Blog by Steve Laug

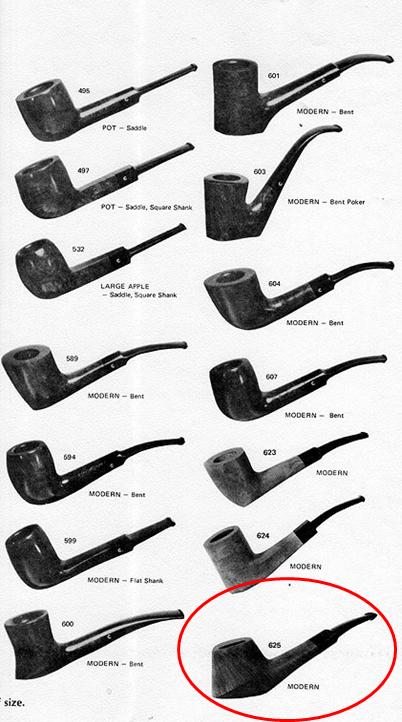

My brother Jeff found this old pipe either on eBay or in his travels and picked it up. He sent me photos of the pipe when he received it. It looked pretty bleak to me but there was some promise in the interesting shape of the pipe and the grain that was visible in the photos. There were also some dark spots on the sides of the bowl that I wondered about as I looked at the photos. The finish was very dirty and underneath the grime it was gone. There were some burn marks around the top of the bowl. The bowl was lightly caked but very dirty. The stem was lightly pitted and oxidized but there were no tooth marks or chatter on the stem.

My brother cleaned the pipe really well and the grime and remnants of the finish were all gone by the time I received the pipe. I took some photos of the pipe before I started to work on it. The dark spots on the sides of the bowl are visible in the photos below. The damage to the rim is also visible. There are some nicks in the top of the bowl and some burned areas that will need to be addressed. He cleaned out the airway in the shank and the stem as well as the mortise area. I noticed however that there was a slight ledge in the mortise that was hard and made me wonder what was happening there.

My brother cleaned the pipe really well and the grime and remnants of the finish were all gone by the time I received the pipe. I took some photos of the pipe before I started to work on it. The dark spots on the sides of the bowl are visible in the photos below. The damage to the rim is also visible. There are some nicks in the top of the bowl and some burned areas that will need to be addressed. He cleaned out the airway in the shank and the stem as well as the mortise area. I noticed however that there was a slight ledge in the mortise that was hard and made me wonder what was happening there.

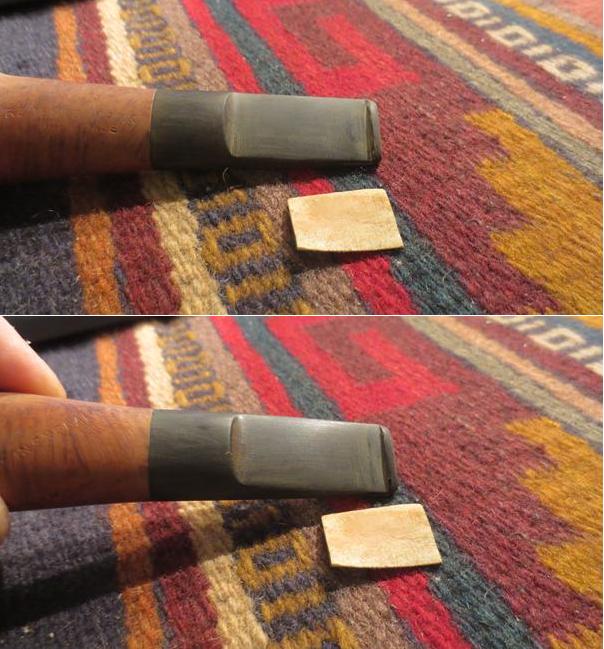

I took a close up photo of the bowl to show the extent of the damage to the inner edge of the rim and the rim top. The bowl was quite out of round and the burn marks though not deep were prevalent in the briar. I took some close up photos of the stem as well to show the condition they were in when I started the clean up.

