Blog by Steve Laug

I am continuing to work through Bob Kerr’s estate. The next pipe on the table is a GBD New Era Billiard. I am continuing to cleanup Bob’s estate for his family and moving them out into the hands of pipemen and women who will carry on the trust that began with Bob and in some pipes was carried on by Bob. In the collection there were a total of 125 pipes along with a box of parts. This is the largest estate that I have had the opportunity to work on. I put together a spread sheet of the pipes and stampings to create an invoice. I was taking on what would take me a fair amount of time to clean up. I could not pass up the opportunity to work on these pipes though. They were just too tempting.

I have been collecting and restoring GBD pipes for as long as I have worked on pipes. This one also has some beautiful mixed grain underneath the grime. It is quite beautiful! The pipe is stamped GBD in an oval over New Era on the left side of the shank. On the right side it is stamped London, England over the shape number 122. It had a rich medium brown stain that does not look too bad. There was a thick cake in the bowl with remnants of tobacco stuck on the walls. There was a lava overflow on the rim. The inner beveled edge of the rim and top are dirty and had a thick lava coat. The edges look pretty pristine under the grime. It was a beautiful pipe that was dirty and tired looking. The stem was oxidized and calcified toward the end. Again, surprisingly did not have the tooth marks that I have come to expect from Bob’s pipes. Jeff took photos of the pipe before he started his cleanup work on it. Jeff took photos of the bowl and rim top to show the cake in the bowl and the lava build up on the edges of the bowl. It was thick and hard but hopefully it had protected the rim and edges from damage. The edges look pretty good.

Jeff took photos of the bowl and rim top to show the cake in the bowl and the lava build up on the edges of the bowl. It was thick and hard but hopefully it had protected the rim and edges from damage. The edges look pretty good.  Jeff took photos of the side and heel of the bowl to show the condition of the finish. You can see the beautiful grain – both birdseye and cross grain. The finish was very dirty.

Jeff took photos of the side and heel of the bowl to show the condition of the finish. You can see the beautiful grain – both birdseye and cross grain. The finish was very dirty.  Jeff took photos of the stamping on the smooth panel on the underside of the shank. The stamping was readable as you can see from the photos. On the left side it read GBD in an oval over New Era. On the right side it is stamped London, England over the shape number 122. On the left side of the tapered stem was an inlaid GBD roundel.

Jeff took photos of the stamping on the smooth panel on the underside of the shank. The stamping was readable as you can see from the photos. On the left side it read GBD in an oval over New Era. On the right side it is stamped London, England over the shape number 122. On the left side of the tapered stem was an inlaid GBD roundel. Jeff took photos of the top and underside of the stem showing the tooth chatter, scratching and oxidation on the stem surface and wear on the edges of the button.

Jeff took photos of the top and underside of the stem showing the tooth chatter, scratching and oxidation on the stem surface and wear on the edges of the button.  I turned to Pipedia’s article on GBD to see if I could find any information on the Popular. It was a line of GBD pipes that was new to me. The article gives a lot in terms of the history of the brand (https://pipedia.org/wiki/GBD). I have included a paragraph from the site below as well as a page from a catalogue.

I turned to Pipedia’s article on GBD to see if I could find any information on the Popular. It was a line of GBD pipes that was new to me. The article gives a lot in terms of the history of the brand (https://pipedia.org/wiki/GBD). I have included a paragraph from the site below as well as a page from a catalogue.

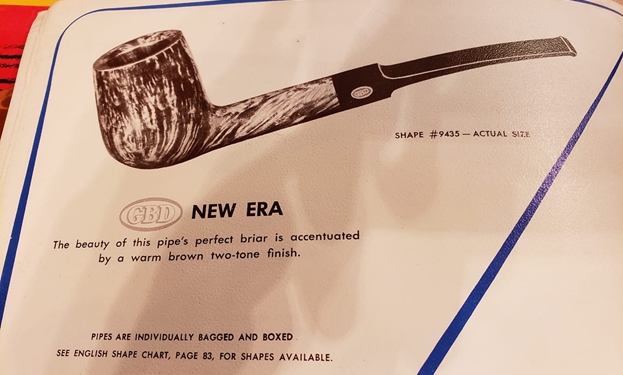

The claims after the 1st World War demanded further distinctions. First of all was the London Made, which became the Standard London Made, followed by the New Era– in 1931 the top model asking 12½ Shilling. The Pedigree, although sketched around 1926, was not produced until the later 1930s. The New Standard was introduced in order to give the popular Standard of the 20s a higher rank in value. The Prehistoric, a deeply sandblasted black pipe, that still carried the small GBD Xtra stamp, was entirely new and unusual. There was a fellow on Facebook Tobacco Pipe Restorers Group who picked up some booklets and pamphlets on GBD pipes. I messaged him and asked him to send me info on the New Era line. This photo gives a pretty good description. Combined with the one above it is an interesting mystery. The first document above says that the pipe has “a rich ruby finish” while the one below says it is “accentuated by a warm brown two-tone finish.” The pipe I am working on definitely sits somewhere between these two descriptions – it has a reddish brown finish.

