Blog by Steve Laug

The next pipe on the table is a Rusticated Ser Jacopo Canadian that is proportionally well done. Jeff and I purchased a group of pipes on 04/26/2022 from a woman who contacted us from Cleveland, Ohio, USA. They had belonged to her husband’s father. We spent time chatting with her and arrived at a price and she sent the pipes to Jeff. It included 28+ pipes including this one.

The next pipe on the table is a Rusticated Ser Jacopo Canadian that is proportionally well done. Jeff and I purchased a group of pipes on 04/26/2022 from a woman who contacted us from Cleveland, Ohio, USA. They had belonged to her husband’s father. We spent time chatting with her and arrived at a price and she sent the pipes to Jeff. It included 28+ pipes including this one.

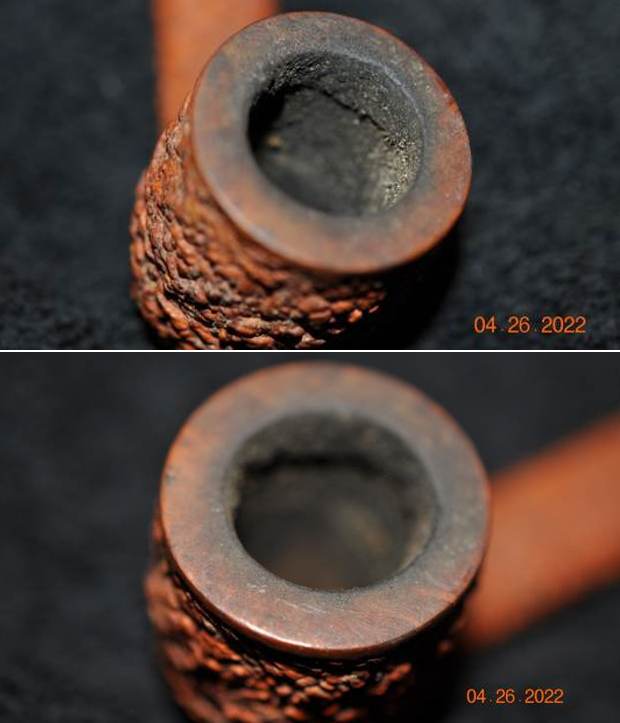

This Ser Jacopo Canadian is stamped on the underside and Maxima followed by Per Aspera [over] Ad Astra. That is followed by Ser Jacopo [over] Fatta A Mano [over] Italia. A circle R2 follows that next to the bowl/shank junction. On the top of the stem is a single coral dot. The finish was very dirty with spots of grime and debris ground into the rustication. The bowl had a thick cake in the bowl and heavy lava overflowing onto the rim top. The rim top appeared to have some burn damage on the inner edge of the bowl. The outer edges looked good. The acrylic stem was a disaster. It was gnawed off with only two points remaining on either side. The externals were filthy with calcification, oxidation and tooth marks and chatter on both sides ahead of what remained of the ruined button. Jeff took photos of the pipe before he started his clean up work on it.

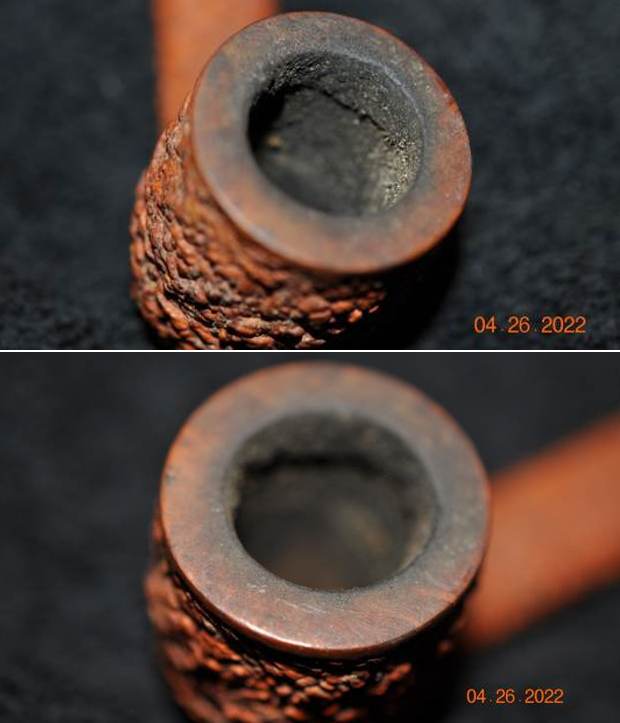

He took photos of the bowl and rim top to show the condition. You can see the thick cake in the bowl and rim top and edges. The lava is so thick that is hard to know what the edges and top look like underneath. The stem was heavily oxidized, calcified and the end of the stem and most of the button had been gnawed off. Overall the pipe is a real mess.