I took a close up photo of the bowl to show the extent of the damage to the inner edge of the rim and the rim top. The bowl was quite out of round and the burn marks though not deep were prevalent in the briar. I took some close up photos of the stem as well to show the condition they were in when I started the clean up. I topped the bowl on the topping board with 220 grit sandpaper until all of the damage was removed.

I topped the bowl on the topping board with 220 grit sandpaper until all of the damage was removed. I sanded the inside of the bowl and the inner edge of the rim with a tube of sandpaper until the edge was smooth and round.

I sanded the inside of the bowl and the inner edge of the rim with a tube of sandpaper until the edge was smooth and round. I sanded the top of the rim with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. The rim took on a shine.

I sanded the top of the rim with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. The rim took on a shine. I wiped the bowl down with acetone on a cotton pad to remove the remaining debris and worked on the dark areas. The dark areas turned out to be fills and the darkening occurred around the edges of the fills.

I wiped the bowl down with acetone on a cotton pad to remove the remaining debris and worked on the dark areas. The dark areas turned out to be fills and the darkening occurred around the edges of the fills.

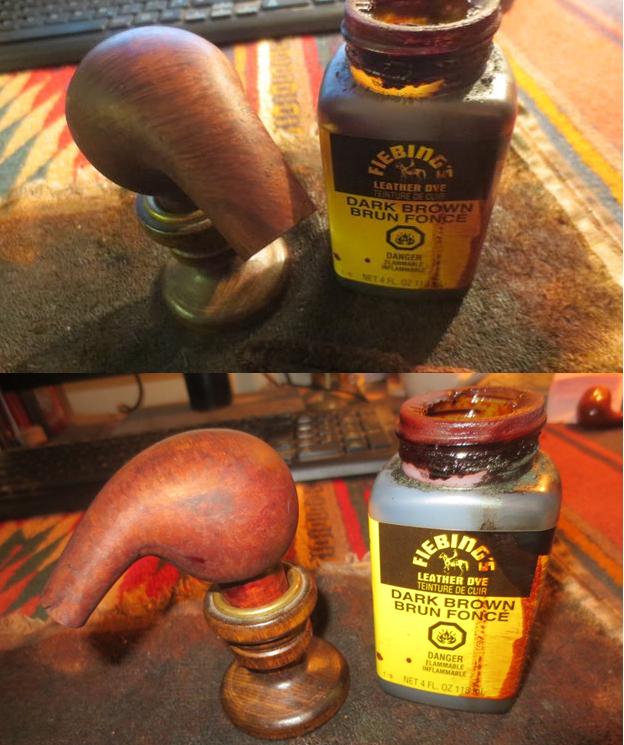

I warmed the briar and then stained it with a dark brown aniline stain mixed 50/50 with isopropyl alcohol. I flamed the stain to set it in the briar and then repeated the process until the coverage on the bowl was good.

I warmed the briar and then stained it with a dark brown aniline stain mixed 50/50 with isopropyl alcohol. I flamed the stain to set it in the briar and then repeated the process until the coverage on the bowl was good. I hand buffed the bowl with a microfiber cloth to see what the coverage looked like particularly over the filled areas. The photos below show the pipe at this point in the process. The putty spots are visible in the first two photos. I have circled them in red to make them clear. Both fills were solid and tight but had a red overtone that stood out.

I hand buffed the bowl with a microfiber cloth to see what the coverage looked like particularly over the filled areas. The photos below show the pipe at this point in the process. The putty spots are visible in the first two photos. I have circled them in red to make them clear. Both fills were solid and tight but had a red overtone that stood out. The top of the rim came out looking really good. The burned spots and damage to the rim top and inner edge have been minimized.

The top of the rim came out looking really good. The burned spots and damage to the rim top and inner edge have been minimized. I recleaned the interior of the shank using the dental spatula to scrape away the hardened tars and oils. I scrubbed it with pipe cleaners, cotton swabs and alcohol until it was clean. I cleaned up the airway in the stem with bristle cleaners and was able to remove the last of the tars.