There was a fellow on Facebook Tobacco Pipe Restorers Group who picked up some booklets and pamphlets on GBD pipes. I messaged him and asked him to send me info on the New Era line. This photo gives a pretty good description. Combined with the one above it is an interesting mystery. The first document above says that the pipe has “a rich ruby finish” while the one below says it is “accentuated by a warm brown two-tone finish.” The pipe I am working on definitely sits somewhere between these two descriptions – it has a reddish brown finish. I also turned to the reference page on the site for GBD shapes and numbers and found the one for the straight bulldog that I was working on (https://pipedia.org/wiki/GBD_Shapes/Numbers). I did a screen capture of the section and from the various Model information. I combined them below (https://pipedia.org/wiki/GBD_Model_Information).

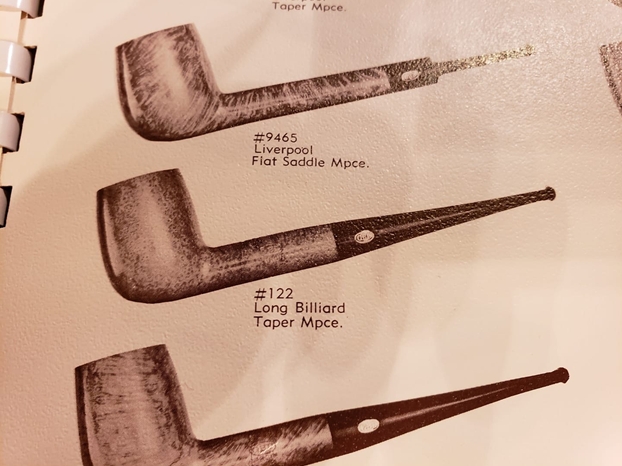

I also turned to the reference page on the site for GBD shapes and numbers and found the one for the straight bulldog that I was working on (https://pipedia.org/wiki/GBD_Shapes/Numbers). I did a screen capture of the section and from the various Model information. I combined them below (https://pipedia.org/wiki/GBD_Model_Information).  The fellow on Facebook also included the next photo that shows the shape and description of the 122. GBD calls it a Long Billiard with a Taper Mouthpiece.

The fellow on Facebook also included the next photo that shows the shape and description of the 122. GBD calls it a Long Billiard with a Taper Mouthpiece. I now knew I was dealing with a well-made hand chosen piece of briar that had gone through a period of long seasoning. In terms of dating the pipe I figure that it fits in with the late 50s to late 60s of Bob’s other pipes but I cannot know for sure. Now it was time to work on the pipe.

I now knew I was dealing with a well-made hand chosen piece of briar that had gone through a period of long seasoning. In terms of dating the pipe I figure that it fits in with the late 50s to late 60s of Bob’s other pipes but I cannot know for sure. Now it was time to work on the pipe.

With over 125 pipes to clean from Bob’s estate I took a batch of them to the states with me on a recent visit and left them with Jeff so he could help me out. Jeff cleaned the pipe with his usual penchant for thoroughness that I really appreciate. This one was a real mess and I did not know what to expect when I unwrapped it from his box. He reamed it with a PipNet pipe reamer and cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed out the internals with alcohol, pipe cleaners and cotton swabs until the pipe was clean. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and grit on the briar and the lava on the rim top. The finish looks very good with good looking grain around the bowl and shank. Jeff soaked the stem in Before & After Deoxidizer to remove the oxidation on the rubber. When the pipe arrived here in Vancouver for the second stop of its restoration tour it looked very good. I took photos before I started my part of the work.

I took some close up photos of the rim top and also of the stem surface. I wanted to show what an amazing job Jeff did in the cleanup of the rim top. The rim top looks good. There is some darkening on the top edge and a few light nicks and scratches on the surface. The bowl looked very good. I also took close up photos of the stem to show the scratches and lack of tooth marks on the stem. You can also see the remaining oxidation on the stem surface.

