Blog by Dal Stanton

I love pipe picking especially in ‘hole in the wall’ treasure hunts on the Black Sea. My wife and I were on summer holiday enjoying Bulgaria’s Black Sea venues. I discovered this ‘hole in the wall’ antique shop on previous trips to the city of Burgas and on this return, I was not disappointed. I purchased 7 pipes waiting to be adopted after negotiating with Kaloyan, the shop owner. His mother was also there watching over things and she called Kaloyan on her cell phone when I asked about the pipes that I had found displayed.  He must have been down the street perhaps at a café taking a break and a smoke because his arrival in a matter of seconds commenced the negotiations for the 7 and a friendship emerged as a byproduct! After taking my phone number he assured me if more treasures came his way that he would call. As my wife and I were leaving, shaking hands with Kaloyan and grandmotherly mom, a look of shocked wonder came over Kaloyan’s face – he told us to wait and he ran back into the shop returning with two other pipes that were not in view that he had almost forgotten.

He must have been down the street perhaps at a café taking a break and a smoke because his arrival in a matter of seconds commenced the negotiations for the 7 and a friendship emerged as a byproduct! After taking my phone number he assured me if more treasures came his way that he would call. As my wife and I were leaving, shaking hands with Kaloyan and grandmotherly mom, a look of shocked wonder came over Kaloyan’s face – he told us to wait and he ran back into the shop returning with two other pipes that were not in view that he had almost forgotten.  He reemerged with treasures in hand, a Vauen 6294 EX Billiard Saddle Stem (still available to be commissioned in For “Pipe Dreamers” Only! Basket 3) and the Altinay now on my worktable. I was immediately drawn to the exquisite detailed carving of the Altinay, a name I’m very familiar with among Meerschaum pipe carvers in Turkey. The Altinay was petite but the detail amazingly complex and tight. It also had developed some of the valued patina at the shank/bowl junction – the normal area. Added as frosting on the Altinay cake was the original case – each carrier box is hand crafted for each pipe because each pipe is uniquely different being hand-carved. The negotiations commenced for a second time adding the Vauen and Altinay to my growing Black Sea treasure trove.

He reemerged with treasures in hand, a Vauen 6294 EX Billiard Saddle Stem (still available to be commissioned in For “Pipe Dreamers” Only! Basket 3) and the Altinay now on my worktable. I was immediately drawn to the exquisite detailed carving of the Altinay, a name I’m very familiar with among Meerschaum pipe carvers in Turkey. The Altinay was petite but the detail amazingly complex and tight. It also had developed some of the valued patina at the shank/bowl junction – the normal area. Added as frosting on the Altinay cake was the original case – each carrier box is hand crafted for each pipe because each pipe is uniquely different being hand-carved. The negotiations commenced for a second time adding the Vauen and Altinay to my growing Black Sea treasure trove. The entire Burgas Black Sea lot made it back to Sofia with us and eventually became available to be commissioned online in virtual “Help Me!” baskets in my For “Pipe Dreamers” Only! collection benefiting the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. This is where Jason found the Altinay and a French Leather Clad Longchamp which he commissioned. The Longchamp came out great and now the Altinay awaits attention.

The entire Burgas Black Sea lot made it back to Sofia with us and eventually became available to be commissioned online in virtual “Help Me!” baskets in my For “Pipe Dreamers” Only! collection benefiting the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. This is where Jason found the Altinay and a French Leather Clad Longchamp which he commissioned. The Longchamp came out great and now the Altinay awaits attention. I took these pictures of the Altinay Meerschaum on my worktable to get a closer look.

I took these pictures of the Altinay Meerschaum on my worktable to get a closer look.