He took photos of the bowl and rim top to show the condition. You can see the thick cake in the bowl and rim top and edges. The lava is so thick that is hard to know what the edges and top look like underneath. The stem was heavily oxidized, calcified and the end of the stem and most of the button had been gnawed off. Overall the pipe is a real mess.

Jeff took photos of the rusticated finish around the bowl sides and heel. It was nice looking if you can see through the grime ground into the surface.

Jeff took photos of the rusticated finish around the bowl sides and heel. It was nice looking if you can see through the grime ground into the surface.

He took photos of the stamping on the underside of the shank. The stamping is clear and readable. It reads as noted above.

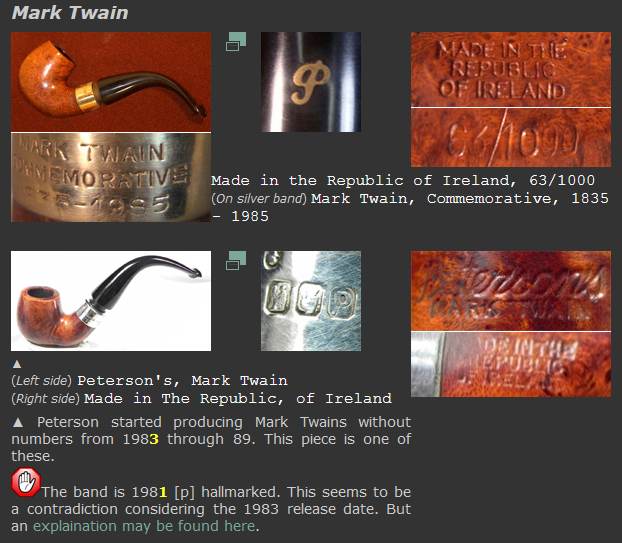

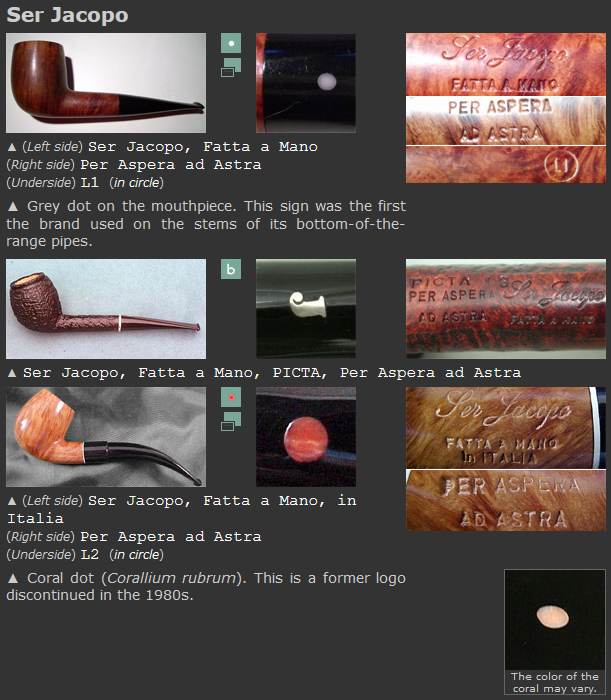

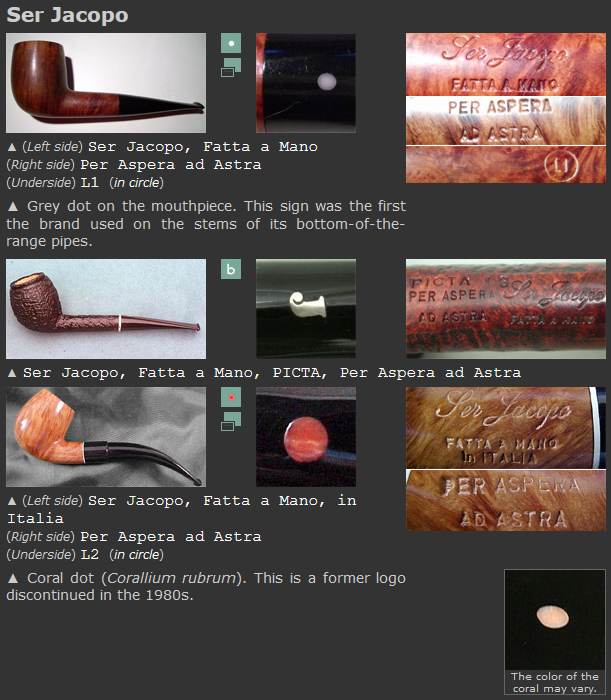

He took photos of the stamping on the underside of the shank. The stamping is clear and readable. It reads as noted above.  I turned to Pipephil (http://pipephil.eu/logos/en/logo-s5.html) to remind myself of the background of the brand. I also wanted to see what the single Coral dot meant on the stem. I knew that the Coral dot was on the older pipes but that was all I knew. I include a screen capture of the section on the brand below. The third photo below shows a similar Coral dot on the stem.

I turned to Pipephil (http://pipephil.eu/logos/en/logo-s5.html) to remind myself of the background of the brand. I also wanted to see what the single Coral dot meant on the stem. I knew that the Coral dot was on the older pipes but that was all I knew. I include a screen capture of the section on the brand below. The third photo below shows a similar Coral dot on the stem. I am also including the information that I found there in the sidebar on PipePhil. I quote that below. I have highlighted the R2 designation below in red.

I am also including the information that I found there in the sidebar on PipePhil. I quote that below. I have highlighted the R2 designation below in red.

Founder of the brand in 1982: Giancarlo Guidi (1943 – †2012). Production (2006): ~ 6000 pipes/year. Ser Jacopo seconds: Gepetto.

Finish mark: Rusticated pipes: R1 (dark brown) R2 (light brown); Sandblasted pipes: S (black), S1 (dark brown), S2 (light brown), S3 (tanshell); Smooth pipes: L (red), L1 (acceptable grain), L2 (nice grain), L3 (exceptional grain).

I then turned to Pipedia (https://pipedia.org/wiki/Ser_Jacopo) to read some more about the brand and see if there were more details regarding the single Coral dot. I quote below.

