Another of the gift bowls that I received was an apple-shaped bowl stamped Mountain Root on the left side of the shank and on the right side Glasschuam Bowl. The Glasschaum Bowl stamping had remnants of silver paint in the indentations. The finish was rough with many scratches in the briar. The shank internally was very black and tarry. The bowl inside was dirty with a thin build up of cake. The internal edge of the meerschaum lining was chipped in several places but there were no cracks in the bowl.  The Mountain Root stamping and the Glasschaum Bowl stamp were both new to me. I looked in “Who Made That Pipe” for the Mountain Root brand and found nothing with that stamping. PipePhil did not have it on his site either, so I looked further on the web and found several posts on the brand on the Grabow forum. The link is: http://drgrabows.myfreeforum.org/about4008.html&highlight=

The Mountain Root stamping and the Glasschaum Bowl stamp were both new to me. I looked in “Who Made That Pipe” for the Mountain Root brand and found nothing with that stamping. PipePhil did not have it on his site either, so I looked further on the web and found several posts on the brand on the Grabow forum. The link is: http://drgrabows.myfreeforum.org/about4008.html&highlight=

At that site a pipeman had posted about a pipe he purchased on Ebay: “I purchased this “Mountain Root” pipe on Ebay. Right shank is stamped “Glasschaum Bowl” and the inside of the bowl is lined with something similar to how Yello-Boles are lined with a yellow colored coating. The stinger is wooden and the stem inlay is a white or faintly yellow ring on top of the stem similar to Yello-Bole stem rings of the ’40’s except for the color.”

My pipe bowl looked just as he described though I would have said it had a meerschaum like bowl insert rather than the yellow coating on the Yello-Bole pipes. It was significantly thicker than the yellow painted coating. Mine also came without a stem so there was no wooden stinger apparatus or yellow ring on the stem.

He went on to inquire if anyone could help him with information on the brand. He received quite a few helpful replies to his query. One that summarized the lot is included below.

“Mountain Root probably refers to Mountain Laurel. That was one alternative wood used in WWII for pipes, when briar was not available or in very short supply. The wood stinger also suggests that era.”

This coincided with what I was thinking in terms of the link to Mountain Laurel and the WWII era pipes. I was not alone in thinking that I was dealing with a pipe from that era made from Laurel. The confirmation of that was not 100% certain and the next details make me wonder about that. I looked up Glasschaum Bowl pipes online and found that Ben Leibowitz, an American pipe maker marketed the Glasschaum pipe in 1941 and quickly disappeared off the scene. This reference was also confirmed in Who Made That Pipe. If it was indeed a Liebowitz pipe it would have been stamped Glasschaum Pipe with no other stamping. This one however had the Mountain Root stamping as well and it led me to believe I was dealing with something other than an American made Leibowitz pipe. Further digging was necessary.

I often turn to EBay to see if I can find a particular brand of pipe for information when it does not show up other places. In looking through the various pipes on EBay that bore the Glasschaum Bowl stamping I found several that had the identical stamping on the right side of the shank.  Some of them had Mountain Root (1st photo below) on the left side the same as the bowl I have, while others were stamped Gordon Deluxe in a Diamond on the left (2nd photo below).

Some of them had Mountain Root (1st photo below) on the left side the same as the bowl I have, while others were stamped Gordon Deluxe in a Diamond on the left (2nd photo below).

I looked in “Who Made That Pipe?”and found that Gordon pipes were made by Villard & Strauss as well as Dan Jacobs/Comoy’s/R. Jack & Sons and Samuel Gordon (1918), all in made in England. There was also confirmation that The Samuel Gordon pipes had Gordon in a diamond logo. The fact that these were English made pipes made me question the Mountain Laurel wood comment above. The bowl also did not look like the wood on other Mountain Laurel pipes that I have in my collection so I am not at all certain of the assessment.

I looked in “Who Made That Pipe?”and found that Gordon pipes were made by Villard & Strauss as well as Dan Jacobs/Comoy’s/R. Jack & Sons and Samuel Gordon (1918), all in made in England. There was also confirmation that The Samuel Gordon pipes had Gordon in a diamond logo. The fact that these were English made pipes made me question the Mountain Laurel wood comment above. The bowl also did not look like the wood on other Mountain Laurel pipes that I have in my collection so I am not at all certain of the assessment.

The information I had found made me lean toward the maker of this pipe being Samuel Gordon a London pipemaker. That meant that the pipe was English made. I don’t have a clear idea of the date of the pipe but looking at others on EBay that had the same stamping of the Gordon Deluxe stamping my thinking is that the pipes came from the 40s or 50s.