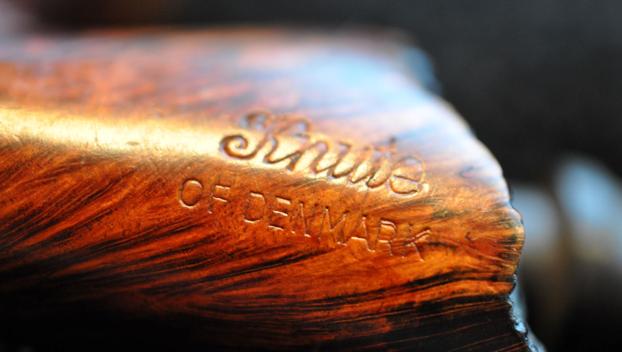

The stem has the inlaid Altinay roundel marking its provenance. The carrier box gives additional information: Altinay – Handcarved Block Meerschaum – Turkey.

The stem has the inlaid Altinay roundel marking its provenance. The carrier box gives additional information: Altinay – Handcarved Block Meerschaum – Turkey.

Altinay’s website (https://www.altinaypipes.com/) is a quality presentation of their craftsmanship. The ‘About’ tab on their site gives this information:

Altinay’s website (https://www.altinaypipes.com/) is a quality presentation of their craftsmanship. The ‘About’ tab on their site gives this information:

ALTINAY TURKISH COMPANY PRODUCING BEAUTIFULLY DESIGNED AND HANDMADE MEERSCHAUM PIPES AT OUR OWN MANUFACTURING FACILITY IN ESKISEHIR, TURKEY.

TIME BEGAN FOR ALTINAY IN 1964, WHEN WE EMBARKED ON A JOURNEY TO MAKE BEAUTIFULLY DESIGNED PIPES OF EXCEPTIONAL QUALITY. INSPIRED BY A LOVE OF CARVING MASTERPIECE PIPES WE ACHIEVED TO HAVE DISTRIBUTORS IN EACH EUROPEAN COUNTRY, USA, RUSSIA AND CHINA.

AND NOW, OUR PIPES ARE THE MOST POPULAR AND MOST WANTED MEERSCHAUM PIPES WORLDWIDE. WE DESIGN AND HAND CARVE TOP QUALITY PIPES BY USING FINEST QUALITY BLOCK MEERSCHAUM.

EACH PIPE IS DESIGNED TO APPEAL TO THOSE WHO SHARE OUR PASSION FOR – AND APPRECIATION OF – MASTERY BEHIND A BEAUTIFUL MEERSCHAUM PIPE. WE HOPE YOU ENJOY THE SAME SATISFACTION WHEN YOU TRY AN ALTINAY PIPE, AS WE DO IN CREATING ONE.

Another tab offers testimonials which I could add to. I added an Altinay Meerschaum to my personal collection on a trip to Istanbul only last summer. I found my Altinay Dimpled Billiard at the Grand Bazaar in Istanbul. After looking at literally 100s of Meerschaums in the various shops in the bazaar maze, and all the carvings that characterize the Meerschaum genre, I settled on this classic shaped Altinay. It now reveals the growing patina as the honey brown color expands on what started as a snow-white Meer surface. The Altinay on my worktable is in good shape regarding the condition of the Meerschaum lattice tear drop bowl. It needs cleaning and the rim has lava darkening especially on the aft quadrant. As you would expect with a healthy Meerschaum, there is very little cake build up in the chamber. A Meer pipe needs/wants no cake build up to protect the chamber as with briar bowls. Another unique feature of Meerschaum pipes is that they do not need to rest. They can be reloaded immediately and another bowl of one’s favorite blend can be enjoyed.