Ser Jacopo (provided by Marble Arch Ltd., US importer and distributor of Ser Jacopo)

Smokingpipes.com has an excellent concise history available on their website Ser Jacopo History at Smoking Pipes.com

Ser Jacopo, better to say Ser Jacopo dalla Gemma, was started by Giancarlo Guidi in 1982 upon leaving Mastro de Paja.

Giancarlo Guidi and Bruto Sordini broke away from Mastro de Paja in 1981 in pursuit of their own company. Ser Jacopo was named after an Italian nobleman. Guidi and Sordini, having taken part in creating the now infamous Pesaro “school” of pipe making, wanted to expand further. To accomplish this, Ser Jacopo focused their efforts on the pairing of the briar with a seemingly endless variety of mounts. Through the use of precious metals and stones, horn, and exotic woods Ser Jacopo pipes are given unique characters that many collectors find quite aesthetically pleasing. Although Ser Jacopo pipes borrow heavily from classical shapes, they are indeed quite unique in style.

In addition to creative mountings, Ser Jacopo is also well known for making themed pipes, and the most famous of these themes is perhaps the Picta Series, where pipes are modeled after pipes seen in pictures by and of famous artists, such as Vincent Van Gough.

Ser Jacopo makes multiple grades of pipes, with the “entry” level being the Geppetto brand, and the highest grade being the “Gem” series.

The small Ser Jacopo shop produces approximately 6000 pipes per year. The pipes are known for using outstanding Italian briar, which is well seasoned. The pipes have earned a well-deserved reputation for having excellent smoking qualities, equal or better than any other fine Italian pipe maker (or, for that matter, any other pipe maker in the world).

Giancarlo Guidi passed away on August 6, 2012, leaving behind a great legacy. He was 64 years old.

Nomenclature – the section on the nomenclature helps understand the stamping on the underside of the shank. It is helpful and really quite interesting.

The standard nomenclature found on Ser Jacopo pipes is as follows:

Ser Jacopo Fatta A Mano In Italia Per Aspera Ad Astra – Fatta A Mano translates to “Made By Hand”. Per Aspera Ad Astra is a Latin phrase found on Ser Jacopo pipes and is the Ser Jacopo motto. It translates to “To the Stars Through Travails”, meaning that success comes through hard work. In the Summer 1997 Pipes and Tobaccos article Giancarlo Guidi translated this as “through a difficult way until the stars are reached”.