I went through my can of stems and found one that fit well in the shank with minimal sanding. When I chose the stem I had not done the research on the brand and found that the stem had a light yellow O on the top of the stem and the one I chose had a brass O on the top. Such is the one of the happy coincidences of the repair.

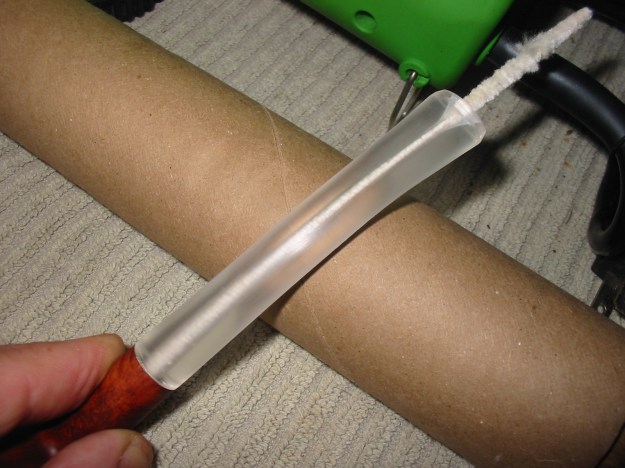

I lightly sanded the tenon of the stem until it fit snugly in the shank. I cleaned out the stem with alcohol and pipe cleaners before beginning the shaping. The diameter of the stem was larger than the diameter of the shank. I used a Dremel with a sanding drum to remove the majority of the excess vulcanite on the stem. I carefully do this with the stem in place and try to get as close as possible to the same diameter as the shank. I try not to nick the shank while I am working on it.

I lightly sanded the tenon of the stem until it fit snugly in the shank. I cleaned out the stem with alcohol and pipe cleaners before beginning the shaping. The diameter of the stem was larger than the diameter of the shank. I used a Dremel with a sanding drum to remove the majority of the excess vulcanite on the stem. I carefully do this with the stem in place and try to get as close as possible to the same diameter as the shank. I try not to nick the shank while I am working on it.

I used a sharp pen knife/letter opener to scrape the inside of the bowl. I wanted to remove the carbon build up around the middle of the bowl particularly and also on the upper sides of the bowl. The bottom half and the bottom of the bowl were quite clean.

I used a sharp pen knife/letter opener to scrape the inside of the bowl. I wanted to remove the carbon build up around the middle of the bowl particularly and also on the upper sides of the bowl. The bottom half and the bottom of the bowl were quite clean.

After scraping the bowl clean the chips around the edges of the rim were visible. They were deeper on the back side of the bowl at about 5 and 7 o’clock. I needed to top the bowl to remove the damaged areas on the rim and bring the top closer to the edge of the meerschaum insert. I set up a topping board and 220 grit sandpaper and sanded down the rim.

After scraping the bowl clean the chips around the edges of the rim were visible. They were deeper on the back side of the bowl at about 5 and 7 o’clock. I needed to top the bowl to remove the damaged areas on the rim and bring the top closer to the edge of the meerschaum insert. I set up a topping board and 220 grit sandpaper and sanded down the rim.

With topping of the rim done the chipped areas were very clear. I sanded the inside edge of the rim with a folded piece of sandpaper to smooth out the areas that were not chipped and to bank the inner edge slightly. With this done the repairs to the insert edge would be quite simple to do.

With topping of the rim done the chipped areas were very clear. I sanded the inside edge of the rim with a folded piece of sandpaper to smooth out the areas that were not chipped and to bank the inner edge slightly. With this done the repairs to the insert edge would be quite simple to do.

Once I had the stem diameter close I took it back to the table and hand sanded it with 150 grit sandpaper until the angles and flow of the stem was also correct. I worked so that there was not a bulge or hip at the junction. I also sanded the button on the stem as it was very thick. I sloped it toward the end of the stem. When the fit and flow were close to what I wanted I removed the stem from the shank and sanded in long strokes from the tenon end to the button to smooth out potential scratches.

Once I had the stem diameter close I took it back to the table and hand sanded it with 150 grit sandpaper until the angles and flow of the stem was also correct. I worked so that there was not a bulge or hip at the junction. I also sanded the button on the stem as it was very thick. I sloped it toward the end of the stem. When the fit and flow were close to what I wanted I removed the stem from the shank and sanded in long strokes from the tenon end to the button to smooth out potential scratches.

I put the stem back on and sanded with 220 grit sandpaper to remove the remaining excess and some of the heavier scratches. At this point I also sanded the shank of the pipe at the same time to make sure that the transition between the briar and the vulcanite was smooth and seamless. This took quite a bit of sanding. I did not want to remove too much briar as I did not want to change the look of the shank or the diameter of the shank. I was more concerned with getting the flow and lines smooth. I sanded it with a medium and a fine grit sanding sponge once I had the fit perfected.