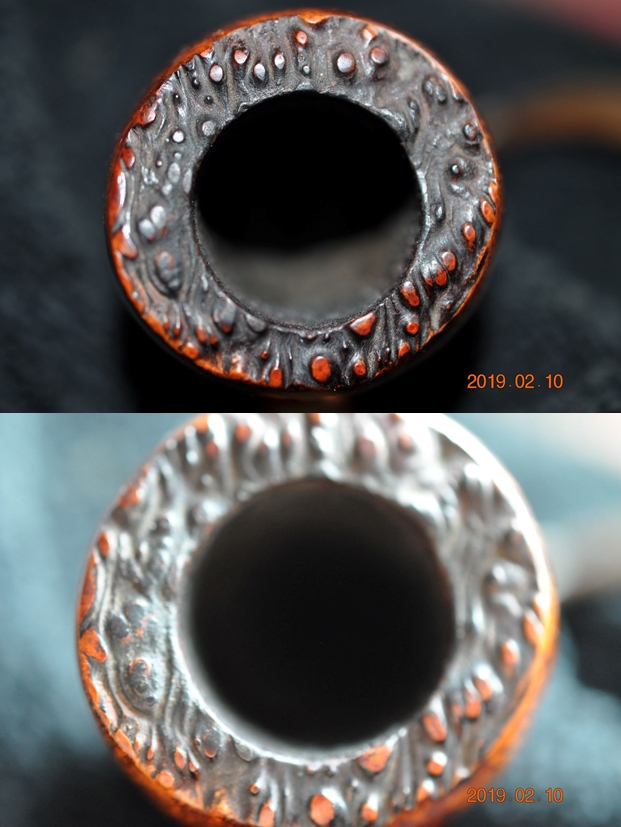

The Altinay on my worktable is in good shape regarding the condition of the Meerschaum lattice tear drop bowl. It needs cleaning and the rim has lava darkening especially on the aft quadrant. As you would expect with a healthy Meerschaum, there is very little cake build up in the chamber. A Meer pipe needs/wants no cake build up to protect the chamber as with briar bowls. Another unique feature of Meerschaum pipes is that they do not need to rest. They can be reloaded immediately and another bowl of one’s favorite blend can be enjoyed. The acrylic stem shows tooth chatter on the upper and lower bit which should sand out easily.

The acrylic stem shows tooth chatter on the upper and lower bit which should sand out easily. Structurally, the only challenge is the lose 9mm filter tenon pictured below. When I first unlinked the stem and the bowl and the plastic tenon was loose, I wasn’t sure which direction the threaded part of the plastic tenon was supposed to go – was it screwed into the mortise or into the stem? I tested both directions and the only configuration that allowed the stem to seat with the shank was with the threaded part inserted into the mortise. Yet, the threads would not grip anything revealing that the threads had been stripped.

Structurally, the only challenge is the lose 9mm filter tenon pictured below. When I first unlinked the stem and the bowl and the plastic tenon was loose, I wasn’t sure which direction the threaded part of the plastic tenon was supposed to go – was it screwed into the mortise or into the stem? I tested both directions and the only configuration that allowed the stem to seat with the shank was with the threaded part inserted into the mortise. Yet, the threads would not grip anything revealing that the threads had been stripped.

For now, I put this issue aside and start on the cleaning of the Altinay Meerschaum. I first clean the acrylic stem airway using pipe cleaners wetted with isopropyl 95%. The filter cavity is cleaned using cotton buds.

For now, I put this issue aside and start on the cleaning of the Altinay Meerschaum. I first clean the acrylic stem airway using pipe cleaners wetted with isopropyl 95%. The filter cavity is cleaned using cotton buds. Turning now to the Meer chamber, the carbon build-up is light, but I address it first by carefully scraping the chamber walls with the Savinelli Fitsall tool. Using a reaming kit with blade heads is not a good idea with Meerschaum as the torque required could possibly crack the Meerschaum and that would not be a good thing. The Savinelli tool works well to scrape evenly as well as to reach into the lower contour’s angles with the end of the tool being gently curved. I scrape a little with a Winchester pocketknife and transition to sanding the walls with 240 grade paper wrapped around the Sharpie Pen.

Turning now to the Meer chamber, the carbon build-up is light, but I address it first by carefully scraping the chamber walls with the Savinelli Fitsall tool. Using a reaming kit with blade heads is not a good idea with Meerschaum as the torque required could possibly crack the Meerschaum and that would not be a good thing. The Savinelli tool works well to scrape evenly as well as to reach into the lower contour’s angles with the end of the tool being gently curved. I scrape a little with a Winchester pocketknife and transition to sanding the walls with 240 grade paper wrapped around the Sharpie Pen.