Ser Jacopo Pipes are generally found in one of three finishes (rusticated, sandblast, smooth) designated by a letter and number code:

R1: Rusticated, dark brown or plum finish.

R2: Rusticated, light brown finish.

S: Sandblast, black

S1: Sandblast, dark brown

S2: Sandblast, light brown

S3: Sandblast, tanshell

L: Smooth, red, usually with silver trim

L1: Smooth, flame grain, various finishes

L2: Smooth, straight grain, various finishes

L3: Smooth, straight grain extra, discontinued

Dating Pipes

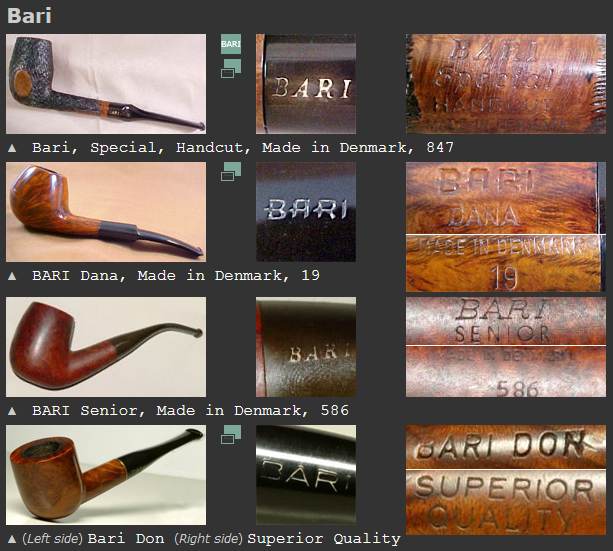

In the photo to the left you can see the development of the stem inserts on the pipes.

In the photo to the left you can see the development of the stem inserts on the pipes.

Top: Early Red Coral Logo Middle: Coral Logo with Silver Ring Bottom: Modern Day Silver J Logo – Courtesy of Mike Ahmadi

Ser Jacopo pipes is somewhat difficult, because Ser Jacopo does not generally use date codes (the exception being the Diamond Gemma series pipes, which are dated coded). Early pipes (from 1983 to 1997) featured a red coral dot on the mouthpiece, sometimes found encircled in a silver ring. This was discontinued and changed to a sterling silver letter “J”. On the Gemma series of pipes, the mouthpiece logo is a precious stone surrounded by an 18k gold ring.

The pipe I am working on is one of the early pipes (1983-1997). It is a lovely pipe with a deep and unique rustication. Now it is time to work on the pipe and bring it back to life.

Armed with that information I turned to work on the pipe itself. Before he sent it to me, Jeff had done an amazing job cleaning the pipe. It almost looked like a different pipe after his work. He reamed the pipe with a PipNet pipe reamer and removed the rest of the cake with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap and a tooth brush. He rinsed it under running warm water to remove the soap and grime. The finish looked very good and the rugged finish felt good in the hand. He cleaned out the inside of the shank and the airway in the stem with isopropyl alcohol, cotton swabs and pipe cleaners. He soaked the stem in Briarville’s Pipe Stem Deoxidizer and then rinsed it off with warm water. He scrubbed the stem with Soft Scrub and a tooth brush and rinsed it off with warm water. It looked amazing when I took it out of the package of pipes he shipped me. I took photos of the pipe before I started my part of the restoration work.