I wiped the bowl down with acetone on cotton pads to remove the finish from the bowl and shank. I have found that this makes staining the rim and shank much easier to achieve and matching the stain is not a problem as it is all quite light.

I wiped the bowl down with acetone on cotton pads to remove the finish from the bowl and shank. I have found that this makes staining the rim and shank much easier to achieve and matching the stain is not a problem as it is all quite light.

I wiped down the inside of the bowl edges with a wet cotton pad to remove loose particles of the liner and also any dust that was present from the sanding. I mixed a small batch of Plaster of Paris to work on the chipped edges of the insert. I mixed it into a thick mud consistency that was still wet but did not clump. I pressed into the chipped areas with the cuticle tool that I cleaned up. The curves on the spoon end are perfect for pressing the mud into the chipped areas of the bowl. The next two photos show the repaired area of the bowl insert. I purposely put the plaster on heavier than necessary and then shaped it with the spoon end of the tool. I set it aside to dry.

I wiped down the inside of the bowl edges with a wet cotton pad to remove loose particles of the liner and also any dust that was present from the sanding. I mixed a small batch of Plaster of Paris to work on the chipped edges of the insert. I mixed it into a thick mud consistency that was still wet but did not clump. I pressed into the chipped areas with the cuticle tool that I cleaned up. The curves on the spoon end are perfect for pressing the mud into the chipped areas of the bowl. The next two photos show the repaired area of the bowl insert. I purposely put the plaster on heavier than necessary and then shaped it with the spoon end of the tool. I set it aside to dry.

When the plaster was dry to the touch I cleaned out the shank with cotton swabs, pipe cleaners and isopropyl alcohol. There was some paper stuck to the inside of the shank from what appeared to be a washer that some previous owner had used to hold the stem tightly in place.

When the plaster was dry to the touch I cleaned out the shank with cotton swabs, pipe cleaners and isopropyl alcohol. There was some paper stuck to the inside of the shank from what appeared to be a washer that some previous owner had used to hold the stem tightly in place.  I sanded the bowl and shank, carefully avoiding the stamping with micromesh sanding pads – 1500-3200 grit to smooth out some of the scratches that were on the surface of the briar. I wiped it down with alcohol on a cotton pad to remove the dust from the finish. Looking at the bowl in this unfinished state it is clear that this is a piece of briar and not a piece of Mountain Laurel. The birdseye and cross grain are quite nice. I cleaned up the top of the bowl and left the inside edge untouched at this point. I wanted the plaster to cure over night before I sanded it and cleaned it up on the inside.

I sanded the bowl and shank, carefully avoiding the stamping with micromesh sanding pads – 1500-3200 grit to smooth out some of the scratches that were on the surface of the briar. I wiped it down with alcohol on a cotton pad to remove the dust from the finish. Looking at the bowl in this unfinished state it is clear that this is a piece of briar and not a piece of Mountain Laurel. The birdseye and cross grain are quite nice. I cleaned up the top of the bowl and left the inside edge untouched at this point. I wanted the plaster to cure over night before I sanded it and cleaned it up on the inside.

The next series of three photos show the work I did on the repair to the edge of the insert. The first shows the repair after it dried over night. It was hard and quite thick. The second photo shows the area after I sanded it with a folded piece of 220 grit sandpaper to smooth it out, bevel it slightly to match the rest of the rim edge and feather it into the surface of the bowl. The third photo shows it after the bowl has been wiped down with a damp cloth to clean up the dust from the sanding. The bright white areas are the repaired portions. After a few smokes this will blend in very well with the rest of the insert and will be unnoticeable.

The next series of three photos show the work I did on the repair to the edge of the insert. The first shows the repair after it dried over night. It was hard and quite thick. The second photo shows the area after I sanded it with a folded piece of 220 grit sandpaper to smooth it out, bevel it slightly to match the rest of the rim edge and feather it into the surface of the bowl. The third photo shows it after the bowl has been wiped down with a damp cloth to clean up the dust from the sanding. The bright white areas are the repaired portions. After a few smokes this will blend in very well with the rest of the insert and will be unnoticeable.

I wiped the bowl and stem down with olive oil on a paper towel. I wipe it on and wipe it off again to give me a clear picture of areas of the bowl that still need work. It shows the scratches very clearly and also gives some colour and life to the bowl highlighting the natural grain. I am still undecided as to whether or not I will give it a coat of a light brown stain.

I wiped the bowl and stem down with olive oil on a paper towel. I wipe it on and wipe it off again to give me a clear picture of areas of the bowl that still need work. It shows the scratches very clearly and also gives some colour and life to the bowl highlighting the natural grain. I am still undecided as to whether or not I will give it a coat of a light brown stain.