After wiping the bowl out with a cotton pad wetted with isopropyl 95% to remove carbon dust, the following picture shows that the lower chamber remains darkened, but it is clean by the touch and looks good. I move on.

After wiping the bowl out with a cotton pad wetted with isopropyl 95% to remove carbon dust, the following picture shows that the lower chamber remains darkened, but it is clean by the touch and looks good. I move on. The pictures above and below show well the blackened state of the rim resulting from lighting. The condition of the Meerschaum will never again be the snow white that Meerschaums start with emerging from the factory or carver. My desire is to remove as much of the charring from the rim without damaging the ornate carving on the rim. My hope is to soften the contrasting coloring and then later, after applying a bee’s wax treatment, which helps color the Meerschaum toward the sought for patina which increases the value of the pipe. The bee’s wax will help blend the hues in the Meerschaum.

The pictures above and below show well the blackened state of the rim resulting from lighting. The condition of the Meerschaum will never again be the snow white that Meerschaums start with emerging from the factory or carver. My desire is to remove as much of the charring from the rim without damaging the ornate carving on the rim. My hope is to soften the contrasting coloring and then later, after applying a bee’s wax treatment, which helps color the Meerschaum toward the sought for patina which increases the value of the pipe. The bee’s wax will help blend the hues in the Meerschaum. I use a cotton pad wetted with alcohol and work on the rim – working to break up the charring.

I use a cotton pad wetted with alcohol and work on the rim – working to break up the charring. I do a very gentle topping on a sanding sponge to encourage the charring to break up. The medium sanding sponge is a very mild abrasive.

I do a very gentle topping on a sanding sponge to encourage the charring to break up. The medium sanding sponge is a very mild abrasive. The results are good. The charring is removed in large measure.

The results are good. The charring is removed in large measure. The plastic filter sheath is placed in alcohol to soak to see if it will help clean up the plastic – to lighten it or to lessen the stain.

The plastic filter sheath is placed in alcohol to soak to see if it will help clean up the plastic – to lighten it or to lessen the stain.  To clean the external Meer lattice surface, I mix a small portion of Murphy’s Oil soap in hot water. It is a very diluted mixture. I want the benefits that the agents that the soap has but I don’t want to saturate the surface with soap. I use a bristled toothbrush to apply the soap water to the bowl and scrub the tear drop windows of the lattice work. The mild soap removes the dirt and grime but does not remove the growing patina on the shank.

To clean the external Meer lattice surface, I mix a small portion of Murphy’s Oil soap in hot water. It is a very diluted mixture. I want the benefits that the agents that the soap has but I don’t want to saturate the surface with soap. I use a bristled toothbrush to apply the soap water to the bowl and scrub the tear drop windows of the lattice work. The mild soap removes the dirt and grime but does not remove the growing patina on the shank. I damp rinse with a dry cotton pad that draws out the moisture. I set the stummel aside to allow it to fully dry.

I damp rinse with a dry cotton pad that draws out the moisture. I set the stummel aside to allow it to fully dry. Shifting to the internals, using pipe cleaners and cotton buds wetted with isopropyl 95%, the internal cavity is clean in short order.

Shifting to the internals, using pipe cleaners and cotton buds wetted with isopropyl 95%, the internal cavity is clean in short order. The plastic filter sheath was soaking in alcohol and after fishing it out, I clean the internal cavity with cotton buds to remove the leftover gunk as well as to lighten the stained surface. I used needle files on the end of the sheath to smooth it on the external threaded side as well as to open the air hole. The brass bristled brush was also helpful to clean the caked crud in the threads and on the end.

The plastic filter sheath was soaking in alcohol and after fishing it out, I clean the internal cavity with cotton buds to remove the leftover gunk as well as to lighten the stained surface. I used needle files on the end of the sheath to smooth it on the external threaded side as well as to open the air hole. The brass bristled brush was also helpful to clean the caked crud in the threads and on the end. Switching now to the stem, the tooth chatter on the upper and lower bit is addressed with 240 sanding paper to erase the chatter.

