the deep flaws in the briar with clear CA glue and briar dust. Once they cured I sanded the repaired areas smooth with 220 grit sandpaper.

I filled in the deep flaws in the briar with clear CA glue and briar dust. Once they cured I sanded the repaired areas smooth with 220 grit sandpaper.

I used a dark Cordovan aniline stain to give the bowl an undercoat. I applied it with a wool dauber and flamed it to set it in the grain.

I used a dark Cordovan aniline stain to give the bowl an undercoat. I applied it with a wool dauber and flamed it to set it in the grain.

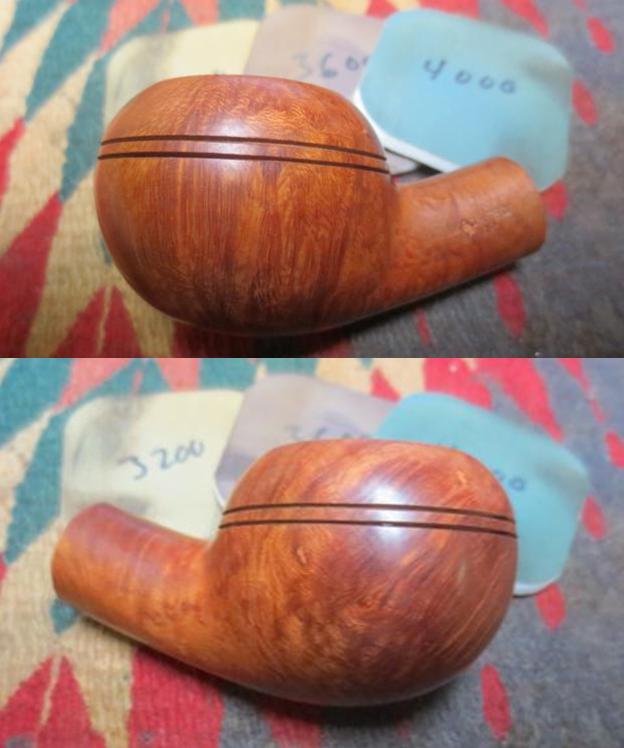

I rusticated the finish with a home made rustication tools. I wanted to dig deep enough in the briar to mask the many fills in the wood and the repaired cracks in the shank. It would also give the pipe a tactile finish. I rusticated the bowl and shank but left the bull cap and rim top smooth. The twin rings around the cap are clean and still very visible.

I rusticated the finish with a home made rustication tools. I wanted to dig deep enough in the briar to mask the many fills in the wood and the repaired cracks in the shank. It would also give the pipe a tactile finish. I rusticated the bowl and shank but left the bull cap and rim top smooth. The twin rings around the cap are clean and still very visible.

I used a light brown aniline wash to restain the bowl. I applied it to the briar and flamed it with a lighter. That set the brown on the top of the rustication.

I used a light brown aniline wash to restain the bowl. I applied it to the briar and flamed it with a lighter. That set the brown on the top of the rustication.

I worked some Before & After Restoration Balm into the finish with a horsehair shoe brush and my finger tips to clean and enliven the briar. If you have read my blogs for a while you know that I do this religiously every time as it really works magic!

I worked some Before & After Restoration Balm into the finish with a horsehair shoe brush and my finger tips to clean and enliven the briar. If you have read my blogs for a while you know that I do this religiously every time as it really works magic!

With that done, the bowl was finished other than the final buffing. I set it aside and turned my attention to the stem. I wiped it down with some Soft Scrub on cotton pads to remove the oxidation and calcification. I was able to remove most of the oxidation and the calcification. It looked much better when I finished.

With that done, the bowl was finished other than the final buffing. I set it aside and turned my attention to the stem. I wiped it down with some Soft Scrub on cotton pads to remove the oxidation and calcification. I was able to remove most of the oxidation and the calcification. It looked much better when I finished. I “painted” the stem surface with the flame of a Bic lighter to lift the tooth marks. I was able to lift all of the marks on the top surface and all but three small deeper marks. I filled in those with black CA glue. I flattened the repair with a small file and further blended it into the surface with 220 grit sandpaper and started polishing it with 600 grit wet dry sandpaper. It really was taking on a shine.