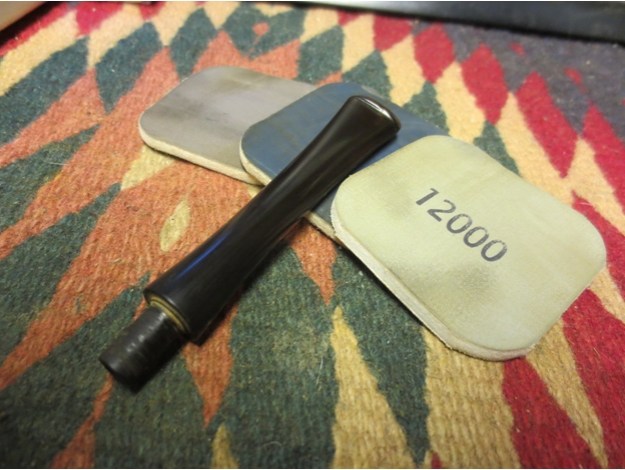

I sanded the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12,000 grit pads. In between each set of three grits I wiped the stem down with Obsidian Oil and when dry continued sanding the stem. I buffed it with White Diamond and gave it a final wipe down with Obsidian Oil before setting it aside to work on the bowl.

I sanded the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12,000 grit pads. In between each set of three grits I wiped the stem down with Obsidian Oil and when dry continued sanding the stem. I buffed it with White Diamond and gave it a final wipe down with Obsidian Oil before setting it aside to work on the bowl.

I wiped down the bowl with alcohol on a cotton pad and then gave the bowl a light coat of Danish Oil and walnut stain. I wiped it on the bowl and then wiped it off and set it aside to dry over night.

I wiped down the bowl with alcohol on a cotton pad and then gave the bowl a light coat of Danish Oil and walnut stain. I wiped it on the bowl and then wiped it off and set it aside to dry over night.

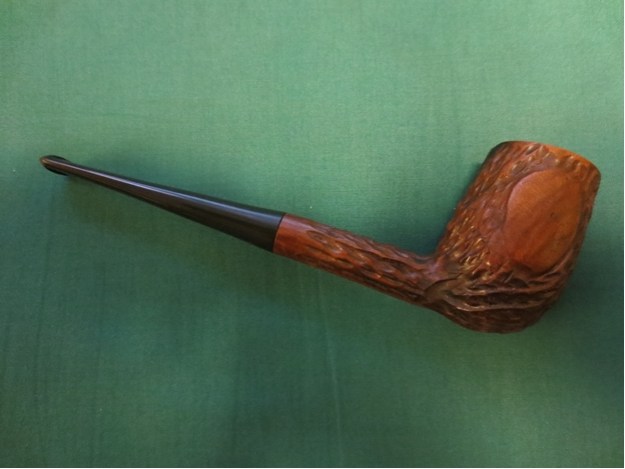

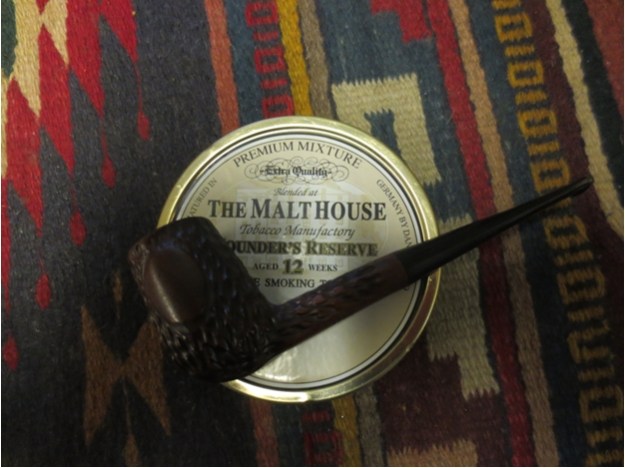

In the morning when it was dry I lightly buffed it with White Diamond on the wheel and then put the stem in place and repeated the buffing. I gave it several coats of carnauba wax and buffed it with a soft flannel buff. The finished pipe is shown in the photos below. It is restored and ready to be smoked. It should last for many more years ahead and provide a typical meerschaum lined smoke for the pipeman who smokes it next.

In the morning when it was dry I lightly buffed it with White Diamond on the wheel and then put the stem in place and repeated the buffing. I gave it several coats of carnauba wax and buffed it with a soft flannel buff. The finished pipe is shown in the photos below. It is restored and ready to be smoked. It should last for many more years ahead and provide a typical meerschaum lined smoke for the pipeman who smokes it next.