Switching now to the stem, the tooth chatter on the upper and lower bit is addressed with 240 sanding paper to erase the chatter.

Following the 240 paper, the entire stem is wet sanded with 600 grade paper followed by applying 000 steel wool,

Following the 240 paper, the entire stem is wet sanded with 600 grade paper followed by applying 000 steel wool, Going directly to the micromesh regimen, using pads 1500 to 2400 the stem is wet sanded. Following this, dry sanding continues the process using pads 3200 to 4000 and 6000 to 12000. I like the way the micromesh pads have brought out the glassy pop of the acrylic stem.

Going directly to the micromesh regimen, using pads 1500 to 2400 the stem is wet sanded. Following this, dry sanding continues the process using pads 3200 to 4000 and 6000 to 12000. I like the way the micromesh pads have brought out the glassy pop of the acrylic stem.

I’m at the point now, before moving to applying bees wax to the bowl, I want to fix the filter sheath – to reattach it. Several months ago I reached out to the general email address I found on the Altinay website (altinaypipes.com). I wanted to find out more information and I was hopeful that I might get a response. I wrote with this question:

I’m at the point now, before moving to applying bees wax to the bowl, I want to fix the filter sheath – to reattach it. Several months ago I reached out to the general email address I found on the Altinay website (altinaypipes.com). I wanted to find out more information and I was hopeful that I might get a response. I wrote with this question:

Greetings, I have one of your pipes. The problem is that in the mortise insert that the filter tenon screws into is missing. So, now the tenon does not screw in to hold the stem firmly in place. Do you have replacement tenon systems? It is a 9mm filter tenon. This is a beautiful pipe and I’m hoping to put it back into action. Thank you.

I was surprised to see this response from Said whose last name is ‘Altinay’ arrive so quickly.

Dear Stanton

Of course we have replacement systems but even if you replace it with a new one, it will not be what you want.

While removing the mouthpiece if the pipe still hot, tenon can become stripped. It’s related to shank not tenon.

The method to be applied at this stage is fixing tenon with epoxy or etc.. Can you send me the photos of the pipe?and tenon?

Kind Regards

Said Altınay

I responded with pictures and this note and Said’s helpful reply:

Said,

Thank you so much for your response. Yes, I understand what you are saying. The internal shank insert is stripped – all that remains that I can see is the ‘skin’. I’ve included pictures. I look forward to hearing back from you.

Regards,

Dal Stanton

Dear Stanton

As I guess, there is no problem at tenon screw. Internal shank is stripped. As I said it needs to be fixed with epoxy or adhesive etc. If you want we can make the maintenance of this pipe….

Kind Regards

Said

I like to record interchanges like this and my appreciation for Said Altinay’s response to my questions. With his information, I was able to confirm that the problem is with the shank and that the threads are stripped. What was especially helpful was what would be his approach to repair – he would use an epoxy glue to reattach the filter holder. I was unclear on this because gluing back into place create a more permanent repair – not like a screw in attachment. So, if the expert whose name is Altinay says he would repair it this way, well… I first start with a test fitting and run a pipe cleaner through to make sure that the path from the insert to the draft hole was in alignment. I had no problem finding the draft hole with the pipe cleaner. After the test fitting, I then apply BSI Maxi-Cure Extra Thick CA glue around the perimeter of the lower plastic filter sheath or tenon. I then carefully insert the tenon and seat it well in the mortise.

After the test fitting, I then apply BSI Maxi-Cure Extra Thick CA glue around the perimeter of the lower plastic filter sheath or tenon. I then carefully insert the tenon and seat it well in the mortise. After the CA glue sets, I rejoin the stem and Meer stummel to look. I like what I see. The stem’s alignment is perfect.