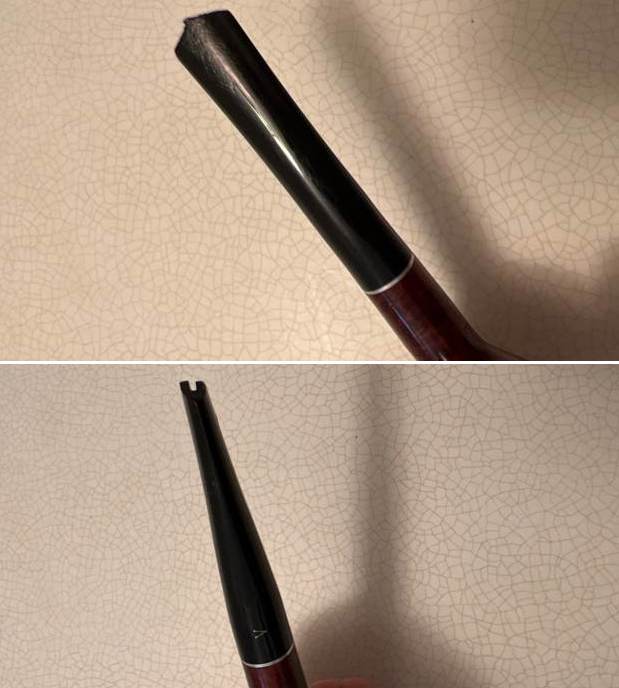

The rim top was cleaner and the inner edge of the bowl showed burn damage on the front right and back left. There was some chipping and damage around entire edge. The rim top and outer edge actually looked to be in good condition. The bowl was slightly out of round. The stem surface looked good with the oxidation gone and large chunk of the button missing. It was odd in that it was an even break on both sides and almost like a slot had been cut leaving behind two small thin posts on each side.

The rim top was cleaner and the inner edge of the bowl showed burn damage on the front right and back left. There was some chipping and damage around entire edge. The rim top and outer edge actually looked to be in good condition. The bowl was slightly out of round. The stem surface looked good with the oxidation gone and large chunk of the button missing. It was odd in that it was an even break on both sides and almost like a slot had been cut leaving behind two small thin posts on each side. I took a photo of the stamping on the underside of the shank. It is faint but is still readable as noted above.

I took a photo of the stamping on the underside of the shank. It is faint but is still readable as noted above. I took the stem off the shank and took a photo of the parts of the pipe. The overall look of the pipe is quite nice. The stem is quite stubby and short so that gave me an idea that I would explore later in the restoration.

I took the stem off the shank and took a photo of the parts of the pipe. The overall look of the pipe is quite nice. The stem is quite stubby and short so that gave me an idea that I would explore later in the restoration. I started my portion of the work on this pipe by addressing the damage to the rim top and the inner edge of the bowl. I worked over the rim top with 220 grit sandpaper to remove the damage and the darkening. I used a folded piece of 220 grit sandpaper to smooth out the inner edge and give it a slight bevel to deal with the chipping and cutting that was present. It cleaned up remarkably well. With polishing and buffing it would look even better.

I started my portion of the work on this pipe by addressing the damage to the rim top and the inner edge of the bowl. I worked over the rim top with 220 grit sandpaper to remove the damage and the darkening. I used a folded piece of 220 grit sandpaper to smooth out the inner edge and give it a slight bevel to deal with the chipping and cutting that was present. It cleaned up remarkably well. With polishing and buffing it would look even better. I polished the smooth rim top with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the briar down with a damp cloth after each pad to remove the debris and sanding dust.

I polished the smooth rim top with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the briar down with a damp cloth after each pad to remove the debris and sanding dust. The bowl looked very good at this point so I rubbed it down with Before & After Restoration Balm. I worked it into the surface of the bowl and shank with my fingertips and a horse hair shoe brush to clean, enliven and protect the briar. I let the balm sit for about 10-15 minutes and buffed with a cotton cloth to raise the shine.

The bowl looked very good at this point so I rubbed it down with Before & After Restoration Balm. I worked it into the surface of the bowl and shank with my fingertips and a horse hair shoe brush to clean, enliven and protect the briar. I let the balm sit for about 10-15 minutes and buffed with a cotton cloth to raise the shine.

I buffed the bowl with a shoe brush to raise the shine on the bowl. It is a really nice looking pipe with a finish that has a look like cut glass to me. The rich brown of the stain vary through the layers of the rustication. It is very nicely done.

I buffed the bowl with a shoe brush to raise the shine on the bowl. It is a really nice looking pipe with a finish that has a look like cut glass to me. The rich brown of the stain vary through the layers of the rustication. It is very nicely done.

I set the bowl aside and turned my attention to the stem. I cut of the two pegs that remained of the button and flattened the end of the stem against a topping board and 220 grit sandpaper. Surprisingly, it did not shorten the stem significantly. I did not feel that the pegs provided enough body to support a repair so I opted on shortening the stem and rebuilding the button with rubberized black super glue. I layered the repair on slowly, letting each layer cure before adding the next one. Once the repair cured I would need to reshape the button with files.