I took some close up photos of the rim top and also of the stem surface. I wanted to show what an amazing job Jeff did in the cleanup of the rim top. The rim top looks good. There is some darkening on the top edge and a few light nicks and scratches on the surface. The bowl looked very good. I also took close up photos of the stem to show the scratches and lack of tooth marks on the stem. You can also see the remaining oxidation on the stem surface.  I am going to keep posting the next paragraph because of the importance of protecting the stamping/nomenclature.

I am going to keep posting the next paragraph because of the importance of protecting the stamping/nomenclature.

One of the things I appreciate about Jeff’s cleanup is that he works to protect and preserve the nomenclature on the shank of the pipes that he works on. The stamping on this one was very faint to start with so I was worried that it would disappear altogether with the cleanup. He was not only able to preserve it but it is clearer than shown in the earlier photos. I took some photos to show the clarity of the stamping. I have noticed that many restorers are not careful to protect the stamping in their cleaning process and often by the end of the restoration the nomenclature is almost destroyed. I would like to encourage all of us to be careful in our work to preserve this as it is a critical piece of pipe restoration! Since this is another pipe Bob’s estate I am sure that some of you have read at least some of the other restoration work that has been done on the previous pipes. You have also read what I

Since this is another pipe Bob’s estate I am sure that some of you have read at least some of the other restoration work that has been done on the previous pipes. You have also read what I  have included about Bob Kerr, the pipeman who held these pipes in trust before I came to work on them (see photo to the left). Also, if you have followed the blog for long you will already know that I like to include background information on the pipeman whose pipes I am restoring. For me, when I am working on an estate I really like to have a sense of the person who held the pipes in trust before I worked on them. It gives me another dimension of the restoration work. I asked Brian if he or his wife would like to write a brief biographical tribute to her father, Bob. His daughter worked on it and I received the following short write up on him and some pictures to go along with the words including one of Bob’s carvings. Once again I thank you Brian and tell your wife thank you as well.

have included about Bob Kerr, the pipeman who held these pipes in trust before I came to work on them (see photo to the left). Also, if you have followed the blog for long you will already know that I like to include background information on the pipeman whose pipes I am restoring. For me, when I am working on an estate I really like to have a sense of the person who held the pipes in trust before I worked on them. It gives me another dimension of the restoration work. I asked Brian if he or his wife would like to write a brief biographical tribute to her father, Bob. His daughter worked on it and I received the following short write up on him and some pictures to go along with the words including one of Bob’s carvings. Once again I thank you Brian and tell your wife thank you as well.

I am delighted to pass on these beloved pipes of my father’s. I hope each user gets many hours of contemplative pleasure as he did. I remember the aroma of tobacco in the rec room, as he put up his feet on his lazy boy. He’d be first at the paper then, no one could touch it before him. Maybe there would be a movie on with an actor smoking a pipe. He would have very definite opinions on whether the performer was a ‘real’ smoker or not, a distinction which I could never see but it would be very clear to him. He worked by day as a sales manager of a paper products company, a job he hated. What he longed for was the life of an artist, so on the weekends and sometimes mid-week evenings he would journey to his workshop and come out with wood sculptures, all of which he declared as crap but every one of them treasured by my sister and myself. Enjoy the pipes, and maybe a little of his creative spirit will enter you!

I hope each user gets many hours of contemplative pleasure as he did. I remember the aroma of tobacco in the rec room, as he put up his feet on his lazy boy. He’d be first at the paper then, no one could touch it before him. Maybe there would be a movie on with an actor smoking a pipe. He would have very definite opinions on whether the performer was a ‘real’ smoker or not, a distinction which I could never see but it would be very clear to him. He worked by day as a sales manager of a paper products company, a job he hated. What he longed for was the life of an artist, so on the weekends and sometimes mid-week evenings he would journey to his workshop and come out with wood sculptures, all of which he declared as crap but every one of them treasured by my sister and myself. Enjoy the pipes, and maybe a little of his creative spirit will enter you!

Now on to the rest of the restoration on this GBD New Era Billiard. Since Jeff had done such an amazing clean up job on the bowl it was very easy for me. There was some darkening on the inner beveled edge of the rim that needed to be addressed. I sanded it with a folded piece of 220 grit sandpaper to remove and minimize the damage to the bevel. I continued by starting to polish it with 400 grit wet dry sandpaper. I wiped the rim edge down with a damp cloth to remove the sanding dust on the briar. The finished rim top looked much better than when I started. There was a deep cut or groove in the briar on the left side of the bowl. It looked like someone had scratched it against hard surface leaving a deep gouge. I filled in the gouge with clear super glue. Once the glue had dried I sanded it smooth with 220 grit sandpaper and blended it with 400 grit wet dry sandpaper.