After the CA glue sets, I rejoin the stem and Meer stummel to look. I like what I see. The stem’s alignment is perfect. Applying bees wax helps to protect the Meerschaum as well as to help cultivate the coloring or the patina. The bees wax is readily available in the outdoor markets here in Bulgaria where honey is sold. I have a mason jar of wax that has already been heated and melted. I use a paint brush, not with synthetic hair which will melt in the heat, to apply the liquefied wax to the stummel.

Applying bees wax helps to protect the Meerschaum as well as to help cultivate the coloring or the patina. The bees wax is readily available in the outdoor markets here in Bulgaria where honey is sold. I have a mason jar of wax that has already been heated and melted. I use a paint brush, not with synthetic hair which will melt in the heat, to apply the liquefied wax to the stummel. I warm the congealed wax with the hot air gun until it liquefies.

I warm the congealed wax with the hot air gun until it liquefies. After heating the Meer stummel as well with the hot air gun, I use the brush to paint the liquefied bees wax onto the Meer surface. I’m not able to take a picture of the process because I don’t have enough hands! I keep the hot air gun on while on my lap (not burning me) and keep it aimed at the Mason jar on the stool in front of me between my legs. I do the painting over the top of the Mason jar so that I’m not traveling too far with the brush and the hot air continues to keep the wax liquefied and the stummel warm. This helps the wax to absorb into the porous Meerschaum surface and not to congeal in clumps on the surface.

After heating the Meer stummel as well with the hot air gun, I use the brush to paint the liquefied bees wax onto the Meer surface. I’m not able to take a picture of the process because I don’t have enough hands! I keep the hot air gun on while on my lap (not burning me) and keep it aimed at the Mason jar on the stool in front of me between my legs. I do the painting over the top of the Mason jar so that I’m not traveling too far with the brush and the hot air continues to keep the wax liquefied and the stummel warm. This helps the wax to absorb into the porous Meerschaum surface and not to congeal in clumps on the surface. After I apply the wax with the brush thoroughly over the surface, including in the tear drop lattice windows, I allow the Meer stummel to cool down and after cooled, I first wipe the surface with a paper towel. I do this to remove the thick areas of the wax sitting on the surface that wasn’t absorbed. I then follow this by buffing the stummel with a microfiber cloth – not pictured.

After I apply the wax with the brush thoroughly over the surface, including in the tear drop lattice windows, I allow the Meer stummel to cool down and after cooled, I first wipe the surface with a paper towel. I do this to remove the thick areas of the wax sitting on the surface that wasn’t absorbed. I then follow this by buffing the stummel with a microfiber cloth – not pictured.  You never know quite how the Meerschaum will receive the bees wax treatment. This Altinay block of Meerschaum darkened a great deal as it soaked in the wax. Nice!

You never know quite how the Meerschaum will receive the bees wax treatment. This Altinay block of Meerschaum darkened a great deal as it soaked in the wax. Nice! After rejoining stem and stummel, I mount the Dremel with a cotton cloth buffing wheel and with the speed set at about 40% full power, Blue Diamond compound is applied to the acrylic stem. After this, after changing to another cotton cloth buffing wheel, a few coats of carnauba wax is applied to the stem at the same Dremel speed. I finish this restoration by giving the pipe a rigorous hand buffing to raise the shine.

After rejoining stem and stummel, I mount the Dremel with a cotton cloth buffing wheel and with the speed set at about 40% full power, Blue Diamond compound is applied to the acrylic stem. After this, after changing to another cotton cloth buffing wheel, a few coats of carnauba wax is applied to the stem at the same Dremel speed. I finish this restoration by giving the pipe a rigorous hand buffing to raise the shine.

The patina that the bees wax treatment teased out of the Meerschaum is an added value to the collectability of this pipe. Altinay is known for the quality of its Meerschaum block. This petite bent Latticed Tear Drop Meerschaum is no exception. The tightly carved intricacy of this classic Meerschaum genre is a great one to add to the collection and the addition of the custom made Altinay case completes the ensemble. Jason has the first opportunity to add this commissioned pipe from The Pipe Steward Store to his Longchamp which benefit the Daughters of Bulgaria. Thanks for joining me!