I recleaned the interior of the shank using the dental spatula to scrape away the hardened tars and oils. I scrubbed it with pipe cleaners, cotton swabs and alcohol until it was clean. I cleaned up the airway in the stem with bristle cleaners and was able to remove the last of the tars. The stem fit against the shank with a slight gap on the right side. I heated the tenon with a Bic lighter and while it was still soft held it straight in the shank until it cooled.

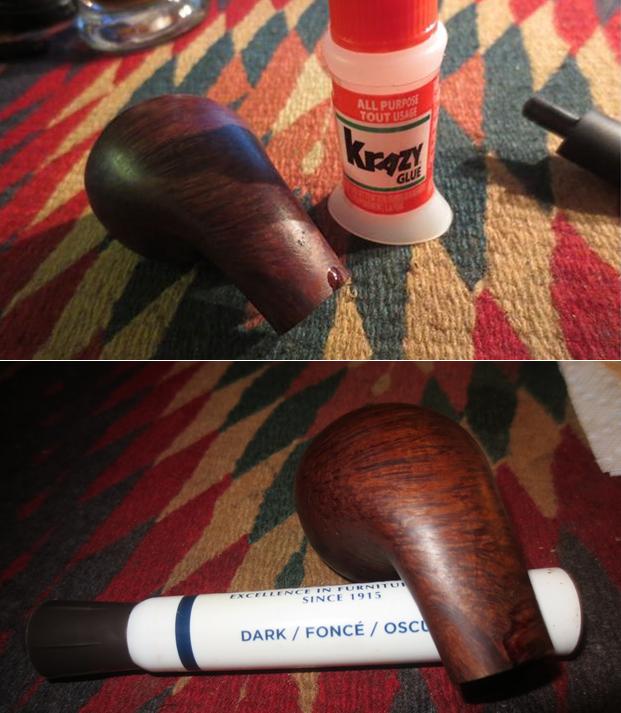

The stem fit against the shank with a slight gap on the right side. I heated the tenon with a Bic lighter and while it was still soft held it straight in the shank until it cooled. On the underside of the shank next to the stem there was a chipped area where the briar was missing from the shank. I cleaned out that area and filled it in with clear super glue and briar dust. Once it dried I sanded it smooth with 220 grit sandpaper and then polished it with 1500-4000 grit micromesh sanding pads. I used a dark brown stain pen to touch up the sanded area.

On the underside of the shank next to the stem there was a chipped area where the briar was missing from the shank. I cleaned out that area and filled it in with clear super glue and briar dust. Once it dried I sanded it smooth with 220 grit sandpaper and then polished it with 1500-4000 grit micromesh sanding pads. I used a dark brown stain pen to touch up the sanded area. I sanded the stem with 220 grit sandpaper to smooth out the pits and roughness. I polished it with micromesh sanding pads. I wet sanded it with 1500-2400 grit pads and dry sanded it with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil between each set of three pads. After the final rubdown I let the stem dry.

I sanded the stem with 220 grit sandpaper to smooth out the pits and roughness. I polished it with micromesh sanding pads. I wet sanded it with 1500-2400 grit pads and dry sanded it with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil between each set of three pads. After the final rubdown I let the stem dry.

I used a black Sharpie Pen to draw “grain” lines through the fills and used the dark brown stain pen to blend the pen lines into the body of the pipe. I buffed the pipe and stem with Blue Diamond polish on the buffing wheel to finish cleaning up the small remnants of oxidation. I gave it several coats of carnauba wax and buffed it with a clean buffing pad. I hand buffed it with a microfibre cloth. The finished pipe is shown in the photos below. Thanks for looking.

I used a black Sharpie Pen to draw “grain” lines through the fills and used the dark brown stain pen to blend the pen lines into the body of the pipe. I buffed the pipe and stem with Blue Diamond polish on the buffing wheel to finish cleaning up the small remnants of oxidation. I gave it several coats of carnauba wax and buffed it with a clean buffing pad. I hand buffed it with a microfibre cloth. The finished pipe is shown in the photos below. Thanks for looking.