I set the bowl aside and turned my attention to the stem. I cut of the two pegs that remained of the button and flattened the end of the stem against a topping board and 220 grit sandpaper. Surprisingly, it did not shorten the stem significantly. I did not feel that the pegs provided enough body to support a repair so I opted on shortening the stem and rebuilding the button with rubberized black super glue. I layered the repair on slowly, letting each layer cure before adding the next one. Once the repair cured I would need to reshape the button with files.

I reshaped the button and the edge with a small file. The repaired button was beginning to look good at this point. I touched up the edge surface with CA glue to smooth and fill it in. Once the glue cured I sanded it with 220 grit sandpaper to continue the shaping. I repaired and resanded until I was happy with it. I started the polishing process with 400 grit wet dry sandpaper.

I reshaped the button and the edge with a small file. The repaired button was beginning to look good at this point. I touched up the edge surface with CA glue to smooth and fill it in. Once the glue cured I sanded it with 220 grit sandpaper to continue the shaping. I repaired and resanded until I was happy with it. I started the polishing process with 400 grit wet dry sandpaper.

I used a small pottery shaping saw to cut the slot in the end of the stem and shape it. It is getting closer and closer to being finished.

I used a small pottery shaping saw to cut the slot in the end of the stem and shape it. It is getting closer and closer to being finished. I sanded the button surface some more with 220 grit sandpaper to further shape it. I filled in the air-pockets with superglue and let it cure until dry. Once it cured I started the polishing with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with some Obsidian Oil. I polished it further with Before & After Stem Polish – both Fine and Extra Fine. I wiped it down a further time with Obsidian Oil and let it cure.

I sanded the button surface some more with 220 grit sandpaper to further shape it. I filled in the air-pockets with superglue and let it cure until dry. Once it cured I started the polishing with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with some Obsidian Oil. I polished it further with Before & After Stem Polish – both Fine and Extra Fine. I wiped it down a further time with Obsidian Oil and let it cure.

This Beautiful Rusticated Ser Jacopo Maxima R2 Canadian with a Coral Dot is a great looking pipe now that it has been restored. The rich and unique rusticated works well with the polished, repaired and rebuilt vulcanite stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Ser Jacopo Maxima Canadian is a large pipe that I am sure will be a great smoker. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ¼ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 43 grams/1.52 ounces. I will be holding on to this one for awhile to test out the durability of the button rebuild. I take a moment to remind myself and each of us that we are trustees of pipes that will outlive us and the lives of many other pipe men and women who carry on the trust of their care and use. Thanks for reading this blog and my reflections on the pipe while I worked on it.

This Beautiful Rusticated Ser Jacopo Maxima R2 Canadian with a Coral Dot is a great looking pipe now that it has been restored. The rich and unique rusticated works well with the polished, repaired and rebuilt vulcanite stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Ser Jacopo Maxima Canadian is a large pipe that I am sure will be a great smoker. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ¼ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 43 grams/1.52 ounces. I will be holding on to this one for awhile to test out the durability of the button rebuild. I take a moment to remind myself and each of us that we are trustees of pipes that will outlive us and the lives of many other pipe men and women who carry on the trust of their care and use. Thanks for reading this blog and my reflections on the pipe while I worked on it.

Jeff and I often purchase pipe bowl/stummels of brands that we like and want to restore. These have included a lot of different bowls. If you have followed us for long you know that some of these have included Peterson’s, Dunhill’s, and a wide range of Danish and English pipes. Awhile ago Jeff and I were sorting through the bowls in our collection and pulled out eight Peterson’s bowls that were dirty and stemless. A friend referred us to a contact named Silas Walls, of Walls Pipe Repair in Wallace, Idaho, USA as he seems to have a good supply of original Peterson’s stems. Our friend has had him fit stems for some of his Petes and was very happy with the work. We made contact with him and sent him eight bowls for restemming.

Jeff and I often purchase pipe bowl/stummels of brands that we like and want to restore. These have included a lot of different bowls. If you have followed us for long you know that some of these have included Peterson’s, Dunhill’s, and a wide range of Danish and English pipes. Awhile ago Jeff and I were sorting through the bowls in our collection and pulled out eight Peterson’s bowls that were dirty and stemless. A friend referred us to a contact named Silas Walls, of Walls Pipe Repair in Wallace, Idaho, USA as he seems to have a good supply of original Peterson’s stems. Our friend has had him fit stems for some of his Petes and was very happy with the work. We made contact with him and sent him eight bowls for restemming.