There was a deep cut or groove in the briar on the left side of the bowl. It looked like someone had scratched it against hard surface leaving a deep gouge. I filled in the gouge with clear super glue. Once the glue had dried I sanded it smooth with 220 grit sandpaper and blended it with 400 grit wet dry sandpaper.  I used a Maple stain pen to touch up the sanded area to match the rest of the bowl. It looked very good and would completely blend once the bowl was polished with micromesh.

I used a Maple stain pen to touch up the sanded area to match the rest of the bowl. It looked very good and would completely blend once the bowl was polished with micromesh. I polished the briar with micromesh sanding pads to blend in the stain and to polish the briar and remove the scratches in the surface of the bowl, heel and shank. I wet sanded with 1500-12000 grit pads and wiped the bowl down between each pad with a damp cloth.

I polished the briar with micromesh sanding pads to blend in the stain and to polish the briar and remove the scratches in the surface of the bowl, heel and shank. I wet sanded with 1500-12000 grit pads and wiped the bowl down between each pad with a damp cloth.

I decided to clean the briar with Mark Hoover’s Before & After Briar Cleaner to clean up the sanded surface of the briar and blend sanded rim edge. I rubbed it into the surface of the briar and let it sit for 10 minutes. I rinsed the bowl off with warm running water to remove the product and the grime.

I decided to clean the briar with Mark Hoover’s Before & After Briar Cleaner to clean up the sanded surface of the briar and blend sanded rim edge. I rubbed it into the surface of the briar and let it sit for 10 minutes. I rinsed the bowl off with warm running water to remove the product and the grime.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth and shoe brush to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth and shoe brush to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on.

I set the bowl aside and turned my attention to the stem. I sanded the stem with 220 grit sandpaper to break up the oxidation. I started the polishing with 400 grit wet dry sandpaper to remove the scratching. It is starting to look good.

I set the bowl aside and turned my attention to the stem. I sanded the stem with 220 grit sandpaper to break up the oxidation. I started the polishing with 400 grit wet dry sandpaper to remove the scratching. It is starting to look good.  I have one more tin of Denicare Mouthpiece Polish left from a few that I have picked up over the years. It is a coarse red pasted that serves to help remove oxidation. I polished the stem with that to further smooth out the surface of the vulcanite (and to be honest – to use it up).

I have one more tin of Denicare Mouthpiece Polish left from a few that I have picked up over the years. It is a coarse red pasted that serves to help remove oxidation. I polished the stem with that to further smooth out the surface of the vulcanite (and to be honest – to use it up).  I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of oil and set it aside to dry.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of oil and set it aside to dry.

I am excited to be finishing another one of Bob Kerr’s Estate pipes and as usual I look forward to what it will look like when it is put back together, polished and waxed. I put the bowl and stem back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl and stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The rich reddish brown finish really popped with buffing showing the contrast colours of stain on the pipe. The polished black vulcanite stem went really well with the colours of the bowl. This old GBD New Era 122 Billiard was another fun pipe to work on thanks to Jeff’s cleanup work. It really has the classic GBD Billiard shape that is very recognizable. The combination of various stains really makes the pipe look attractive. It is a comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 ¼ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. If you are interested in carrying on Bob’s legacy with this pipe send me a message or an email. I have a lot more to work on of various brands. Perhaps one of those will catch your attention. Thanks for reading this blog and my reflections on the pipe while I worked on it. This is an interesting estate to bring back to life.

I am excited to be finishing another one of Bob Kerr’s Estate pipes and as usual I look forward to what it will look like when it is put back together, polished and waxed. I put the bowl and stem back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl and stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The rich reddish brown finish really popped with buffing showing the contrast colours of stain on the pipe. The polished black vulcanite stem went really well with the colours of the bowl. This old GBD New Era 122 Billiard was another fun pipe to work on thanks to Jeff’s cleanup work. It really has the classic GBD Billiard shape that is very recognizable. The combination of various stains really makes the pipe look attractive. It is a comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 ¼ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. If you are interested in carrying on Bob’s legacy with this pipe send me a message or an email. I have a lot more to work on of various brands. Perhaps one of those will catch your attention. Thanks for reading this blog and my reflections on the pipe while I worked on it. This is an interesting estate to bring back to life.