I “painted” the stem surface with the flame of a Bic lighter to lift the tooth marks. I was able to lift all of the marks on the top surface and all but three small deeper marks. I filled in those with black CA glue. I flattened the repair with a small file and further blended it into the surface with 220 grit sandpaper and started polishing it with 600 grit wet dry sandpaper. It really was taking on a shine.

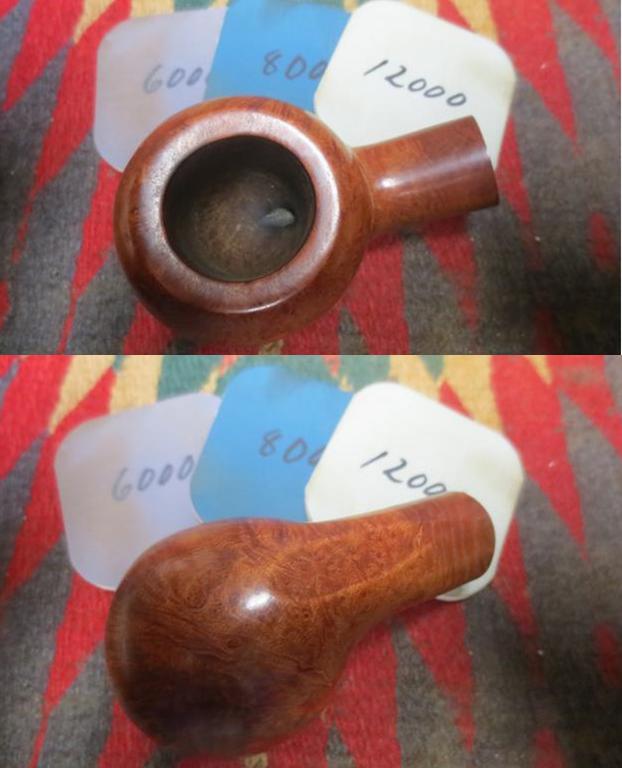

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil.

I finished polishing the stem with Before & After Pipe Stem polish (both Fine and Extra Fine) then wiped the stem down with another coat of Obsidian Oil.

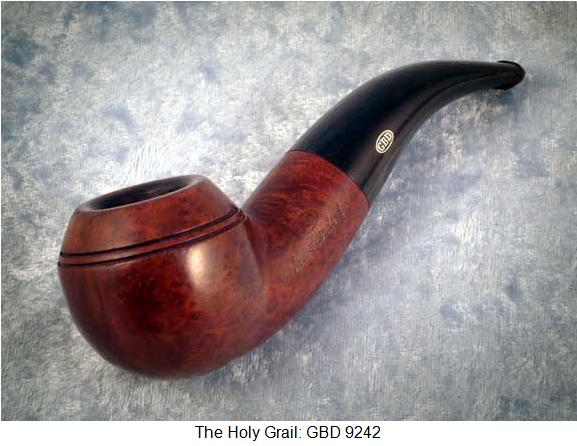

I finished polishing the stem with Before & After Pipe Stem polish (both Fine and Extra Fine) then wiped the stem down with another coat of Obsidian Oil.  I am excited to finish the reconstruction of this No Name Rhodesian. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine and hand buffed it with microfiber cloth to deepen the shine. It is fun to see what the polished reworked bowl looks like with the polished black, saddle vulcanite stem was beautiful. This No Name Rhodesian turned out very well and feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ½ inches long, Chamber diameter: 7/8 of an inch. The weight of the pipe is 1.80 ounces/51 grams. It is a beautiful pipe and one that I am not sure what I am going to do with at the moment. It is unique and rebuilt but looks like new. Thanks for walking through the cleanup with me as I worked over this pipe.

I am excited to finish the reconstruction of this No Name Rhodesian. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine and hand buffed it with microfiber cloth to deepen the shine. It is fun to see what the polished reworked bowl looks like with the polished black, saddle vulcanite stem was beautiful. This No Name Rhodesian turned out very well and feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ½ inches long, Chamber diameter: 7/8 of an inch. The weight of the pipe is 1.80 ounces/51 grams. It is a beautiful pipe and one that I am not sure what I am going to do with at the moment. It is unique and rebuilt but looks like new. Thanks for walking through the cleanup with me as I worked over this pipe.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.