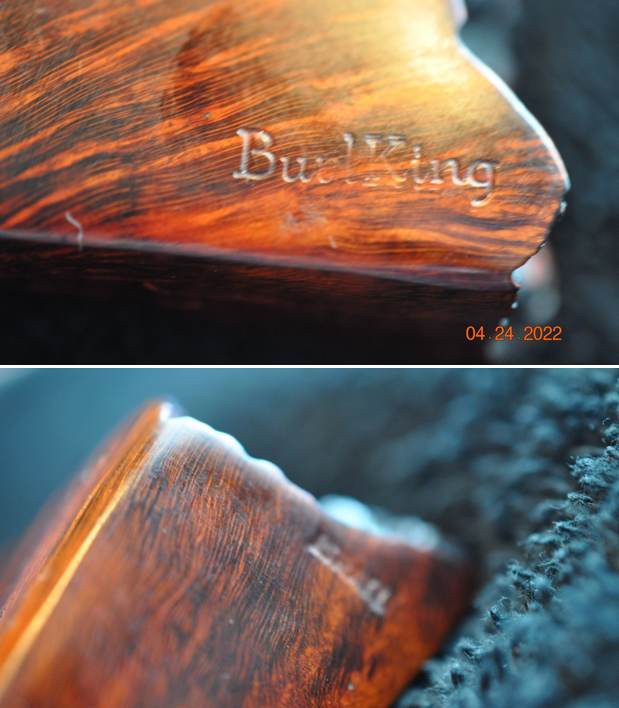

I took some close up photos of the rim top and also of the stem surface. I wanted to show how well it had cleaned up. The rim top had some darkening and damage on the top. The inner edge was out of round and had some damage on the front and the back of the bowl. It should clean up really well. I also took close up photos of the new stem to show how well it was fit to the shank. It is a tiny looking stem and thin shank! Thanks to Walls Pipe Repair!!

I took some close up photos of the rim top and also of the stem surface. I wanted to show how well it had cleaned up. The rim top had some darkening and damage on the top. The inner edge was out of round and had some damage on the front and the back of the bowl. It should clean up really well. I also took close up photos of the new stem to show how well it was fit to the shank. It is a tiny looking stem and thin shank! Thanks to Walls Pipe Repair!!  I took photos of the stamping on the sides of the shank. It is readable as noted above.

I took photos of the stamping on the sides of the shank. It is readable as noted above.  I removed the stem and took a photo of the pipe to have a look at the parts and overall look. The new stem looked really good with the bowl. I am impressed by how the stem was shaped to fit the stem.

I removed the stem and took a photo of the pipe to have a look at the parts and overall look. The new stem looked really good with the bowl. I am impressed by how the stem was shaped to fit the stem. I am including the link to the Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson).

I am including the link to the Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson). I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad. There was a dark spot on the top of the shank toward the bowl that appears to be a deep stain rather than a burn mark. It is solid and makes me wonder if the was just a spot on the briar that took the dark understain more deeply than the rest.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad. There was a dark spot on the top of the shank toward the bowl that appears to be a deep stain rather than a burn mark. It is solid and makes me wonder if the was just a spot on the briar that took the dark understain more deeply than the rest.

The polishing of the rim top and inner edge brought the rim top colour to match the rest of the bowl. I did not need to stain the rim at all. I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The grain just came alive!

The polishing of the rim top and inner edge brought the rim top colour to match the rest of the bowl. I did not need to stain the rim at all. I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The grain just came alive!

Since the stem was new the pipe was basically finished. I am excited to put the final touches on this newly restemmed Made in the Republic of Ireland Peterson’s System Standard 301 Pot. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful mixed grain all around it. Added to that the polished black vulcanite stem combined with the bowl and made a stunning pipe. This smooth Classic Peterson’s System Standard 301 is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 55 grams/1.94 ounces. It is a beautiful pipe that I will soon be putting on the rebornpipes store in the Irish Pipe Makers section. If you are interested in adding it to your collection send me an email or a message. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

Since the stem was new the pipe was basically finished. I am excited to put the final touches on this newly restemmed Made in the Republic of Ireland Peterson’s System Standard 301 Pot. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful mixed grain all around it. Added to that the polished black vulcanite stem combined with the bowl and made a stunning pipe. This smooth Classic Peterson’s System Standard 301 is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 55 grams/1.94 ounces. It is a beautiful pipe that I will soon be putting on the rebornpipes store in the Irish Pipe Makers section. If you are interested in adding it to your collection send me an email or a message. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.